Patents

Literature

31results about How to "Resolve low activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

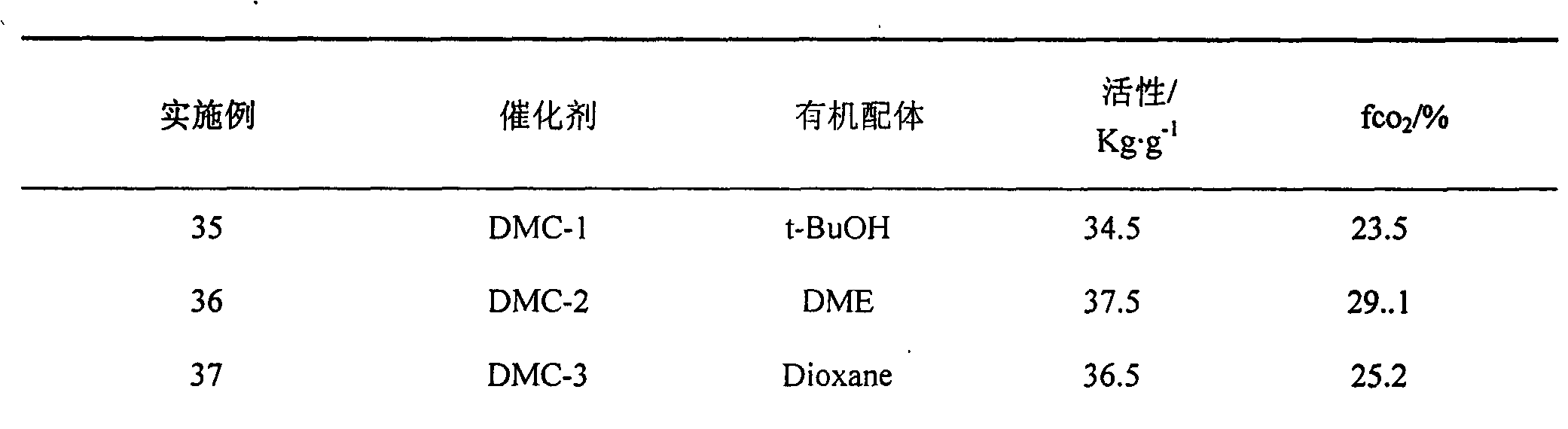

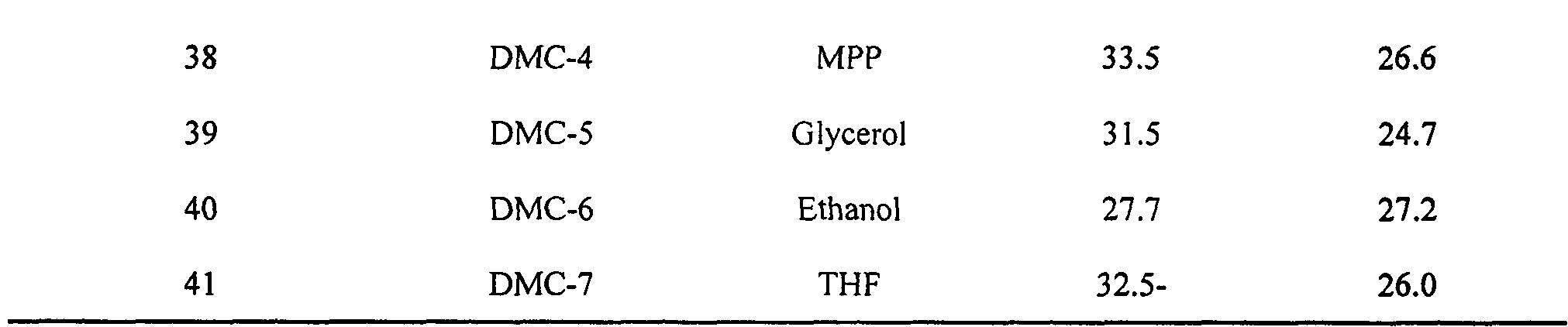

Preparation method for double metal cyanide catalyst for polycarbonate synthesis

ActiveCN102179262AAvoid synergistic effectsImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsCyanideMethyl carbonate

