Virtual prediction method for material hardening behavior under large strain condition

A prediction method and large-strain technology, applied in computer material science, computational theoretical chemistry, design optimization/simulation, etc., can solve problems such as lack of universal applicability and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

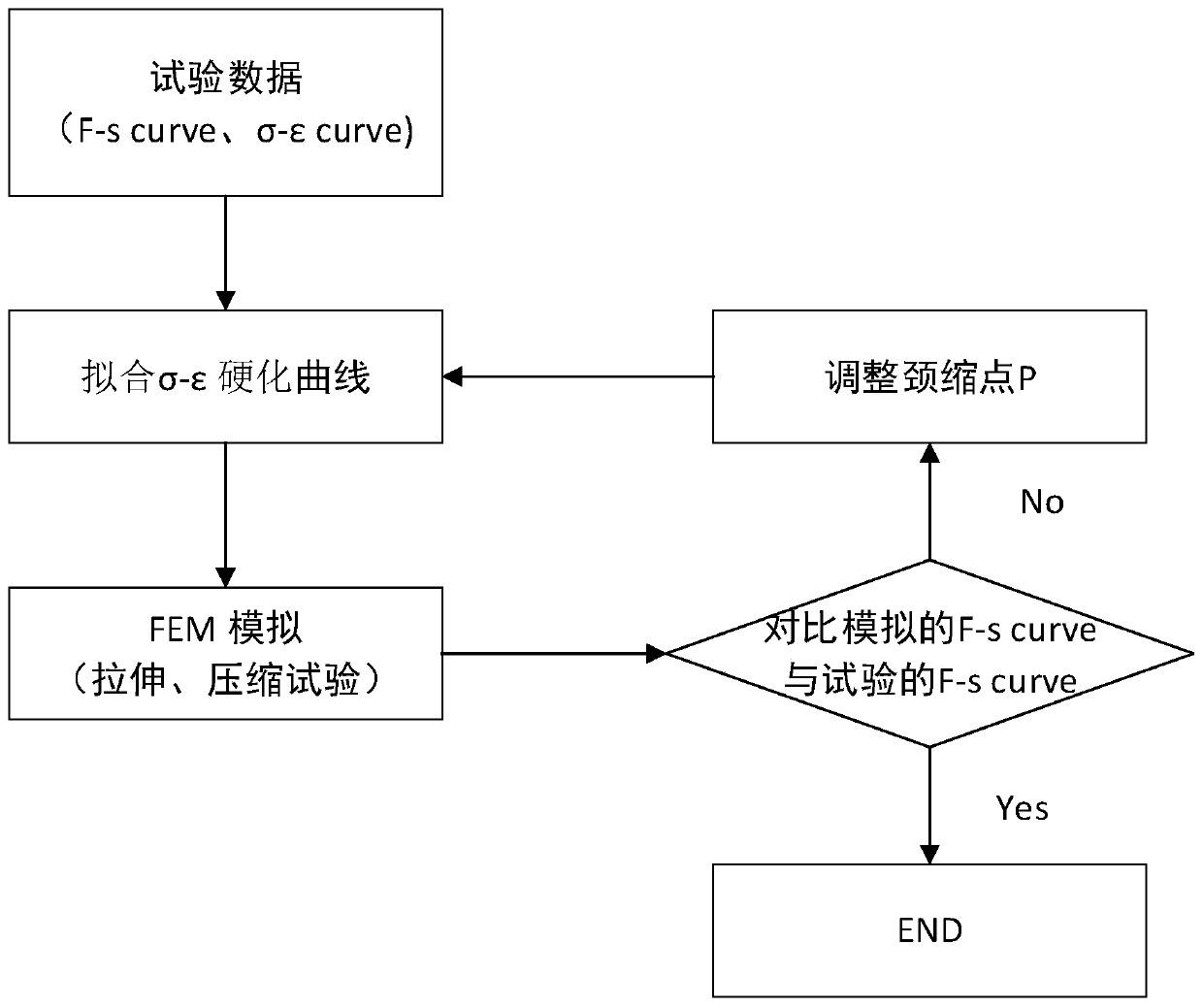

Method used

Image

Examples

Embodiment

[0056] (1) Zr-4 alloy rod sample

[0057] The original material is annealed Zr-4 alloy;

