Silicate cement grinding aid and preparation method thereof

A Portland cement and grinding aid technology, applied in the field of cement production, can solve the problems of large dosage, fluctuating cement quality, unstable quality, etc., achieve convenient mixing control, reduce grinding energy consumption, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

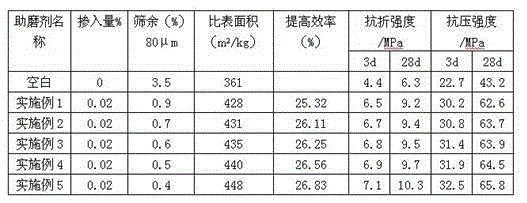

Examples

Embodiment 1

[0039] Example 1 A portland cement grinding aid prepared from the following main raw materials in parts by weight (1 kg per part): 3 parts of sodium hexametaphosphate, 2 parts of aluminum sulfate, 5 parts of tetrasodium aminotrimethylene phosphate, ethyl 4 parts of sodium diaminetetramethylene phosphate, 38 parts of polymeric alcohol amine, 34 parts of triisopropanolamine, 8 parts of waste engine oil, 2 parts of sodium α-olefin sulfonate, 10 parts of sorbitol, 15 parts of diethylene glycol, 8 parts of polypropylene wax, 6 parts of oxidized polyethylene wax, 4 parts of montan wax, 20 parts of molasses, 12 parts of sodium thiosulfate, and 15 parts of quicklime powder.

[0040] The preparation method of above-mentioned portland cement grinding aid is:

[0041] (1) Take 1 / 10 of triisopropanolamine (purchased from Shijiazhuang Haisen Chemical Co., Ltd.), adjust the pH to 6.2 with 0.1mol / L glacial acetic acid, raise the temperature to 65°C, and add epoxy chlorine dropwise while sti...

Embodiment 2

[0045] Example 2 A Portland cement grinding aid prepared from the following main raw materials in parts by weight (1 kg per part): 6 parts of sodium hexametaphosphate, 5 parts of aluminum sulfate, 8 parts of tetrasodium aminotrimethylene phosphate, ethyl 6 parts of sodium diamine tetramethylene phosphate, 45 parts of polymeric alcohol amine, 42 parts of triisopropanolamine, 12 parts of waste engine oil, 5 parts of sodium α-olefin sulfonate, 16 parts of sorbitol, 20 parts of diethylene glycol, 13 parts of polypropylene wax, 10 parts of oxidized polyethylene wax, 8 parts of montan wax, 30 parts of molasses, 18 parts of sodium thiosulfate, 20 parts of quicklime powder.

[0046] The preparation method of above-mentioned portland cement grinding aid is:

[0047] (1) Take 1 / 10 of triisopropanolamine (purchased from Shijiazhuang Haisen Chemical Co., Ltd.), adjust the pH to 6.2 with 0.1mol / L glacial acetic acid, raise the temperature to 65°C, and add epoxy chlorine dropwise while stir...

Embodiment 3

[0051] Example 3 A portland cement grinding aid prepared from the following main raw materials in parts by weight (1 kg per part): 3.5 parts of sodium hexametaphosphate, 2.5 parts of aluminum sulfate, 5.5 parts of tetrasodium aminotrimethylene phosphate, and 5 parts of sodium diamine tetramethylene phosphate, 40 parts of polymeric alcohol amine, 35 parts of triisopropanolamine, 9 parts of waste engine oil, 3 parts of sodium α-olefin sulfonate, 12 parts of sorbitol, 16 parts of diethylene glycol, 10 parts of polypropylene wax, 7 parts of oxidized polyethylene wax, 5 parts of montan wax, 24 parts of molasses, 14 parts of sodium thiosulfate, 17 parts of quicklime powder.

[0052] The preparation method of above-mentioned portland cement grinding aid is:

[0053] (1) Take 1 / 10 of triisopropanolamine (purchased from Shijiazhuang Haisen Chemical Co., Ltd.), adjust the pH to 6.2 with 0.1mol / L glacial acetic acid, raise the temperature to 65°C, and add epoxy chlorine dropwise while ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com