Anti-aging anti-precipitation long glass fiber reinforced polypropylene material and preparation method thereof

A technology of polypropylene material and long glass fiber, which is applied in the field of long glass fiber reinforced polypropylene material and its preparation, anti-aging and anti-precipitation long glass fiber reinforced polypropylene material and its preparation field, to achieve increased interface strength, good wetting, and prevention of The effect of migration and precipitation of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

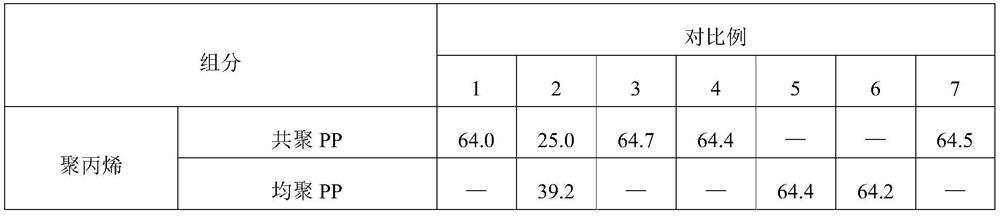

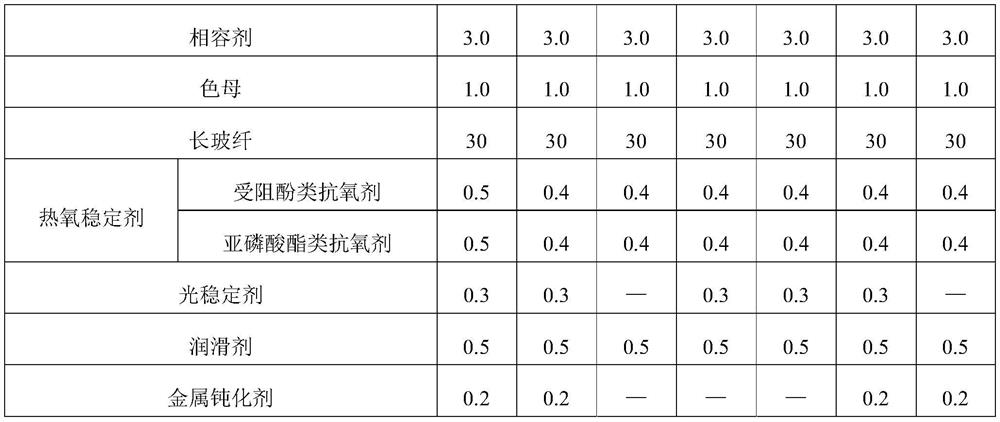

[0024] After weighing polypropylene, long glass fiber, compatibilizer, color masterbatch, thermal oxygen stabilizer, light stabilizer, metal passivator and lubricant according to the proportioning of each specific embodiment in Table 1, the above-mentioned long glass fiber The other raw materials are placed in a high-speed mixer with a blade speed of 1000r / min and mixed uniformly to obtain a premix; the above premix is added to a twin-screw extruder for melt dispersion, wherein the temperature of the twin-screw extruder is 210-250°C and the screw speed is 300-500r / min to obtain molten resin; pass the uniformly dispersed molten resin through the infiltration die with a temperature of 270-320°C, and then pre-disperse the long The glass fiber enters the infiltration die, and after the molten resin and the long glass fiber are evenly dispersed in the infiltration die, the anti-aging and anti-precipitation long glass fiber reinforced polypropylene with a length of 9-12mm is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com