Thin film special material for polyether-ether-ketone as well as preparation method and application thereof in preparing polyether-ether-ketone/polyetherimide alloy thin film

A technology of polyetheretherketone resin and polyetherimide is applied in the application field of preparing polyetheretherketone/polyetherimide alloy film, which can solve processing difficulties, hinder the large-scale application of film, polyetherether Ketones Are Expensive and More

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 43.35Kg of diphenyl sulfone into a reaction kettle equipped with mechanical stirring, temperature control system and nitrogen protection, heat to 160°C and add 10.921Kg (50.05mol) of 4,4'-difluorobenzophenone, anhydrous 6.36Kg (60mol) of sodium carbonate, then heated to 165°C, added 5.502Kg (50mol) of hydroquinone, continued to heat to 200°C for 1 hour, then gradually raised the temperature to 250°C for 35 minutes, and then reacted for 1 hour at 280°C. Finally, it was heated to 315° C. for 4 hours to react. Then 85.1 g (0.5 mol) of 4-hydroxybiphenyl monomer was added. After continuing the reaction for 30 minutes, it can be found that the viscosity of the reaction solution no longer increases with the reaction time, which proves that 4-hydroxybiphenyl can react with the end group of the polymer to terminate the polymerization reaction. The reaction solution was pumped into a filter tank at 260° C. containing 57.8 Kg of diphenyl sulfone solution to adjust the solid c...

Embodiment 2

[0034] According to the reaction steps of Example 1, only 10.916Kg (50.03mol) of 4,4'-difluorobenzophenone was changed and the reaction steps were unchanged.

