Powder material for preparing high-strength high-toughness yttrium stabilized tetragonal polycrystal zirconia ceramics and preparation method of powder material

A technology for zirconia ceramics and powder materials, which is applied in the field of powder materials for preparing tetragonal polycrystalline zirconia ceramics and its preparation, can solve the problem that the performance of 3Y-TZP ceramics is not significantly improved, which is unfavorable to the development of zirconia powder technology and is difficult to achieve. Adapt to application needs and other issues to achieve the effect of obvious energy saving and emission reduction, easy promotion and application, and promotion of application and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

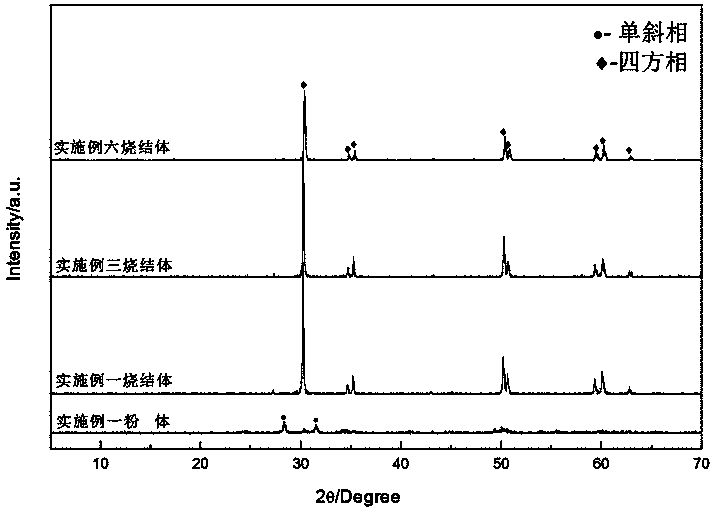

Embodiment 1

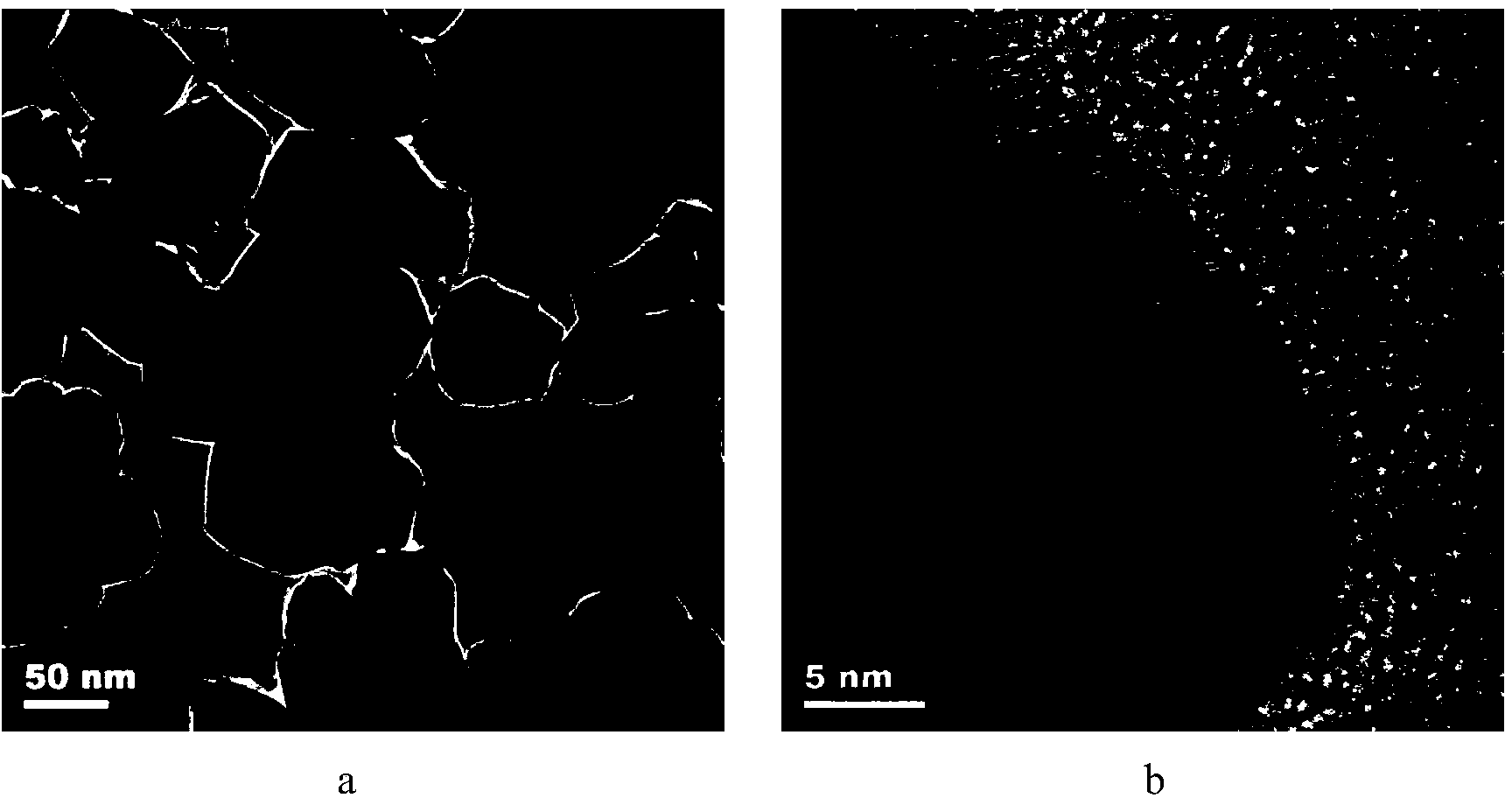

[0029] This embodiment is a method for preparing a powder material suitable for preparing high-strength and high-toughness yttrium-stabilized tetragonal polycrystalline zirconia ceramics. The steps are as follows:

[0030] (1) Zr 4+ Zirconium oxychloride solution with a concentration of 0.5mol / L is added to the reaction vessel, and then yttrium oxide is added in four times to form a reaction system; wherein the total amount of yttrium oxide added is Zr 4+ 2.0mol% of the total amount;

[0031] (2) Heating the reaction system to 50°C and keeping it warm for 2h until the yttrium oxide is dissolved, then adding 0.5wt% fatty acid and polyacrylic acid; then heating to 220°C and keeping it warm for 60h for hydrolysis-hydrothermal reaction, keeping the internal pressure at 3MPa, Make it gradually hydrolyze and precipitate;

[0032] (3) Filtrate the hydrolyzate, wash the filter residue repeatedly with deionized water, and then perform low-temperature calcination at a temperature of 6...

Embodiment 2

[0035] This embodiment is a method for preparing a powder material suitable for preparing high-strength and high-toughness yttrium-stabilized tetragonal polycrystalline zirconia ceramics. The steps are as follows:

