Patents

Literature

30results about How to "Lightweight advantage is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

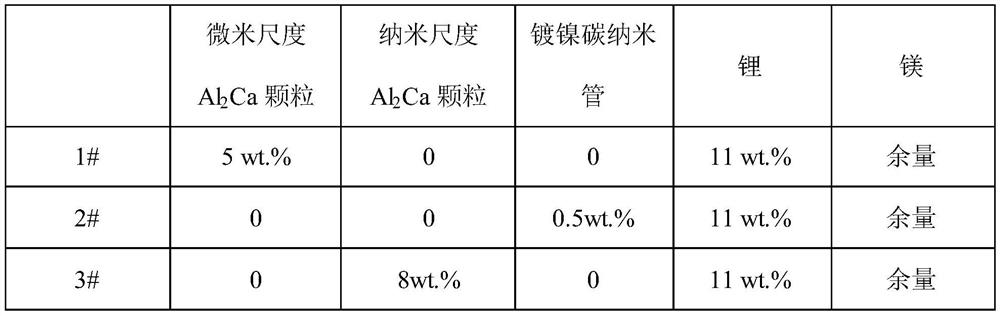

Al2Ca particle and carbon nano tube hybrid reinforced ultra-light magnesium-lithium-based composite material and preparation method

ActiveCN109321794ALightweight advantage is obviousAchieving the effect of synergistic reinforcementLiquid/solution decomposition chemical coatingMicron scaleCarbon nanotube

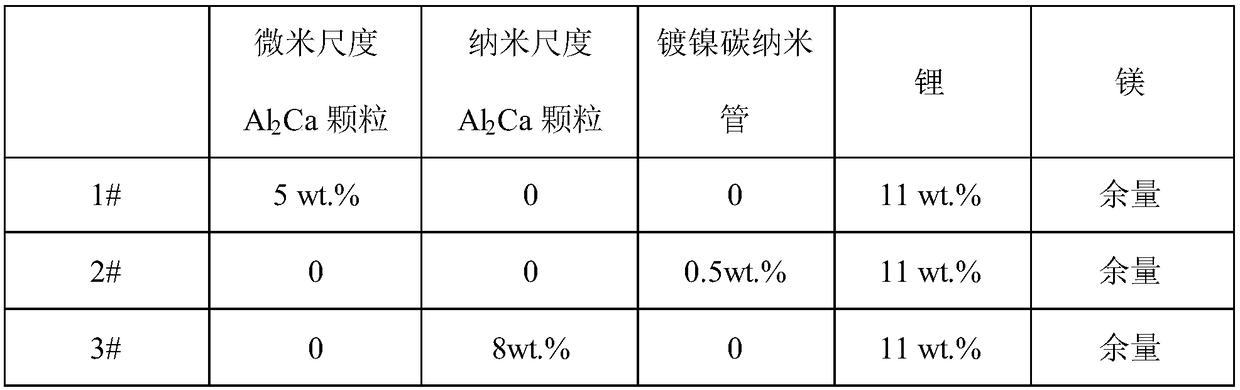

The invention relates to the technical field of metal materials, in particular to an Al2Ca particle and carbon nano tube hybrid reinforced ultra-light magnesium-lithium-based composite material and apreparation method. The composite material comprises the following components of, by weight, 5-20wt.% of micron-scale Al2Ca particles, 1-5wt.% of submicron-scale Al2Ca particles, 0.5-3wt.% of a carbonnano tube with the surface plated with nickel, 11-25wt.% of Li and the balance Mg, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt.%. The preparation method comprisesthe three steps of pretreatment of the micron-scale / submicron-scale Al2Ca particles, pretreatment of the carbon nano tube and smelting. The beta-Li single-phase ultra-light magnesium-lithium alloy isused as a matrix, and the reinforced phase with relatively low density is selected, and then the obtained magnesium-lithium-based composite material still has the excellent light-weight advantage; themicron-scale / submicron-scale Al2Ca particles and the carbon nano tube are used as the reinforced phases, then different functions of the reinforced phases of different types and scales in the reinforcement aspect are played, the cooperative reinforcement effect is achieved through the hybrid enhancement, and the reinforcement effect is far higher than that of a traditional magnesium-lithium-basedcomposite material reinforced by the reinforced phase of the single type and the single scale.

