Geosynthetic biaxial tension creep tester

A geosynthetic material, biaxial stretching technology, applied in the direction of analyzing materials, using stable tension/pressure testing materials, instruments, etc., can solve the problems of small stretching range, difficulty, large error, etc., and achieve large stretching Deformation space, high long-term stability and reliability, resolving time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

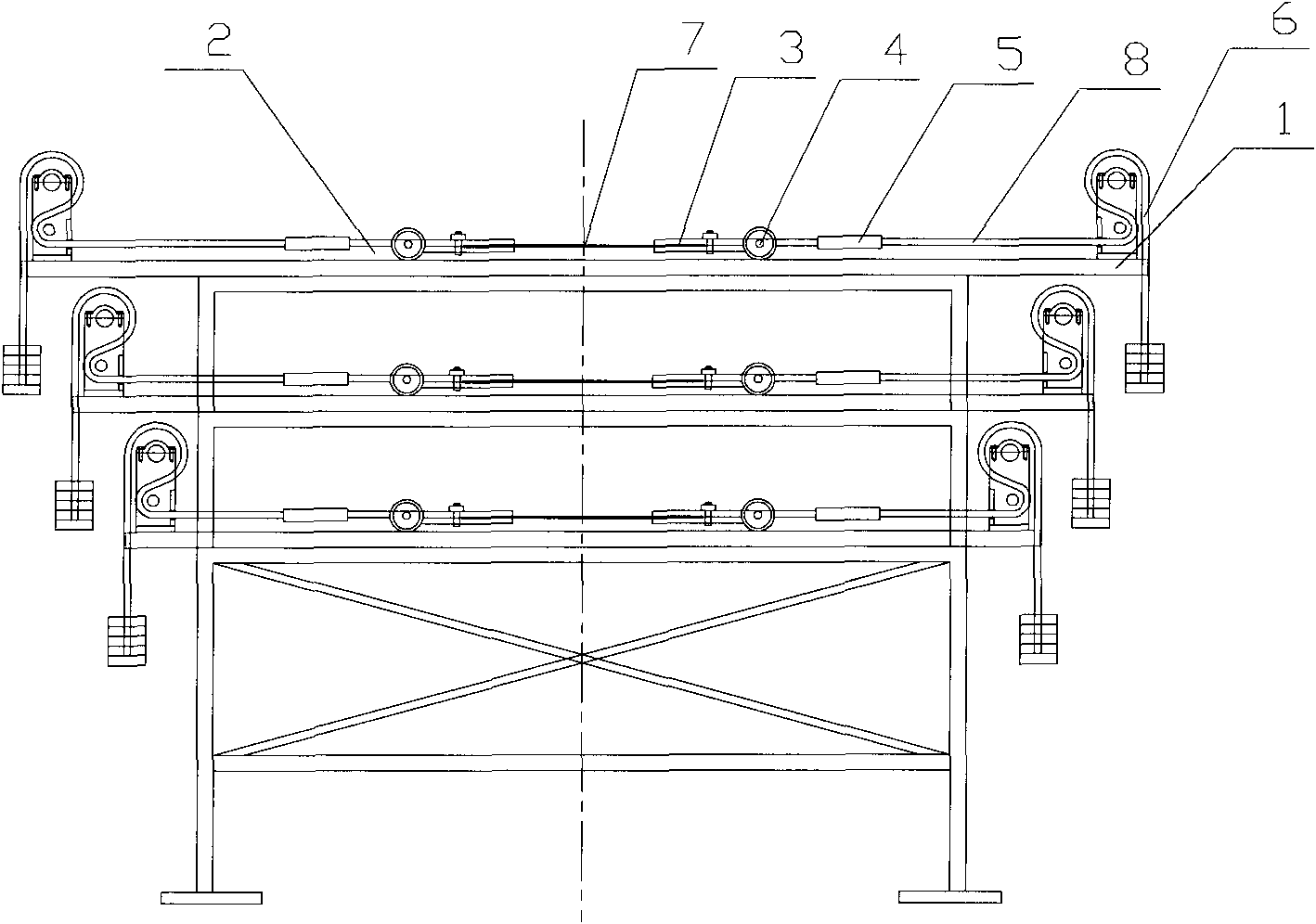

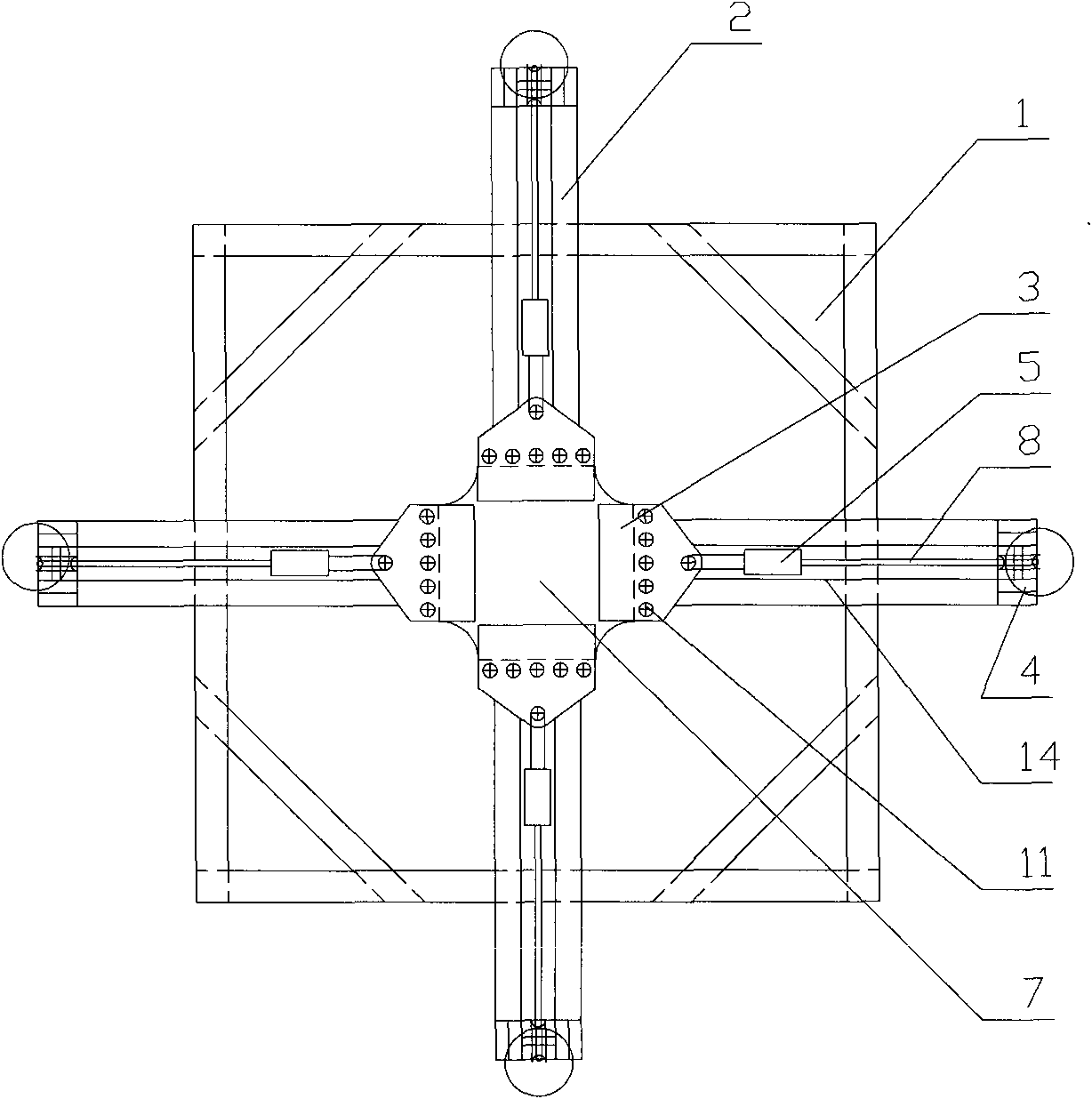

[0031] Geosynthetics bidirectional tensile creep tester, comprising a main frame platform 1 and a cross-shaped tensile test device 2 arranged on the main frame platform 1, the main frame platform 1 has three layers, and the size of each layer platform and The structural