Active cutting vibrating scarifier

A ripper, active technology, applied in the fields of soil preparation machinery, lawn treatment machinery, agricultural machinery and implements, etc., can solve the problems of poor operation effect, large surface disturbance, poor agronomic adaptability, etc., to improve the water storage capacity of grassland, Enhance the effect of loosening, reduce cutting resistance and loosening resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

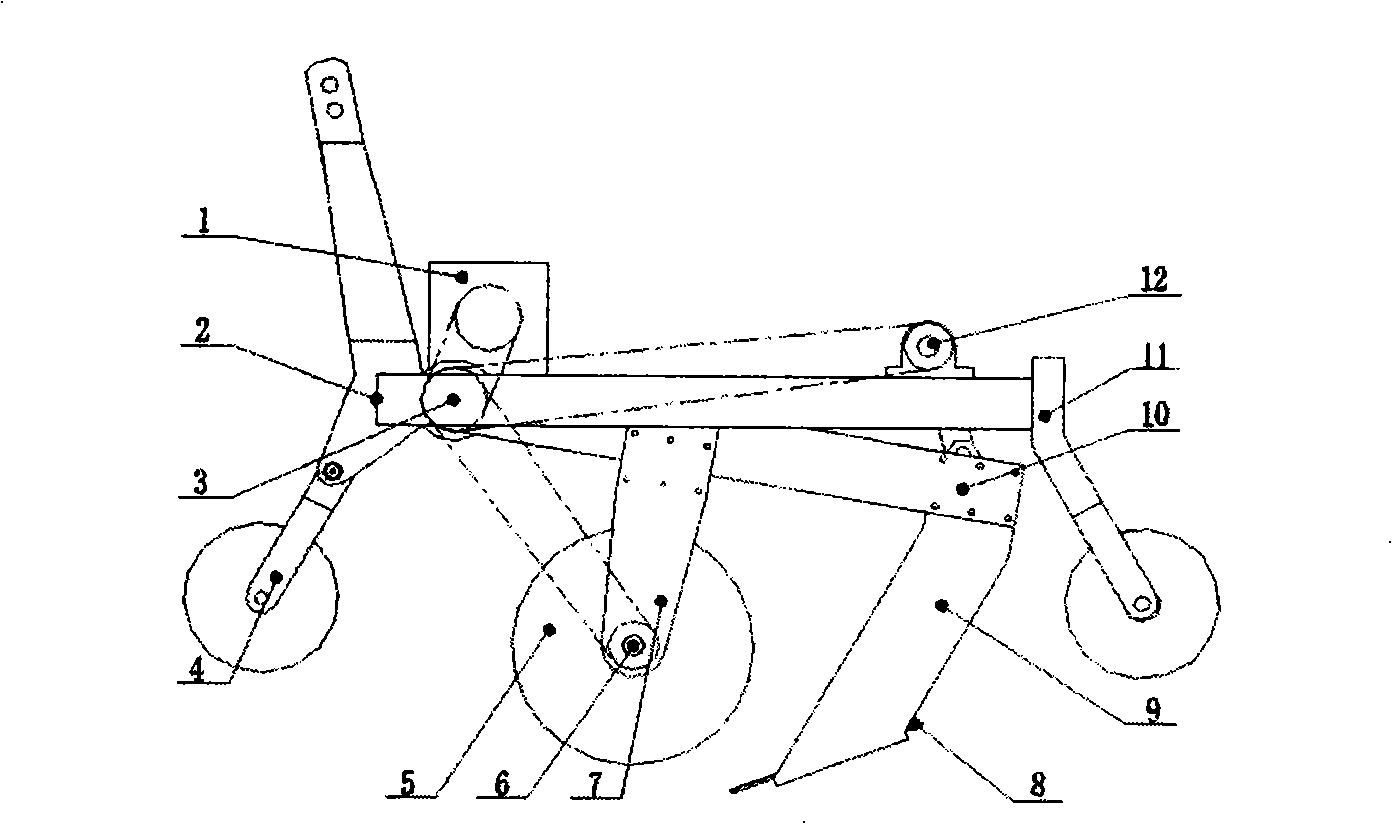

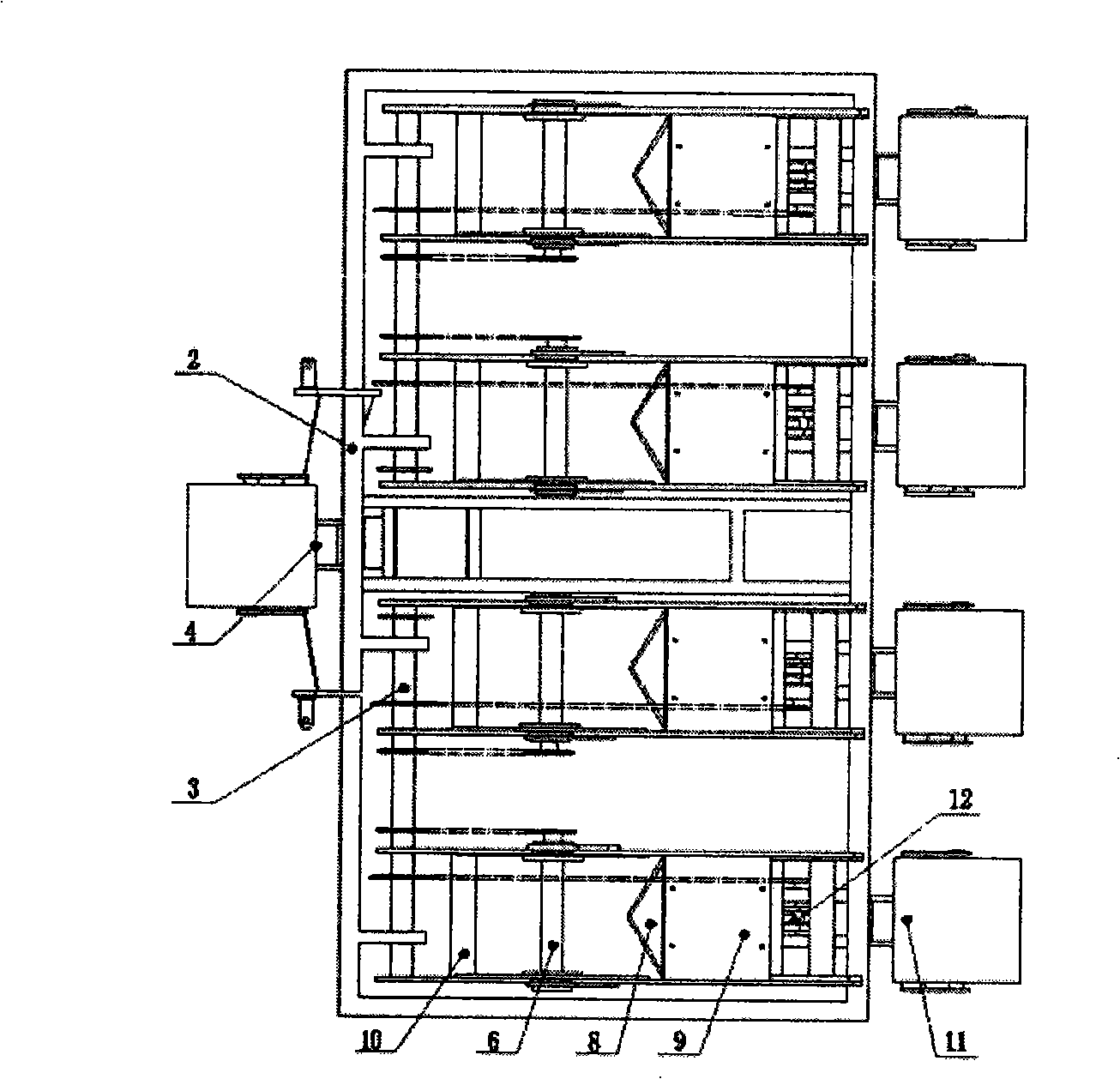

[0018] The active cutting vibration scarifier of the present invention comprises a gearbox 1, a frame 2, a main drive shaft 3, a support wheel 4, a cutting disc 5, a cutting drive shaft 6, a cutting bracket 7, a working shovel 8, a working shovel frame 9, Working frame 10, pressing wheel 11, crank connecting rod assembly 12.

[0019] The cutting system includes two pieces of cutting discs 5, cutting drive shaft 6, cutting support 7, and the working shovel group including working shovel 8 and working shovel frame 9 are fixed on the working frame 10; The crank connecting rod assembly 12 is connected to the rear end of the working frame 10; the cutting disc 5, the cutting drive shaft 6, the cutting support 7, the working shovel 8, the working shovel frame 9, the working frame 10, the crank connecting rod assembly 12 and the like form a work sheet body; the front end of the work frame 10 is fixed on the frame 2 by the main transmission shaft 3 of the transmission system, and can s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com