A kind of adhesive composition and solar cell back film

A composition and adhesive technology, applied in the field of solar cells, can solve the problems such as the loss of toughness and bonding performance of the adhesive, the inability to meet the low temperature resistance of the back film, and the inability to meet the low temperature resistance, so as to broaden the temperature adaptation range and improve the The effect of hydrolysis resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

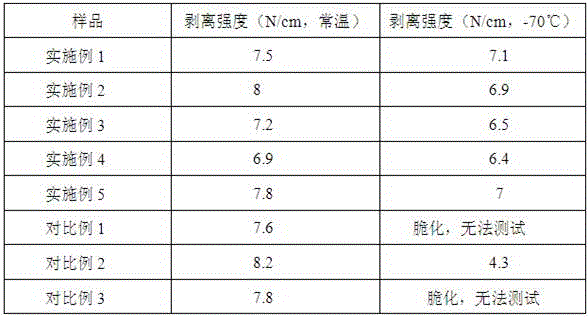

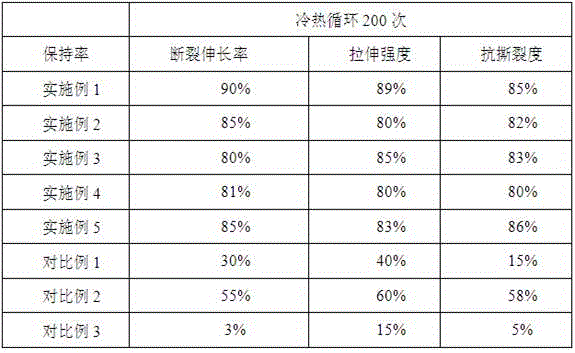

Embodiment 1

[0044] Adhesive formulation 1, consisting of 5g-2-hydroxypropyl acrylate, 55g ethyl acrylate, 15g ethyl methacrylate, 10g isobutyl methacrylate, 10g acryltrimethoxysilane, 5g γ-methacryloyl Silicone-modified acrylate polyol a1 formed by copolymerization of oxysilane at 70°C under the catalysis of 2g of azobisisobutyronitrile for 2 hours, with a molecular weight of 8000 and a weighed mass of 15g; Under the catalysis of 2.5g of oleum, the polymerization reaction is initiated by 2g of propylene glycol at -5°C, and after static layering, neutralization, filtration, vacuuming and other processes, polyether polyol a2 with a molecular weight of 6000 is obtained , weighed 3.5g; 33.6g of 1,6-diisocyanate hexane and 9g of 1,4 butanediol were catalyzed by 0.5ml of dibutyltin dilaurate, and reacted at 60°C for 4h to prepare isocyanate b. According to silicone modified acrylate polyol a1, the molar ratio of the hydroxyl group in polyether polyol a2 and the isocyanate group in isocyanate b ...

Embodiment 2

[0046] Adhesive formulation 2, composed of 8g-2-hydroxyethyl acrylate, 45g ethyl acrylate, 20g methyl acrylate, 15g isobutyl methacrylate and 12g vinyltrimethoxysilane at 80°C, 1.6g azobis Under the catalysis of isobutyronitrile, the organosilicon-modified acrylate polyol a1 with a molecular weight of 10,000 and a molecular weight of 10,000 obtained by reacting for 2.5 hours, weighed 18 g; 68 g of tetrahydrofuran monomer and 58 g of propylene oxide were catalyzed by 2.3 g of Lewis acid 1.6g of propylene glycol was used as an initiator to react for 3 hours at -5°C, and after static layering, neutralization, filtration, and vacuuming, a polyether polyol a2 with a molecular weight of 8000 was obtained, which was called Get 5g; Antioxidant is triphenyl phosphite, and quality is 0.5g, and anti-hydrolysis stabilizer is monomer carbodiimide, and content is 0.8g, and solvent is butyl acetate, acetone, and quality is 70.1g, by 33.6g of 1,6-diisocyanate hexane and 9g of 1,4 butanediol, ...

Embodiment 3

[0048] Adhesive formula 3, by 7g-2-hydroxyethyl acrylate, 50g ethyl acrylate, 18 methyl acrylate, 10 isobutyl methacrylate and 5g ethoxy polydimethylsiloxane, in 1.4g Initiated by ammonium sulfate, 80°C, copolymerization reaction for 3 hours to obtain silicone-modified acrylate polyol a1 with a molecular weight of 12,000, weighing 21g; Under the condition of 1.3g propylene glycol initiates the polymerization reaction, after static layering, neutralization, filtration, vacuumizing and other processes, the polyether polyol a2 with a molecular weight of 10000 is obtained, and 6.5g is weighed; the antioxidant is 2 , 6-di-tert-butyl, p-cresol phosphite triester, the mass is 1.4g, the hydrolysis stabilizer is silane coupling agent KH-570, the content is 1g, the solvent is the mixed solution of ethyl acetate and acetone, the mass is 64.2g; from 42g of 1,6-diisocyanato-2,2,4-trimethylhexane and 9g of chain extender 1,4-butanediol, at 60°C, from 0.5ml of dilaurel Dibutyltin acid catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com