Method for embankment by blasting and silt squeezing on complex soft foundation

A technology of blasting silting and soft foundation, which is applied in the field of blasting silting and embankment construction, which can solve the problems of difficult construction in water operations, increased project investment costs, and increased volume of rock filling, achieving considerable economic benefits and saving construction time , the effect of accelerated speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

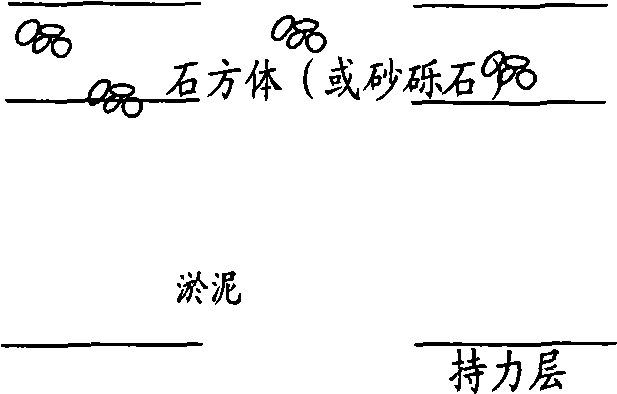

[0023] Embodiment 1: A method for blasting and silting embankment on a complex soft foundation, comprising the following steps: ①Using the characteristics of ocean ebb and flow, when the complex soft foundation is exposed to the water at low tide, the top surface of the complex soft foundation Explosive packs are arranged on the ground, each pack of explosives is 1.5 kg, and the distance between each explosive pack is 4 meters; ② When the water depth covered on the explosive packs reaches 2.5 meters during high tide, blasting is carried out to squeeze out the complex soft foundation downwards Silt; ③ load riprap on the treated complex soft foundation, and the length of the riprap embankment is 7 meters; ④ When the slope foot of the riprap layer is exposed to the water at low tide, arrange a row of Explosive packs, the amount of explosives in each pack is 0.3 kg, the width of the explosives is equal to the width of the bottom of the embankment, and the distance between each expl...

Embodiment 2

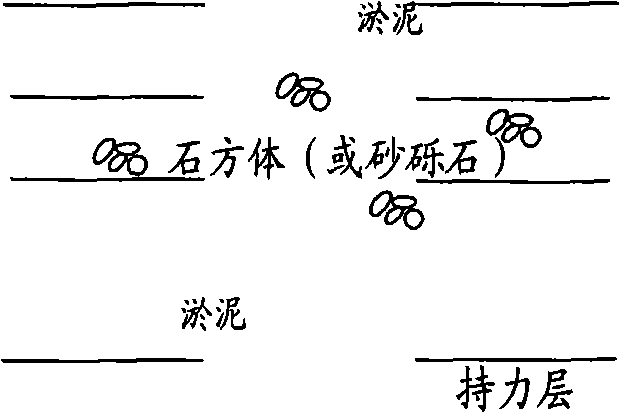

[0024] Embodiment 2: A method for blasting and squeezing silt on a complex soft foundation, comprising the following steps: ①Using the characteristics of ocean ebb and flow, when the complex soft foundation is exposed to the water at low tide, the top surface of the complex soft foundation Explosive packs are arranged on the ground, each pack of explosives is 1.2 kg, and the distance between each explosive pack is 3 meters; ②When the water depth covered on the explosive packs reaches 3 meters during high tide, blasting is carried out, and the complex soft foundation is squeezed out 3. Load riprap on the treated complex soft foundation, and the length of the riprap embankment is 6 meters; ④ When the toe of the riprap layer is exposed to the water at low tide, arrange two rows on the stone surface of the toe of the riprap layer Explosive packs, the amount of explosives in each pack is 0.2 kg, the width of the explosives is 1.2 times the width of the bottom of the embankment, and ...

Embodiment 3

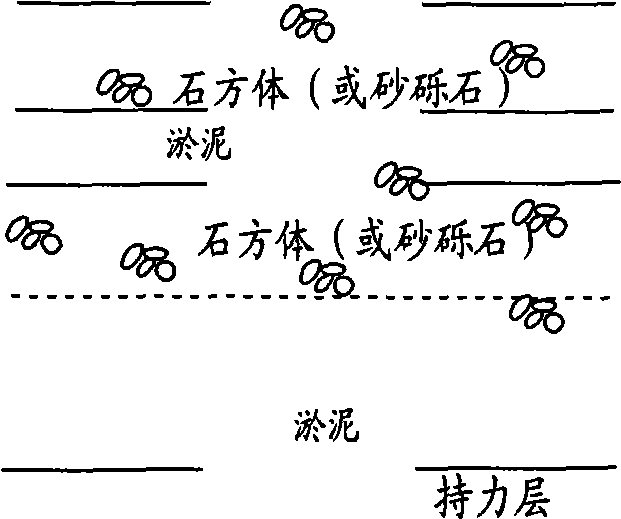

[0025] Embodiment 3: A method for blasting and silting embankment on a complex soft foundation, comprising the following steps: ①Using the characteristics of ocean ebb and flow, when the complex soft foundation is exposed to the water at low tide, the top surface of the complex soft foundation Explosive packs are arranged on the ground, each pack of explosives is 1.8 kg, and the distance between each explosive pack is 5 meters; ②When the water depth covered on the explosive packs reaches 2 meters during high tide, blasting is carried out, and the complex soft foundation is squeezed out 3. Load riprap on the treated complex soft foundation, and the length of the riprap embankment is 8 meters; ④ When the toe of the riprap layer is exposed to the water at low tide, arrange a row of Explosive packs, the amount of explosives in each pack is 0.4 kg, the width of the explosives is 0.8 times the width of the bottom of the embankment, and the distance between each explosive pack is 3.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com