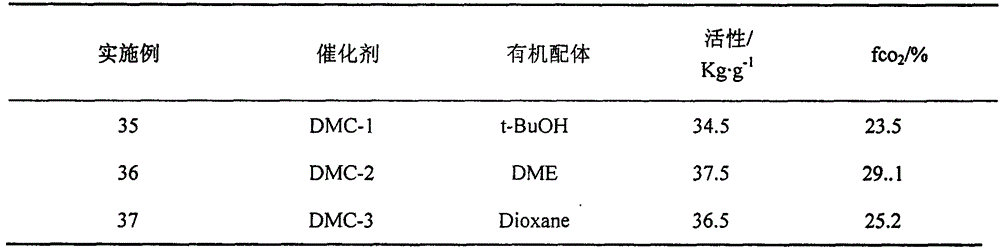

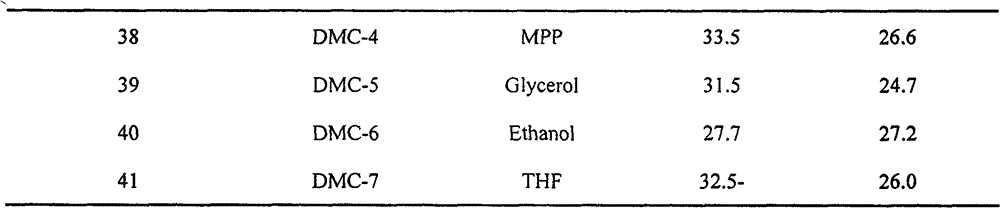

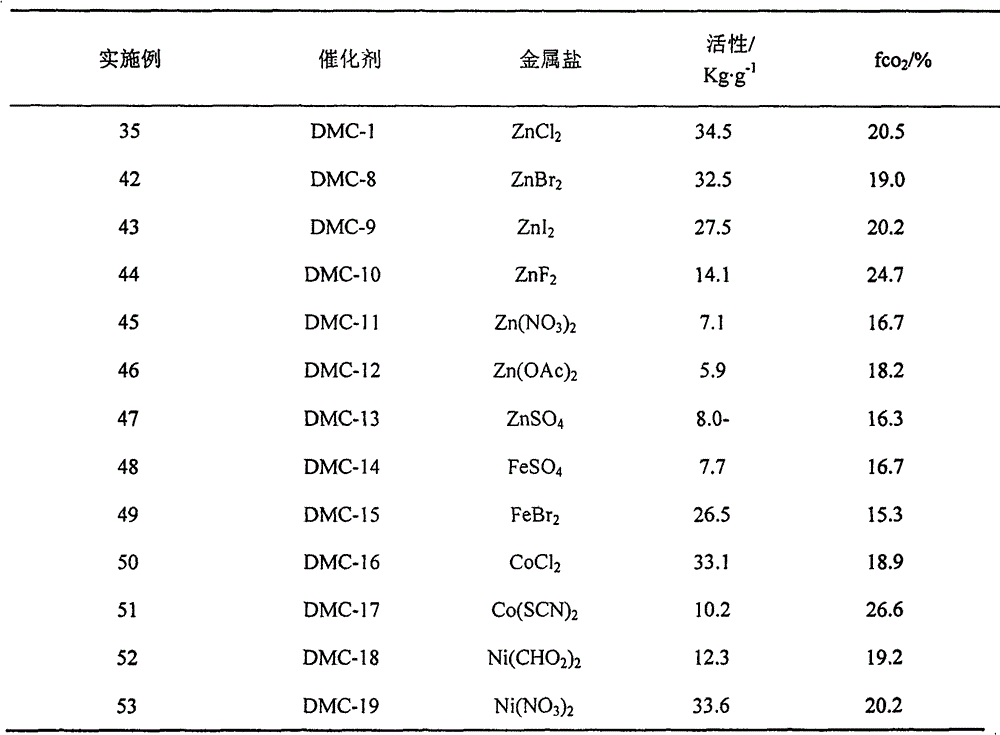

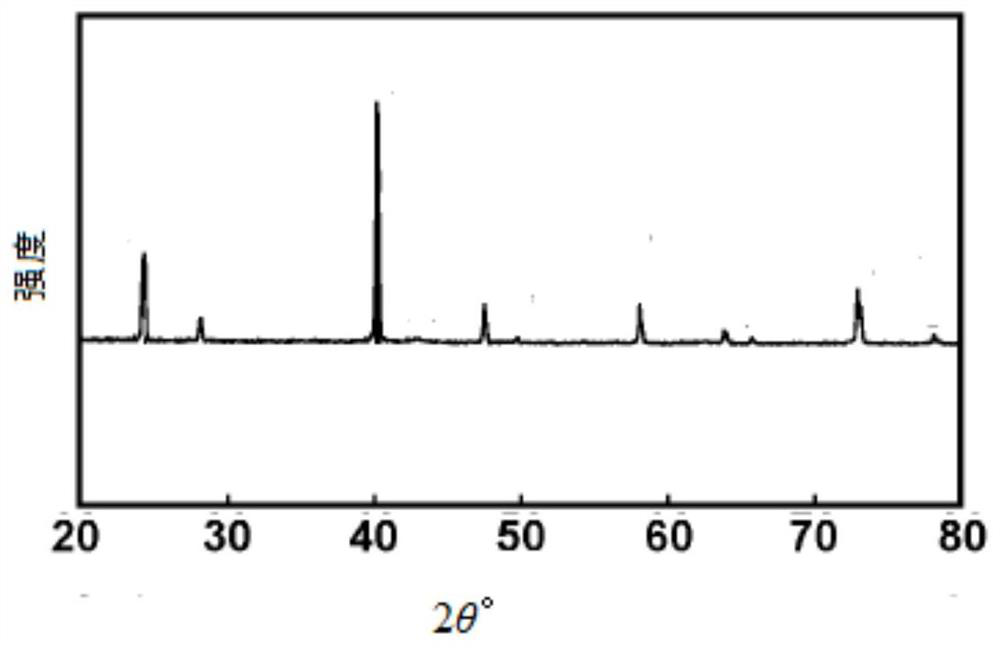

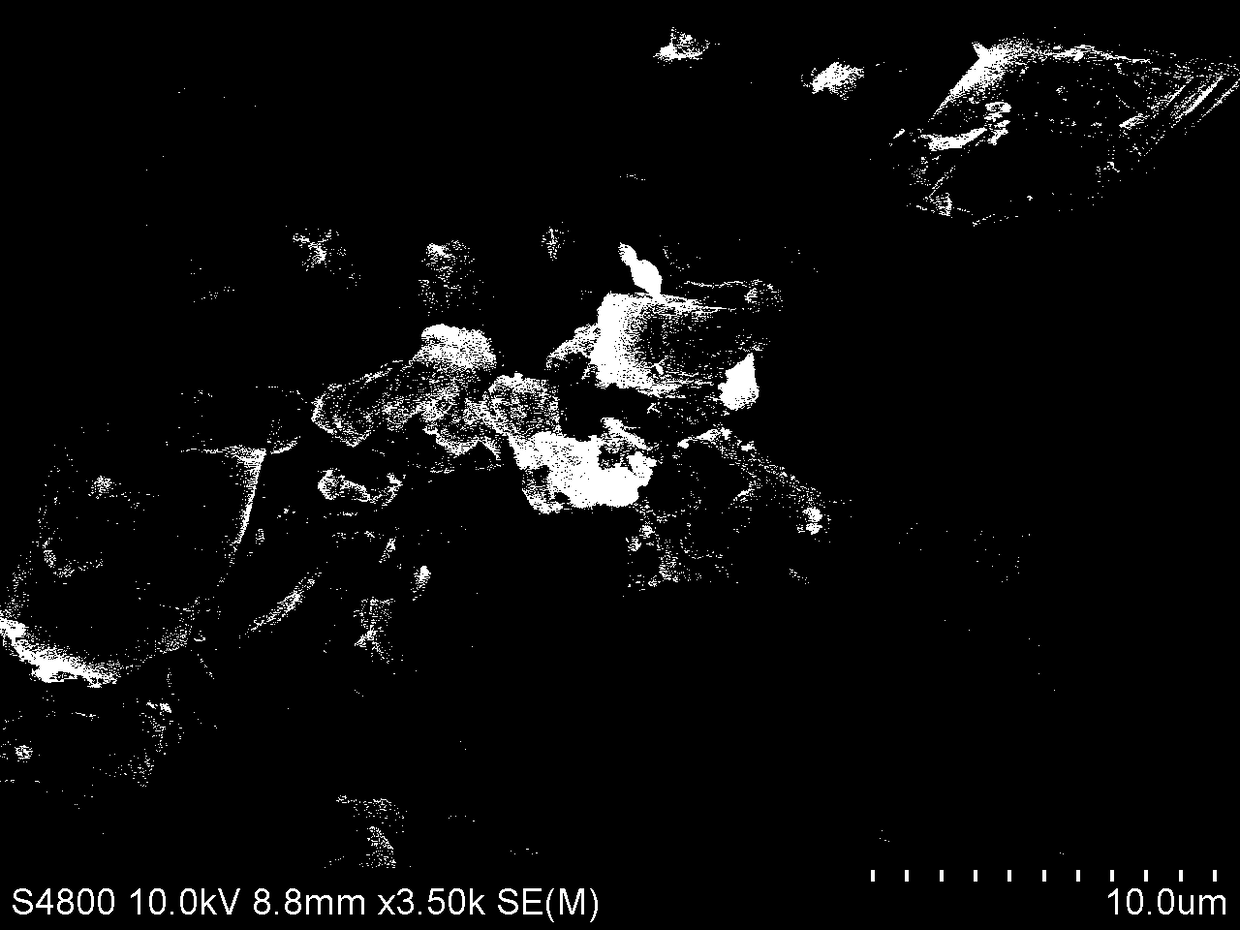

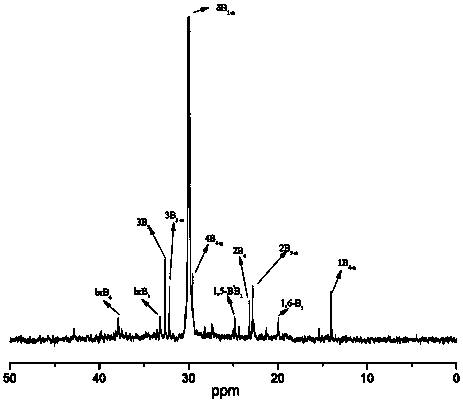

The invention discloses a preparation method for a double metal cyanide catalyst for polycarbonate synthesis. The preparation method comprises the following steps of: firstly dissolving soluble metallic salt in organic ligand, and then adding deionized water to serve as a solution 1; dissolving water-soluble metallic cyanide salt in the deionized water to serve as a solution 2, wherein the volume ratio of the solution 1 to the solution 2 is 0.1: 1-5: 1; and then dripping the solution 2 to the solution 1 to obtain a solid catalyst after stirring and drying. In the invention, the influence of the deionized water to the synergic action between the organic ligand and the soluble metal salt is avoided; the synergic action between the organic ligand and the soluble metal salt in the DMC (Di Methyl Carbonate) catalyst is exerted at the greatest degree; and the reaction time when the catalyst catalyzes a copolymerization of propylene oxide and CO2 does not exceed 8h, the activity reaches to above 30Kg polymer / g catalyst, and the CO2 unit content in the polymer reaches up to 45.0%.

Owner:HEBEI UNIV OF TECH +1

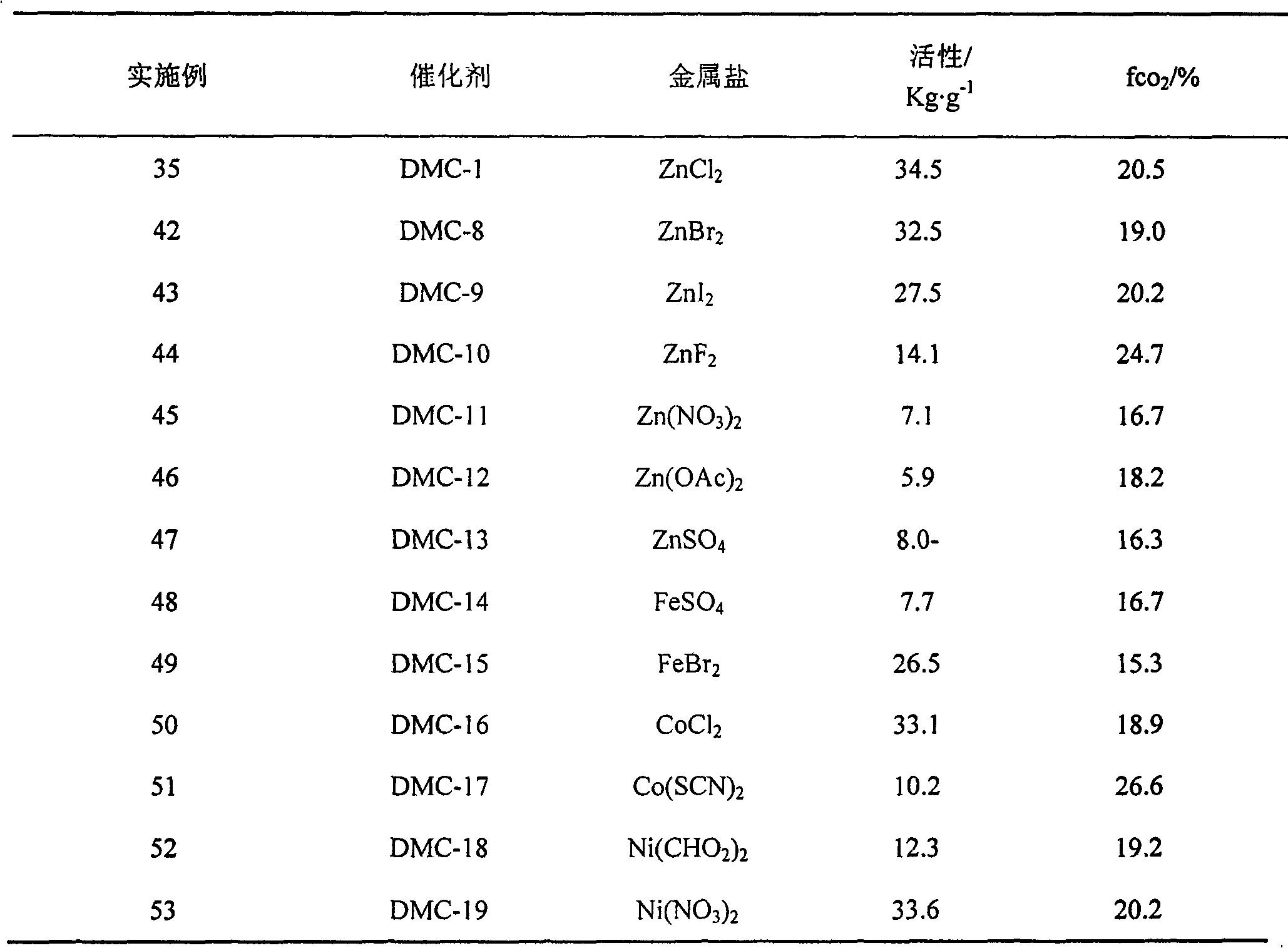

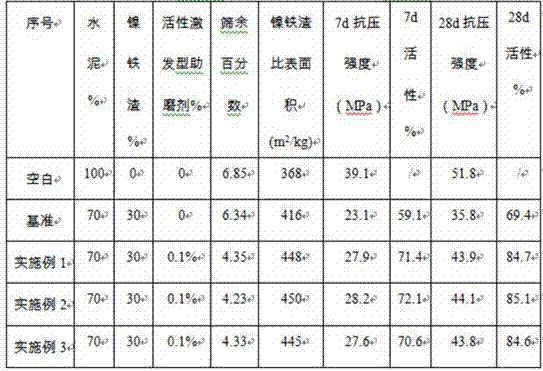

Active excitatory grinding aid for ferronickel slag and preparation method for active excitatory grinding aid

ActiveCN105084793ASolve the problem of poor wearabilityResolve low activitySolid waste managementPolyolMetallurgy

The invention discloses an active excitatory grinding aid for ferronickel slag and a preparation method for the active excitatory grinding aid. The grinding aid is composed of polymeric glycol, cocoanut fatty acid diethanolamide, sodium pyrophosphate, ethyl acetate, an excitant and water, wherein the excitant is composed of calcined alunite, water glass and sodium abietate. The additive amount of the grinding aid in the ferronickel slag is 0.02-0.10% by mass of the ferronickel slag. The active excitatory grinding aid disclosed by the invention is sufficient in raw materials, simple to process and prepare, low in doping amount, stable in performance and high in cost performance. As the ferronickel slag which is ground is added, the problem that the ferronickel slag is poor in grindability can be solved. Under the condition that the grinding time is equal, the specific surface area of the ferronickel slag micropowder can be improved by 4.5-9%, the mill output is increased by over 15%, the energy consumption is remarkably reduced, and moreover, the active index of the ferronickel slag can be further improved by 10-35%.

Owner:UNIV OF JINAN +1

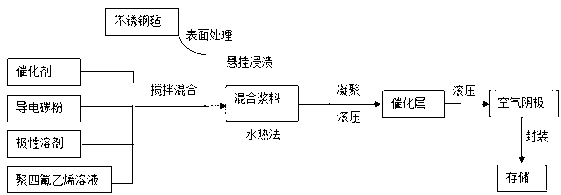

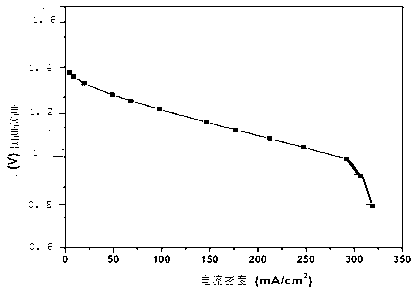

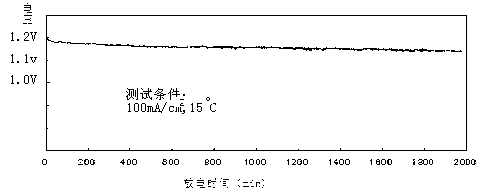

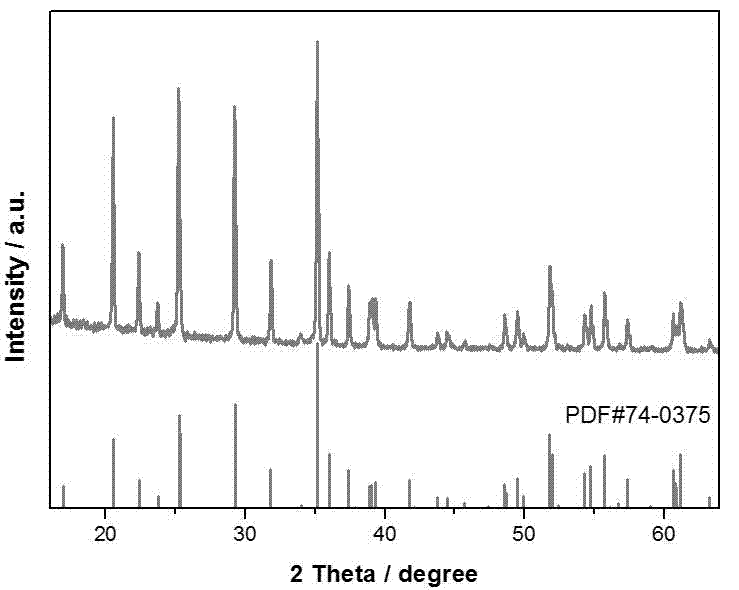

Simple preparation method of integrated metal-air cathode for metal-air battery

InactiveCN103199272AResolve low activityAchieving all-in-one self-assembled growthCell electrodesInternal resistanceSlurry

The invention discloses a simple preparation method of an integrated metal-air cathode for a metal-air battery. The simple preparation method comprises the following steps: in the preparation process of the catalyst, directly immersing the porous metal with a processed surface into the original catalyst seriflux mixed with polytetrafluoroethylene (PTFE), utilizing the surface of the porous metal with a negative charge polar group and the catalyst with a positive charge polar group to realize the bonding of the porous metal and the catalyst, and further processing by adopting a hydrothermal method. As the catalyst directly grows on the current collector, the catalyst layer of the gas-diffusion electrode has a very stable physical structure. According to the simple preparation method disclosed by the invention, the self-assembled growth between the catalyst and a support body is realized by the mutual effect between the porous metal current collector and the graphene with manganese dioxide catalyst, so as to reduce the internal resistance of the battery, and strengthen the adhesive force of the catalyst, thus improving the performance of the whole electrode and the stability of long-term discharging. The simple preparation method has good practicability, and can generate high economic benefits and social effects.

