Active stimulating grinding aid for ferronickel slag and preparation method thereof

A technology of activity excitation and ferronickel slag, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of low activity and poor wearability of ferronickel slag, achieve simple preparation process, increase grinding The effect of machine output and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add 1kg of calcined alumite, 5kg of water glass and 1kg of sodium rosinate into the stirring equipment, and stir for 5 minutes to obtain material A1; add 6kg of polymerized polyol, 15kg of coconut oil fatty acid diethanolamide, 10kg of ethyl acetate, and 1kg of sodium pyrophosphate 66kg of water was stirred for 10 minutes to obtain material A2; 2kg of material A1 was added to 98kg of material A2 and stirred for 5 minutes to obtain product 1 of the present invention.

Embodiment 2

[0018] Add 2kg of calcined alunite, 2kg of water glass and 3kg of sodium rosinate into the stirring equipment, and stir for 5 minutes to obtain material B1; add 15kg of polymerized polyol, 9kg of coconut oil fatty acid diethanolamide, 4kg of ethyl acetate, and 2kg of sodium pyrophosphate 65kg of water was stirred for 10 minutes to obtain material B2; 5kg of material B1 was added to 95kg of material B2, and stirred for 5 minutes to obtain product 2 of the present invention.

Embodiment 3

[0020] Add 4kg of calcined alunite, 1kg of water glass and 6kg of sodium rosinate into the stirring equipment, stir for 5 minutes to obtain material C1; add 20kg of polymerized polyol, 3kg of coconut oil fatty acid diethanolamide, 1kg of ethyl acetate, and 3kg of sodium pyrophosphate 65kg of water was stirred for 10 minutes to obtain material C2; 8kg of material C1 was added to 92kg of material C2, and stirred for 5 minutes to obtain product 3 of the present invention.

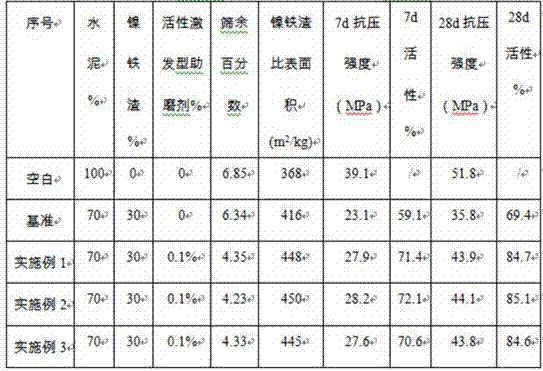

[0021] With the ferronickel slag that embodiment 1, embodiment 2, embodiment 3 make active stimulation type grinding aid, add 5kg mean particle diameter respectively in the ferronickel slag that is 1.70mm by 0.1%, in the standard of phi 500 * 500mm Grinding in the test mill for 60min. According to 70% of PI cement and 30% of nickel-iron slag powder, according to GB / T 20491-2006 "Steel slag powder used in cement and concrete" to test the activity of nickel-iron slag, according to GB / T 17671-1999 "Cement mortar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com