Gravity type point-adhered rubble stone plant caulking ecological retaining wall and construction method thereof

A sticky rubble and gravity type technology, applied in the field of gravity point sticky rubble plant caulking ecological retaining wall and its construction, can solve the problems of accelerated urban heat island effect, difficult operation of workers, soil loss, etc., to reduce urban Effects of heat island effect, rapid plant growth and less cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

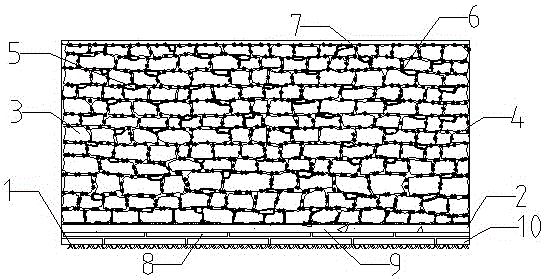

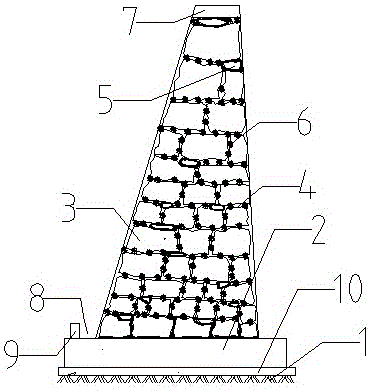

[0055] like figure 1 , figure 2 , the present invention is a kind of gravity-type point-bonded rubble plant caulking ecological retaining wall, which includes rammed plain soil 1, a concrete cushion 2 positioned above the rammed plain soil 1, and a rubble base layer positioned above the concrete cushion 2 10. There is a trapezoidal wall above the rubble foundation layer 10; the back surface of the wall and the water surface are inclined trapezoidal structures; the wall is composed of multiple rubble layers parallel to each other below and the concrete topping 7 above; the rough The stone layer is composed of multiple pieces of rubble 3 that are closely arranged in front, back, left, and right, and is built with cement mortar. The gaps on the outer wall of the rubble layer on the back surface are filled with a little sticky rubble 5 or residual soil slurry 4, and the spot sticky rubble 5 and rubble 3 are built by cement mortar; the outer wall of residual soil slurry 4 caulki...

Embodiment 2

[0074] The present invention is a kind of gravity-type point-bonded rubble plant caulking ecological retaining wall, which comprises rammed plain soil, a concrete cushion above the rammed plain soil, and a rubble base layer located above the concrete cushion, and the rubble base layer There is a trapezoidal wall on the top; the back surface and the water-facing surface of the wall are trapezoidal structures; the wall is composed of multiple rubble layers parallel to each other below and the concrete topping above; the rubble layer is composed of multiple closely arranged front, rear, left, and right The rubble is composed of cement mortar masonry, and the gaps between the outer wall of the rubble layer on the back surface are filled with some sticky rubble or residual soil slurry, and the gap between the point sticky rubble and the rubble is built with cement mortar; the residual soil slurry caulking Vegetation is evenly transplanted on the outer wall at a certain distance; a d...

Embodiment 3

[0093] The present invention is a kind of gravity-type point-bonded rubble plant caulking ecological retaining wall, which comprises rammed plain soil, a concrete cushion above the rammed plain soil, and a rubble base layer located above the concrete cushion, and the rubble base layer There is a trapezoidal wall on the top; the back surface and the water-facing surface of the wall are trapezoidal structures; the wall is composed of multiple rubble layers parallel to each other below and the concrete topping above; the rubble layer is composed of multiple closely arranged front, rear, left, and right The rubble is composed of cement mortar masonry, and the gaps between the outer wall of the rubble layer on the back surface are filled with some sticky rubble or residual soil slurry, and the gap between the point sticky rubble and the rubble is built with cement mortar; the residual soil slurry caulking Vegetation is evenly transplanted on the outer wall at a certain distance; a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com