Preparation method for double metal cyanide catalyst for polycarbonate synthesis

A double metal cyanide and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low unit content, low activity and long reaction time and other problems, to achieve performance improvement, high catalytic efficiency, and solve the effect of long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

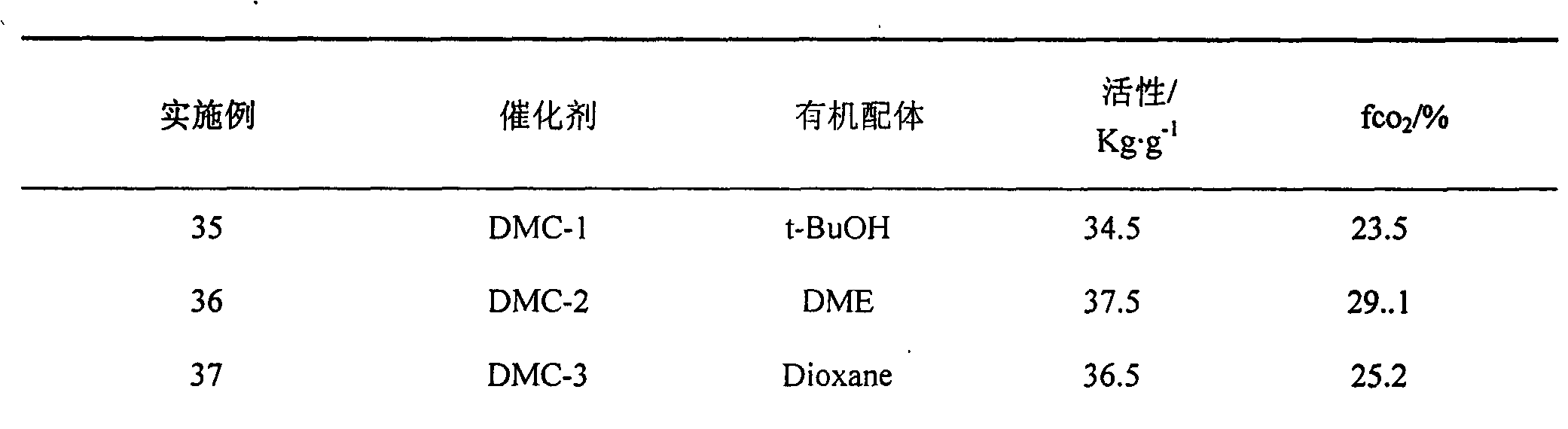

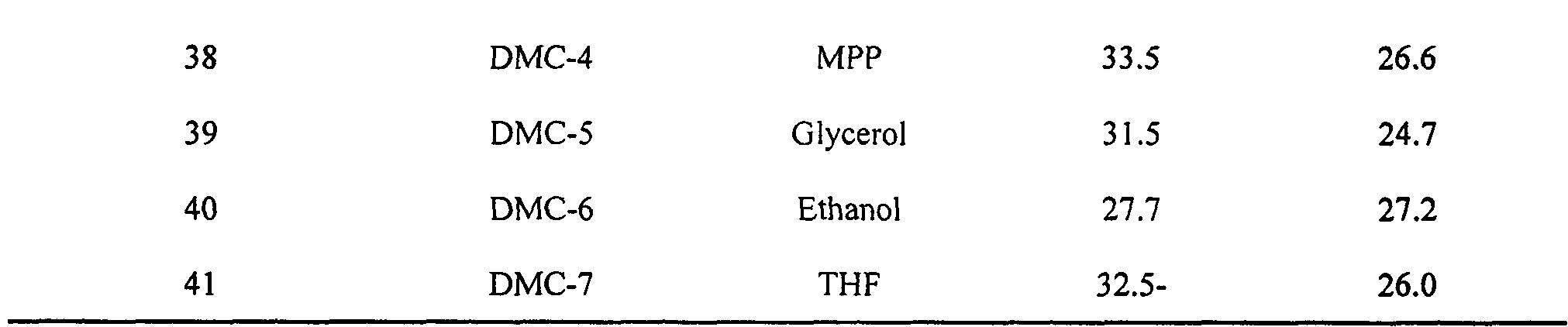

Embodiment 1

[0037] Preparation of DMC-1 containing only tert-butanol ligand:

[0038] (1) will 1×10 -1 Add 50ml of tert-butanol (t-BuOH) in a beaker to 50ml of zinc chloride, stir until the zinc chloride is completely dissolved, then add 300ml of deionized water (solution 1). Will 2.5×10 -2 mol of potassium hexacyanocobaltate was dissolved in 250 ml of deionized water in a second beaker (Solution 2).

[0039] (2) Add solution 2 dropwise to solution 1 under the condition of rapid stirring at 30° C., and the dropping time is controlled at 30-60 minutes. After the dropwise addition, continue to stir for 1 hour to obtain the catalyst slurry, and then use filtration to separate the precipitate.

[0040] (3) Add the precipitate to 100ml of tert-butanol and stir for 10min, then add 500ml of water and continue to stir for 10min, then filter and separate the precipitate. Repeat this step and the total volume of the solvent remains unchanged, and the consumption of tert-butanol is gradually inc...

Embodiment 2

[0042] Embodiment 2: Catalyst preparation mode is the same as embodiment 1, just organic ligand does not use tert-butanol, but uses dimethyl ether (DME), obtains the structural formula of gained catalyst DMC-2 through analysis: Zn 3 [Co(CN) 6 ] 2 1.4ZnCl 2 2.1DME 0.6H 2 o

Embodiment 3

[0043] Embodiment 3: catalyst preparation mode is the same as embodiment 1, just organic ligand does not use tert-butanol, but uses dioxane (Dioxane), obtains the structural formula of gained catalyst DMC-3 through analysis:

[0044] Zn 3 [Co(CN) 6 ] 2 1.5ZnCl 2 2.1Dioxane 0.5H 2 o

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com