A kind of processing method of waste material containing electrolyte

A treatment method and electrolyte technology, applied in battery recycling, aluminum fluoride, aluminum halide, etc., can solve the problems of high energy consumption, low added value, poor product quality, etc., and achieve low energy consumption, easy waste zero discharge, and disposal. The effect of process energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

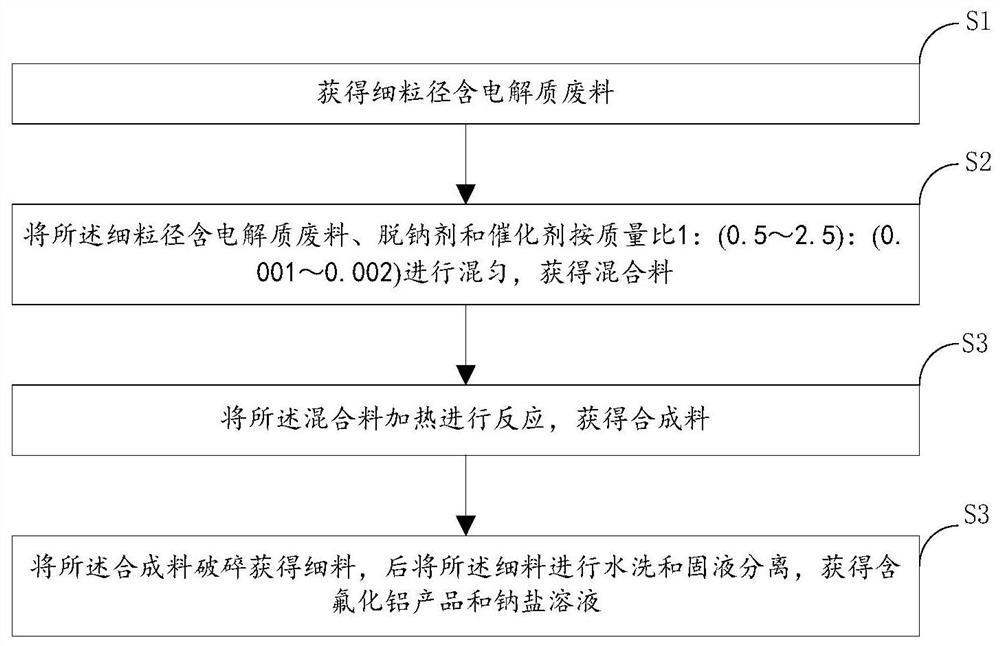

[0036] According to a typical embodiment of the present invention, there is provided a treatment method for waste materials containing electrolytes, such as figure 1 shown, including:

[0037] S1. Obtain fine particle size electrolyte-containing waste;

[0038] S2. Mix the electrolyte-containing waste material with fine particle size, sodium removing agent and catalyst according to the mass ratio of 1: (0.5-2.5): (0.001-0.002) to obtain a mixture;

[0039] S3, heating the mixed material to react to obtain a synthetic material;

[0040] S4. Crushing the synthetic material to obtain a fine material, and then washing the fine material with water and separating solid and liquid to obtain an aluminum fluoride-containing product and a sodium salt solution.

[0041]The present invention provides a method for treating waste material containing electrolyte, which utilizes the strong sodium-removing performance of the sodium-removing agent, and under the action of the catalyst, destro...