Owner:NANJING UNIV

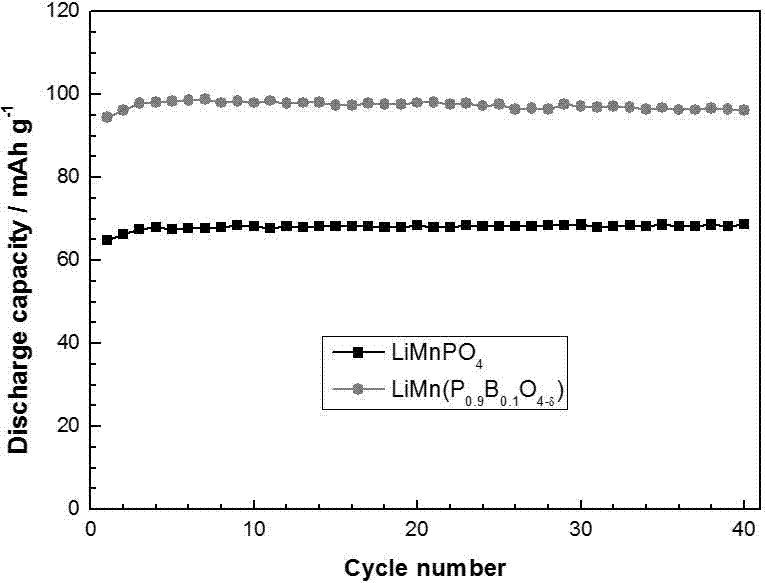

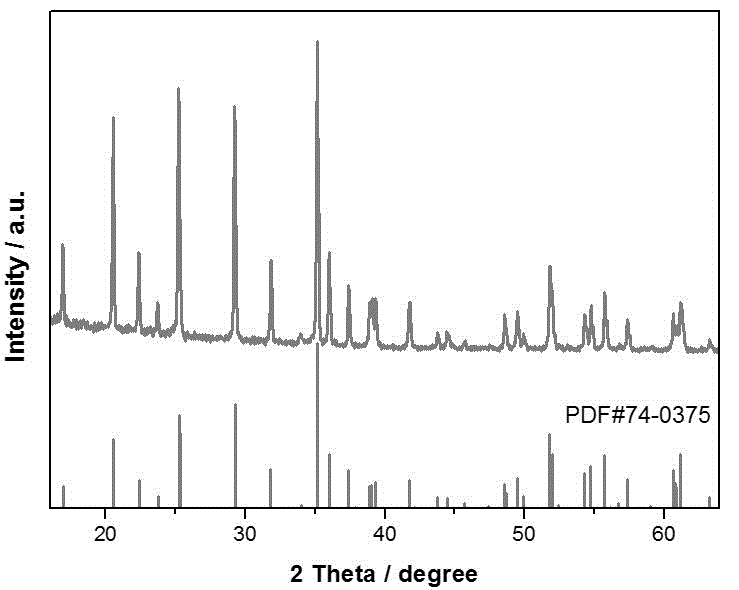

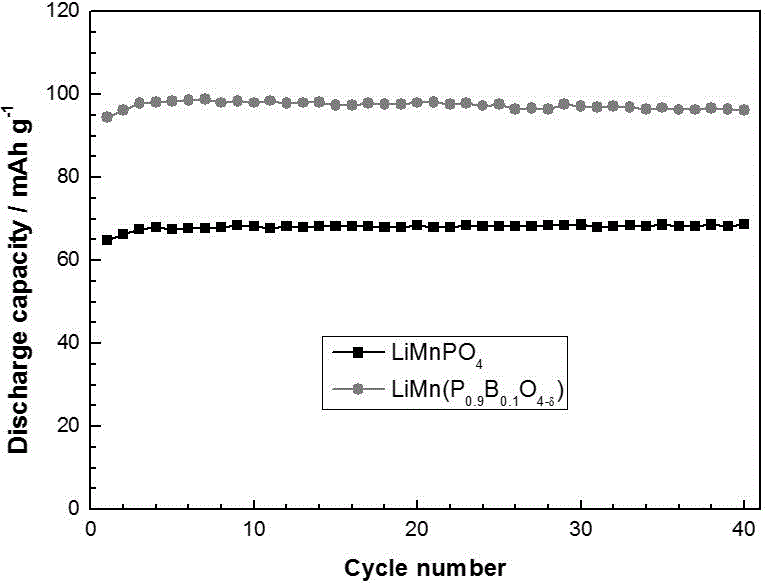

Phosphate potential boron-doped manganese phosphate lithium / carbon composite materials and preparation method thereof

InactiveCN102931404AResolve low activityCell electrodesPhosphorus compoundsCarbon compositesElectrochemistry

The invention belongs to the technical field of electrochemical power sources and discloses boron-doped manganese phosphate lithium / carbon composite materials and a preparation method thereof. The preparation method of the boron-doped manganese phosphate lithium / the carbon composite materials is characterized in that boron compounds, a lithium source, a manganese source, a phosphorus source and carbon source compounds are mixed uniformly through ball-milling and calcined for one shot under inert atmosphere, and therefore boron-doped manganese phosphate lithium material can be obtained. The general formula of the preparation method of the boron-doped manganese phosphate lithium / the carbon composite materials is LiMnP1-xBxO4-delta / C. Doped boron improves electrochemical performance of manganese phosphate lithium. The boron-doped manganese phosphate lithium / the carbon composite materials can be used as lithium-ion secondary battery anode materials.

Owner:FUDAN UNIV

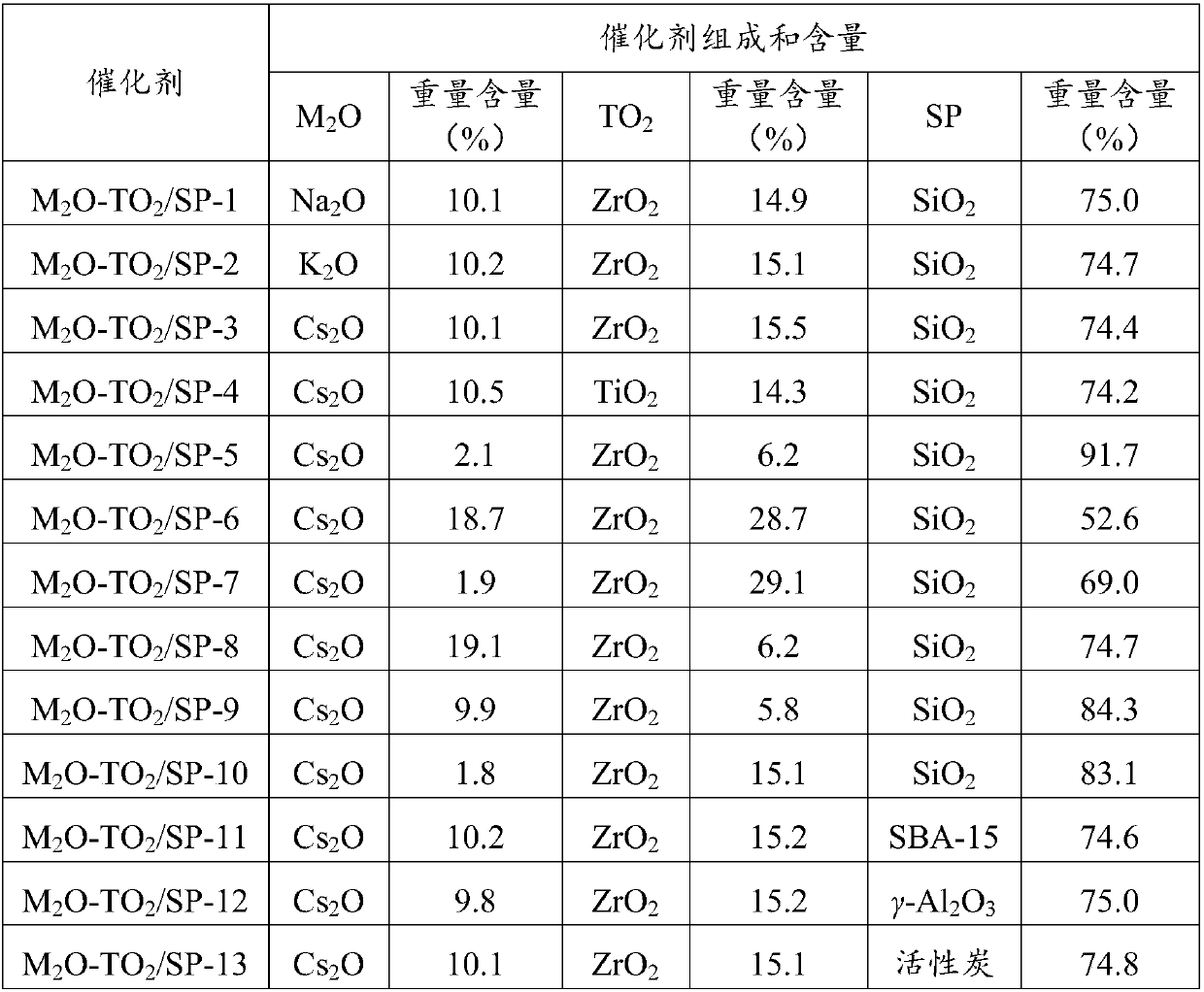

Method for producing EC (ethylene carbonate)

ActiveCN107915710AStable in natureNot easy to loseOrganic chemistryMolecular sieve catalystsLow activityActivated carbon

