A kind of supported bridge bisphenoxy IVB metal catalyst and preparation method thereof

A metal catalyst, bisphenoxy technology, applied in the field of supported bridged bisphenoxy IVB metal catalyst and its preparation, can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

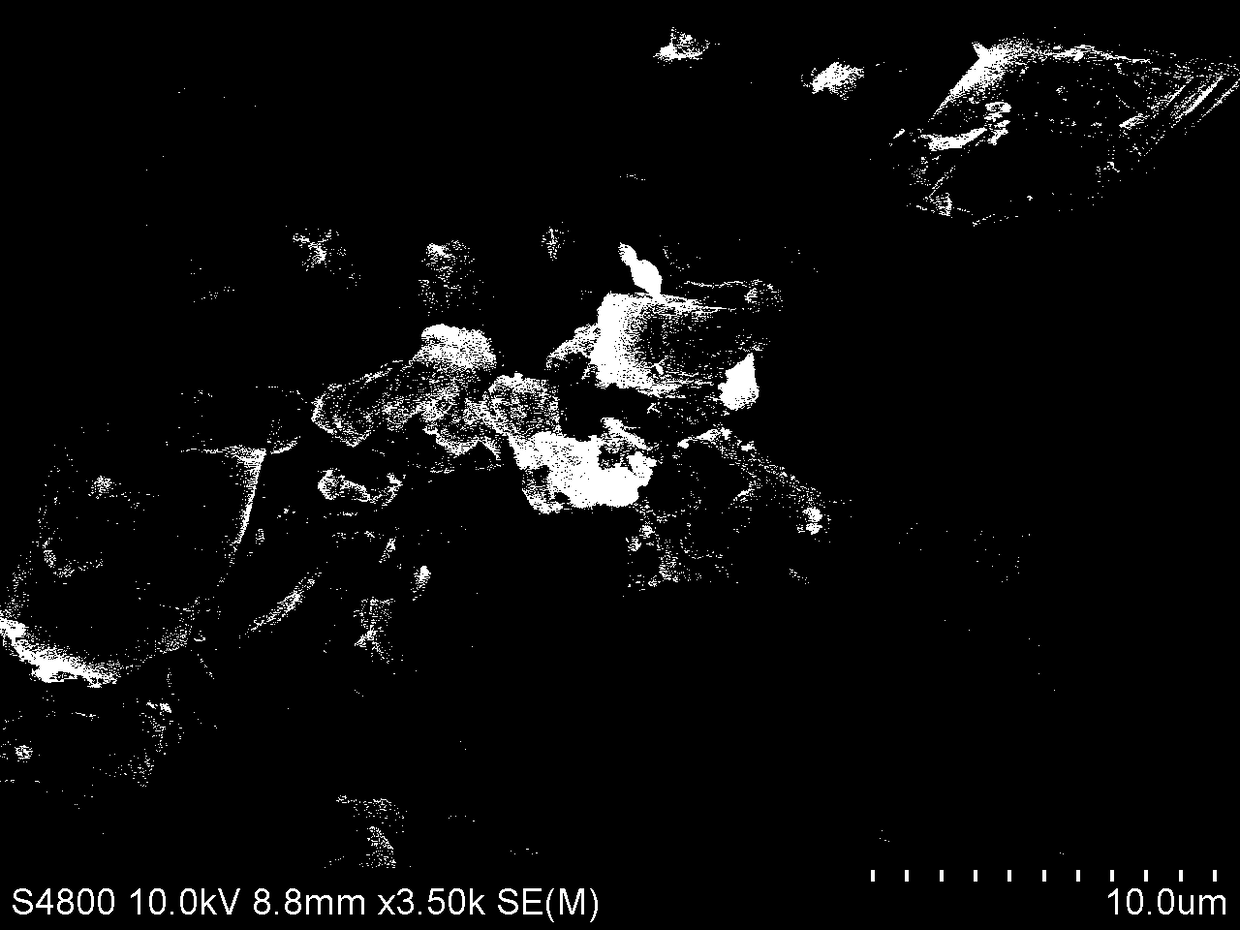

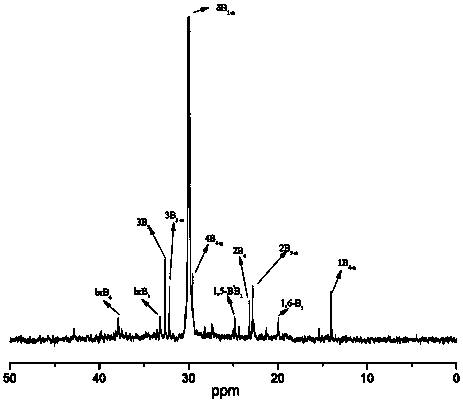

Image

Examples

Embodiment 1

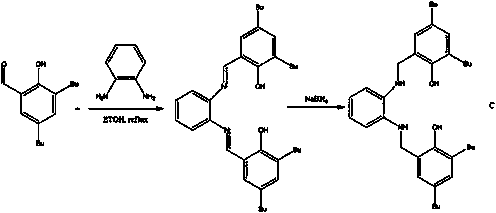

[0045] Example 1 Synthesis of Ligand Precursor L1

[0046] Add 100 mL of ethanol, 11.7 g of 3,5-di-tert-butyl salicylaldehyde, and 2.45 g of o-phenylenediamine into a 250 mL round-bottomed flask equipped with a magnet, N 2 Protected, heated to reflux for 6-8 h, cooled to room temperature and precipitated a yellow precipitate, after suction filtration, dried at 50 ℃ to obtain a yellow cotton flocculent solid, yield: 56.4%, to obtain diimine type [ONNO] type bridged bisphenoxy The base metal catalyst ligand precursor is denoted as L1. 1 H NMR (300 MHz, CDCl 3 ): δ :1.31 (s, 18H, C(CH 3 ) 3 ), 1.42 (s, 18H, C(CH 3 ) 3 ), 7.22(m, 4H, Ar-H), 7.30(m, 2H, Ar-H), 7.42(m, 2H, Ar-H), 8.63 (s, 2H,C=), 13.48(s, 2H , OH).

Embodiment 2

[0047] Example 2 Synthesis of Ligand Precursor L2