[0058] The gauge length of the bar sample is 25mm, and the diameter of the cross section is

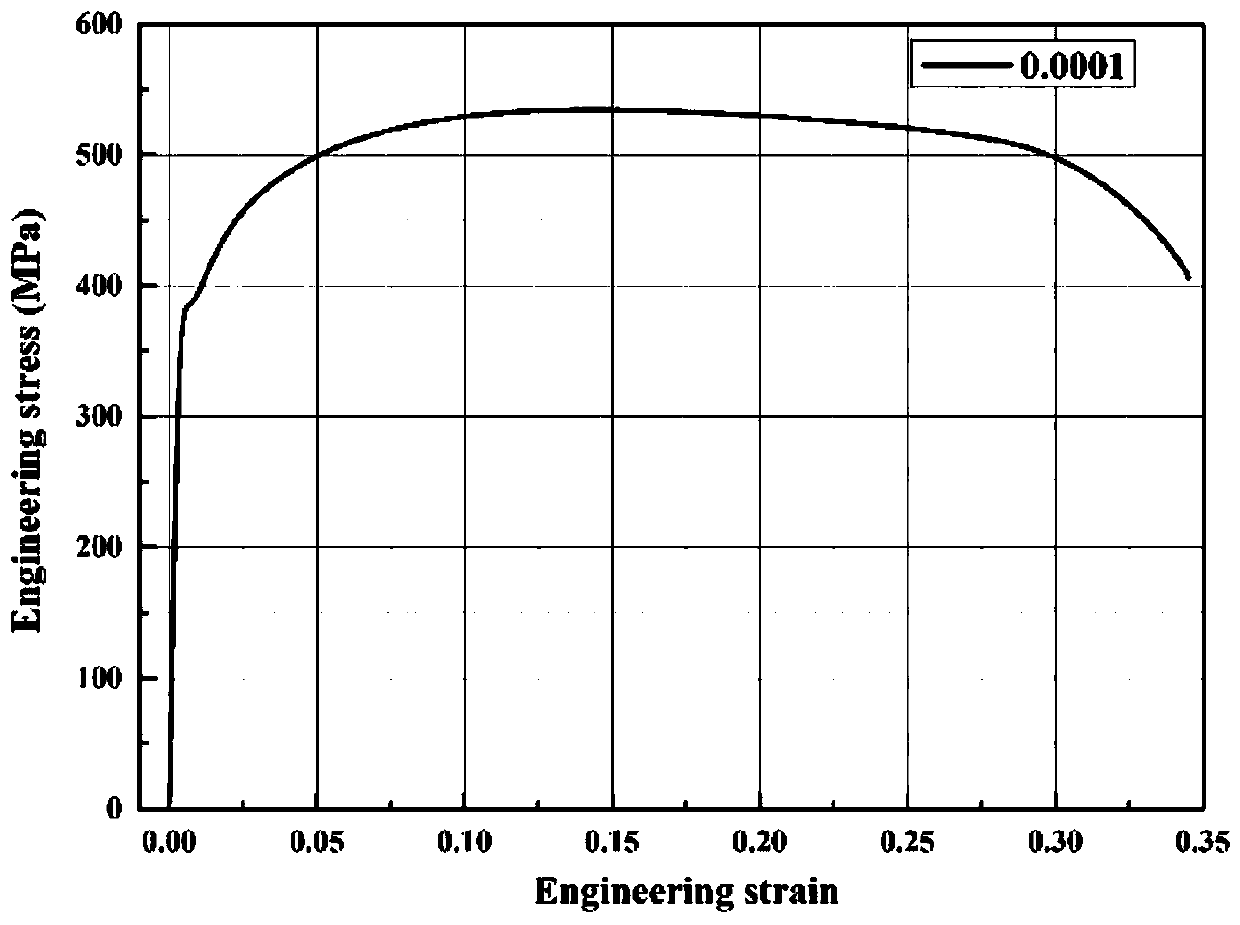

[0059] Such as image 3 As shown, the test measured strain rate is 0.0001s -1 The engineering stress-strain curve for the case is given by image 3 It can be seen that the Zr-4 alloy fractured when the engineering strain was 0.34, and the hardening curve under the condition of large strain could not be obtained directly from the test results;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com