Ultrasonic leaching-extracting separation method for low-yttrium middle-heavy rare earth mine

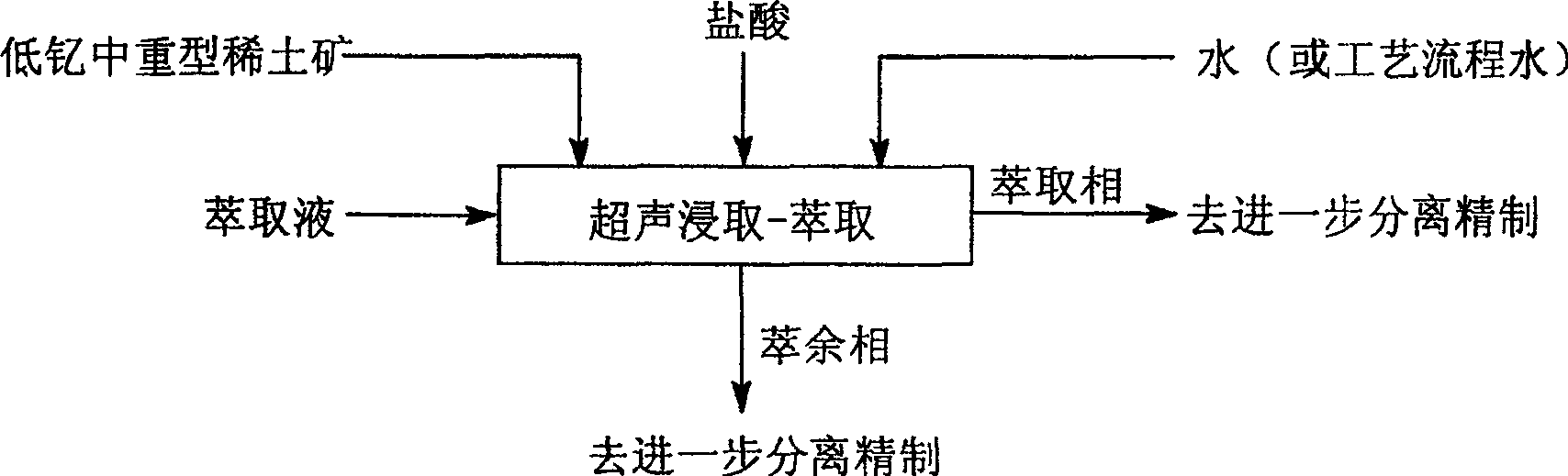

A separation method and technology for rare earth ore, applied in the field of separation of low yttrium medium and heavy rare earth ore, can solve the problems of leaching, low extraction rate and efficiency, low economic and social benefits, increased load of evaporation and concentration, etc. Omit group leaching or extraction equipment, improve the leaching-extraction process, increase the effect of speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

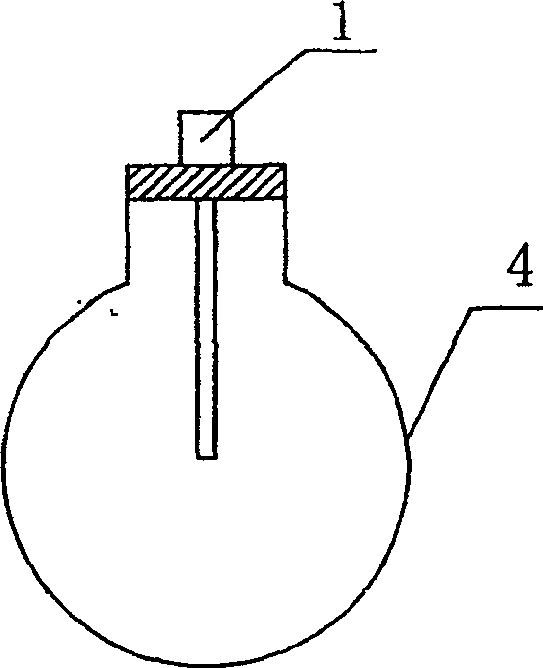

[0038] Equipment: probe-type ultrasonic generator, 1L stirring tank, analysis and testing equipment.

[0039] Raw materials: water, hydrochloric acid, P507 (2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester), kerosene, low yttrium medium and heavy rare earth ore.

[0040] The process steps of separation are as follows:

[0041] Put low-yttrium medium-heavy rare-earth ore, leaching solution, and extract into a 1L stirred tank in a ratio of 1000g: 2L: 1L, and the addition of concentrated low-yttrium medium-heavy rare-earth mineral material is 100g, then add hydrochloric acid aqueous solution (leaching Liquid) 0.2L and P507 and kerosene mixed solution (extract) 0.1L, place the probe of the ultrasonic generator in the mixed material, adjust the ultrasonic frequency to 19kHz, the intensity 0.2W / cm 2 , control the operating temperature at 5°C, and perform ultrasonic leaching-extraction separation for 30 minutes to obtain the extract phase (upper layer), raffinate phase (middle l...

Embodiment 2

[0043] Equipment: probe type ultrasonic generator, 2L stirring tank, analysis and testing equipment.

[0044] Raw materials: water, hydrochloric acid, P507 (2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester), kerosene, low yttrium medium and heavy rare earth ore.

[0045] The process steps of separation are as follows:

[0046] Put low-yttrium medium-heavy rare-earth ore, leaching solution, and extract into a 2L stirring tank in a ratio of 1000g: 10L: 3L, and the addition of concentrated low-yttrium medium-heavy rare-earth mineral material is 100g, then add hydrochloric acid aqueous solution (leaching Liquid) 1L and P507 and kerosene mixed solution (extract) 0.3L, the probe of the ultrasonic generator is placed in the mixed material, the ultrasonic frequency is adjusted to 25kHz, the intensity is 2.0W / cm 2 , control the operating temperature at 40°C, and perform ultrasonic leaching-extraction separation for 15 minutes to obtain the extract phase (upper layer), raffinate ph...

Embodiment 3

[0048] Equipment: probe-type ultrasonic generator, 5L stirring tank, analysis and testing instruments;

[0049] Raw materials: water, hydrochloric acid, P507 (2-ethylhexyl phosphonic acid mono-2-ethylhexyl ester), kerosene, low yttrium medium and heavy rare earth ores;

[0050] The process steps of separation are as follows:

[0051] Put low-yttrium medium-heavy rare-earth minerals, leaching solution, and extract into a 10L stirred tank in a ratio of 1000g: 25L: 10L, and the addition of concentrated low-yttrium medium-heavy rare-earth minerals is 200g, then add hydrochloric acid aqueous solution (leaching Liquid) 5L and P507 and kerosene mixed solution (extract) 2L, the probe of the ultrasonic generator is placed in the mixed material, the ultrasonic frequency is adjusted to 80kHz, the intensity is 20.0W / cm 2 , control the operating temperature at 60°C, and perform ultrasonic leaching-extraction separation for 35 minutes to obtain the extract phase (upper layer), raffinate ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com