A kind of compound synergistic system of water clearing agent and method for avoiding the generation of viscoelastic sludge

A compound synergistic and clearing agent technology, applied in the field of industrial water treatment, can solve the problems of high oil content in sewage, short treatment time and large amount of dosing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, preparation clear water agent compound synergistic system

[0023] 1ml of hydroxamic acid modified polyacrylamide (purchased from SNF Company in France, trade name KM800, made into an aqueous solution with a mass fraction of 1%) and 2.2ml of acrylamide-dimethyldiallylammonium chloride copolymer (CAS number is 26590-05-6, molecular weight is 10 4-5 ) mixed to obtain a water agent compound synergistic system.

[0024] In the compound type clear water agent prepared in this example, the quality of the cationic type clear water agent (acrylamide-dimethyl diallyl ammonium chloride copolymer) and the anionic type clear water agent (hydroxamic acid modified polyacrylamide) The ratio is 2.2:1.

Embodiment 2

[0025] Embodiment 2, preparation clear water agent compound synergistic system

[0026] 1.2ml of hydroxamic acid-modified polyacrylamide (purchased from SNF Company in France, trade name KM800, prepared as an aqueous solution with a mass fraction of 1%) and 2ml of acrylamide-dimethyldiallylammonium chloride copolymer (CAS number is 26590-05-6, molecular weight is 10 4-5 ) and mixed to obtain a compound type clear water medicament.

[0027] In the compound type clear water agent prepared in this example, the quality of the cationic type clear water agent (acrylamide-dimethyl diallyl ammonium chloride copolymer) and the anionic type clear water agent (hydroxamic acid modified polyacrylamide) The ratio is 2:1.2.

Embodiment 3

[0028] Embodiment 3, preparation clear water agent compound synergistic system

[0029] 1.6ml of sodium butyl xanthate (purchased from Yantai Junbang) and 1.6ml of dimethylamine-epichlorohydrin-ethylenediamine copolymer (molecular weight 10 4 ) and mixed to obtain a compound type clear water medicament.

[0030] In the compound type clear water agent prepared by the present embodiment, the mass ratio of the cation type clear water agent (the copolymer of dimethylamine-epichlorohydrin-ethylenediamine) and the anionic type clear water agent (organic amine phosphate) is 1: 1.

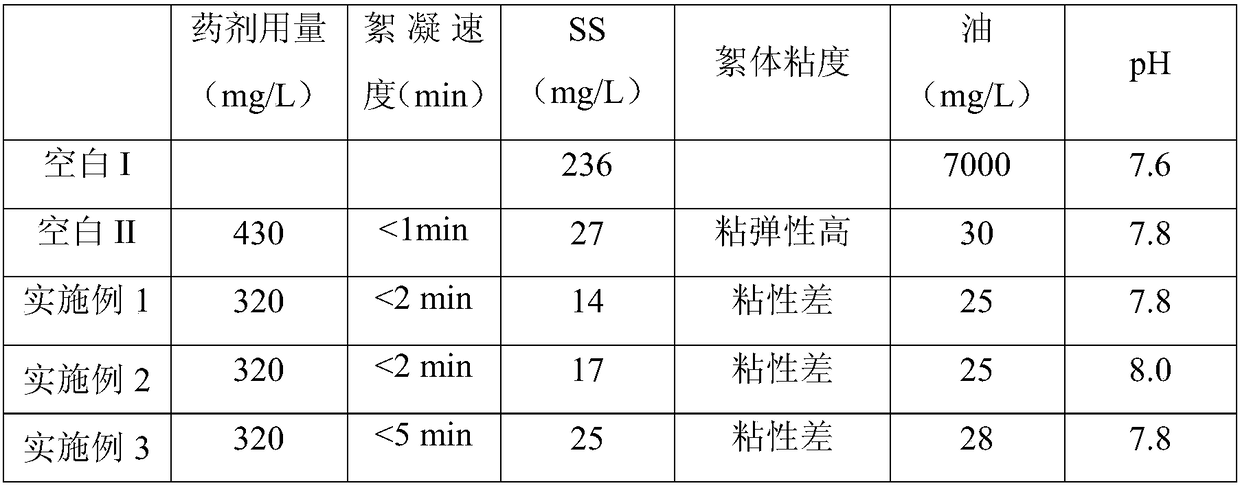

[0031] The composite clear water medicament prepared in Example 1-3 was used to treat the sewage containing polymer, and the bottle test method was used to evaluate the performance of the composite clear water medicament of the present invention:

[0032] The specific steps are:

[0033] 1. The polymer-containing sewage water sample is provided by an oilfield in the Bohai Sea. The polymer-containing sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com