Supported bridged bis-phenoxy IVB metal catalyst and preparation method thereof

A metal catalyst, bisphenoxy technology, applied in the field of supported bridged bisphenoxy IVB metal catalyst and its preparation, can solve the problem of low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

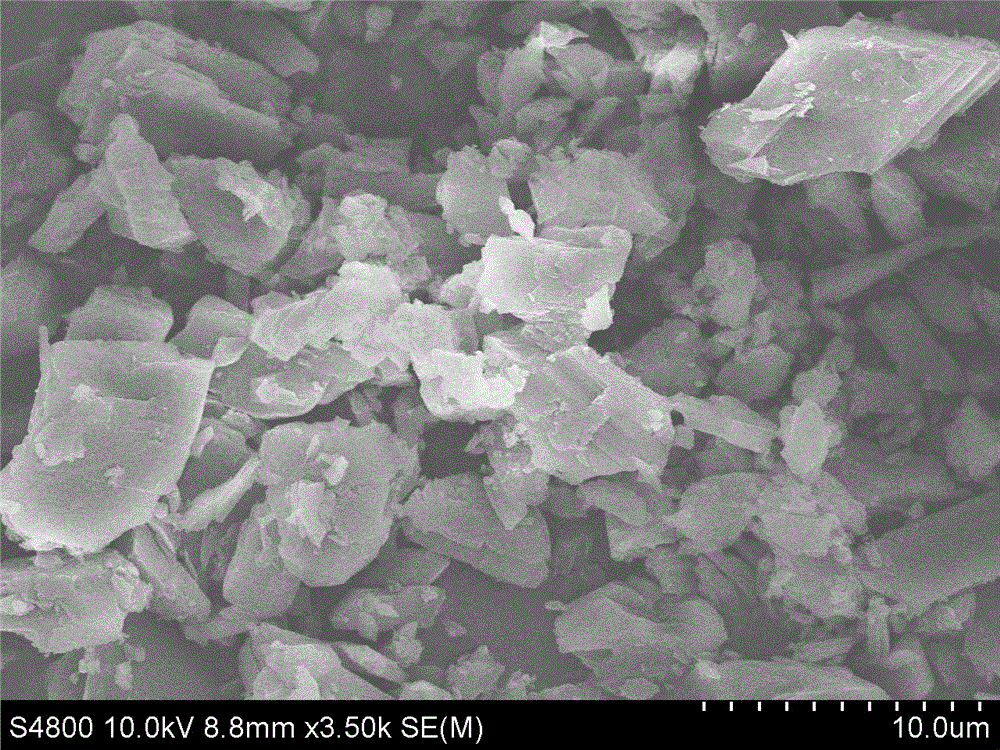

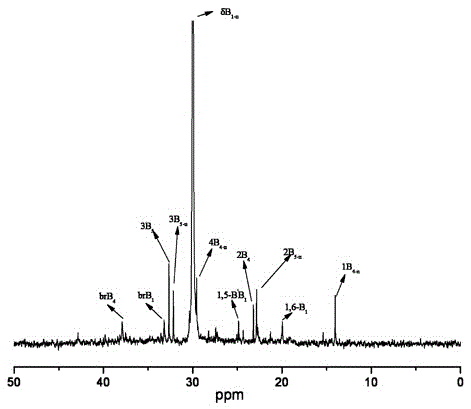

Image

Examples

Embodiment 1

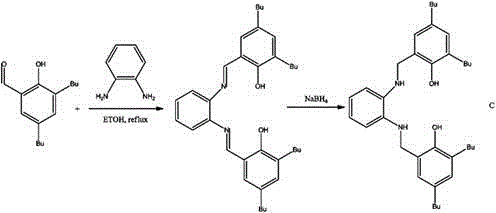

[0045] Example 1 Synthesis of Ligand Precursor L1

[0046] Add ethanol 100mL, 3,5-di-tert-butyl salicylaldehyde 11.7g, o-phenylenediamine 2.45g, N 2 Protected, heated to reflux for 6-8 hours, cooled to room temperature and precipitated a yellow precipitate, after suction filtration, dried at 50°C to obtain a yellow cotton flocculent solid, yield: 56.4%, to obtain diimine type [ONNO] type bridged bisphenoxy The metal catalyst ligand precursor is denoted as L1. 1 HNMR (300MHz, CDCl 3 ):δ:1.31(s,18H,C(CH 3 ) 3 ),1.42(s,18H,C(CH 3 ) 3 ),7.22(m,4H,Ar-H),7.30(m,2H,Ar-H),7.42(m,2H,Ar-H),8.63(s,2H,C=),13.48(s,2H ,OH).

Embodiment 2

[0047] Example 2 Synthesis of Ligand Precursor L2

[0048] Add 100mL of ethanol, 15.6g of 3,5-di-tert-butyl salicylaldehyde, 2.2mL of ethylenediamine into a 250mL round bottom flask equipped with a magnet, N 2 Protected, heated to reflux for 4-6 hours, cooled to room temperature and precipitated a yellow precipitate, filtered, and dried at 50°C to obtain a yellow cotton-like solid, yield: 89.4%, to obtain a diimine type [ONNO] type bridged bisphenoxide metal The catalyst ligand precursor is denoted as L2. 1 HNMR (300MHz, CDCl 3 ):δ:1.28(s,18H,C(CH 3 ) 3 ),1.43(s,18H,CH(CH 3 ) 3 ),7.04(d,J=2.4Hz,2H,Ar-H),7.34(J=2.4Hz,2H,Ar-H),8.36(s,2H,C=),13.59(s,2H,OH)

Embodiment 3

[0049] Example 3 Synthesis of [ONNO] type bridged bisphenoxy metal catalyst 1

[0050] At a temperature of -20 ° Under C, add 2.536g of ligand L1 to the Sehlenk bottle under nitrogen atmosphere, slowly add 5.0mL of 1.0mol / L titanium tetrachloride toluene solution dropwise, stir at this temperature for 60min, then rise to room temperature and continue stirring for 24h , remove the toluene solvent by vacuum filtration; wash with n-hexane, filter, and remove the n-hexane solvent by vacuum filtration to obtain 2.81g gray powder with a yield of 92%. Elemental analysis (C 36 h 46 Cl 2 N 2 o 2 Ti, mass %), theoretical value: C, 65.76; H, 7.05; N, 4.2.; measured value: C, 64.93; H, 6.97; N, 4.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com