Method for obtaining valuable ores from multi-metal sulfide ores containing lead and zinc through flotation separation

A technology for polymetallic and sulfide ore, applied in the field of flotation process, can solve the problems of increasing difficulty in operation, high cost of reagents, and high requirements for flotation equipment, so as to improve the efficiency and effect of beneficiation, reduce the cost of reagents, and reduce the grinding energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

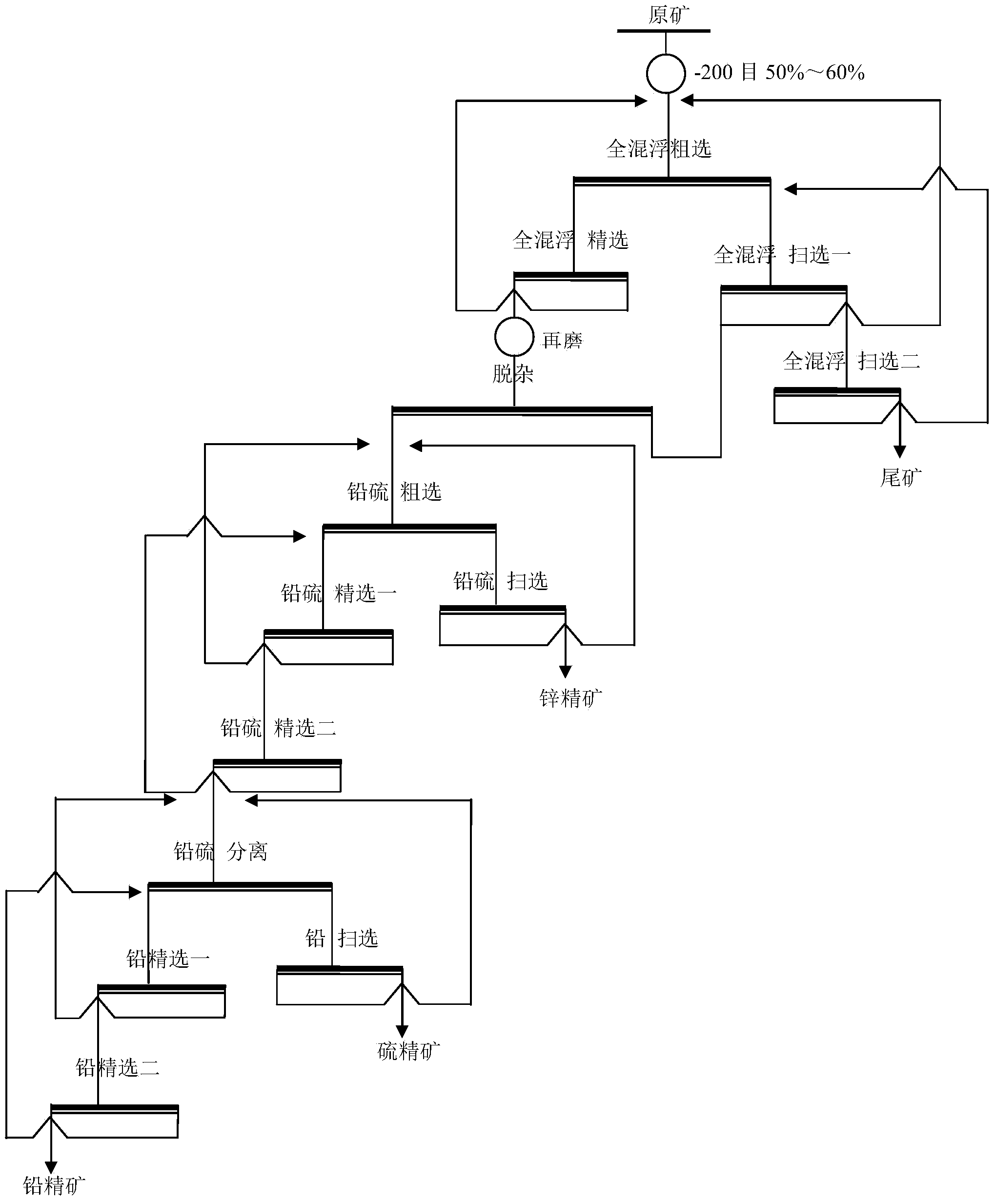

[0037] Taking a lead-zinc-silver sulfide ore in Hunan as the object of treatment, the main metal minerals of this ore include galena, sphalerite, and pyrite, and the main gangue mineral is quartz. The oxidation rate of lead and zinc in the ore is about 5%. use as figure 1 The shown method for flotation separation of valuable minerals from lead-zinc-containing polymetallic sulfide ores comprises the following steps:

[0038] (1) Grinding: Grinding the raw ore first, grinding the raw ore to -0.074mm (or -200 mesh) accounts for 60%;

[0039](2) roughing: add combined flotation agent to carry out full-mix flotation roughing treatment to the ore after the above-mentioned step (1) grinding; the flotation concentration is 37%; the combined flotation agent includes dixanthate, Xanthate and MIBC, and the addition amount of second xanthate is 90g / t raw ore, the addition amount of butyl xanthate is 30g / t raw ore, the addition of MIBC is 60g / t raw ore, the dosage ratio of second xanthate...

