A system device and method for preparing recycled sand from waste concrete

A technology for waste concrete and regenerated sand, which is applied in the direction of grain processing, etc., can solve the problems such as the lack of relevant patent literature on the device and method of the regenerated sand system, the short service life of fine crushing and wear-resistant parts, and the low efficiency of the grinding system, so as to achieve a material balance. Easy to master, less equipment, strong source properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

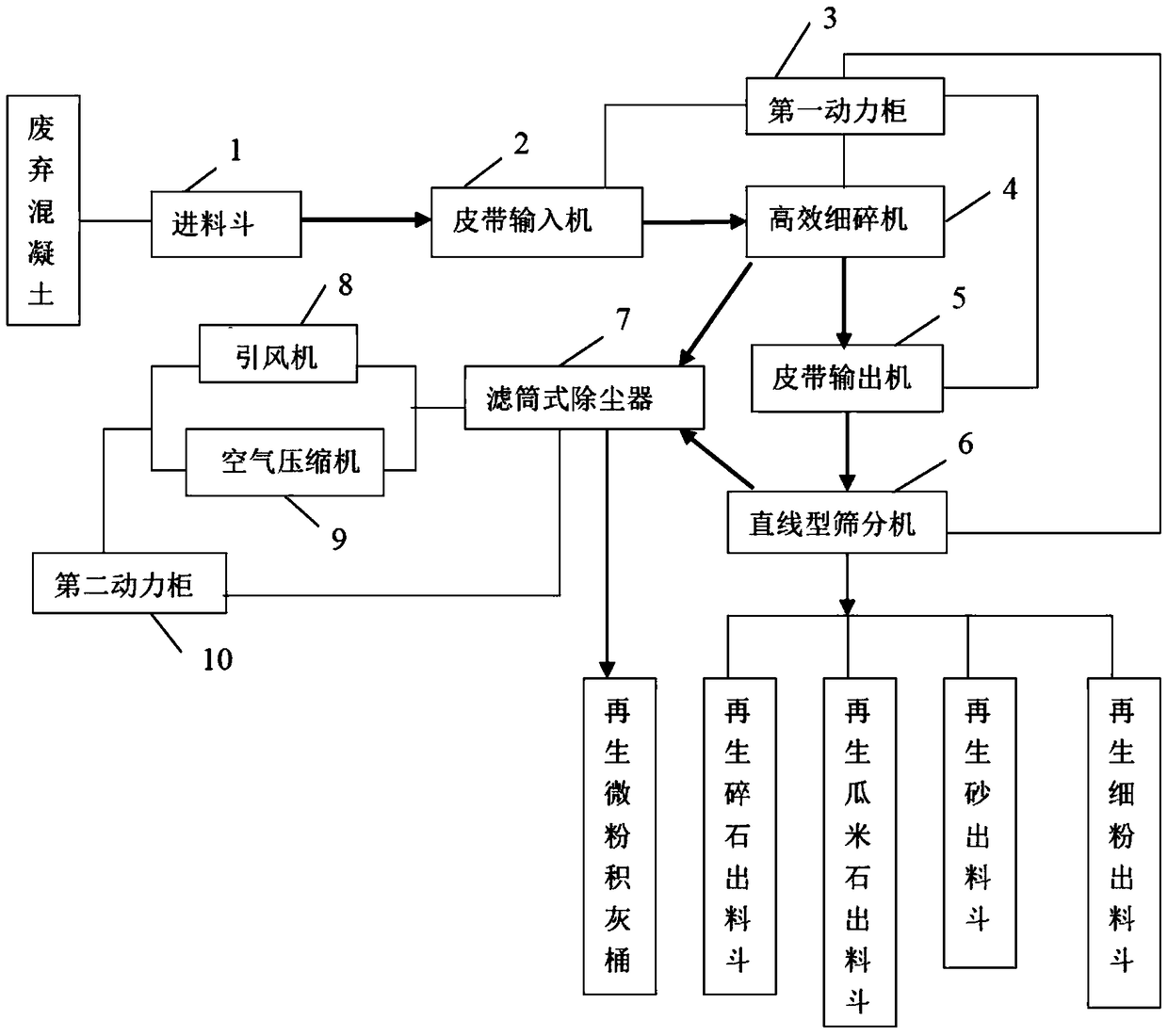

[0042] see figure 1 , a system device for preparing recycled sand from waste concrete. The waste concrete in the present invention refers to waste concrete materials produced by concrete production enterprises, concrete engineering quality inspection units, cement roads or concrete structure engineering construction sites. The system device includes a feed hopper 1, a belt feeder 2, a fine crusher 4, a belt output machine 5, and a screening machine 6; the output port of the feed hopper 1 is connected with the entrance of the belt feeder 2, and the belt feeder The outlet of the machine 2 is connected with the inlet of the fine crusher 4, the discharge port of the fine crusher 4 is connected with the inlet of the belt output machine 5, and the outlet of the belt output machine 5 is connected with the screening machine 6 The feeding port is connected, and the belt input machine 2, the fine crusher 4, the belt output machine 5 and the screening machine 6 are respectively electrica...

experiment example 1

[0059] The regenerated sand prepared by the system device for preparing regenerated sand from waste concrete can be used in concrete enterprises to comprehensively utilize waste concrete to produce regenerated concrete.

