Novel prestressed duct mudjack material and preparation method of same

A duct grouting and prestressing technology, applied in the field of building material concrete admixtures, can solve the problems of neglecting the performance of prestressed duct grouting, comprehensive consideration of economy and environmental protection, etc. The effect of environmental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also proposes a preparation method of prestressed tunnel pressure slurry, which is characterized in that it comprises the following steps:

[0047] S1: Raw materials are put into the warehouse for raw material testing, prestressed tunnel pressure slurry test is carried out before each production, and the distribution ratio of components is fine-tuned to ensure that the excellent invention can be obtained, and the raw materials of each component that meet the requirements are accurately measured;

[0048] S2: Put the ordinary Portland cement measured in S1, industrial waste residue, mineral admixture, plastic expansion agent, expansion agent, and Wacker rubber powder into the mixer and continue stirring;

[0049] S3: After stirring S2 for 15-20 minutes, add water reducer, defoamer, air-entraining agent, and preservative to S1 one after another. The feeding time of each component is not less than 2 minutes, and continue stirring for 30 minutes after a...

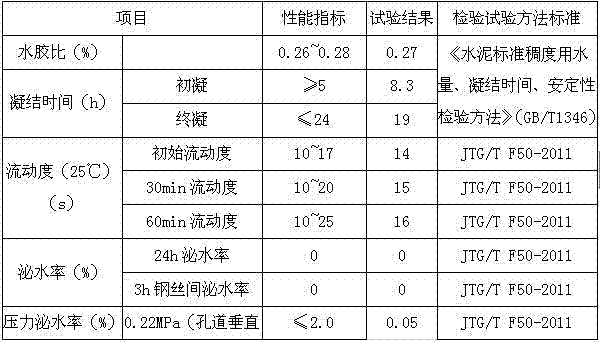

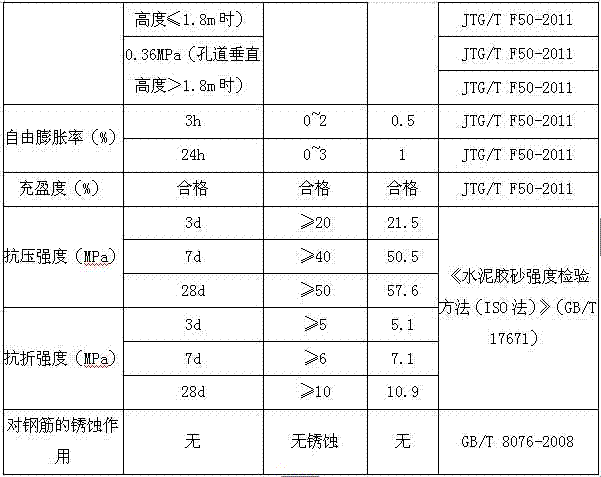

Embodiment 1

[0057] A method for preparing a novel prestressed tunnel pressure slurry, comprising the following steps:

[0058] S1: Raw materials are put into the warehouse for raw material testing, prestressed tunnel pressure slurry test is carried out before each production, and the distribution ratio of components is fine-tuned to ensure that the excellent invention can be obtained, and the raw materials of each component that meet the requirements are accurately measured;

[0059] S2: Take 92.2 parts of ordinary Portland cement (P·O 42.5) measured in S1, 2.7 parts of phosphate slag, 3.3 parts of microbeads, 0.02 parts of CSA plastic expansion agent, 1.0 part of UEA expansion agent, Wacker glue Put 0.5 parts of the mixture into the mixer and continue stirring;

[0060] S3: After stirring S2 for 15-20 minutes, add 0.2 parts of water reducer, 0.005 parts of defoamer, 0.002 parts of air-entraining agent, and 0.01 parts of preservative into S1 one after another. The feeding time of each com...

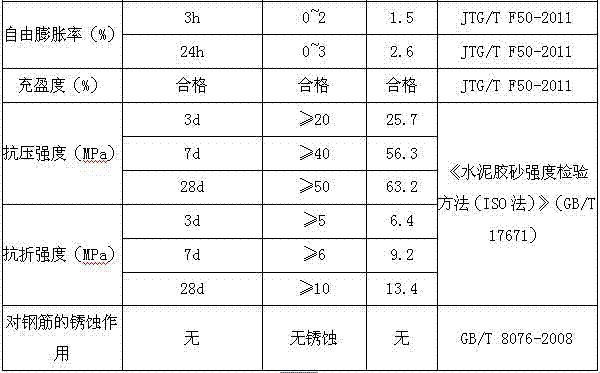

Embodiment 2

[0067] A method for preparing a novel prestressed tunnel pressure slurry, comprising the following steps:

[0068] S1: Raw materials are put into the warehouse for raw material testing, prestressed tunnel pressure slurry test is carried out before each production, and the distribution ratio of components is fine-tuned to ensure that the excellent invention can be obtained, and the raw materials of each component that meet the requirements are accurately measured;

[0069] S2: Take 85 parts of ordinary Portland cement (P·O 42.5) measured in S1, 2 parts of phosphate slag, 2.5 parts of microbeads, 0.01 part of CSA plastic expansion agent, 0.5 part of UEA expansion agent, Wacker glue Put 0.7 parts of the mixture into the mixer for continuous stirring;

[0070] S3: After stirring S2 for 15-20 minutes, add 0.1 part of water reducer, 0.001 part of defoamer, 0.001 part of air-entraining agent, and 0.01 part of preservative into S1 one after another. The feeding time of each component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com