Plastic concrete water evaporation inhibitor and preparation method thereof

An evaporation inhibitor, plastic concrete technology, applied in the field of concrete, to achieve the effect of reducing water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

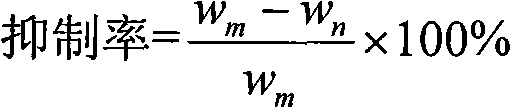

Method used

Image

Examples

Embodiment 1

[0016] Amphiphilic compound: 0.1g stearyl alcohol (0.1% by weight), nonionic surfactant: 0.15g polyoxyethylene lauryl ether (0.15% by weight), anionic surfactant: 0.5g sodium oleate (weight percent % 0.5%), thickener: 0.1g polyacrylamide (0.1% by weight), add water to 100g, uniformly stir at 60°C for 30 minutes, and discharge. The prepared emulsion is diluted 10 times and sprayed on the surface of plastic concrete, which can reduce 32% of water evaporation.

Embodiment 2

[0018] Amphiphilic compound: 5g stearyl alcohol (5% by weight) and 0.6g tetradecyl alcohol (0.6% by weight), nonionic surfactant: 10g polyoxyethylene alkylphenol ether (10% by weight), Anionic surfactant: 4g sodium oleate (4% by weight), thickener: 3g polyacrylamide (3% by weight), add water to 100g, uniformly stir at 50°C for 30 minutes, and discharge. The prepared emulsion is diluted 10 times and sprayed on the surface of plastic concrete, which can reduce 62% of water evaporation.

Embodiment 3

[0020] Amphiphilic compound: 10g hexadecanic acid (10% by weight), nonionic surfactant: 4g polyoxyethylene alkylphenol ether (4% by weight), anionic surfactant: 2g dodecylsulfonic acid Sodium (2% by weight), thickener: 9g polyethylene glycol (9% by weight), add water to 100g, uniformly stir at 90°C for 30 minutes, and discharge. The prepared emulsion is diluted 10 times and sprayed on the surface of plastic concrete, which can reduce the evaporation of water by 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com