[0060] The reclaimed sand prepared by the invention is used to replace yellow sand to prepare C30 strength grade concrete. Take conventional C30 strength grade concrete as the control group 1.1m 3 The weights of the materials in the concrete of the control group are: 150-170Kg of cement, 85-100Kg of grade 95 mineral powder, 80-90Kg of grade II fly ash, 700-800Kg of natural yellow sand and the regenerated sand, and 1000-1200kg of natural gravel (The maximum particle size is 20mm, which contains 300kg of 5~10mm natural melon stone), water 155~165Kg, water reducing agent 6.00~7.50. The above-mentioned water reducer is a high-efficiency polycarboxylate water reducer, purchased from Guangzhou Luomei Building Materials Co., Ltd., and the brand is LM-S2. The 5~10m...

experiment example 2

[0065] The regenerated sand prepared by the system device for preparing regenerated sand from waste concrete can be used in dry-mixed mortar enterprises to comprehensively utilize waste concrete to produce regenerated masonry mortar.

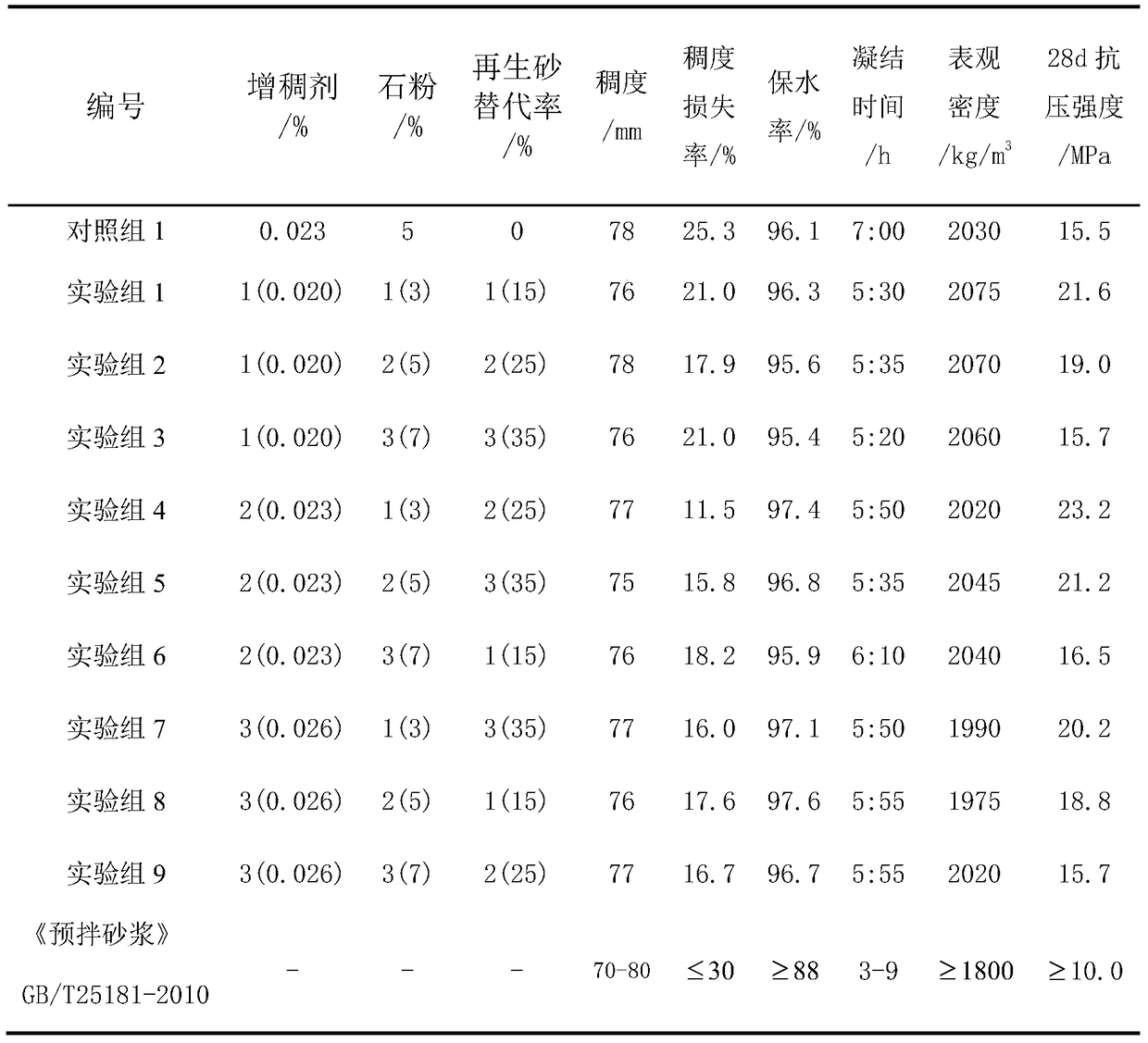

[0066]The regenerated sand prepared by the present invention is used to replace yellow sand to prepare dry-mixed M10 masonry mortar. The conventional dry-mixed masonry mortar was used as the control group 1. The weight percentages of each dry material in the mortar of the control group are: 10-20% of cement, 3-7% of stone powder, 0.020-0.026% of thickener, 75-85% of recycled sand and natural yellow sand, and the weight of recycled sand accounts for and 15-35% of the total weight of natural yellow sand, and the water-material ratio is 14-16%. The above-mentioned thickener is hydroxypropyl methylcellulose ether, which is purchased from Shandong Yiteng New Material Co., Ltd., and the brand name is 60YT100000.

[0067] Taking the amount of thicken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com