Photodegradation-resistant biodegradable film and preparation method thereof

A biodegradation and photodegradation technology, applied in the field of biodegradable film and its preparation, can solve environmental pollution, accumulation and other problems, achieve the effect of improving mechanical properties, good compatibility and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 light stabilizer:

[0038] Refer to attached Figure 1-3 , including the following steps:

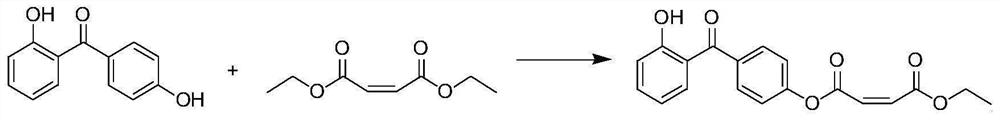

[0039] S1. Add 1mol UV-5 and 1mol diethyl maleate into the reactor, then add 100mL toluene, heat to 45°C to dissolve, add 0.01mol p-toluenesulfonic acid, and react at reflux for 4h under nitrogen protection. Precipitate with anhydrous ether and dry to obtain intermediate II with the following structure:

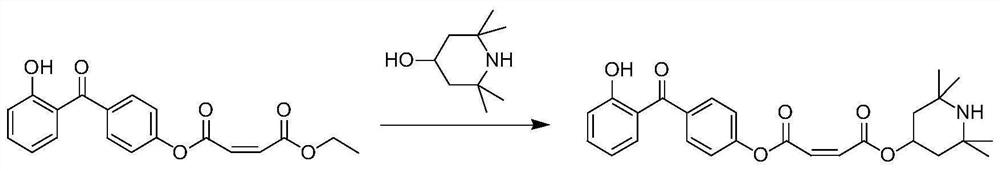

[0040] S2. Add 1 mol of intermediate II, 1.1 mol of 2,2,6,6-tetramethylpiperidinol and 150 mL of toluene into the reactor, heat to 50°C and stir to dissolve, then add 5 mL of tetra-n-butyl titanate and heat up to Reflux, nitrogen protection, react for 5h, the product was precipitated with anhydrous ether and washed several times, dried to obtain intermediate III, the structure is as follows:

[0041]

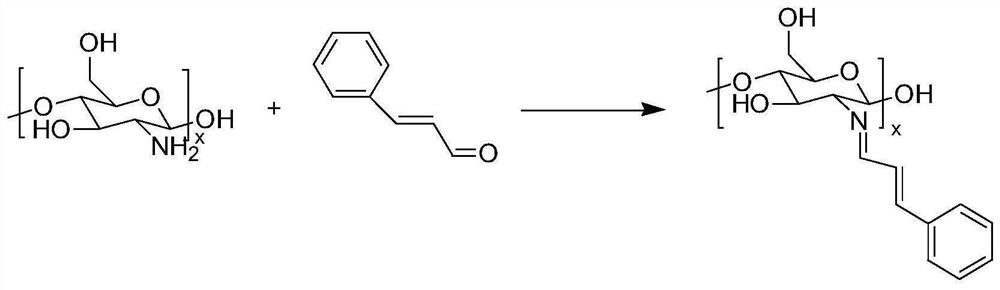

[0042] S3. Dissolve 1mol cinnamaldehyde in 100mL ethanol to obtain cinnamaldehyde solution, disperse 10g chitosan in 100mL methanol, swell ...

Embodiment 2

[0047] The preparation of embodiment 2 light stabilizers:

[0048] Refer to attached Figure 1-3 , including the following steps:

[0049] S1. Add 1mol UV-5 and 1.1mol diethyl maleate into the reactor, then add 200mL toluene, heat to 50°C to dissolve, add 0.05mol p-toluenesulfonic acid, and react at reflux for 5h under nitrogen protection. Precipitate with anhydrous ether and dry to obtain intermediate II;

[0050] S2. Add 1 mol of intermediate II, 1.2 mol of 2,2,6,6-tetramethylpiperidinol and 300 mL of toluene into the reactor, heat to 60°C and stir to dissolve, then add 10 mL of tetra-n-butyl titanate, and raise the temperature to Reflux, nitrogen protection, react for 10h, the product was precipitated with anhydrous ether and washed several times, dried to obtain intermediate III;

[0051] S3. Dissolve 1mol cinnamaldehyde in 150mL ethanol to obtain cinnamaldehyde solution, disperse 10g chitosan in 200mL methanol, swell at room temperature for 2h, heat to 90°C with microw...

Embodiment 3

[0062] The preparation method of the biodegradable film of embodiment 3 anti-photodegradation

[0063] Include the following steps:

[0064] S1. Mix and dissolve 100g starch and 200g lignin in PBS buffer solution with a pH of 7, add 2.5g amylase and 3g cellulase, heat in a water bath to 50°C, react for 1h, heat at 100°C for 10min to inactivate the enzyme, and pump After filtering and drying, configure a slurry with a mass fraction of 45% with distilled water, carry out mechanical treatment with a refiner, stop beating when the beating degree reaches 88°SR, and use a homogenizer to homogenize the beaten slurry , to obtain fine starch cellulose;

[0065] S2. Mix 100g of fine starch cellulose, 1g of silane coupling agent KH570 and 1000g of 35wt% ethanol solution, heat to 50°C for 0.5h, then filter with suction, and add 200g of polylactic acid-glycolic acid copolymer into the distillate to dissolve the solid. In 500mL of methyl chloride solution, after stirring and mixing evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com