Owner:JIANGSU UNIV OF TECH

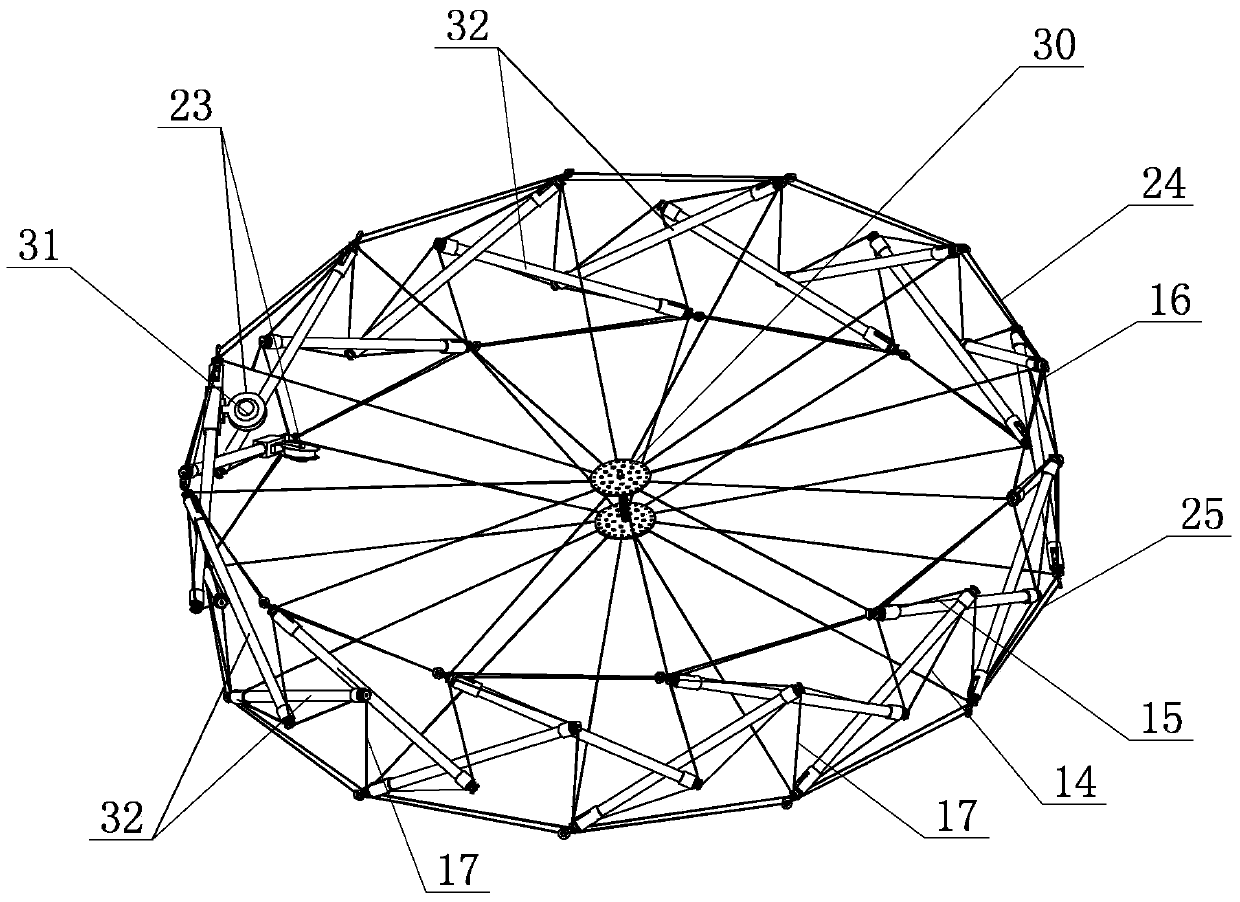

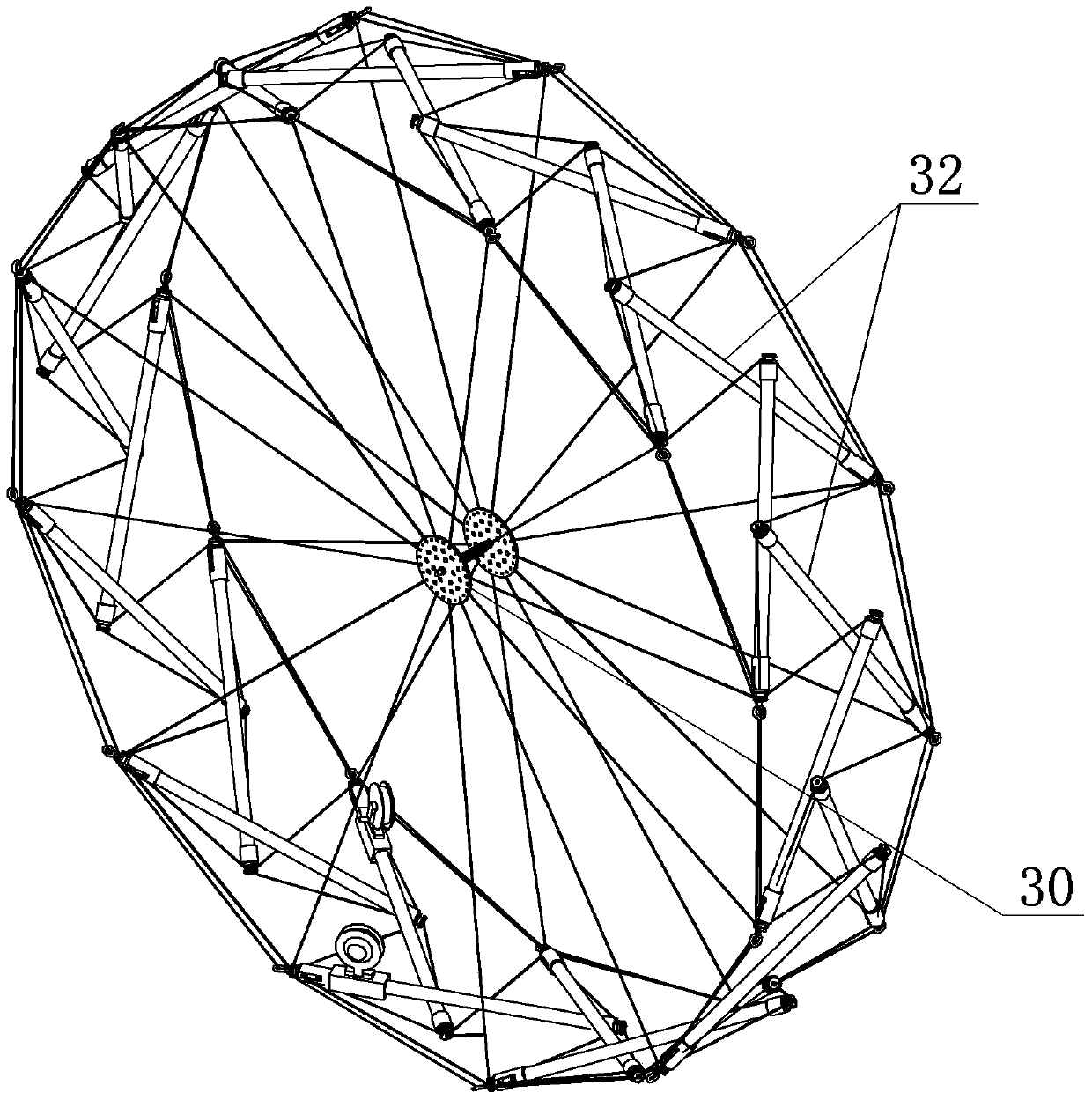