Embodiment 2

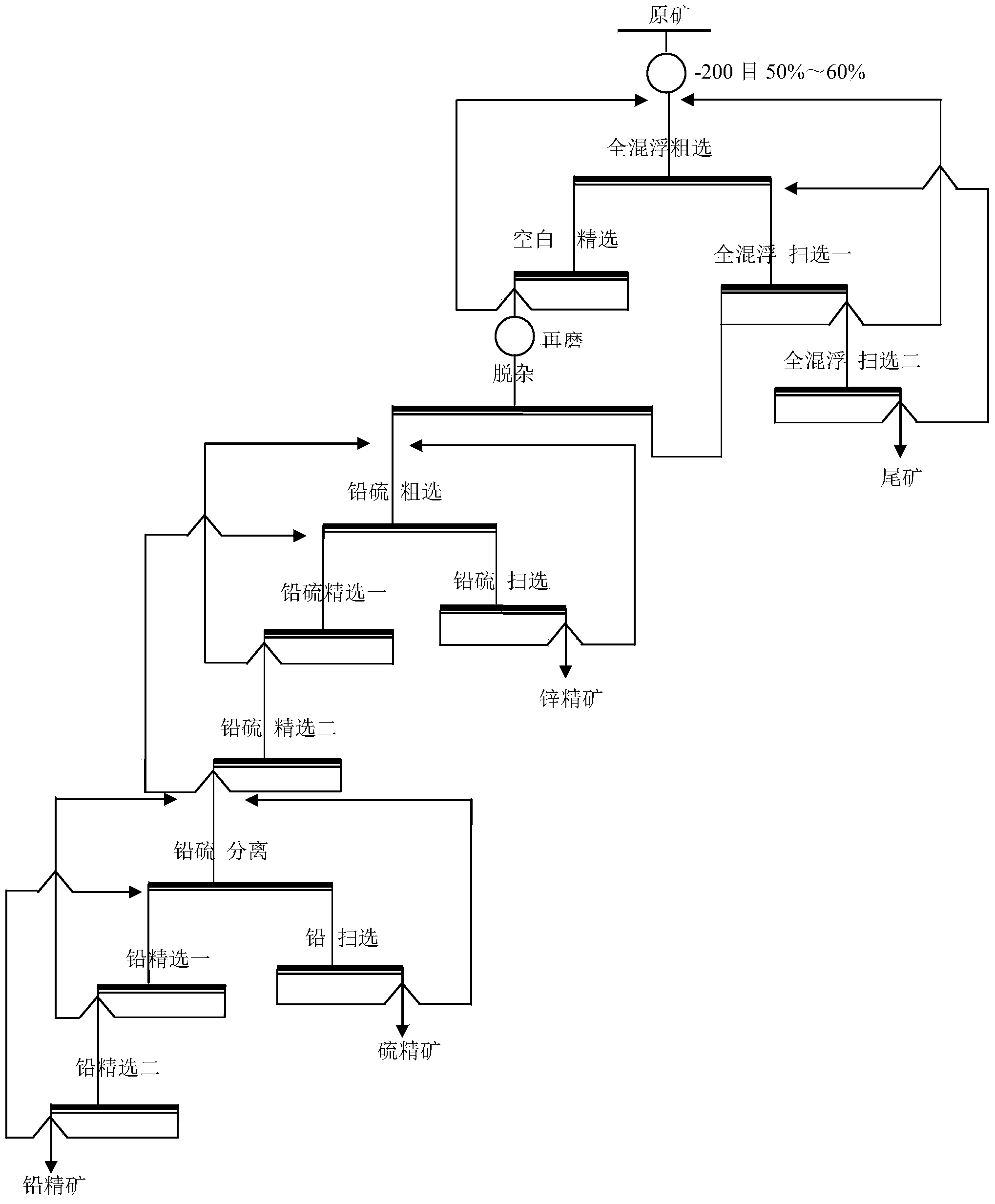

[0048] Taking a lead-zinc mine in Guangxi as the object of treatment, the main metal minerals of this ore include galena, sphalerite, and pyrite, and the main gangue mineral is quartz. The oxidation rate of lead in the ore is relatively high, reaching about 30%, and zinc The oxidation rate is about 10%. use as figure 2 The shown method for flotation separation of valuable minerals from lead-zinc-containing polymetallic sulfide ores comprises the following steps:

[0049] (1) Grinding: Grinding the raw ore first, grinding the raw ore to -0.074mm (or -200 mesh) accounts for 50%;

[0050] (2) roughing: add combined flotation agent to carry out full-mix flotation roughing treatment to the ore after the above-mentioned step (1) grinding; flotation concentration is 37%; the combined flotation agent includes sodium sulfide, copper sulfate , dixanthate, butyl xanthate and MIBC, and the addition of sodium sulfide is 40g / t raw ore, the addition of copper sulfate is 40g / t raw ore, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com