Method for treating refractory red iron ore based on staged combined magnetizing roasting

A technology of magnetization roasting and flash magnetization roasting, which is applied in the field of metallurgy, fluidization, and mineral processing, can solve the problems of low grade of concentrated ore in strong magnetic separation, coarse particle size of roasted ore, and uneven quality of roasted ore, so as to reduce grinding Cost, good quality of beneficiation products, improvement of reaction speed and roasting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The useful minerals of the refractory hematite processed in this embodiment are mainly siderite, and also contain a small amount of hematite, limonite and false hematite; the gangue minerals are mainly quartz and sericite, and a small amount of long Stone, kaolinite, barite, apatite and other sporadic distribution. Siderite minerals crystallize well, and the crystal grains are often euhedral and semi-euhedral in different sizes, and some are irregular. The embedded particle size is generally between 0.02 and 0.35mm, and the small ones can be less than 0.01mm. The content of hematite and limonite is not high, the two are closely inlaid, and often exist in the form of aggregates, the aggregate particle size is generally 0.02 ~ 0.20mm.

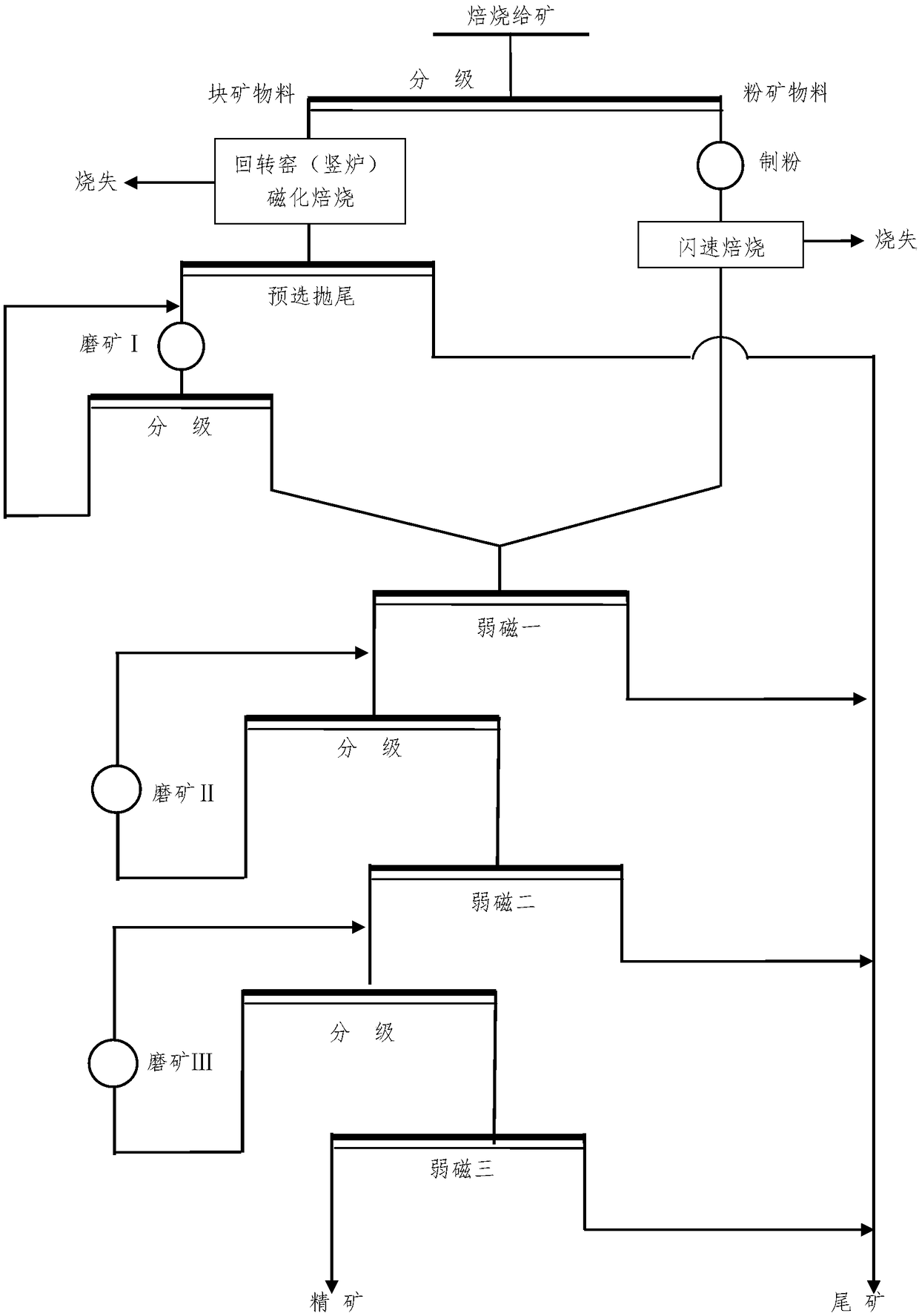

[0036] A method of refractory red iron ore processing based on graded combined magnetization roasting of the present invention, its process flow chart is as follows figure 1 shown, including the following steps:

[0037] (1) Use a vibrat...

Embodiment 2

[0043] The useful minerals in the refractory red iron ore processed in this embodiment are mainly specularite, siderite and limonite, a small amount of magnetite and pyrite, and the gangue minerals are mainly jasper, quartz and barite , iron dolomite, chlorite and sericite, etc. The specularite and limonite are mainly fine-grained, the siderite is mainly medium-grained, and the gangue minerals are medium-coarse-grained and mainly medium-grained.

[0044] A method for processing refractory red iron ore based on graded combined magnetization roasting of the present invention comprises the following steps:

[0045] (1) Use a vibrating screen to screen and classify the crushed refractory red iron ore raw ore, and divide it into powder mineral materials of 0-15 mm and lump mineral materials of 15-75 mm;

[0046] (2) Use Raymond Mill to carry out dry powder milling on the powdered mineral material to obtain fine-grained powdered mineral material with a uniform particle size of -0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com