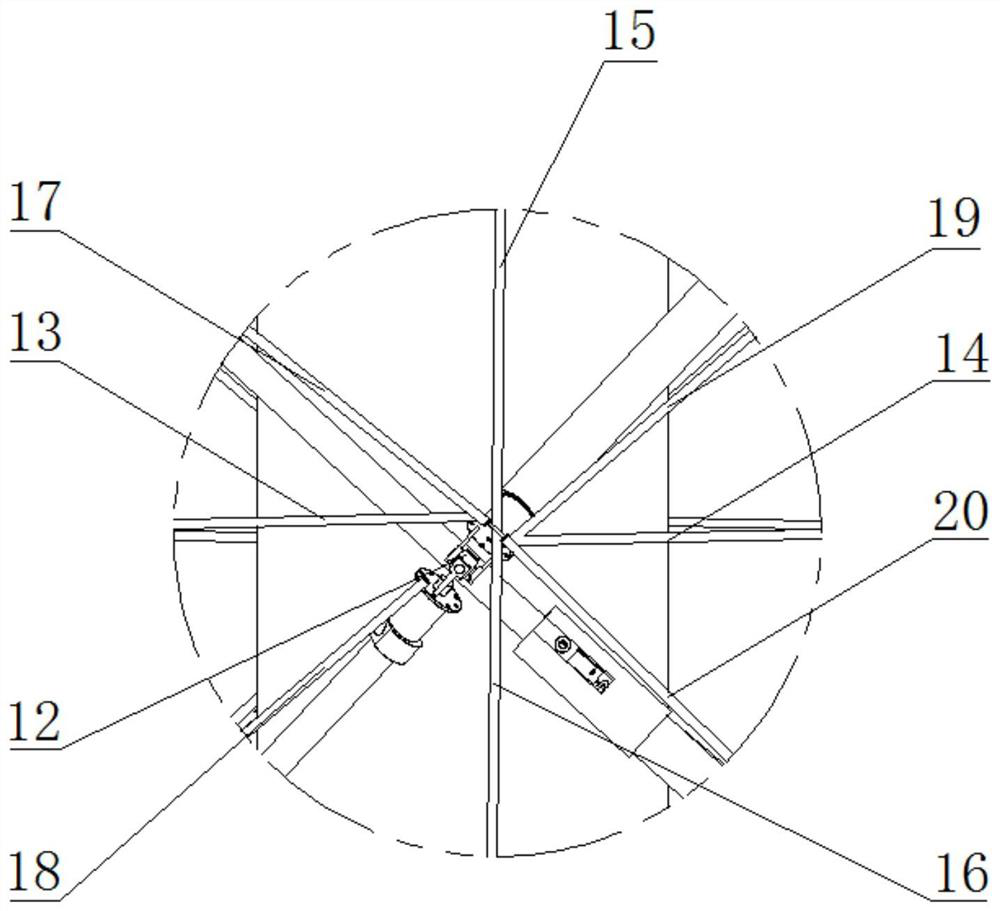

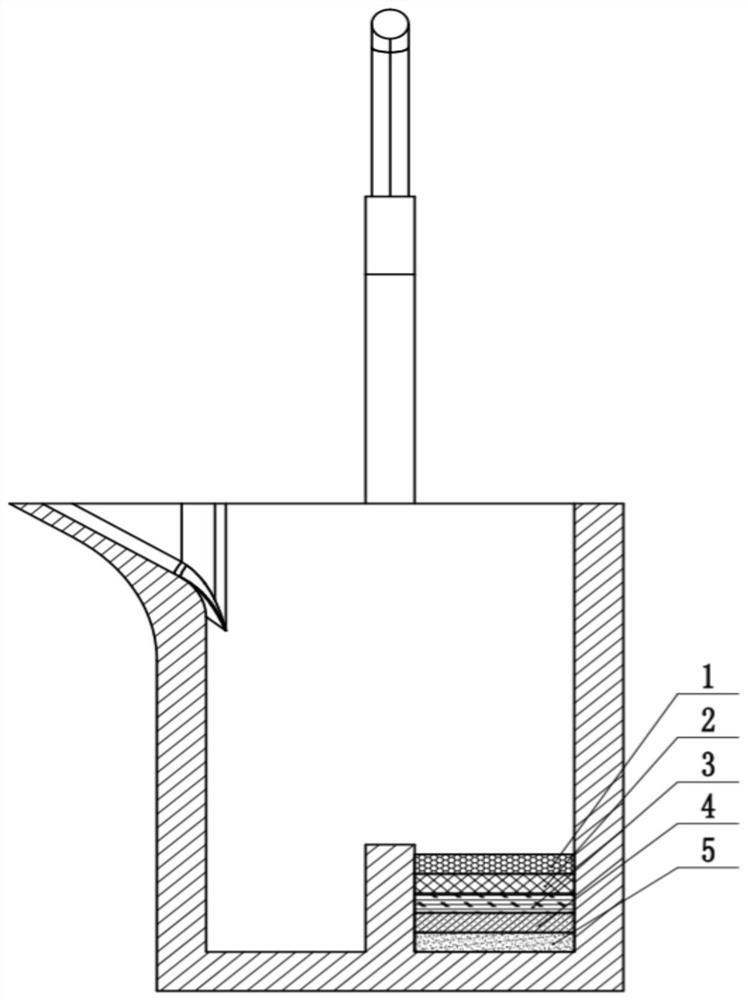

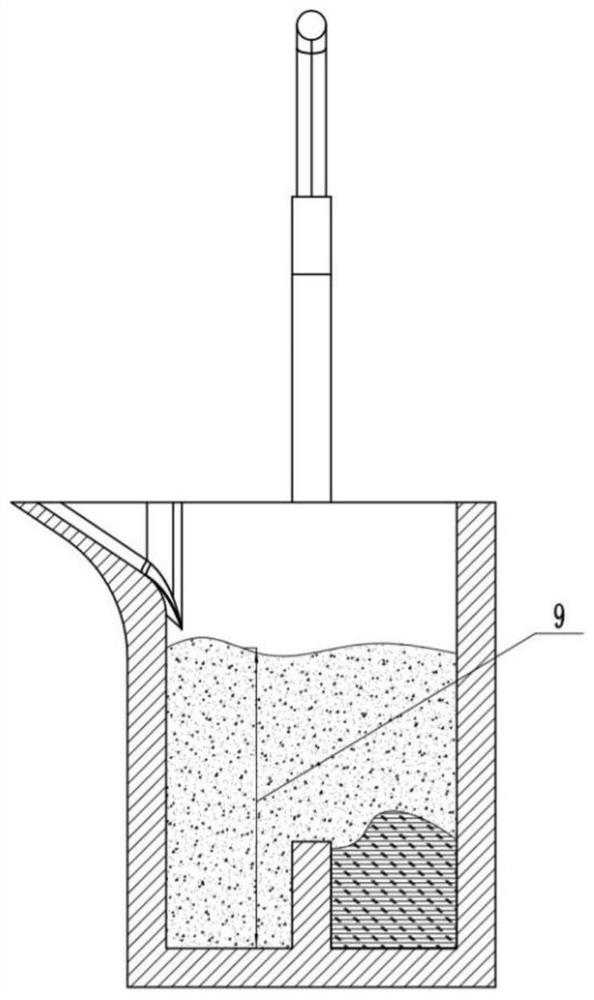