[0036] (1) Zr 4+ Zirconium oxychloride solution with a concentration of 0.5mol / L is added to the reaction vessel, and then yttrium oxide is added in four times to form a reaction system; wherein the total amount of yttrium oxide added is Zr 4+ 2.3mol% of the total amount;

[0037](2) Heat the reaction system to 50°C, keep it warm for 2h until the yttrium oxide is dissolved, add 0.5wt% fatty acid and polyvinyl alcohol; then heat it to 180°C, keep it warm for 60h to carry out hydrolysis-hydrothermal reaction, and keep the internal pressure at 2MPa , making it gradually hydrolyzed and precipitated;

[0038] (3) Filtrate the hydrolyzate, wash the filter residue repeatedly with deionized water, and then perform low-temperature calcination at a temperature of 600°C for...

Embodiment 3

[0041] This embodiment is a method for preparing a powder material suitable for preparing high-strength and high-toughness yttrium-stabilized tetragonal polycrystalline zirconia ceramics. The steps are as follows:

[0042] (1) Zr 4+ Zirconium oxychloride solution with a concentration of 0.5mol / L is added to the reaction vessel, and then yttrium oxide is added in four times to form a reaction system; wherein the total amount of yttrium oxide added is Zr 4+ 1.4mol% of the total amount;

[0043] (2) Heat the reaction system to 50°C, keep it warm for 2h until the yttrium oxide is dissolved, then add 0.5wt% polyvinyl alcohol; then heat it to 200°C, keep it warm for 60h to carry out hydrolysis-hydrothermal reaction, keep the internal pressure at 2.5MPa, Make it gradually hydrolyze and precipitate;

[0044] (3) Filtrate the hydrolyzed solution, wash the filter residue repeatedly with deionized water, then perform low-temperature calcination at a temperature of 700°C for 2 hours and...

PUM

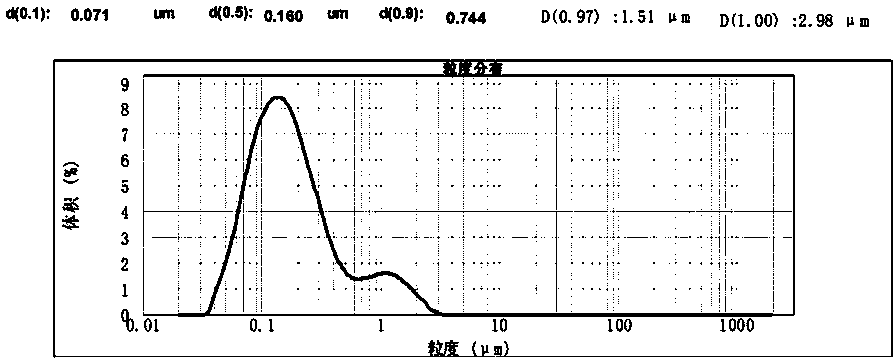

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com