Embodiment 1

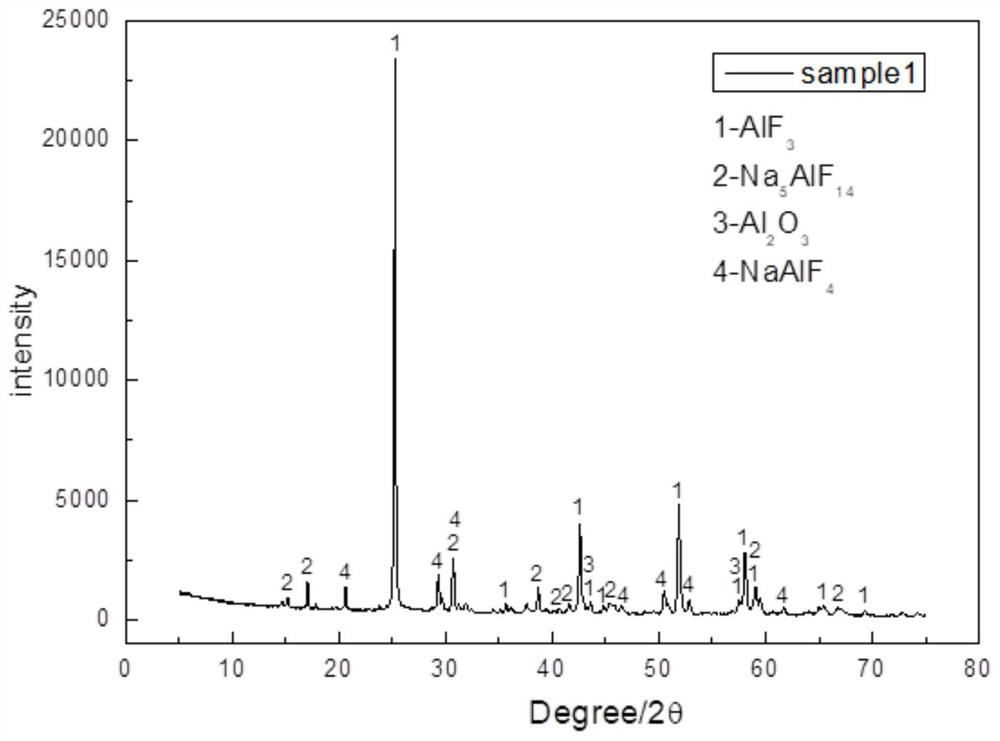

[0056] Weigh a certain amount of carbon residue and crush it in a jaw crusher for 10 minutes, and screen out carbon residues with a particle size of less than 5 mm; then treat it in a ball mill for 15 minutes, and screen out fine carbon residues with a particle size of less than 1 mm; The sodium removal agent aluminum sulfate, magnesium sulfate and catalyst manganese trioxide are uniformly mixed and compounded, wherein the sodium removal dosage and catalyst amount required for compounding are 1.30 times and 0.0013 times the mass of the electrolyte respectively; then in an intermediate frequency furnace at 650 ° C Heating for 45min; after crushing and grinding the heat-treated synthetic material to 60 mesh, stirring and washing with water according to the liquid-solid ratio of 6, the filter cake after solid-liquid separation, the phase after drying is as follows figure 2 As shown, its main component is aluminum fluoride, and in addition, it contains a small amount of sub-cryoli...

Embodiment 2

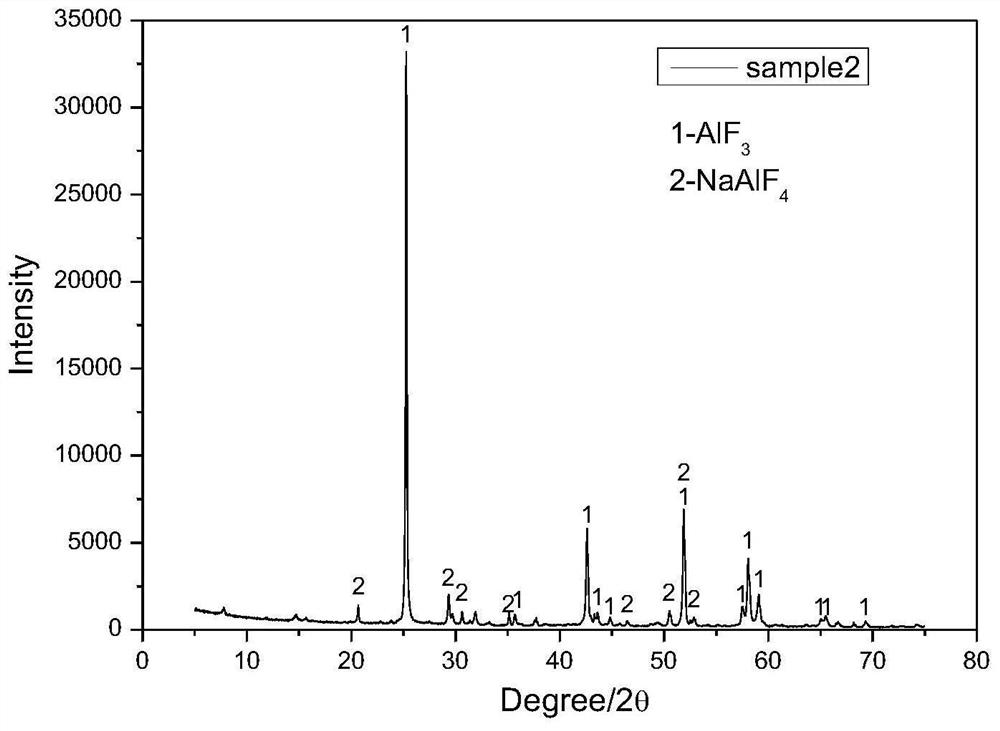

[0058] Weigh a certain amount of carbon residue flotation electrolyte, and mix it with sodium removing agent polyaluminum sulfate, lithium chloride and catalyst potassium hexafluorophosphate, wherein the amount of sodium removing agent and catalyst is 0.95 times of the electrolyte quality. and 0.001 times; then heat the compounded material in an intermediate frequency furnace at 800°C for 30 minutes; after crushing and grinding the heat-treated synthetic material to 200 mesh, stir and wash with water according to the liquid-solid ratio of 3. The separated filter cake, after drying, looks like image 3 As shown, its main component is aluminum fluoride, and in addition, it contains a small amount of sub-cryolite, alumina and single cryolite, no impurities harmful to electrolysis, and fully meets the requirements of the electrolytic cell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com