Construction process of novel counterfort retaining wall

A construction technology, buttress-type technology, which is applied in the field of construction technology of new buttress-type retaining walls, can solve the problems of wasteful masonry and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Example 1, in the design of the rail material platform for large and medium repair projects, considering that the existing rail material platform is generally filled relatively high, basically brick retaining walls are used to close the slope, and the walls generally have bulging and cracking diseases, which affect It is safe to use, so the present invention proposes the rationalization improvement of adopting the buttress-type retaining wall to close the slope and make the rail material platform. The buttress-type retaining wall is a light-weight retaining structure. Compared with the traditional gravity-type retaining wall, it not only saves masonry but also occupies a small area, and does not require new land acquisition during the implementation process. After the present invention was tested, the two newly-built rail material platforms of Suning North Railway Station were safe and stable, well used, and had good popularization value.

[0053] Specific implementatio...

Embodiment 2

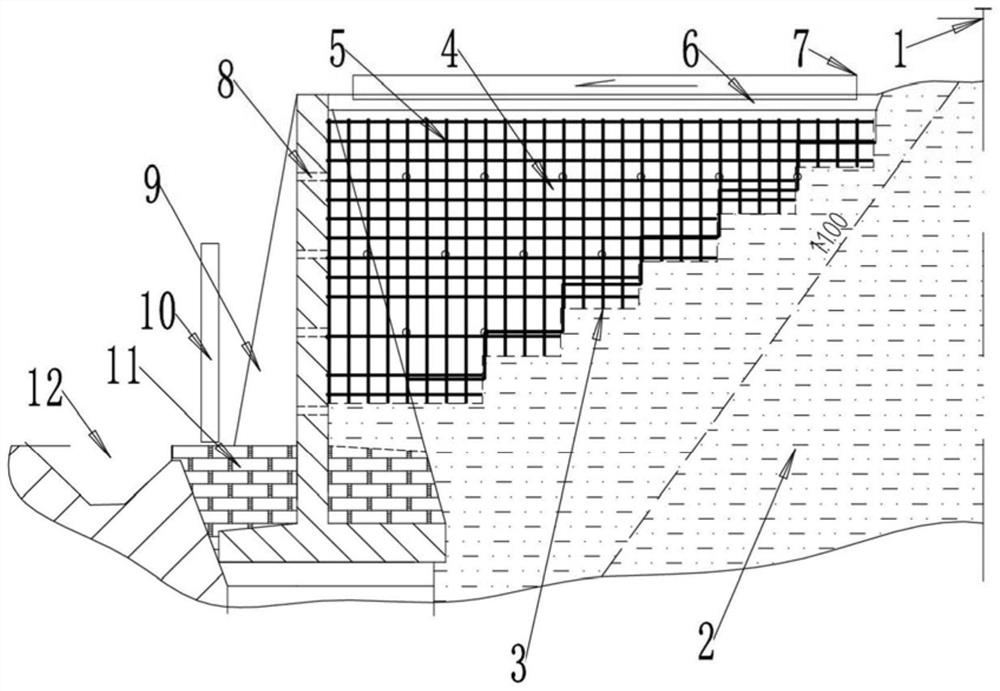

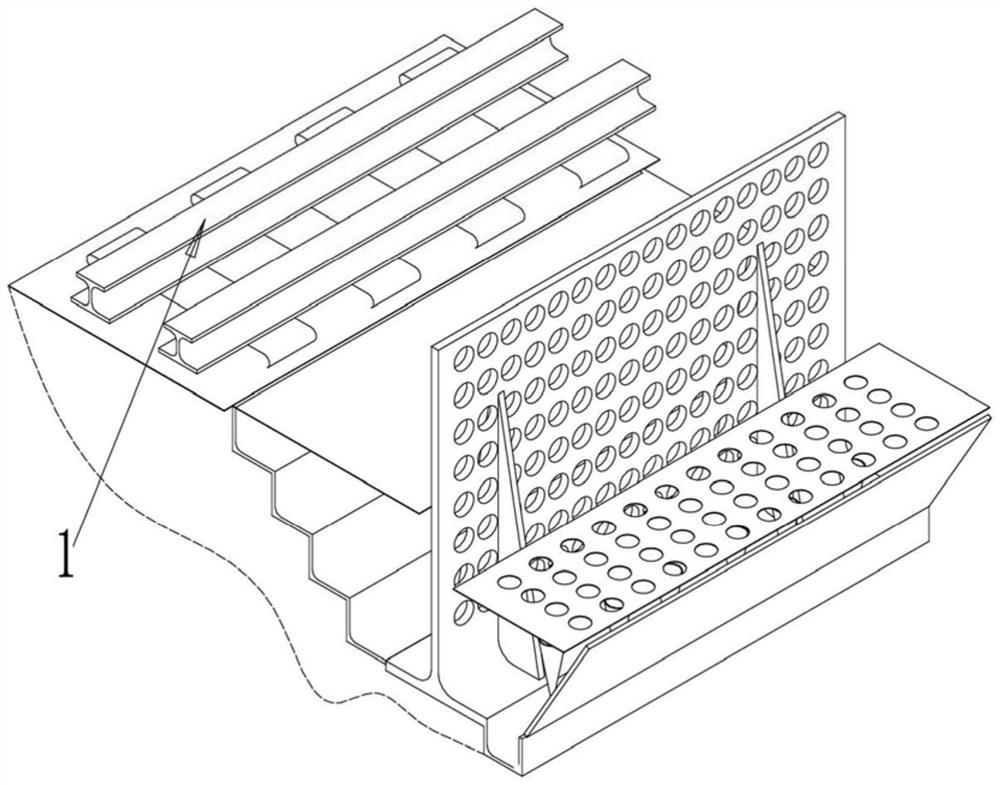

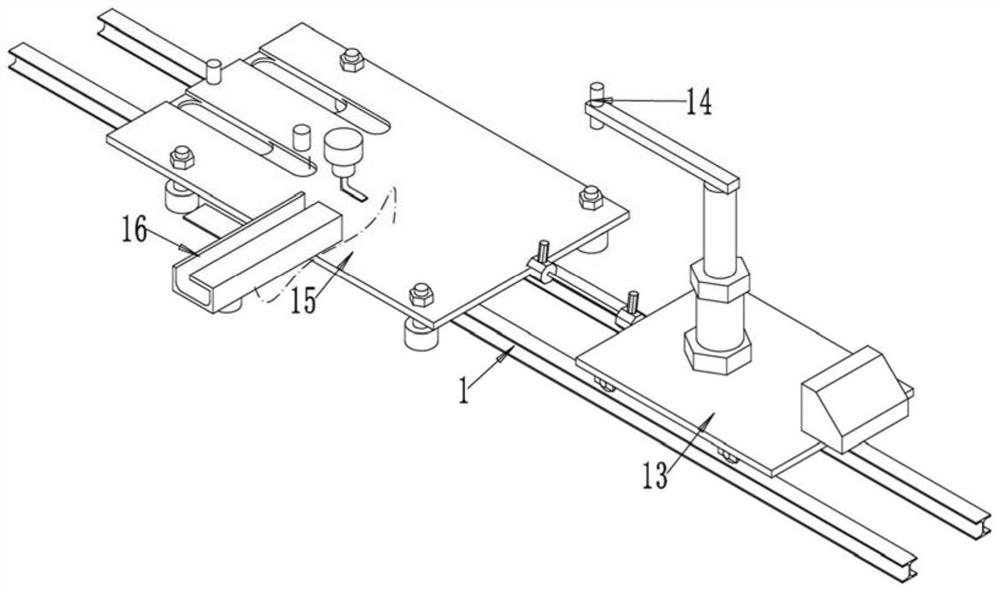

[0055] Example 2, such as Figure 1-7 As shown, the buttress-type retaining wall used for the rail material platform in this embodiment is arranged on the concrete retaining wall toe 3 on both sides of the existing road shoulder 2 of the rail member 1, which is a stepped structure;

[0056] Ditch the outer bottom of the toe 3 of the concrete retaining wall and place the bottom of the buttress 9; fill and compact the gravel soil layer 11 on the bottom upper surface and bottom of the buttress 9;

[0057] A backfill earth-stone layer 4 is placed between the vertical wall of the buttress 9 and the toe 3 of the concrete retaining wall; drain holes 8 are respectively arranged on the backfill earth-rock layer 4 and the vertical wall of the buttress 9;

[0058] In the backfill earth-stone layer 4, a steel bar assembly 5 in the wall is arranged and overlapped with the steel bar of the buttress 9;

[0059] A concrete hardening surface 6 is arranged on the backfill earth-rock layer 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com