Method for wet desulfurization flue gas dewhitening and desulfurization wastewater emission reduction

A wet flue gas desulfurization and desulfurization wastewater technology is applied in the fields of flue gas desulfurization, soluble desulfurization product recovery, and desulfurization wastewater emission reduction, and can solve the problems of reducing heat exchange efficiency, reducing heat exchange temperature difference, and bulky condenser volume. Achieve the effect of reducing water evaporation, improving operational reliability, and reducing final emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

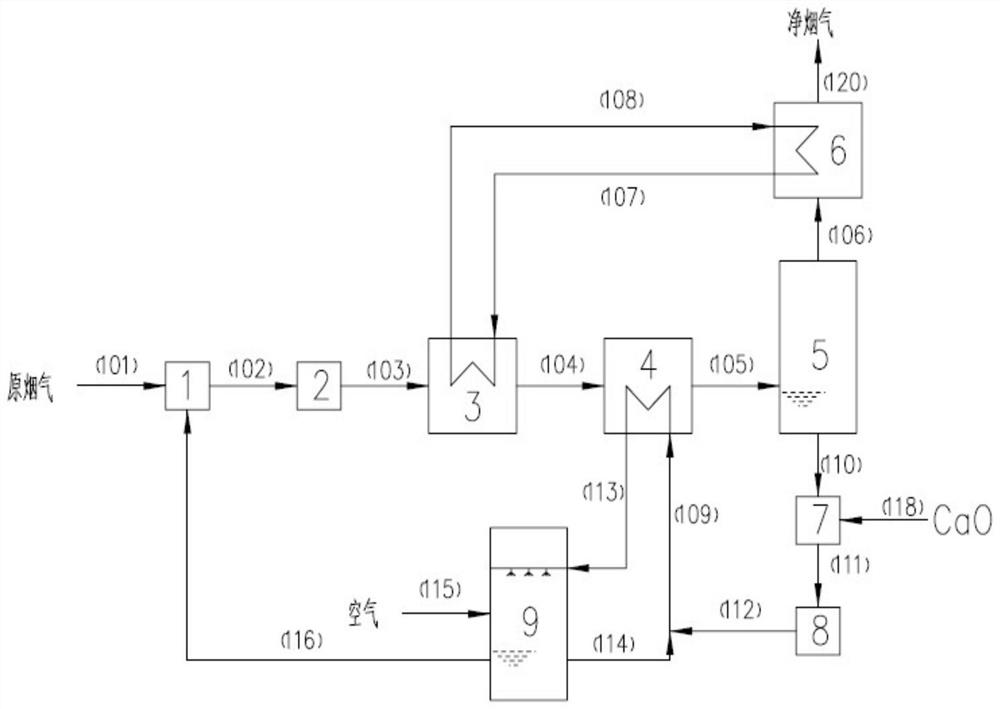

Embodiment 1

[0032] A 360 square meter sintering machine lime-gypsum flue gas desulfurization system, its process parameters are as follows: flue gas volume 1200000Nm 3 / h, raw flue gas temperature 150°C, moisture content 8% (v / v), SO 2 Concentration 800mg / m 3 , C1 concentration 80mg / m 3 ; Net flue gas SO 2 Concentration 50mg / m 3 , C1 concentration 0mg / m 3 . The ambient temperature is 20°C.

[0033] Such as process flow figure 1 As shown, the raw flue gas from the sintering machine enters the desulfurization wastewater evaporation section 1 through the pipeline (101), and exchanges heat with the 1.92t / h desulfurization wastewater introduced from the pipeline (116). The water in the desulfurization wastewater is evaporated into the The original flue gas, the calcium chloride particle that forms enters dust collector 2 by pipeline (102) along with original flue gas, and flue gas temperature drops to 146.7 ℃ by 150 ℃, and the moisture content of former flue gas increases from 8% (v / v) ...

