Simple preparation method of integrated metal-air cathode for metal-air battery

A metal-air battery, metal-air technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low activity, and achieve the effects of high activity, enhanced adhesion, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

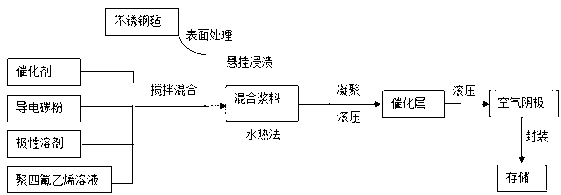

[0018] The preparation process of the simple preparation method for the integrated metal-air cathode of the metal-air battery, such as figure 1 As shown, in the catalyst preparation process, the surface-treated porous metal is directly immersed in the original catalyst slurry mixed with PTFE, and the negatively charged polar groups on the surface of the porous metal and the positively charged polar groups on the catalyst are used to realize the interaction between the two. Bonding, which is further processed by the hydrothermal method, that is, the catalyst can be directly grown on the current collector, so that the catalytic layer of the gas diffusion electrode has a very stable physical structure. In the traditional preparation process, the catalyst layer is prepared by smearing or printing the catalyst on the surface of the current collector and the micropores, which is only a mechanical combination and has poor long-term working stability. However, in the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com