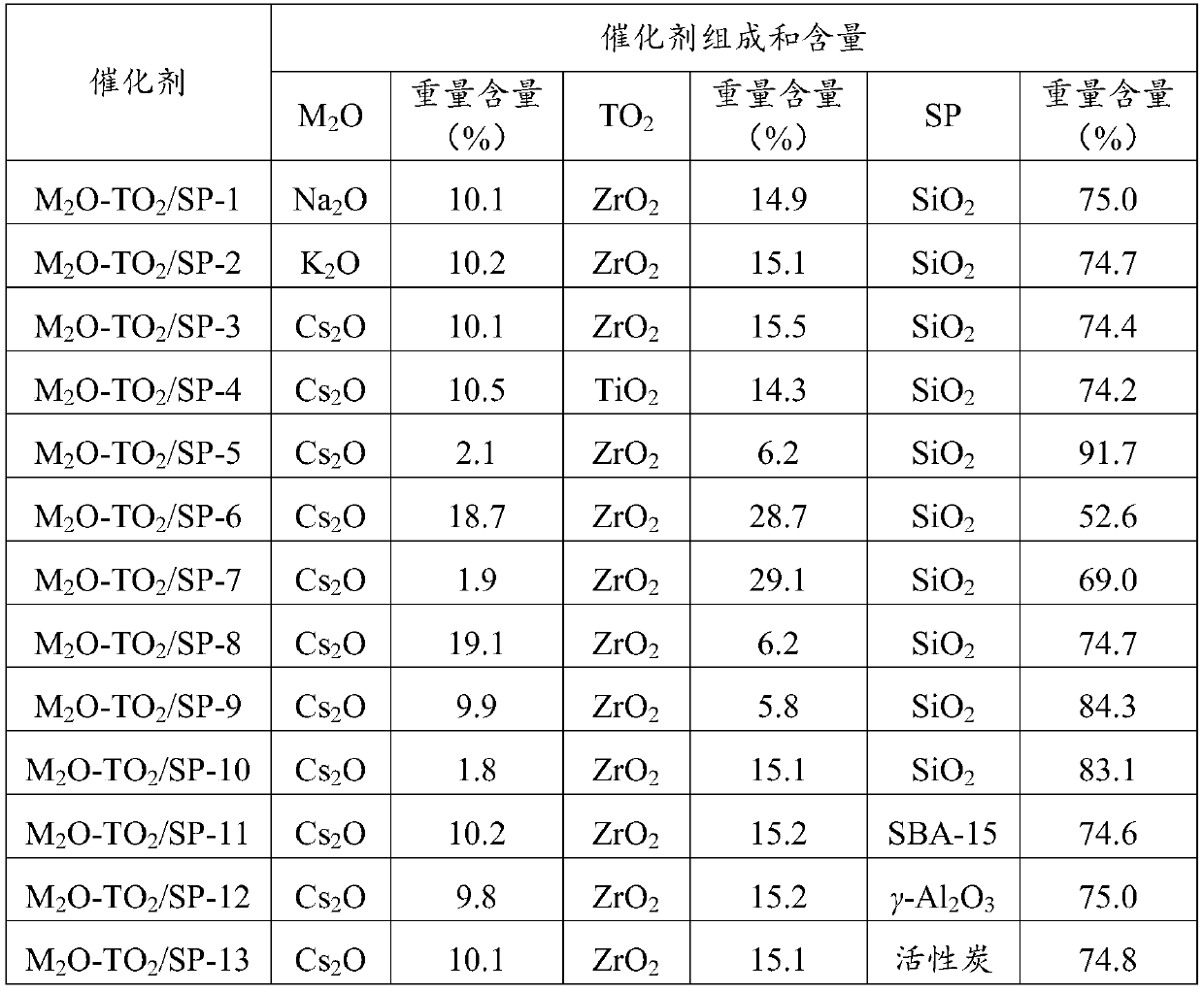

The invention relates to a method for producing EC (ethylene carbonate) and mainly solves the problem of low activity of a heterogeneous catalyst in the prior art. The problem is better solved by means of the technical scheme as follows: the method comprises the step that ethylene oxide and carbon dioxide are contacted with a catalyst under the reaction condition, wherein the catalyst is a supported type composite metal oxide catalyst M2O-TO2 / SP; M is at least one of alkaline metal Na, K, Rb or Cs; T is at least one of Ti or Zr; SP is at least one of porous silica, SBA-15, MCM-41, MCF, HMS, alumina or activated carbon; the content of M2O is 1%-20% by weight, the content of TO2 is 5%-30% by weight, and the content of SP is 50%-94% by weight. The method for producing EC can be applied to industrial production of EC prepared from ethylene oxide and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

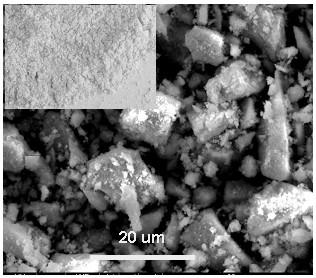

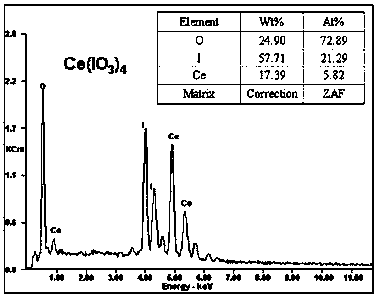

Application of ce(io3)4

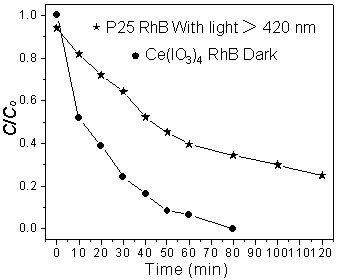

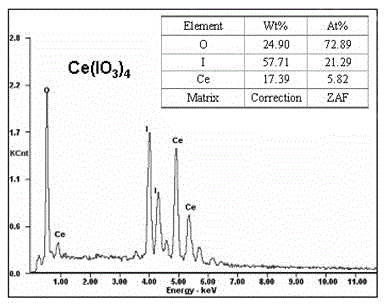

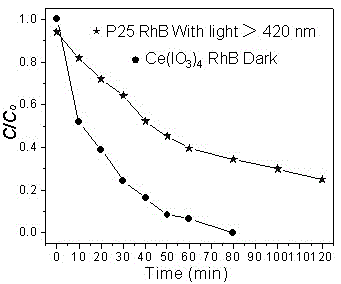

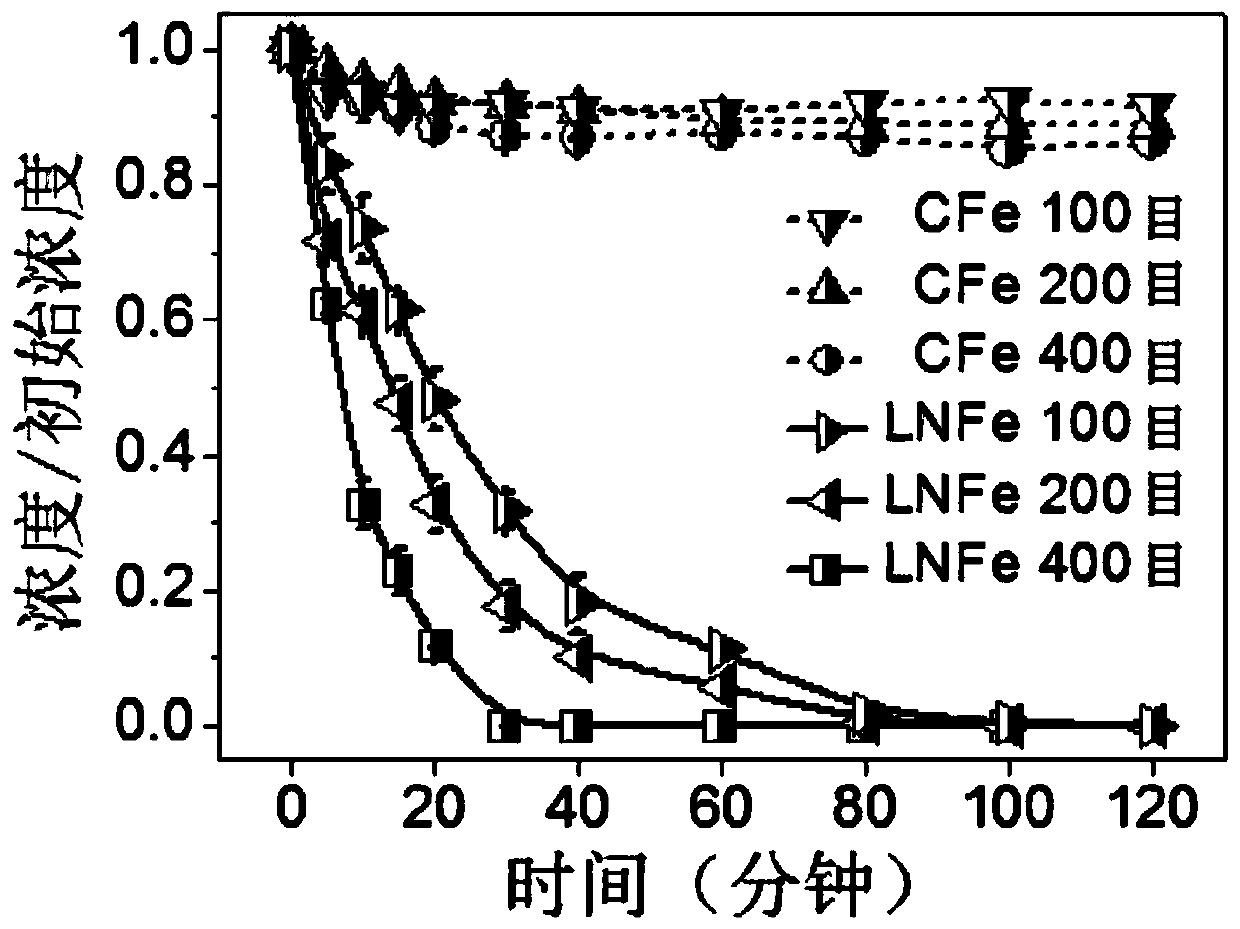

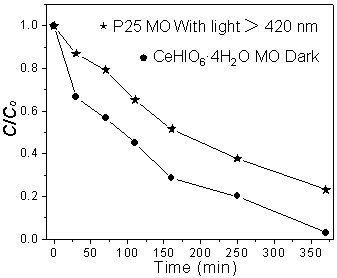

InactiveCN106807408BResolve low activitySolve the problem that activity is heavily dependent on light conditionsPhysical/chemical process catalystsWater/sewage treatment by irradiationRoom temperatureMethyl orange

The invention discloses an application of Ce(IO3)4, and provides an application example of the compound for the first time. As a catalyst, the Ce(IO3)4 can degrade organic dyestuff pollutants under a condition of completely lucifugal room temperature. The Ce(IO3)4 catalyzes and degrades the activity of Rhodamine B (RhB) and methyl orange (MO) dyestuff under a completely lucifugal condition, and is apparently superior to a commercial titanium dioxide (P25) photocatalyst under visible light irradiation. When the Ce(IO3)4 disclosed by the invention catalyzes and degrades dyestuff, illumination is not required; the activity is relatively high; the preparation method for the Ce(IO3)4 is simple; the preparation condition is mild; therefore, the Ce(IO3)4 is favorably popularized and applied.