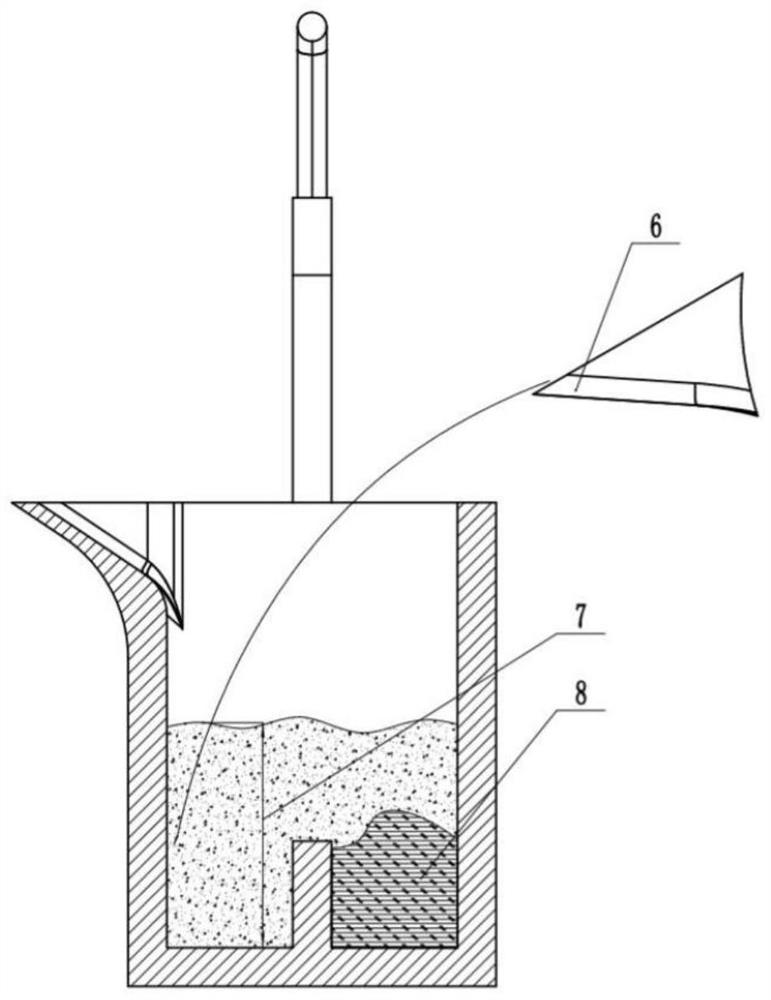

Spatially expandable annular tensegrity antenna mechanism

ActiveCN105071012BLight in massLightweight advantage is obviousCollapsable antennas meansFiberCarbon fibers

