Situ plow-putting vibrating scarifier

A scarifier and in-situ technology, applied in the field of agricultural machinery, can solve problems such as poor operation effect, large surface disturbance, and poor agronomic adaptability, so as to improve water storage capacity of pasture, enhance loosening effect, reduce cutting resistance and loosening The effect of soil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

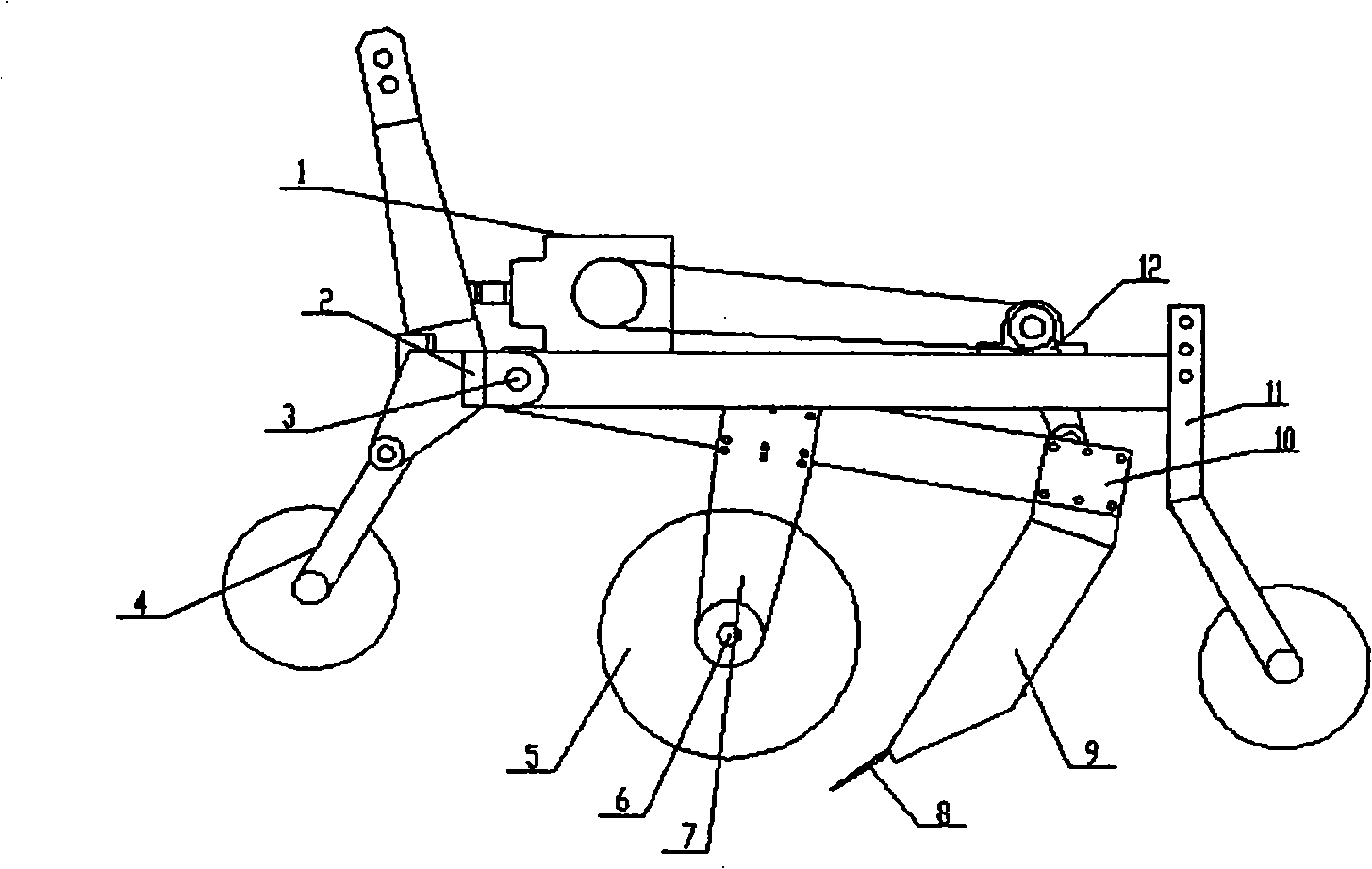

[0021] The in-situ vibration ripper of the present invention mainly includes a gearbox (1), a frame (2), a pin shaft (3), a support wheel (4), a cutting disc (5), a cutting knife shaft (6), Cutting support (7), working shovel (8), working shovel frame (9), working frame (10), pressing wheel (11), eccentric shaft connecting rod assembly (12).