Owner:CHONGQING THREE GORGES UNIV

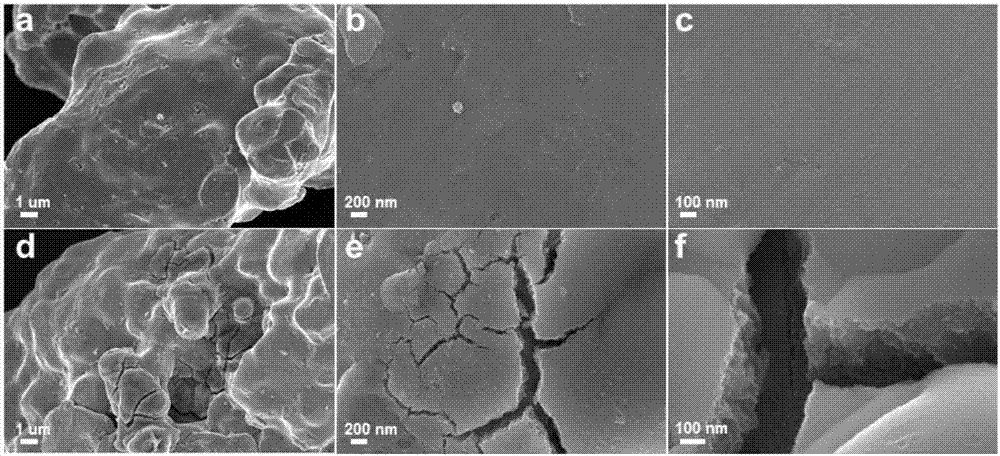

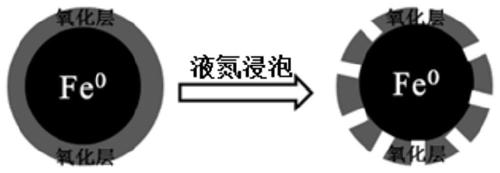

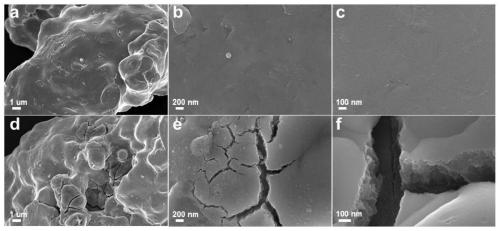

Method for treating commercial iron powder by liquid oxygen at low temperature for enhancing pollutant reductive removal ability

ActiveCN107188291ASimple methodEasy to operateTransportation and packagingMetal-working apparatusIonLow activity

The invention relates to a method for treating commercial iron powder by liquid oxygen at low temperature for enhancing pollutant reductive removal ability. Because the commercial iron powder is easily oxidized in the preparation and storage process, one layer of iron oxide with nanometer thickness covers the surface, and then the reduction ability is greatly decreased. The method aims at solving the problem of poor activity of the commercial iron powder by using the simple and easy method. The method comprises the following step of chilling the commercial iron powder, so as to obtain the commercial iron powder of which the pollutant reductive removal ability is enhanced. The oxide layer at the surface of the iron powder is cracked by the chilling step, and the active zero-valence ion at the interior (bottom layer) is exposed. Compared with other chemical or physical methods, the method for treating the commercial iron powder by the liquid nitrogen at low temperature has the characteristics that the method is simple, the implementing is easy, the efficiency is high, the pollution is avoided, the environment-friendly property is realized, the problem of low activity of pollutant in the existing commercial iron powder treatment process is solved, and the method is expected to be widely applied into the environment pollution control aspect.

Owner:DONGGUAN PUREMATE ENVIRONMENTAL PROTECTION TECH CO LTD

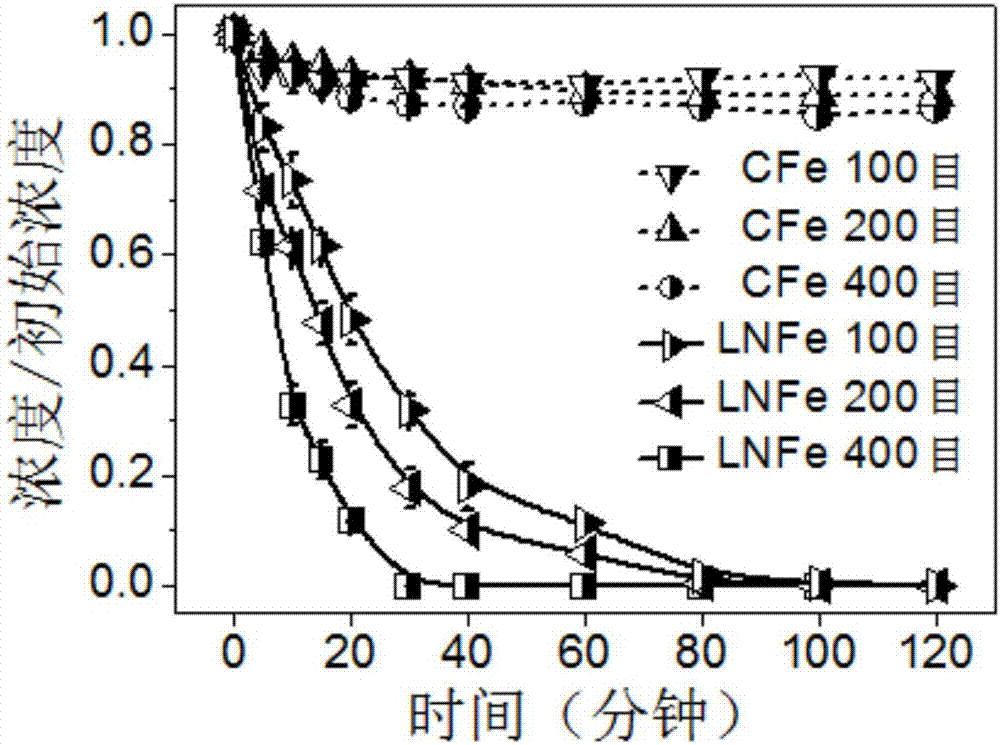

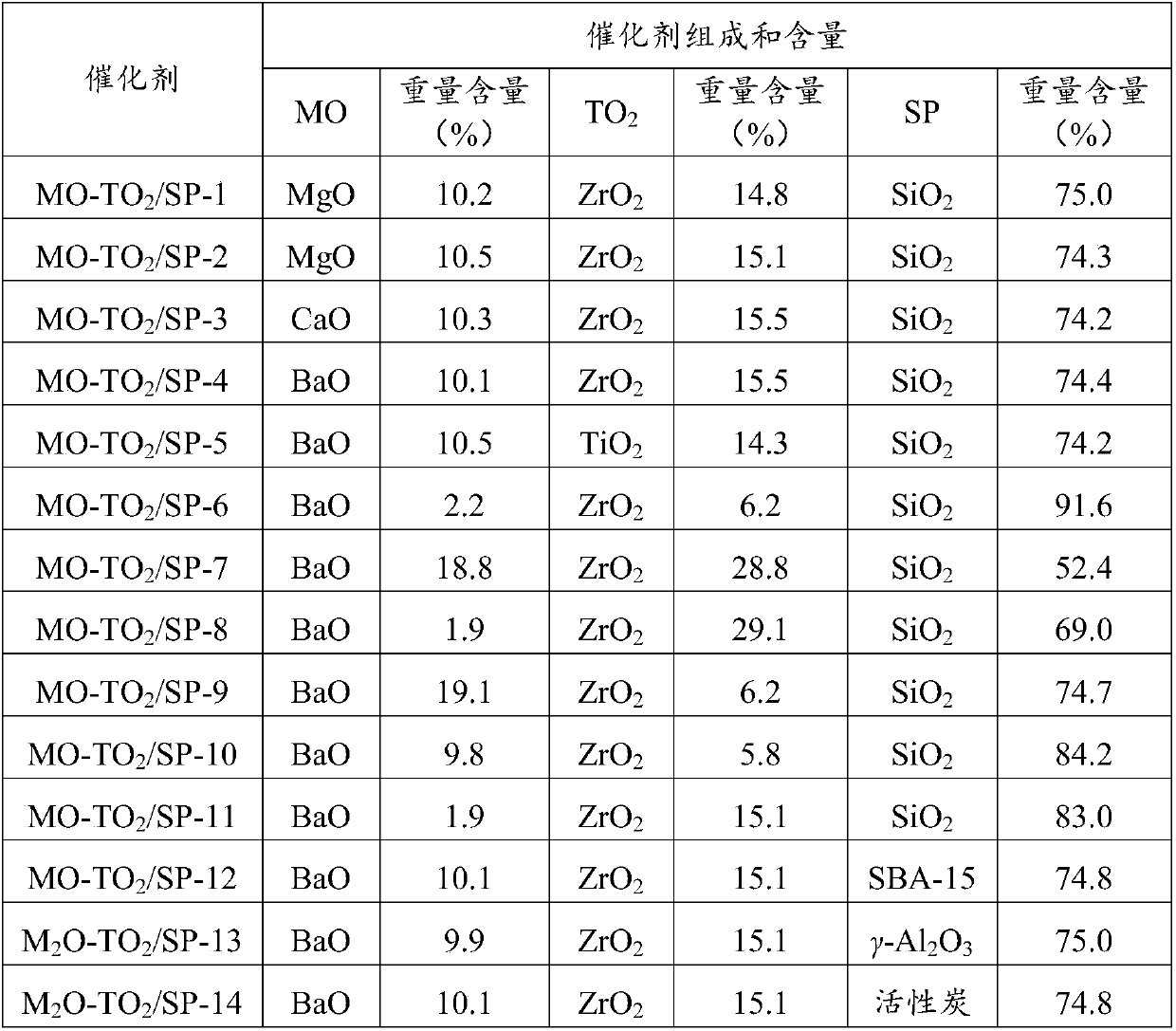

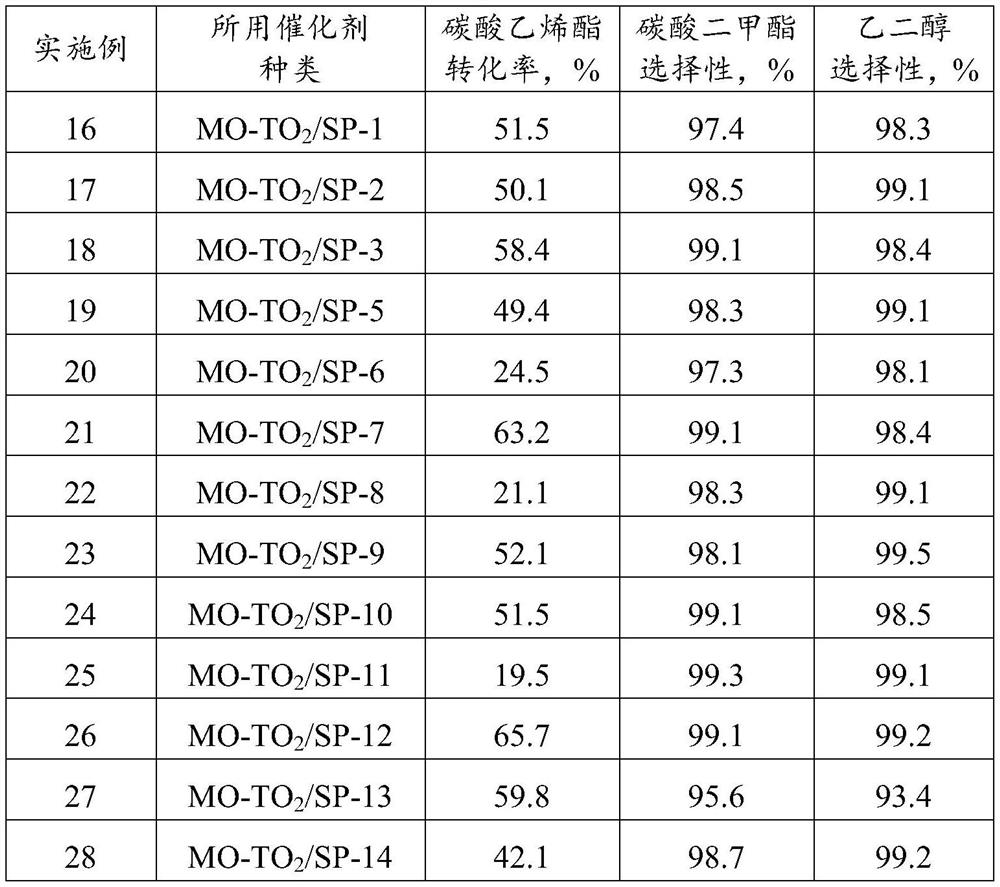

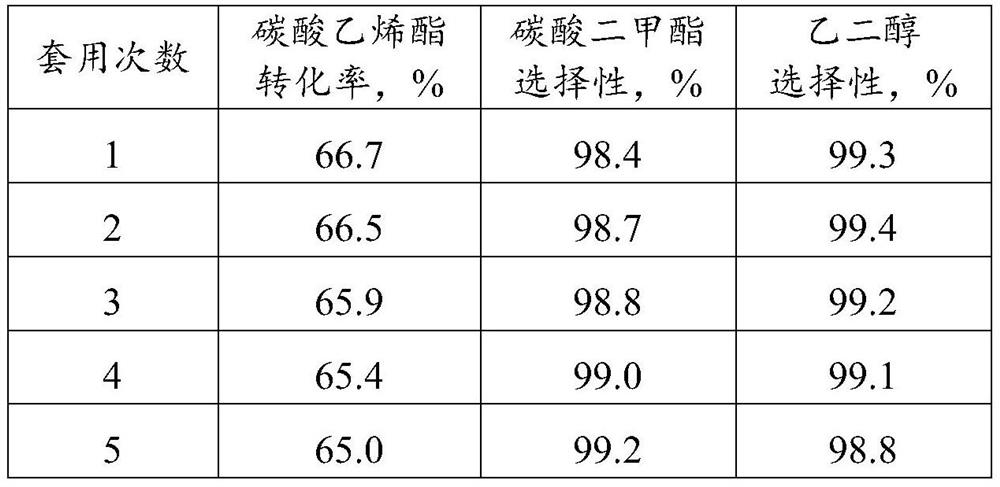

Method for producing ethylene carbonate from ethylene oxide and CO2

ActiveCN107915709AStable in natureNot easy to loseOrganic chemistryMolecular sieve catalystsAlkaline earth metalHomogeneous catalysis

