Manufacturing method of polycrystalline diamond compacts with super-thick diamond layers

A technology of polycrystalline diamond and diamond layer, applied in the field of superhard material manufacturing, can solve the problem that polycrystalline diamond composite sheets cannot be synthesized, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

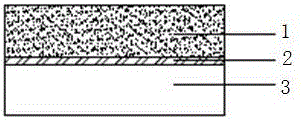

[0013] The following is an embodiment of the present invention, which is used to manufacture a polycrystalline diamond compact with a total thickness of 11 mm, a diameter of 30 mm, and a diamond thickness of 5.5 mm.

[0014] The manufacturing steps adopted in this embodiment are:

[0015] The first step is to synthesize a polycrystalline diamond blank with a diameter of 31mm and a thickness of 6.5mm by combining diamond micropowder and mixed metal powder of cobalt, nickel, tungsten, iron, and silver at a temperature of 1350-1600°C and a pressure of 6.5GPa , the polycrystalline diamond blank is processed into a polycrystalline diamond blank disc with a diameter of 30.0 mm and a thickness of 5.5 mm through EDM and grinding, and the surface is cleaned.

[0016] In the second step, a certain quality and the proportion of silver is 1-5%, the proportion of copper is 35-70%, the proportion of zinc is 5-20%, the proportion of tin is 1-5%, and the proportion of lead is 1-5%. The mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com