Hybrid fiber reinforced strain hardening cement-based composite material and preparation method thereof

A composite material and strain hardening technology, applied in the field of building materials, can solve the problems of low cost performance, brittle cracking of organic polymer materials, neglect of compressive strength, etc., to achieve high cost performance, improve fluidity, and improve the effect of tensile stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

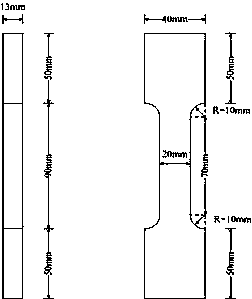

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of hybrid fiber reinforced strain hardening cement-based composite material, its raw material is composed of: Portland cement, water reducing agent, fly ash, sand, PVA fiber, steel fiber, calcium carbonate whisker and water, the above-mentioned The mass ratio of raw materials is: Portland cement 300Kg / m 3 , superplasticizer 6Kg / m 3 , fly ash 1200Kg / m 3 , sand 540Kg / m 3 , PVA fiber 18Kg / m 3 , steel fiber 45Kg / m 3 , calcium carbonate whisker 110Kg / m 3 , water 510Kg / m 3 .

Embodiment 2

[0022] Embodiment 2: A kind of hybrid fiber reinforced strain hardening cement-based composite material, its raw material is composed of: Portland cement, water reducing agent, fly ash, sand, PVA fiber, steel fiber, calcium carbonate whisker and water, the above-mentioned The mass ratio of raw materials is: Portland cement 305Kg / m 3 , superplasticizer 5Kg / m 3 , fly ash 1250Kg / m 3 , sand 520Kg / m 3 , PVA fiber 22Kg / m 3 , steel fiber 20Kg / m 3 , calcium carbonate whisker 150Kg / m 3 , water 505Kg / m 3 .

Embodiment 3

[0023] Embodiment 3: A kind of hybrid fiber reinforced strain hardening cement-based composite material, its raw material is composed of: Portland cement, water reducing agent, fly ash, sand, PVA fiber, steel fiber, calcium carbonate whisker and water, the above-mentioned The mass ratio of raw materials is: Portland cement 295Kg / m 3 , superplasticizer 7Kg / m 3 , fly ash 1150Kg / m 3 , sand 560Kg / m 3 , PVA fiber 14Kg / m 3 , steel fiber 70Kg / m 3 , calcium carbonate whisker 70Kg / m 3 , water 515Kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com