Multi-element multi-size mixed enhanced magnesium lithium-based composite material and preparation method thereof

A composite material and multi-scale technology, applied in the field of metal materials, can solve problems such as low absolute strength, limiting the advancement of research and application of metal matrix composite materials, adverse effects of plasticity and density, etc., to achieve good lightweight and avoid alloy plasticity The effect of sharp deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

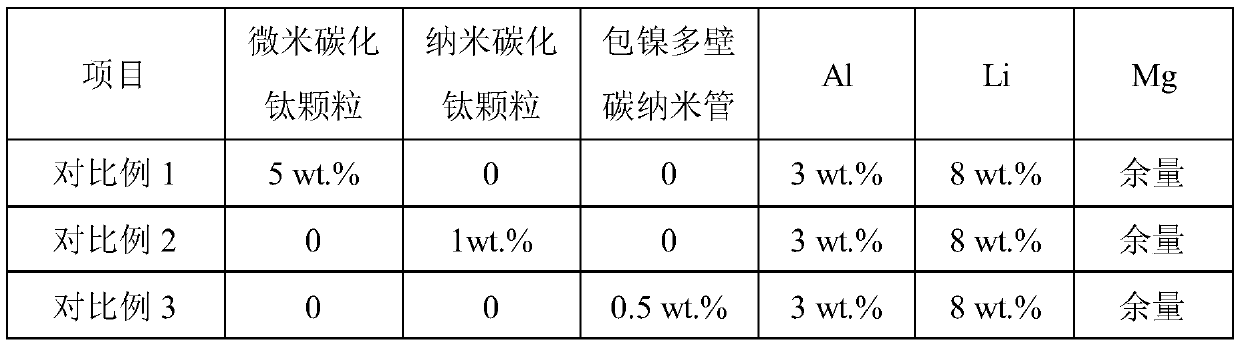

Examples

Embodiment 1

[0026] A multi-component multi-scale hybrid reinforced magnesium-lithium matrix composite material, comprising the following components by weight ratio: 5wt% micron titanium carbide particles, 1wt% nanometer titanium carbide particles, 0.5wt% nickel-coated multi-walled carbon nanotubes , 3wt% of Al, 8wt% of Li, the balance of Mg, the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt%.

[0027] The preparation method of the multi-component multi-scale hybrid reinforced magnesium-lithium matrix composite material is as follows:

[0028] The first step is to mix micron titanium carbide particles, nano titanium carbide particles, nickel-coated multi-walled carbon nanotubes with Al powder, and then ball mill in a planetary ball mill to obtain composite powder. The ball milling speed is 100r / min, and the ball milling time is 3h ;

[0029] The second step is to pre-press the composite powder obtained by ball milling to obtain a pre-pressed block, the pre-pressi...

Embodiment 2

[0032] A multi-element and multi-scale hybrid reinforced magnesium-lithium matrix composite material, comprising the following components by weight ratio: 10wt% micron titanium carbide particles, 2wt% nanometer titanium carbide particles, 1wt% nickel-coated multi-walled carbon nanotubes, 4.5wt% of Al, 11wt% of Li, the balance of Mg, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt%.

[0033] The preparation method of the multi-component multi-scale hybrid reinforced magnesium-lithium matrix composite material is as follows:

[0034] The first step is to mix micron titanium carbide particles, nickel-coated multi-walled carbon nanotubes and Al powder, and then ball mill in a planetary ball mill to obtain a composite powder. The ball milling speed is 200r / min, and the ball milling time is 2h;

[0035] The second step is to pre-press the composite powder obtained by ball milling to obtain a pre-pressed block, the pre-pressing pressure is 20MPa, and t...

Embodiment 3

[0039] A multi-component multi-scale hybrid reinforced magnesium-lithium matrix composite material, comprising the following components by weight ratio: 15wt% micron titanium carbide particles, 3wt% nanometer titanium carbide particles, 1.5wt% nickel-coated multi-walled carbon nanotubes , 6wt% of Al, 14wt% of Li, the balance of Mg, the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt%.

[0040] The preparation method of the multi-component multi-scale hybrid reinforced magnesium-lithium matrix composite material is as follows:

[0041] The first step is to mix micron titanium carbide particles, nano titanium carbide particles, nickel-coated multi-walled carbon nanotubes with Al powder, and then ball mill in a planetary ball mill to obtain a composite powder. The ball milling speed is 300r / min, and the ball milling time is 1h ;

[0042] The second step is to pre-press the composite powder obtained by ball milling to obtain a pre-pressed block, the pre-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com