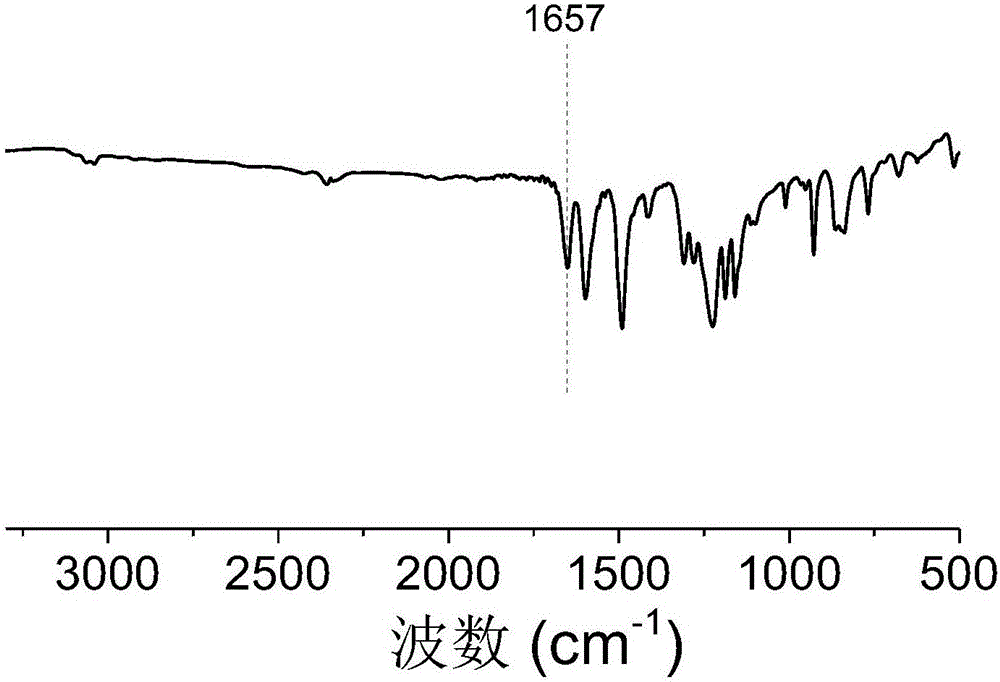

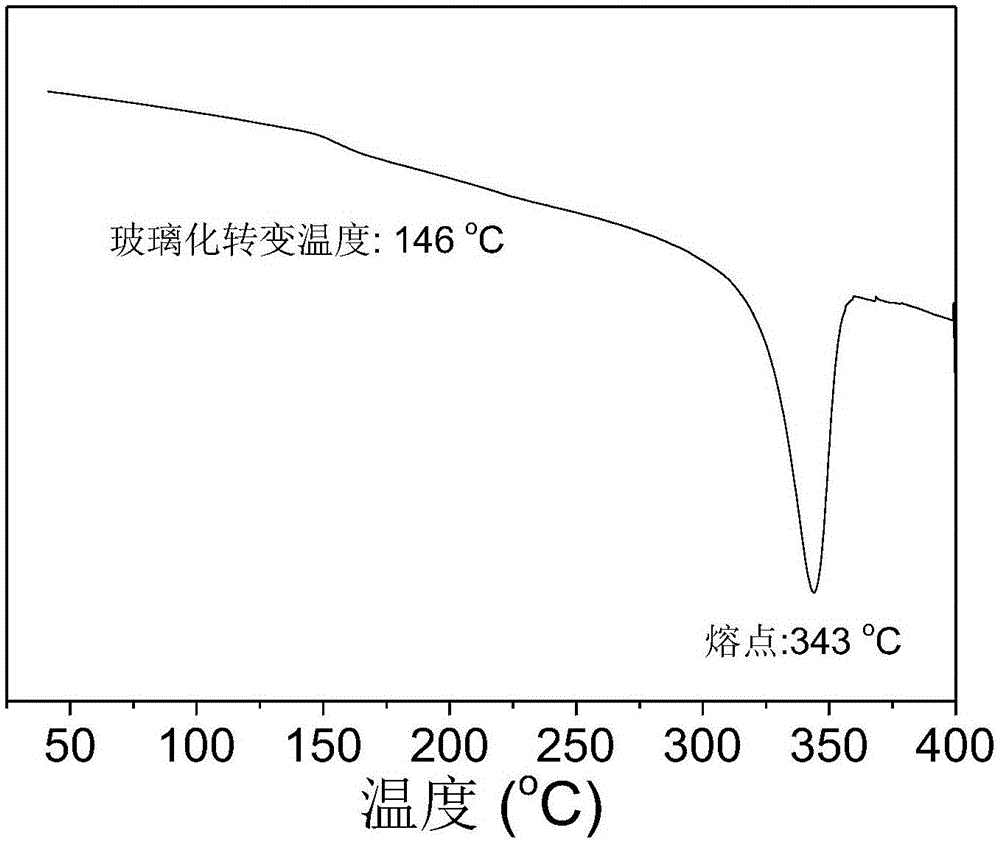

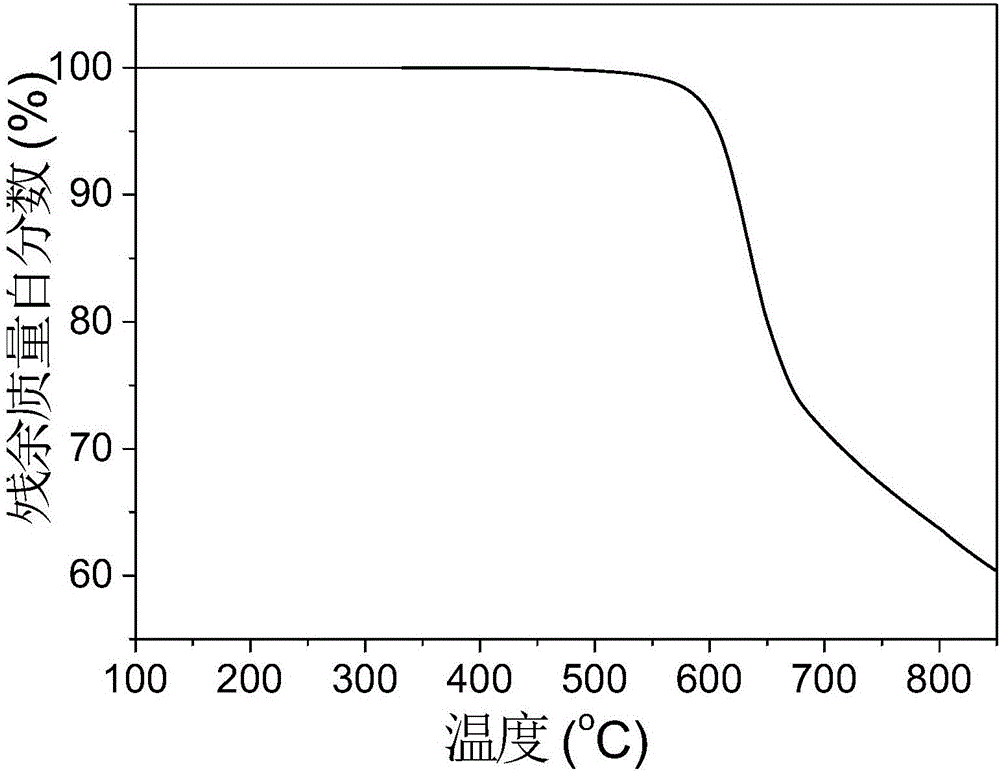

[0035]The melt index of the test material is 15g / 10min (melt index meter, 400°C, 5kg pressure, the melt index can reflect the molecular weight), and the initial thermal weight loss temperature of the polymer under nitrogen environment is higher than 550°C. Its glass transition temperature is 146°C and its melting point is 343°C.

Embodiment 3

[0037] The raw material is the melt index 26g / 10min film-grade polyetheretherketone resin prepared in Example 1, polyetherimide resin (Sabic company Altem1000), polyetheretherketone / polyetherimide film according to each component and 100.0wt % calculation, containing 95.0wt% film-grade polyether ether ketone resin, 5.0wt% polyetherimide resin, premixed in a high-speed mixer and dried at 130 ° C for 2.5 hours at a high temperature, and then passed through a feeding screw The hopper is added to the twin-screw extruder. The temperature of each section of the twin-screw extruder barrel is 335°C, 350°C, 365°C, and 380°C. The ratio of the speed of the feeding screw in the hopper to the speed of the twin-screw of the extruder is 3: 2; The width of the mouth film is 150mm, the film lip thickness of the bow-shaped slit film is 0.18mm, the temperature of the mouth film is 360°C, the distance between the mouth film and the three-roll calender is 2mm, and the three-roll calender roll The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com