arrangement is the same, and the cross-shaped tensile test device 2 includes a clamping device 3, a guiding device 4, a displacement sensor 5 and a force applying device 6;

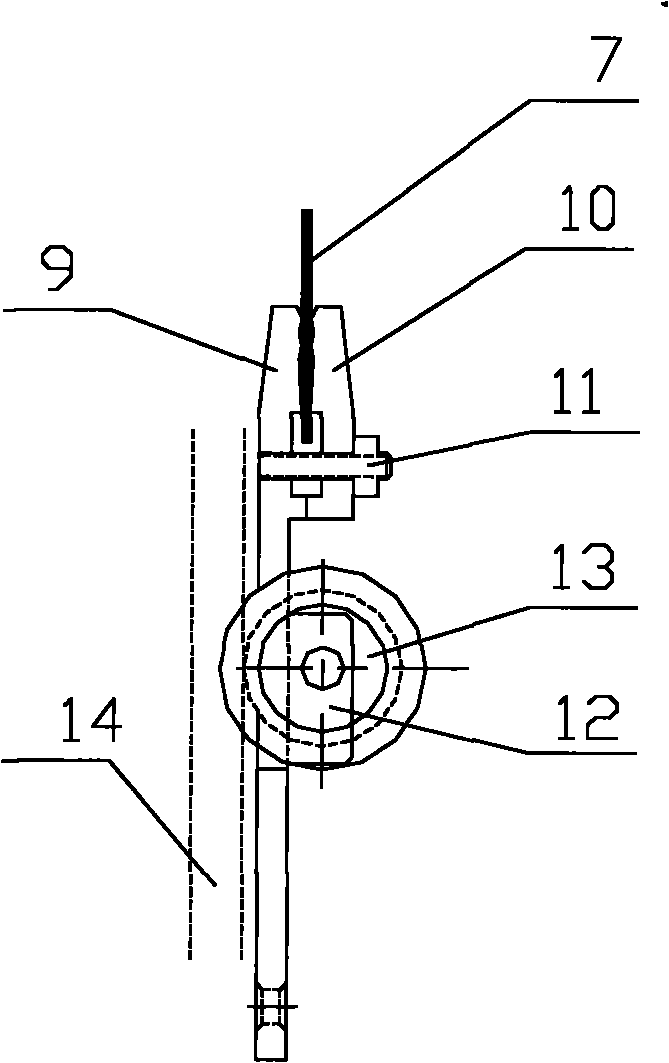

[0032] The clamping device 4 is four groups, and each group of clamping devices 3 includes a fixed splint 9 and a movable splint 10, which are anchored by bolts 11; the jaws of the fixed splint 9 and the movable splint 10 are sinusoidal; clamping The device 4 clamps the four sides of the test piece 7 placed in the middle of the cross-shaped tensile test device 2, and passes through the steel cables 8 and the four ends of the cross-shaped tensile test device 2 respectively. The force applying device 6 is connected;

[0033] Described guidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com