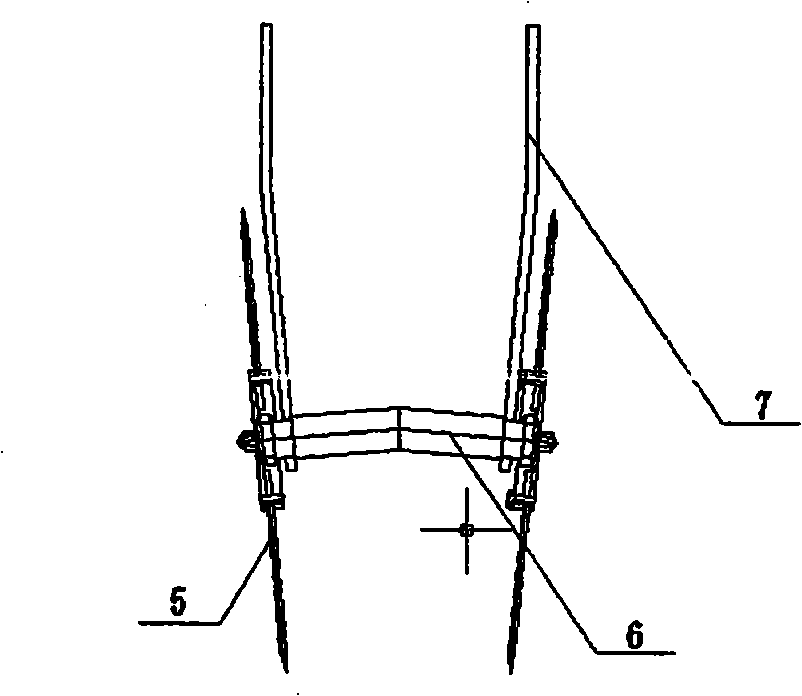

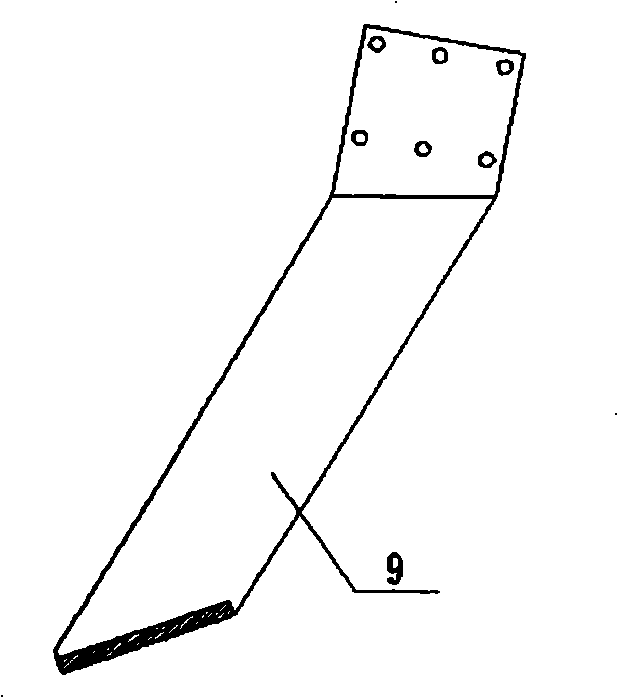

[0022] The cutting system includes a cutting disc (5), a cutting knife shaft (6), and a cutting support (7). The cutting disc (5) is preferably two pieces, and the cutting system includes a working shovel (8) and a working shovel. The working shovel group of the frame (9) is fixed on the working frame (10). The vibration system includes an eccentric shaft connecting rod assembly (12) fixed on the frame (2) and connected with the rear end of the work frame (10). The front end of the work frame (10) is hinged to the frame 2 through a pin shaft 3, and can swing up and down around it. The gearbox (1) distributes power to the eccentric shaft conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com