The invention relates to a method for producing ethylene carbonate from ethylene oxide and CO2 and mainly solves the problem that heterogeneous catalysts have low activity in the prior art. The methodcomprises the step of contacting ethylene oxide and CO2 with a catalyst under the reaction condition, wherein the catalyst is a supported compound e metal oxide catalyst MO-TO2 / SP; M is at least oneof alkaline earth metals Mg, Ca, Sr and Ba; T is at least one of Ti and Zr; SP is at least one of porous silicon oxide, SBA-15, MCM-41, MCF, HMS, aluminum oxide and activated carbon; the weight content of MO is 1%-20%, the weight content of TO2 is 5%-30% and the weight content of SP is 50%-94%. With the adoption of the technical scheme, the problem is better solved and the method can be applied toindustrial production of preparation of ethylene carbonate from ethylene oxide and CO2.

Owner:CHINA PETROLEUM & CHEM CORP +1

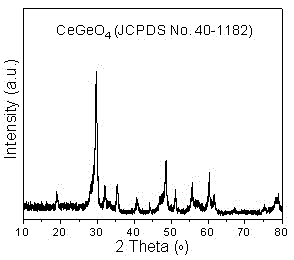

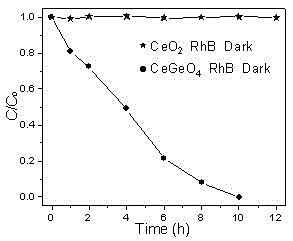

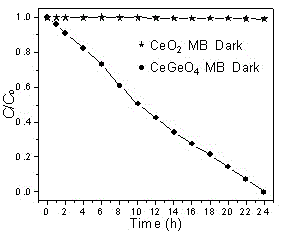

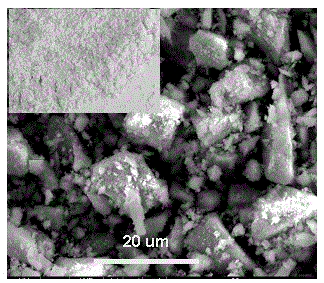

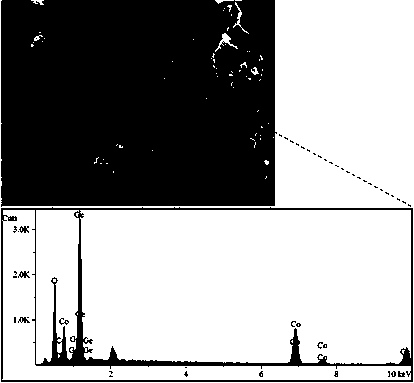

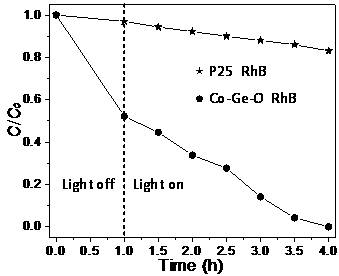

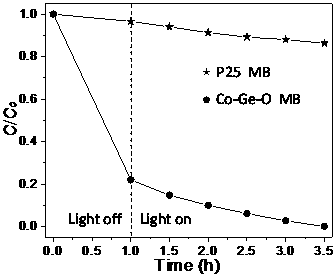

Application of CeGeO4

InactiveCN106745348AExpand the scope of applicationResolve low activityWater contaminantsWater/sewage treatmentPollutantOrganic dye

The invention discloses an application of CeGeO4. CeGeO4 as a catalyst has catalytic activity under an illumination condition and also can degrade organic dye pollutants under a completely lucifugal room temperature condition, and an application scope of CeGeO4 is enlarged. CeGeO4 ha apparently higher activity of catalytic degradation of rhodamine B (RhB) and methylene blue (MB) dyes under the completely lucifugal condition as compared with a CeO2 catalyst. CeGeO4 does not require illumination and has higher activity during catalytic degradation of the dyes; a preparation method of CeGeO4 is simple; a preparation condition is mild; and the popularization and application of CeGeO4 is facilitated.

Owner:HUNAN UNIV OF SCI & TECH

Application of Ce(IO3)4

InactiveCN106807408AEasy to prepareMild preparation conditionsPhysical/chemical process catalystsWater/sewage treatment by irradiationRoom temperatureMethyl orange

The invention discloses an application of Ce(IO3)4, and provides an application example of the compound for the first time. As a catalyst, the Ce(IO3)4 can degrade organic dyestuff pollutants under a condition of completely lucifugal room temperature. The Ce(IO3)4 catalyzes and degrades the activity of Rhodamine B (RhB) and methyl orange (MO) dyestuff under a completely lucifugal condition, and is apparently superior to a commercial titanium dioxide (P25) photocatalyst under visible light irradiation. When the Ce(IO3)4 disclosed by the invention catalyzes and degrades dyestuff, illumination is not required; the activity is relatively high; the preparation method for the Ce(IO3)4 is simple; the preparation condition is mild; therefore, the Ce(IO3)4 is favorably popularized and applied.

Owner:CHONGQING THREE GORGES UNIV

Process for producing ethylene carbonate

ActiveCN107915710BStable in natureNot easy to loseOrganic chemistryMolecular sieve catalystsActivated carbonPtru catalyst

The invention relates to a method for producing EC (ethylene carbonate) and mainly solves the problem of low activity of a heterogeneous catalyst in the prior art. The problem is better solved by means of the technical scheme as follows: the method comprises the step that ethylene oxide and carbon dioxide are contacted with a catalyst under the reaction condition, wherein the catalyst is a supported type composite metal oxide catalyst M2O-TO2 / SP; M is at least one of alkaline metal Na, K, Rb or Cs; T is at least one of Ti or Zr; SP is at least one of porous silica, SBA-15, MCM-41, MCF, HMS, alumina or activated carbon; the content of M2O is 1%-20% by weight, the content of TO2 is 5%-30% by weight, and the content of SP is 50%-94% by weight. The method for producing EC can be applied to industrial production of EC prepared from ethylene oxide and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

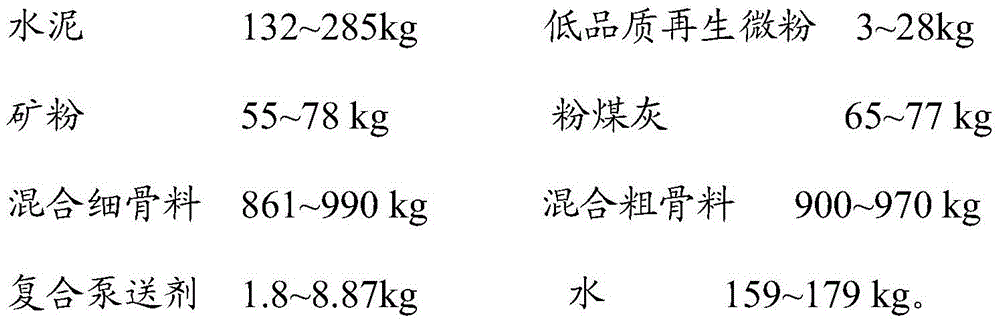

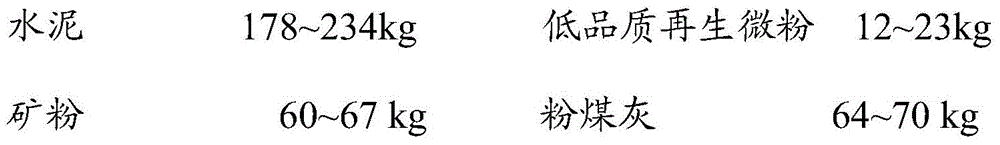

A pumping concrete mixed with low-quality recycled micropowder and low-quality recycled aggregate

ActiveCN104261730BResolve low activityEnhanced inhibitory effectSolid waste managementWork performanceSlag

The invention provides pump concrete doped with low-quality recycled micropowder and low-quality recycled aggregate, and belongs to the field of building materials. The pump concrete is composed of the following raw materials including cement, the low-quality recycled micropowder, slag powder, fly ash, mixed fine aggregate, mixed coarse aggregate, a compound pumping agent and water, wherein the mixed fine aggregate is composed of low-quality recycled fine aggregate and common fine aggregate; the mixed coarse aggregate is composed of low-quality recycled coarse aggregate and common coarse aggregate; and the compound pumping agent comprises a salt of sulfonated polystyrene-acrylic acid copolymer and a salt. The pump concrete has the characteristics of good work performance and excellent mechanical properties and durability, and can be pumped easily.

Owner:北京东方建宇混凝土科学技术研究院有限公司

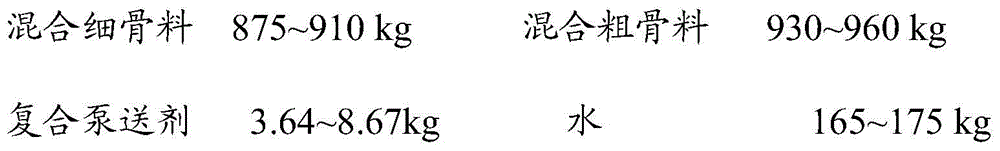

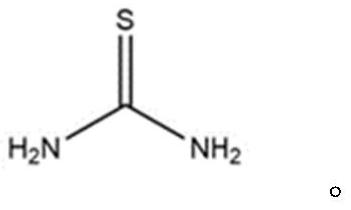

Epoxy curing agent as well as preparation method and application thereof

PendingCN114163614AImprove low curing agent activityIncrease deflectionEpoxy resin coatingsFirming agentPolymer chemistry

The invention belongs to the technical field of epoxy resin, and particularly relates to an epoxy curing agent and a preparation method and application thereof. The epoxy curing agent comprises the following raw materials: aliphatic amine / alicyclic amine, thiourea and polyether amine. The thiourea modified curing agent can still keep high activity at low temperature, and the problem of low activity of the curing agent caused by low temperature during construction in autumn and winter is effectively solved. Polyether amine has a bifunctional flexible chain segment, so that the molecular deflection of the curing agent is increased, long chain segments are mutually wound after curing, and the low-temperature toughness and impact resistance of a cured product are greatly improved. According to the preparation process of the epoxy curing agent, fatty amine / alicyclic amine and polyether amine react with thiourea respectively in two steps, and the situation that due to the fact that the two kinds of amine generate competitive reaction due to different activities, a designed product cannot reach an expected standard is avoided.

