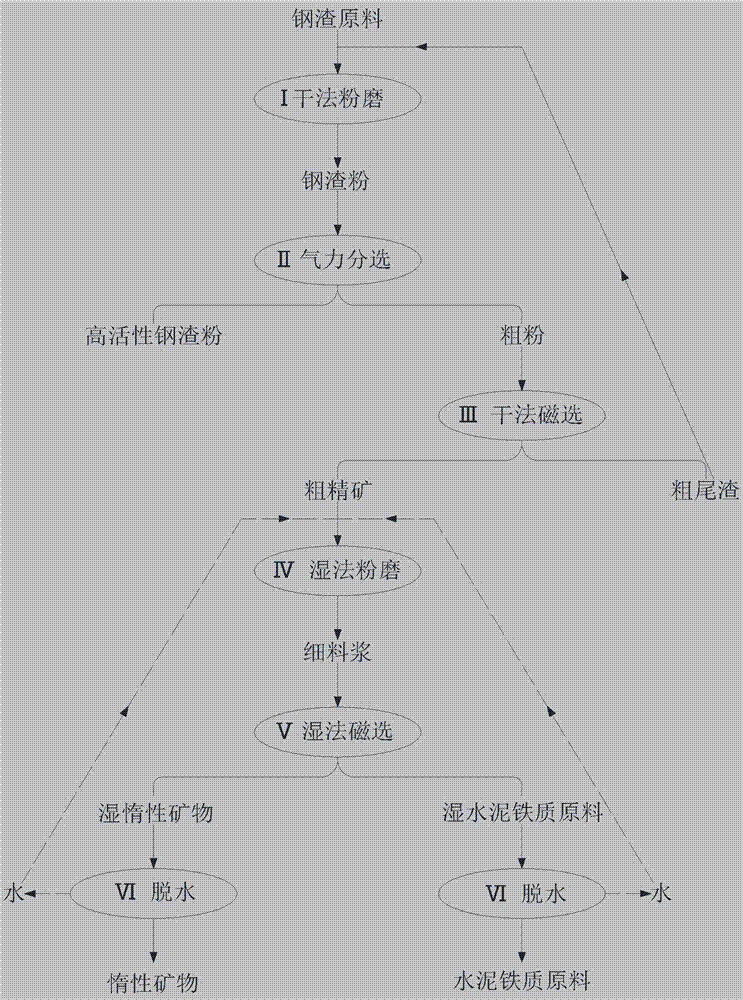

Process for producing highly active steel slag powder and inert mineral products from steel slag

A technology of steel slag powder and high activity, which is applied in the direction of cement production, process efficiency improvement, chemical instruments and methods, etc. It can solve the problems of complicated process, difficult to use, and inability to clearly reflect the grinding resistance of minerals, so as to achieve the connection of process Scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Steel slag produced by a steel company in Shanxi is ground into steel slag powder by roller press, with a specific surface area of 310m 2 / kg. Using GB / T 20491-2006 "Steel slag powder used in cement and concrete" inspection, the activity index of steel slag powder: 74% for 3d, 78% for 7d, and 82% for 28d. Determination of three kinds of inert content in steel slag powder: Fe content 1.25%, Fe content 3 o 4 content of 5.25%, the content of RO phase is 34.87%, and the total content of inert minerals is 41.37%. The steel slag powder is sorted by an industrial small ultra-fine powder separator with a cutting particle size of 18 μm to obtain a high-activity steel slag powder product. The activity index of high activity steel slag powder: 3d is 80%, 7d is 88%, 28d is 91%. After pneumatic separation, the activity index of steel slag powder is increased by about 10%, the total content of inert minerals is 8.96%, and the product quality fully meets the market requirements....

Embodiment 2

[0045] The steel slag produced by an iron and steel company in Yunnan is ground into steel slag powder by ball milling industrial facilities, and its specific surface area is 400m 2 / kg. Using GB / T 20491-2006 "Steel slag powder used in cement and concrete" inspection, the activity index of steel slag powder: 7d is 68%, 28d is 75%. Determination of three kinds of inert content in steel slag powder: Fe content 2.04%, Fe content 3 o 4 content of 6.05%, the content of RO phase is 35.43%, and the total content of inert minerals is 43.52%.

[0046] The steel slag powder is sorted by an industrial small-scale ultra-fine powder separator with a cutting particle size of 18.1 μm to obtain a high-activity steel slag powder product. The activity index of high activity steel slag powder: 79% for 7d and 87% for 28d. The activity index of steel slag powder is increased by about 12% after pneumatic separation, the total content of inert minerals is 9.52%, and the product quality of steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com