Device for testing uniaxial tension mechanical property of conducting material under high temperature environment

A high temperature environment, uniaxial stretching technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of slow heating speed, low heating temperature, inaccurate temperature measurement, etc., to achieve easy disassembly, simple production , responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

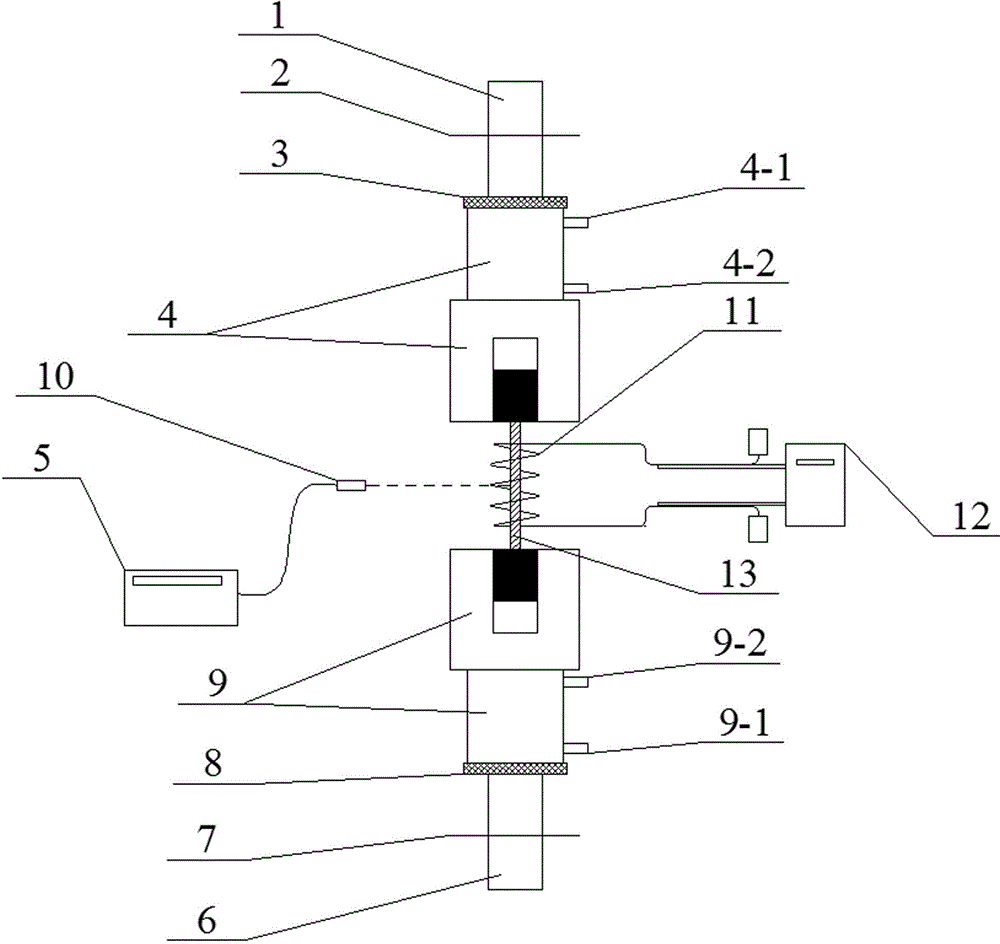

[0011] Specific implementation mode one: combine figure 1 As shown, it includes upper insulating tension rod 1, upper positioning pin 2, upper insulating gasket 3, upper fixture 4, temperature measurement controller 5, lower insulating tension rod 6, lower positioning pin 7, lower insulating gasket 8, lower Fixture 9, temperature measuring probe 10, induction coil 11, induction heating system controller 12;

[0012] The upper fixture 4 is a fixture with a circulating water cooling channel inside, and a cooling water inlet 4-1 and a cooling water outlet 4-2 are arranged on it; the lower fixture 9 is a fixture with a circulating water cooling channel inside, And it is provided with a cooling water inlet 9-1 and a cooling water outlet 9-2; the induction coil 11 is made of a copper tube, and cooling water is provided in the tube; the upper insulating tension rod 1 passes through the upper insulating gasket 3 is connected to the upper end surface of the upper fixture 4; the lower ...

Embodiment 1

[0023] Si-ZrBr 2 High Temperature Uniaxial Tensile Test of Ceramics

[0024] First, measure the dimensions of the test piece. Use an electronic vernier caliper to measure the width of the specimen, measure the widths at both ends and the middle of the gauge section respectively, and then take the average value as the width of the gauge section of the specimen; use the same method to measure the height of the specimen. The cross-sectional area of the test piece is equal to the product of the average width and the average thickness of the gauge length section.

[0025] Then place the test piece, adjust the positions of the induction coil and the test piece, and ensure that the central axis of the test piece, the axis of the induction coil and the axis of the stretching rod coincide with each other.

[0026] Turn on the dual colorimetric temperature measurement system, adjust the position and distance of the temperature measurement probe so that the probe is facing the center...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com