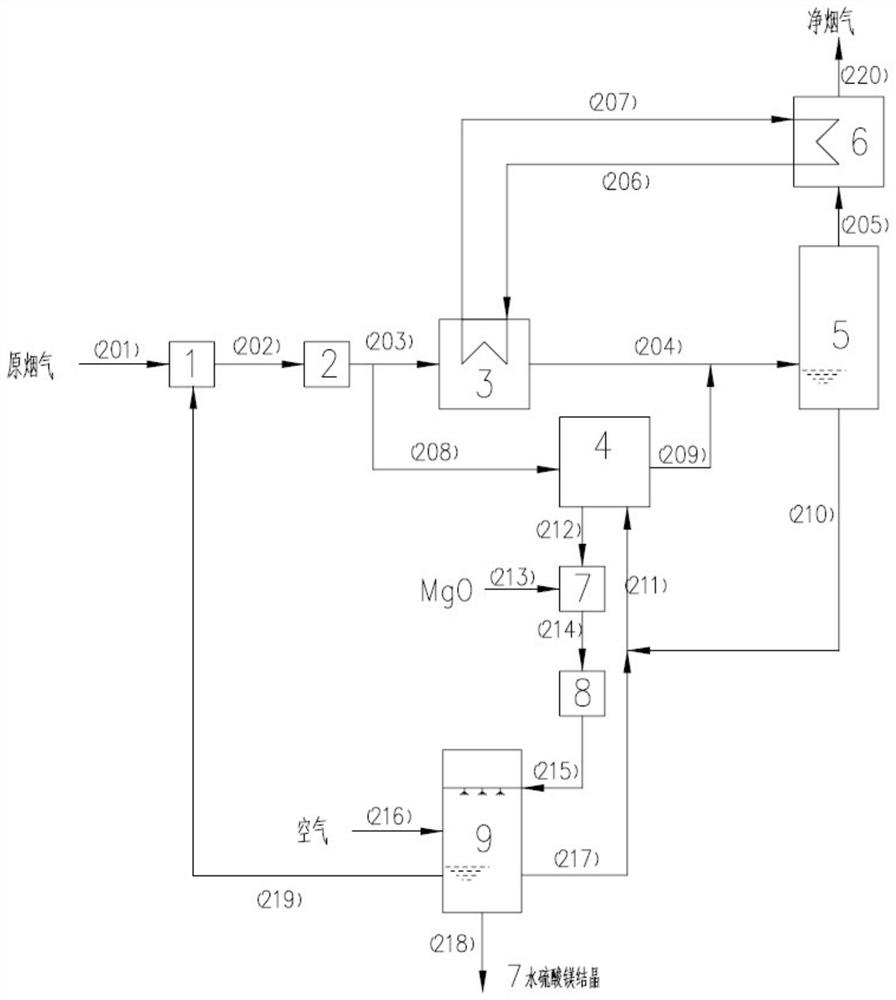

Embodiment 2

[0038] A 360 square meter sintering machine magnesium oxide wet flue gas desulfurization system, its process parameters are as follows: flue gas volume 1200000Nm 3 / h, raw flue gas temperature 150°C, moisture content 8% (v / v), SO 2 Concentration 800mg / m 3 , C1 concentration 80mg / m 3 ; Net flue gas SO 2 Concentration 50mg / m 3 , C1 concentration 0mg / m 3 . The ambient temperature is 20°C.

[0039] Such as process flow figure 2 As shown, the raw flue gas from the sintering machine enters the desulfurization wastewater evaporation section 1 through the pipeline (201), and exchanges heat with the 2.4t / h desulfurization wastewater introduced from the pipeline (219). The water in the desulfurization wastewater is evaporated into the The raw flue gas generates magnesium salt particles and enters the dust collector 2 from the pipeline (202) along with the raw flue gas, the temperature of the raw flue gas drops from 150°C to 145.9°C, and the moisture content of the raw flue gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com