Size-fractionated pre-selection tailing discarding process of extremely-poor hematite

A hematite and granulation technology, which is applied in magnetic separation, solid separation, sieving, etc., can solve the problem of semi-autogenous mill stubborn stone accumulation, and achieve the effects of increasing processing capacity, reducing cost, and reducing cycle load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

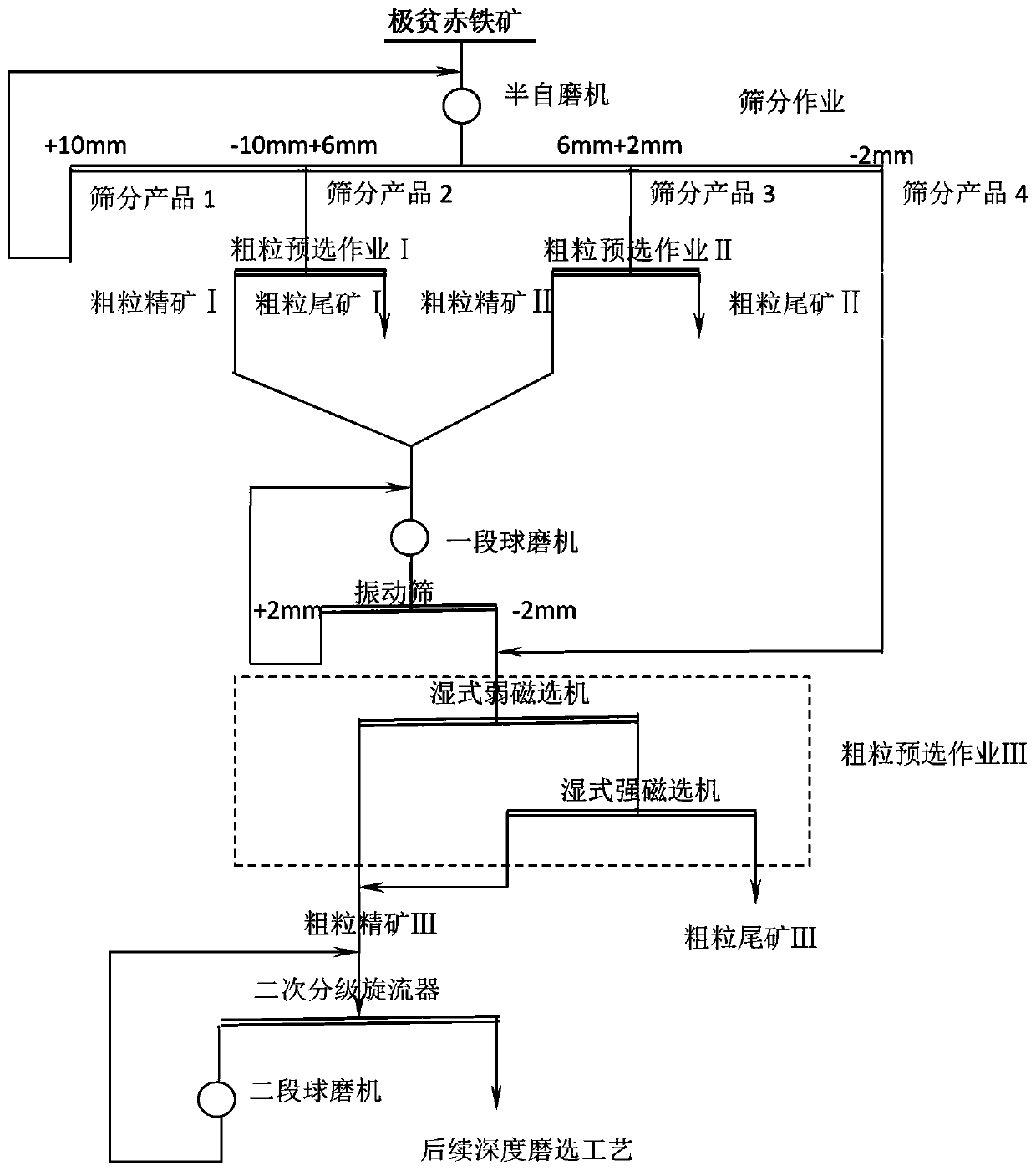

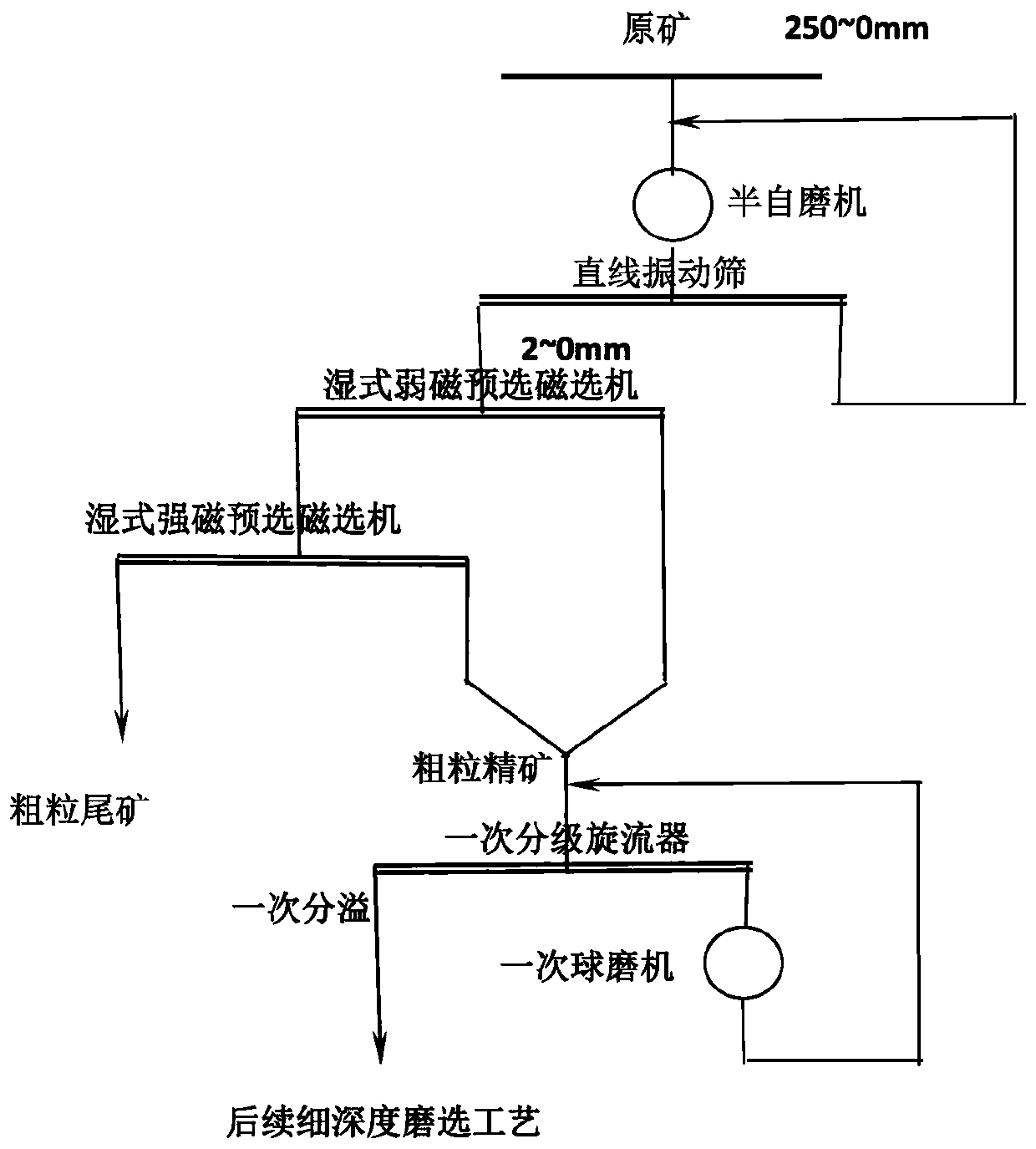

[0023] Such as figure 1 As shown, a kind of ultra-poor hematite pre-selection and tailings throwing process of the present invention comprises that the ultra-poor hematite whose feeding particle size is 250-0mm and grade is 18% is fed into the semi-autogenous grinding operation, and the semi-autogenous The self-grinding operation uses a Φ9.15×5.03m wet semi-autogenous mill to obtain a semi-autogenous mill discharge product with a particle size of 14-0mm. Operation II, one-stage closed-circuit grinding operation, coarse grain pre-selection operation III and second-stage closed-circuit grinding operation;

[0024] The screening operation processes semi-autogenous grinding operation ore discharge products, and a total of 4 screening products are obtained; the screening operation adopts a laminated linear vibrating screen, which has three layers of screen surfaces, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com