Method and product of sputtering and depositing bioactive gradient hydroxyapatite/Ti layer on Ti alloy surface

A hydroxyapatite, bioactive technology, applied in sputtering plating, metal material coating process, coating and other directions, to achieve the effect of simple film-making process, increased stability, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

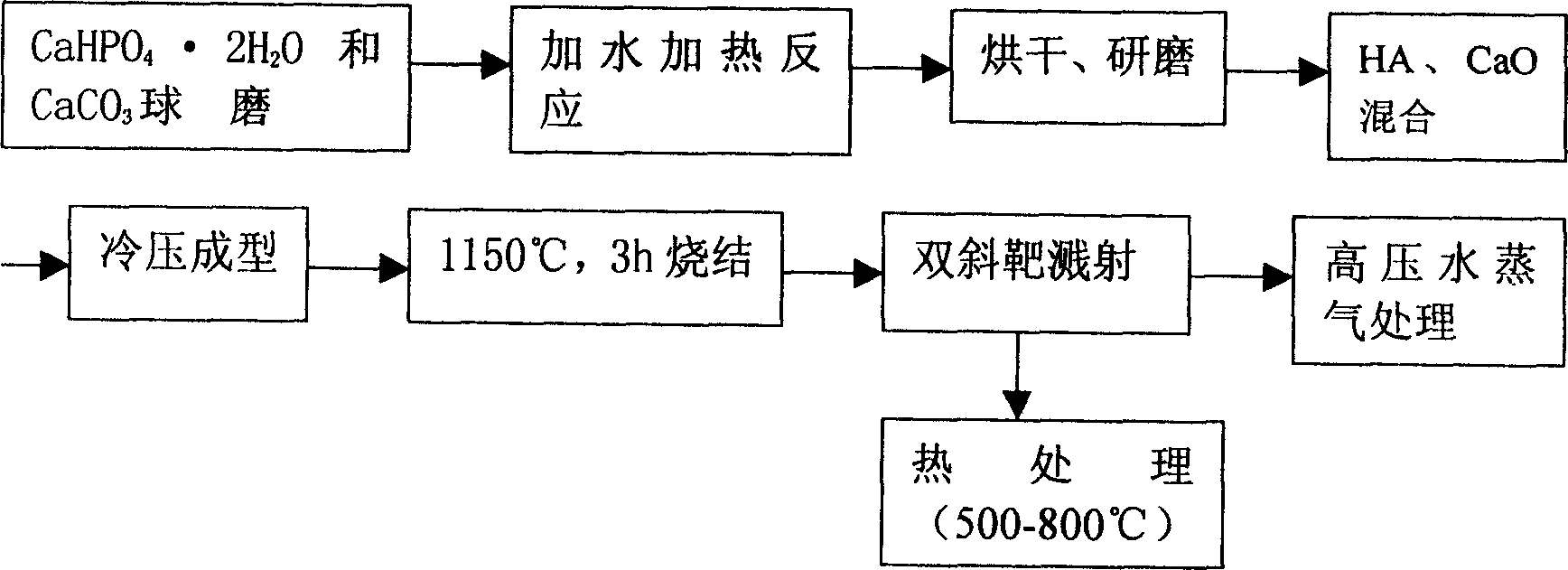

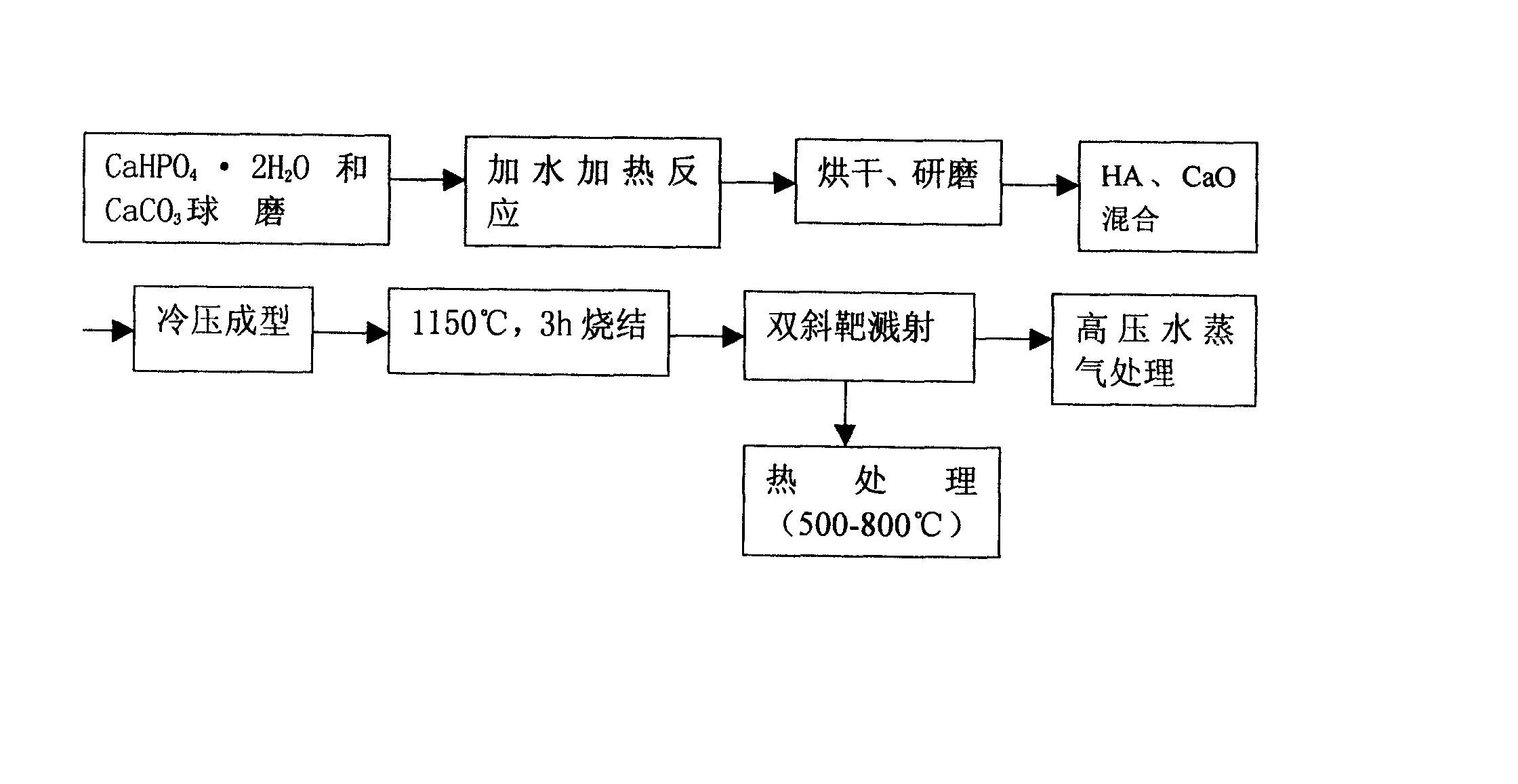

[0017] Embodiment: a kind of method (see figure 1 ), characterized in that it is realized by the following steps:

[0018] ①Raw material powder mixed ball mill: Calcium hydrogen phosphate dihydrate (CaHPO 4 2H 2 O) and calcium carbonate (CaCO 3 ) was mixed and ball-milled at a molar ratio of 6:4 for 16 hours;

[0019] ② Hydrothermal reaction: add enough deionized water, the temperature is 90°C, and the reaction time is 2 hours;

[0020] ③Drying and grinding, the drying temperature is 80°C, and the drying time is 8 hours. ;

[0021] ④ Target material mixing: Hydroxyapatite (HA) powder is mixed with 10% calcium oxide (CaO) powder, and the time in target material mixing is 8 hours;

[0022] ⑤Cold press forming: the pressure is 200-300MPa;

[0023] ⑥ Sintering: the temperature is 1150°C, placed in an air furnace for 3 hours;

[0024] ⑦ Double-slant target sputtering: use a multi-target magnetron sputtering apparatus for double-slant target sputtering, and the flow rate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com