High-voltage electric pulse pretreatment method for intensifying leaching of difficult-to-treat gold ore

A high-voltage electric pulse, refractory gold mine technology, applied in grain processing and other directions, can solve problems such as not being applicable, and achieve the effect of saving enterprise costs, improving the degree of monomer dissociation, and increasing enterprise profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

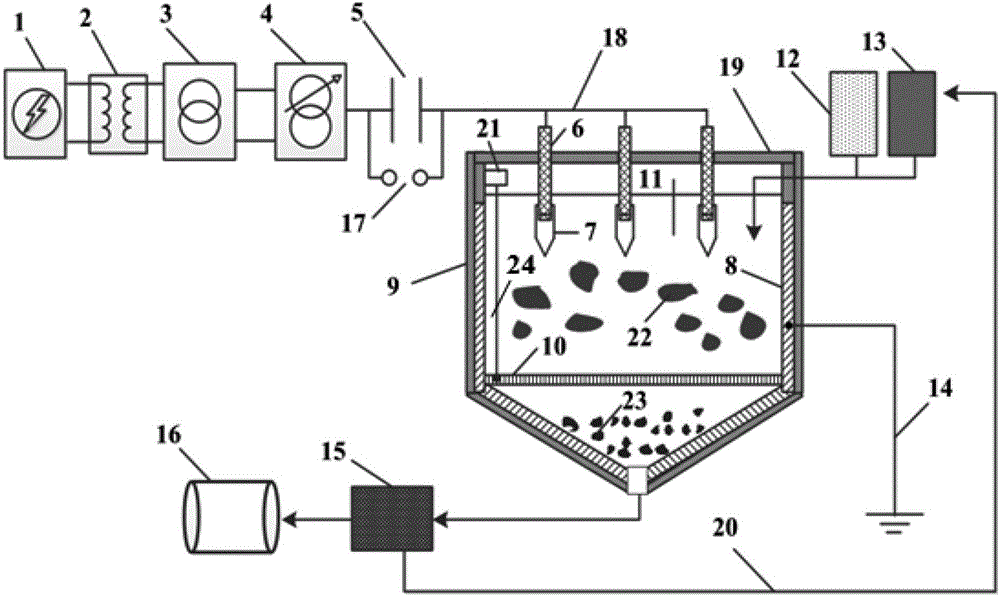

Method used

Image

Examples

Embodiment 1

[0024] The ore samples used in this example are Carlin-type gold deposits. In this type of gold ore, metal sulfides mainly composed of pyrite, stibnite and arsenopyrite are disseminated in the ore in scattered form, and gold is usually wrapped in sulfide minerals in the form of fine particles or submicroscopic particles. It is also difficult to dissociate and belongs to refractory ore. The chemical composition analysis results are as follows, see Table 1 and Table 2:

[0025] Table 1 The semi-quantitative analysis results of raw ore spectrum

[0026] Analytical components SiO 2

Al 2 o 3

CaO Fe 2 o 3

K 2 o

content% 57.59 19.98 8.01 4.88 4.17 Analytical components MgO SO 3

TiO 2

As 2 o 3

Na 2 o

content% 2.30 1.25 0.67 0.43 0.18 Analytical components Sb 2 o 3

P 2 o 5

MnO SrO WO 3

content% 0.14 0.14 0.13 0.034 0.029 Analytical components ZnO...

Embodiment 2

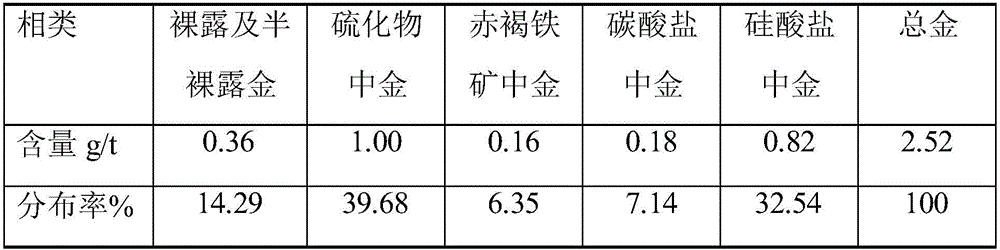

[0032] The ore sample used in this embodiment is a certain arsenic-containing refractory gold ore, in which quartz porphyry gold ore accounts for 45% and sandstone-type gold ore accounts for 55%. The results of multi-element analysis and raw ore gold phase analysis are shown in Table 3 and Table 4. It can be seen from Table 3 that the gold grade of this gold mine is 2.38g / t, and the Cu content is 0.09%. higher gold ore. Table 4 shows that the content of exposed and semi-exposed gold in the ore is very small, only 14.29%, and about 80% of the gold is wrapped by sulfide, carbonate and silicate, which brings difficulties to the gold extraction process .

[0033] Table 3 Results of multi-element analysis of raw ore

[0034] element Aug / t Agg / t Cu Pb Zn S P K 2 o

content% 2.38 2.0 0.09 0.061 0.030 1.24 0.28 3.16 element As Sb Mo co Tc TF mn Na 2 o

content% 0.87 0.21 0.0008 0.001 1.52 3.40 0.086 0.54 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com