[0048] Add 100 mL of ethanol, 15.6 g of 3,5-di-tert-butyl salicylaldehyde, and 2.2 mL of ethylenediamine into a 250 mL round-bottomed flask equipped with magnets, N 2 Protected, heated to reflux for 4-6 h, cooled to room temperature and precipitated a yellow precipitate, filtered by suction, and dried at 50 ℃ to obtain a yellow cotton flocculent solid, yield: 89.4%, to obtain a diimine type [ONNO] type bridged bisphenoxy The metal catalyst ligand precursor is denoted as L2. 1 H NMR (300 MHz, CDCl 3 ): δ :1.28 (s, 18H, C(CH 3 ) 3 ), 1.43 (s, 18H, CH(CH 3 ) 3 ), 7.04(d, J=2.4 Hz, 2H, Ar-H), 7.34(J=2.4 Hz, 2H, Ar-H), 8.36 (s, 2H, C=), 13.59(s, 2H, OH)

Embodiment 3

[0049] Example 3 Synthesis of [ONNO] type bridged bisphenoxy metal catalyst 1

[0050] At a temperature of -20 ° Under C, add 2.536 g of ligand L1 to the Sehlenk bottle under nitrogen atmosphere, slowly add 5.0 mL of 1.0 mol / L titanium tetrachloride toluene solution dropwise, stir at this temperature for 60 min, then rise to room temperature and continue stirring After 24 h, the toluene solvent was removed by vacuum filtration; after washing with n-hexane, filtration, and removal of the n-hexane solvent by vacuum filtration, 2.81 g of gray powder was obtained, with a yield of 92%. Elemental analysis (C 36 h 46 Cl 2 N 2 o 2 Ti, mass %), theoretical value: C, 65.76; H, 7.05; N, 4.2.; found value: C, 64.93; H, 6.97; N, 4.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com