Owner:瑞奇新材料(广州)有限公司

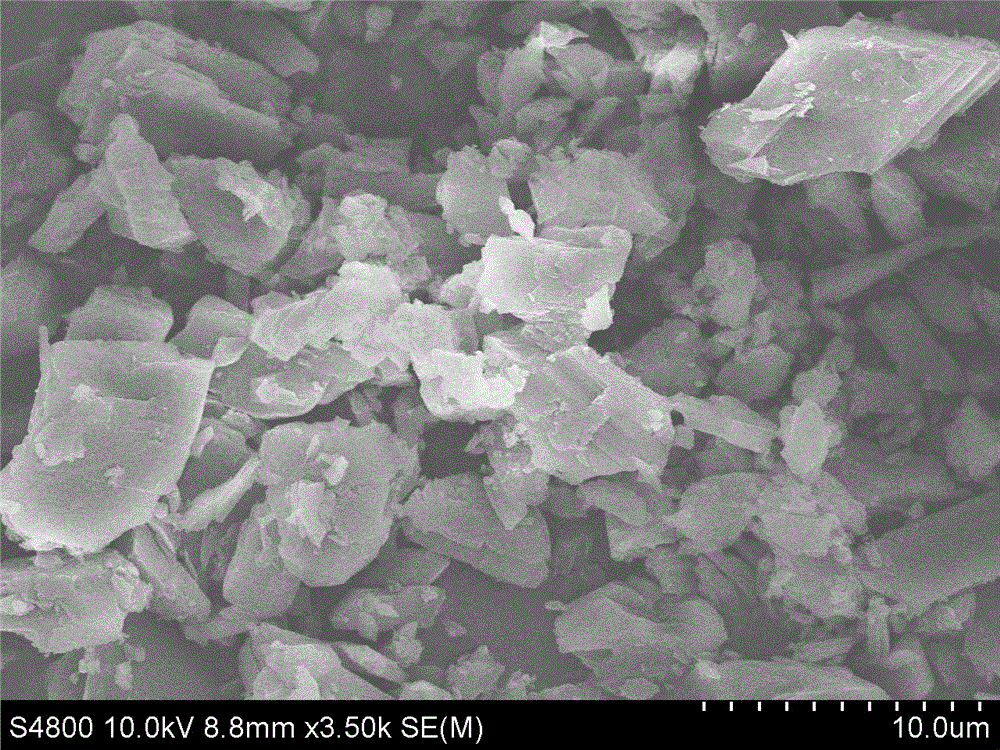

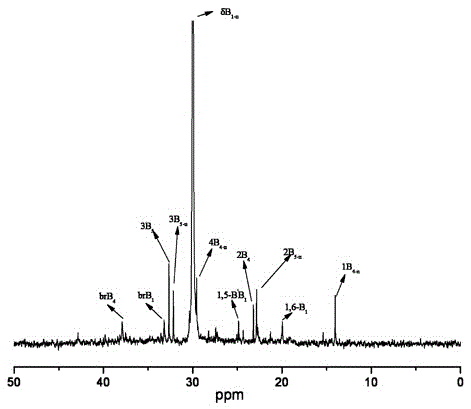

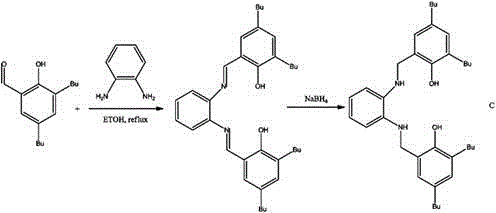

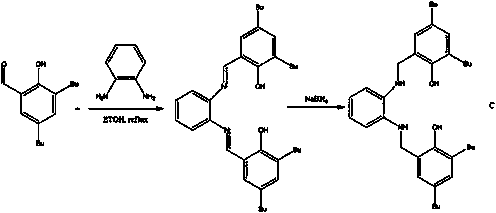

Supported bridged bis-phenoxy IVB metal catalyst and preparation method thereof

InactiveCN105646737ASolve the problem of low catalyst activityResolve low activityStructural formulaHydroxy compound

The invention discloses a supported bridged bis-phenoxy IVB metal catalyst and a preparation method thereof. The structural formula of the active component [ONNO]MX2 of the catalyst is disclosed as Formula (I) or Formula (II). The active component of the catalyst is supported on a triethyl-aluminum-modified MgCl2 / EtnAl(OR)[3-n] supporter, wherein R is C2-C5 straight-chain alkyl; and n represents the quantity of hydroxyl hydrogens substituted by triethyl aluminum in ethanol, and n=0-3. According to the characteristics of the [ONNO] bridged bis-phenoxy IVB metal catalyst framework ligand, the [ONNO] bridged bis-phenoxy IVB metal catalyst is supported on the MgCl2 / EtnAl(OR)[3-n] supporter to form a novel supported catalyst, thereby solving the problem of low activity in the homogeneous [ONNO] bridged bis-phenoxy IVB metal catalyst. The kinetic reaction of the novel supported catalyst is stable and efficient, has higher catalytic activity, and can be used for preparing branched polyethylene.

Owner:SUN YAT SEN UNIV

Preparation method of hydrotreating catalyst

ActiveCN113019429AImprove acid propertiesIncreased acidity of moderately strong acidsMolecular sieve catalystsHydrocarbon oils refiningPtru catalystEngineering

The invention discloses a preparation method of a hydrotreating catalyst. The method comprises the following steps: (i) preparing an Al-SBA-15 molecular sieve by taking amorphous silica-alumina dry glue as a raw material and adopting a P123 triblock copolymer as a template agent; (ii) subjecting the Al-SBA-15 mesoporous molecular sieve prepared in the step (i) and aluminum oxide to mixing, kneading and forming so as to obtain a carrier; and (iii) impregnating the carrier obtained in the step (ii) with an impregnating solution containing an active metal component and a trihydroxymethyl compound, and then carrying out drying and roasting to obtain the hydrotreating catalyst. The hydrotreating catalyst shows relatively high activity when being used in a hydrogenation denitrification reaction of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Active stimulating grinding aid for ferronickel slag and preparation method thereof

ActiveCN105084793BSolve the problem of poor wearabilityResolve low activitySolid waste managementSlagPyrophosphate

The invention discloses an active excitatory grinding aid for ferronickel slag and a preparation method for the active excitatory grinding aid. The grinding aid is composed of polymeric glycol, cocoanut fatty acid diethanolamide, sodium pyrophosphate, ethyl acetate, an excitant and water, wherein the excitant is composed of calcined alunite, water glass and sodium abietate. The additive amount of the grinding aid in the ferronickel slag is 0.02-0.10% by mass of the ferronickel slag. The active excitatory grinding aid disclosed by the invention is sufficient in raw materials, simple to process and prepare, low in doping amount, stable in performance and high in cost performance. As the ferronickel slag which is ground is added, the problem that the ferronickel slag is poor in grindability can be solved. Under the condition that the grinding time is equal, the specific surface area of the ferronickel slag micropowder can be improved by 4.5-9%, the mill output is increased by over 15%, the energy consumption is remarkably reduced, and moreover, the active index of the ferronickel slag can be further improved by 10-35%.

Owner:UNIV OF JINAN +1

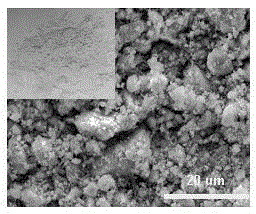

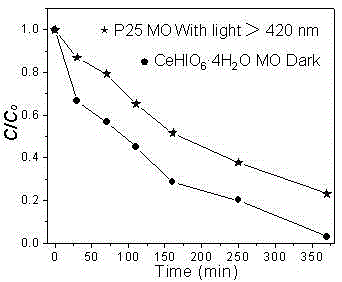

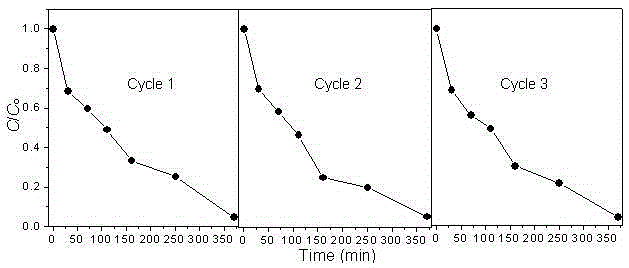

Applications of cerium hydrogen iodate tetrahydrate

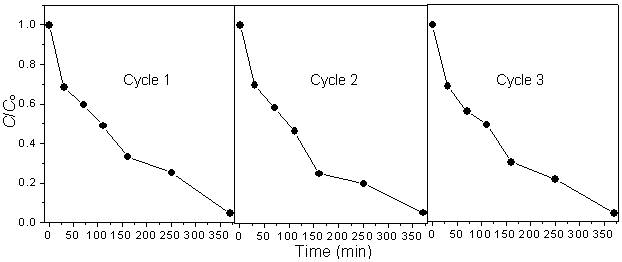

InactiveCN106745647AIncreased durabilityFix low durabilityPhysical/chemical process catalystsWater/sewage treatment by oxidationMo degradationOrganic dye

The present invention discloses applications of cerium hydrogen iodate tetrahydrate (CeHIO6.4H2O), and firstly provides the application example of the compound. According to the present invention, the cerium hydrogen iodate tetrahydrate adopted as a catalyst can degrade organic dye contaminants at a room temperature under a completely dark condition; the methyl orange (MO) dye catalytic degradation activity of CeOIO6.4H2O under a completely dark condition is significantly higher than the methyl orange (MO) dye catalytic degradation activity of commercial titanium dioxide (P25) photocatalysts under visible light irradiation; CeHIO6.4H2O is highly durable, wherein the activity is not significantly reduced after CeHIO6.4H2O is recycled 3 times in the MO degradation experiment; when the CeHIO6.4H2O performs the catalytic degradation of dyes, the characteristics of no requirement of illumination, high activity and high durability are provided; and the preparation method is simple, the preparation condition is mild, and the method is suitable for popularization and application.

Owner:CHONGQING THREE GORGES UNIV

Method for producing ethylene carbonate

ActiveCN107915713AGood technical effectResolve low activityPhysical/chemical process catalystsOrganic chemistryLow activityChemistry

The invention relates to a method for producing ethylene carbonate and mainly solves the problem of low activity of a heterogeneous catalyst in the prior art. The problem is better solved by means ofthe technical scheme as follows: the method comprises the following steps: ethylene oxide and carbon dioxide are contacted with a catalyst under the reaction condition, wherein the catalyst is prepared from 1wt%-30wt% of alkali metal on the basis of M2O and 70wt%-99wt% of aluminum phosphorus oxide carriers APO. The method can be applied to industrial production of preparation of ethylene carbonatefrom ethylene oxide and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphorous boron doped lithium manganese phosphate/carbon composite material and preparation method thereof

The invention belongs to the technical field of electrochemical power sources and discloses boron-doped manganese phosphate lithium / carbon composite materials and a preparation method thereof. The preparation method of the boron-doped manganese phosphate lithium / the carbon composite materials is characterized in that boron compounds, a lithium source, a manganese source, a phosphorus source and carbon source compounds are mixed uniformly through ball-milling and calcined for one shot under inert atmosphere, and therefore boron-doped manganese phosphate lithium material can be obtained. The general formula of the preparation method of the boron-doped manganese phosphate lithium / the carbon composite materials is LiMnP1-xBxO4-delta / C. Doped boron improves electrochemical performance of manganese phosphate lithium. The boron-doped manganese phosphate lithium / the carbon composite materials can be used as lithium-ion secondary battery anode materials.

