Anti-aging aluminum alloy and preparation method thereof

An aluminum alloy, anti-aging technology, applied in the direction of anodic oxidation, coating, hyaluronic acid coating, etc., to achieve the effect of preventing electrochemical corrosion, good compatibility and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In the preparation method of the modified boron nitride, the rotation speed of the stirrer in step S22 is 35000r / min.

[0033] In the preparation method of the modified boron nitride, the temperature of the vacuum drying oven in both step S21 and step S22 is 70° C., and the drying time is 12 hours.

[0034] Comparative example 1

[0035] A kind of anti-aging aluminum alloy, its preparation method comprises the following steps:

[0036] The volume ratio of perchloric acid and ethanol in the described perchloric acid ethanol solution is: 4:1;

[0037] The preparation method of described modified boron nitride comprises the following steps:

[0038] In the preparation method of the modified boron nitride, the speed of the mixer in step S22 is 25000r / min;

[0039] Comparative example 2

[0040] A kind of anti-aging aluminum alloy, its preparation method comprises the following steps:

[0041] The volume ratio of perchloric acid and ethanol in the described perchloric a...

Embodiment 2

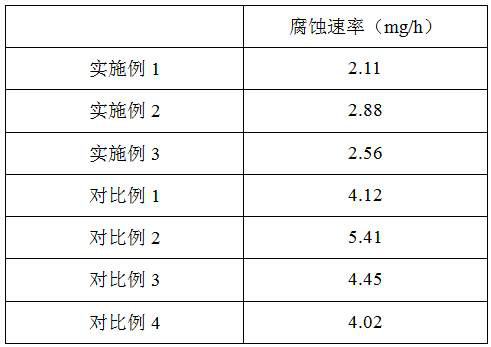

[0050] The anti-aging ability of the aluminum alloy is tested by the constant current corrosion weight loss method, and the experimental conditions are: in the water environment of 75°C, 0.3A / cm 2 The current was charged at a constant current for 100 hours, and then compared using the weight loss method. The test results are shown in Table 1.

[0051] Table 1 Performance test results

[0052] In addition, it can also be seen from the test results of Examples 1-3 that different proportions of coating components can affect the anti-aging effect of the anti-aging aluminum alloy, and Example 1 is the best proportion.

[0053] From the test results of Example 1 and Comparative Example 1, it can be seen that the anti-aging ability of the aluminum alloy with anodic oxidation treatment is significantly improved compared with the untreated aluminum alloy.

[0054] From the test results of Example 1 and Comparative Example 2, it can be known that adding boron nitride to the coating, th...

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com