Steel slag multistage crushing and grinding ultrafine powder preparation device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

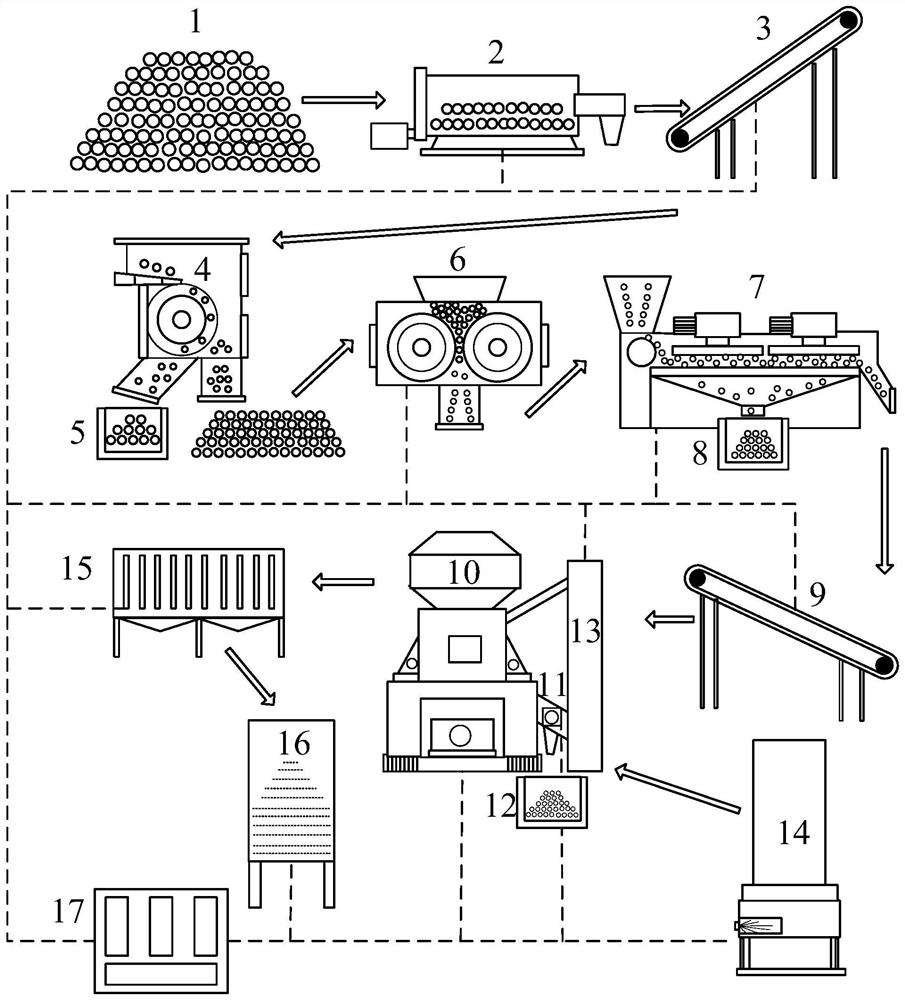

[0040] A steel slag multi-stage crushing and grinding ultra-fine powder preparation device is attached figure 1 As shown, including: steel slag tailing bin 1, rod mill slag breaker 2, No. 1 belt line 3, electromagnetic drum iron remover 4, magnetic separation powder 1 bin 5, double roller slag breaker 6, disk magnetic separator 7. Magnetic separation powder 2 warehouse 8, No. 2 belt line 9, vertical slag grinding machine 10, strong magnetic separator 11, magnetic separation powder 3 warehouse 12, bucket elevator 13, hot air stove 14, dust collector 15, preferably It is a bag filter 15 and a finished product bin 16. The steel slag tailings are piled in the steel slag tailing bin 1, and the steel slag tailings in the steel slag tailing bin 1 can be sent to the rod mill 2 for primary crushing treatment; the No. 1 belt line 3 The starting end is located below the rod mill slag breaker 2, and the No. 1 belt line 3 terminal is located above the electromagnetic drum iron remover 4, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com