GBL concrete waterproof compacting agent

A waterproof and compact concrete technology, applied in the field of GBL concrete waterproof and compact agent, can solve the problems of concrete durability damage, large engineering period, concrete volume shrinkage, etc., to prevent water molecule penetration, improve strength and performance, and improve resistance Osmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

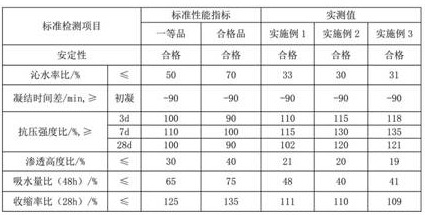

Examples

Embodiment 1

[0019] GBL concrete waterproof compacting agent, including the following raw materials in parts by weight: 10 parts of sodium silicate, 20 parts of potassium aluminum sulfate dodecahydrate, 1 part of polyether, 0.05 part of polyhydroxy compound, 1 part of polyethylene glycol, n-butanol 0.5 part, 0.01 part of mineral fiber, 0.2 part of diethanolamine, 2 parts of lithium carbonate, 0.2 part of triethanolamine stearate, 0.05 part of surfactant, 0.002 part of NNO dispersant and 40 parts of water.

Embodiment 2

[0021] GBL concrete waterproof compacting agent, including the following raw materials in parts by weight: 15 parts of sodium silicate, 24 parts of potassium aluminum sulfate dodecahydrate, 3 parts of polyether, 0.2 part of polyhydroxy compound, 4 parts of polyethylene glycol, n-butanol 1 part, 0.03 part of mineral fiber, 0.3 part of diethanolamine, 3 parts of lithium carbonate, 0.3 part of triethanolamine stearate, 0.07 part of polyoxyethylene-polyoxypropylene copolymer, 0.004 part of NNO dispersant and 50 parts of water, also Including silicone oil, the addition ratio of silicone oil and potassium aluminum sulfate dodecahydrate is 0.1:1.

Embodiment 3

[0023] GBL concrete waterproof compacting agent, including the following raw materials in parts by weight: 17 parts of sodium silicate, 28 parts of potassium aluminum sulfate dodecahydrate, 4 parts of polyether, 0.5 part of polyhydroxy compound, 6 parts of polyethylene glycol, n-butanol 1.2 parts, 0.06 parts of mineral fiber, 0.4 parts of diethanolamine, 5 parts of lithium carbonate, 0.4 parts of triethanolamine stearate, 0.1 parts of polyoxyethylene-polyoxypropylene copolymer, 0.006 parts of NNO dispersant and 70 parts of water, also Including silicone oil, the addition ratio of silicone oil and potassium aluminum sulfate dodecahydrate is 0.2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com