Owner:FUDAN UNIV

A method for low-temperature treatment of commercial iron powder with liquid nitrogen to enhance its ability to reduce and remove pollutants

ActiveCN107188291BEasy to handleEfficient treatment methodTransportation and packagingMetal-working apparatusIron powderEnvironmental engineering

The invention relates to a method for low-temperature treatment of commercial iron powder with liquid nitrogen to enhance its ability to reduce and remove pollutants. Since commercial iron powder is easily oxidized during the preparation and storage process, the surface is covered with a layer of nano-scale iron oxide, which greatly reduces its reducing ability. The purpose of the present invention is to adopt a simple and easy method to solve the problem of poor activity of commercial iron powder. The method comprises: quenching the commercial iron powder to obtain the commercial iron powder with enhanced ability to reduce and remove pollutants. The quenching treatment cracks the oxide layer on the surface of the iron powder, exposing the active zero-valent iron inside (bottom layer). Compared with other chemical or physical methods, the method for low-temperature treatment of commercial iron powder with liquid nitrogen provided by the invention is simple and easy, and has the characteristics of high efficiency, no pollution and environmental friendliness, and solves the problem of low activity of pollutants in the current commercial iron powder treatment. It is expected to be widely used in environmental pollution control.

Owner:DONGGUAN PUREMATE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for synthesizing dimethyl carbonate

ActiveCN107915574BStable in natureNot easy to loseOxygen-containing compound preparationMolecular sieve catalystsAlkaline earth metalPtru catalyst

The invention relates to a method for synthesizing dimethyl carbonate, which mainly solves the problems of poor catalyst activity and easy loss of active components in the prior art. The present invention is by adopting to comprise under transesterification reaction condition, the step that ethylene carbonate and methyl alcohol contact with catalyzer; Described catalyzer is supported composite metal oxide catalyst MO-TO 2 / SP; M is at least one of alkaline earth metal Mg, Ca, Sr or Ba; T is at least one of Ti or Zr; SP is porous silica, SBA-15, MCM-41, MCF, HMS, oxide At least one of aluminum or activated carbon; the weight content of MO is 1-20%, TO 2 The technical scheme that the weight content of SP is 5-30%, and the weight content of SP is 50-94% solves this problem well, and can be used in the industrial production of dimethyl carbonate prepared by transesterification of ethylene carbonate and methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Application of cerium hydrogen iodate tetrahydrate

InactiveCN106745647BHigh catalytic degradation activityResolve low activityPhysical/chemical process catalystsWater/sewage treatment by oxidationMo degradationPtru catalyst

The present invention discloses applications of cerium hydrogen iodate tetrahydrate (CeHIO6.4H2O), and firstly provides the application example of the compound. According to the present invention, the cerium hydrogen iodate tetrahydrate adopted as a catalyst can degrade organic dye contaminants at a room temperature under a completely dark condition; the methyl orange (MO) dye catalytic degradation activity of CeOIO6.4H2O under a completely dark condition is significantly higher than the methyl orange (MO) dye catalytic degradation activity of commercial titanium dioxide (P25) photocatalysts under visible light irradiation; CeHIO6.4H2O is highly durable, wherein the activity is not significantly reduced after CeHIO6.4H2O is recycled 3 times in the MO degradation experiment; when the CeHIO6.4H2O performs the catalytic degradation of dyes, the characteristics of no requirement of illumination, high activity and high durability are provided; and the preparation method is simple, the preparation condition is mild, and the method is suitable for popularization and application.

Owner:CHONGQING THREE GORGES UNIV

Process for the preparation of ethylene carbonate

ActiveCN107915712BSignificant acid-base synergistic catalytic effectNot easy to loseOrganic chemistryMolecular sieve catalystsAlkaline earth metalPtru catalyst

The invention relates to a method for preparing ethylene carbonate and mainly solves the problem of low activity of heterogeneous catalysts in the prior art. The method comprises the step of contacting ethylene oxide and carbon dioxide with a catalyst under reaction conditions; the catalyst contains 5wt%-40wt% of alkaline-earth metal based on MO and 60wt%-95wt% of a phosphorus aluminum oxide carrier APO. With adoption of the technical scheme, the problems are better solved, and the method can be used for preparation of ethylene carbonate from ethylene oxide and carbon dioxide in industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ethylene carbonate from ethylene oxide and carbon dioxide

ActiveCN107915709BStable in natureNot easy to loseOrganic chemistryMolecular sieve catalystsAlkaline earth metalPtru catalyst

The invention relates to a method for producing ethylene carbonate from ethylene oxide and CO2 and mainly solves the problem that heterogeneous catalysts have low activity in the prior art. The methodcomprises the step of contacting ethylene oxide and CO2 with a catalyst under the reaction condition, wherein the catalyst is a supported compound e metal oxide catalyst MO-TO2 / SP; M is at least oneof alkaline earth metals Mg, Ca, Sr and Ba; T is at least one of Ti and Zr; SP is at least one of porous silicon oxide, SBA-15, MCM-41, MCF, HMS, aluminum oxide and activated carbon; the weight content of MO is 1%-20%, the weight content of TO2 is 5%-30% and the weight content of SP is 50%-94%. With the adoption of the technical scheme, the problem is better solved and the method can be applied toindustrial production of preparation of ethylene carbonate from ethylene oxide and CO2.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of polycarbonate synthesis double metal cyanide catalyst

ActiveCN102179262BAvoid synergistic effectsImprove performanceOrganic-compounds/hydrides/coordination-complexes catalystsCyanide compoundPtru catalyst

The invention discloses a preparation method for a double metal cyanide catalyst for polycarbonate synthesis. The preparation method comprises the following steps of: firstly dissolving soluble metallic salt in organic ligand, and then adding deionized water to serve as a solution 1; dissolving water-soluble metallic cyanide salt in the deionized water to serve as a solution 2, wherein the volume ratio of the solution 1 to the solution 2 is 0.1: 1-5: 1; and then dripping the solution 2 to the solution 1 to obtain a solid catalyst after stirring and drying. In the invention, the influence of the deionized water to the synergic action between the organic ligand and the soluble metal salt is avoided; the synergic action between the organic ligand and the soluble metal salt in the DMC (Di Methyl Carbonate) catalyst is exerted at the greatest degree; and the reaction time when the catalyst catalyzes a copolymerization of propylene oxide and CO2 does not exceed 8h, the activity reaches to above 30Kg polymer / g catalyst, and the CO2 unit content in the polymer reaches up to 45.0%.

Owner:HEBEI UNIV OF TECH +1

Method for preparing dimethyl carbonate

ActiveCN112552177AResolve low activityStable in naturePhysical/chemical process catalystsOrganic compound preparationTrans esterificationPtru catalyst

The invention relates to application of magnesium silicide and / or lithium carbide as a catalyst in transesterification reactions, in particular in the production of dimethyl carbonate. The invention further provides a method for preparing dimethyl carbonate, which comprises the step of contacting alkylene carbonate and methanol with a catalyst, wherein the catalyst comprises magnesium silicide and / or lithium carbide. According to the method provided by the invention, the magnesium silicide and / or lithium carbide catalyst is adopted, so that the problems of low heterogeneous catalyst activity and easy loss of active components in transesterification in the prior art are solved. The catalyst provided by the invention is used for preparing dimethyl carbonate through transesterification of alkylene carbonate and methanol, and the conversion rate and selectivity of alkylene carbonate are relatively high.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of supported bridge bisphenoxy IVB metal catalyst and preparation method thereof

InactiveCN105646737BSolve the problem of low catalyst activityResolve low activityStructural formulaHydroxy compound

The invention discloses a supported bridged bis-phenoxy IVB metal catalyst and a preparation method thereof. The structural formula of the active component [ONNO]MX2 of the catalyst is disclosed as Formula (I) or Formula (II). The active component of the catalyst is supported on a triethyl-aluminum-modified MgCl2 / EtnAl(OR)[3-n] supporter, wherein R is C2-C5 straight-chain alkyl; and n represents the quantity of hydroxyl hydrogens substituted by triethyl aluminum in ethanol, and n=0-3. According to the characteristics of the [ONNO] bridged bis-phenoxy IVB metal catalyst framework ligand, the [ONNO] bridged bis-phenoxy IVB metal catalyst is supported on the MgCl2 / EtnAl(OR)[3-n] supporter to form a novel supported catalyst, thereby solving the problem of low activity in the homogeneous [ONNO] bridged bis-phenoxy IVB metal catalyst. The kinetic reaction of the novel supported catalyst is stable and efficient, has higher catalytic activity, and can be used for preparing branched polyethylene.

Owner:SUN YAT SEN UNIV

Application of Co-Ge-O photocatalysis-adsorption bifunctional material

InactiveCN109603733AMild application conditionsGood effectWater/sewage treatment by irradiationOther chemical processesOrganic dyePhotocatalytic degradation

The invention discloses an application of a Co-Ge-O photocatalysis0adsorption bifunctional material. As a bifunctional material, Co-Ge-O not only can adsorb organic dye pollutants, but also can degrade the organic dye pollutants under visible light, thereby widening the application range of the material. The adsorption performance and photocatalytic degradation performance under visible light of Co-Ge-O material for organic dyes are much higher than those of commercial titanium dioxide (P25) photocatalytic materials. The Co-Ge-O material has high adsorption and photocatalytic dye degradation activity, and the preparation method of the material is simple and is beneficial to popularization and application.

Owner:CHONGQING THREE GORGES UNIV

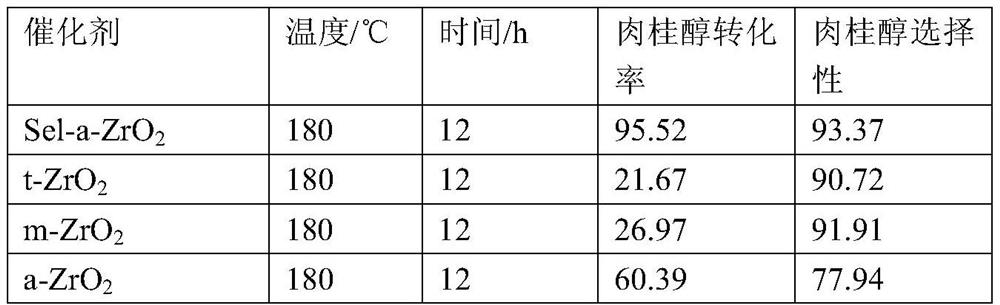

A self-selective in-situ synthesis of amorphous zirconia and its application in the transfer hydrogenation of cinnamaldehyde to prepare cinnamyl alcohol

ActiveCN111115682BImprove conversion rateLow pricePhysical/chemical process catalystsOrganic compound preparationPtru catalystCombinatorial chemistry

The invention discloses a method for preparing self-selected in-situ synthesized amorphous zirconia and its application in the transfer hydrogenation of cinnamaldehyde to prepare cinnamyl alcohol. The present invention adopts the self-selective in-situ synthesis method to obtain amorphous zirconia, and then uses it in the preparation of cinnamyl alcohol by transfer hydrogenation of cinnamaldehyde, which can prepare cinnamyl alcohol with high conversion rate and high selectivity; the raw materials used are low in price, and non- Noble metals have a short preparation period, which solves the problem of complex catalyst screening process and solves the problem of low activity of non-noble metal catalysts, and has good cycle stability. The present invention reduces the complex process of catalyst screening by self-selecting in-situ synthesis of catalysts, and is simpler than the preparation process of supported catalysts and saves costs.

Owner:XIANGTAN UNIV

Process for producing ethylene carbonate

ActiveCN107915713BResolve low activityReduced activityOrganic chemistryPhysical/chemical process catalystsPtru catalystEthylene oxide

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com