The utility model relates to a spatially expandable annular tensegrity integral antenna mechanism, which relates to an antenna mechanism. The invention solves the problems that a large number of mechanical connections are required in the process of unfolding and retracting the existing deployable loop antenna, resulting in large overall mass and low deployment reliability. The main-end firmware is fixedly connected to one end of the main-end connecting pipe through pins, and the other end of the main-end connecting pipe is fixedly connected to one end of the carbon fiber pipe. Two openings are processed on the side wall of the main-end connecting pipe along its length direction, each There is a locking leaf spring corresponding to each strip-shaped opening. The driving spring is located in the carbon fiber tube. The middle part of the guide slider is processed with an annular groove along its circumference. When the antenna mechanism is unfolded, the lower part of the locking leaf spring is clamped on the guide slider. At the annular groove of the block, the lower end of the guide slider is connected with the slider screw, the guide slider is located at the upper end of the driving spring, the auxiliary end firmware is fixed on the other end of the carbon fiber tube through the auxiliary end connector, and the tension of the overall rod The number is an even number. The invention is used in the field of wireless communication.

Owner:HARBIN INST OF TECH

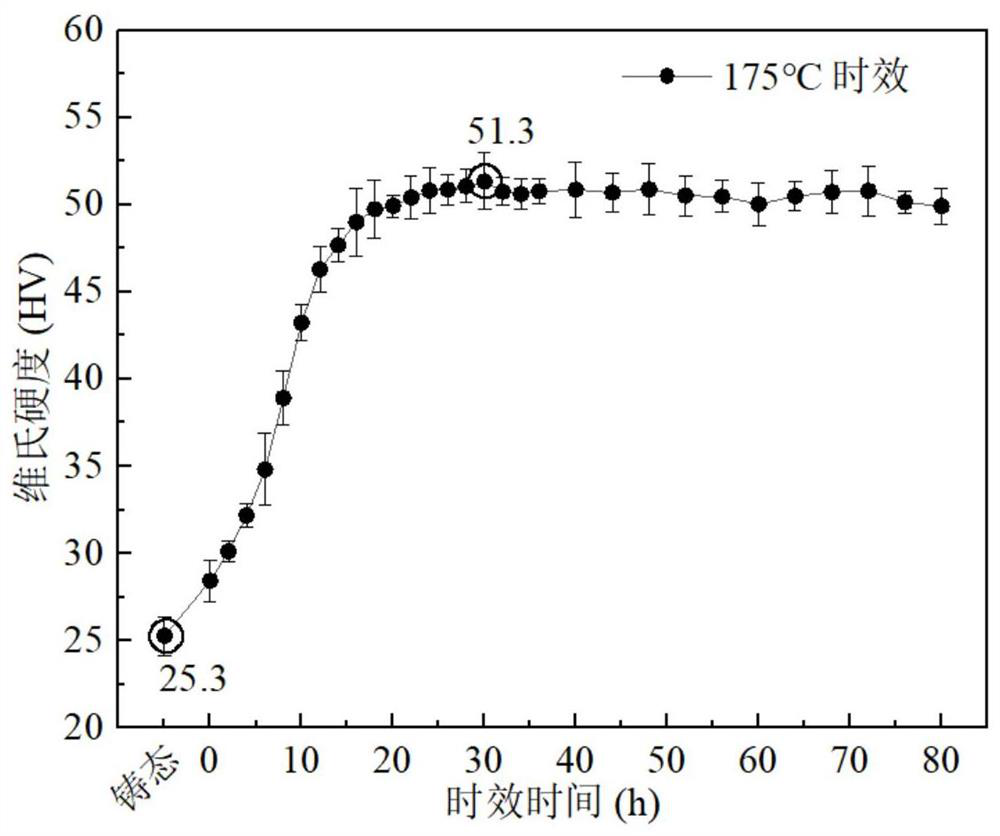

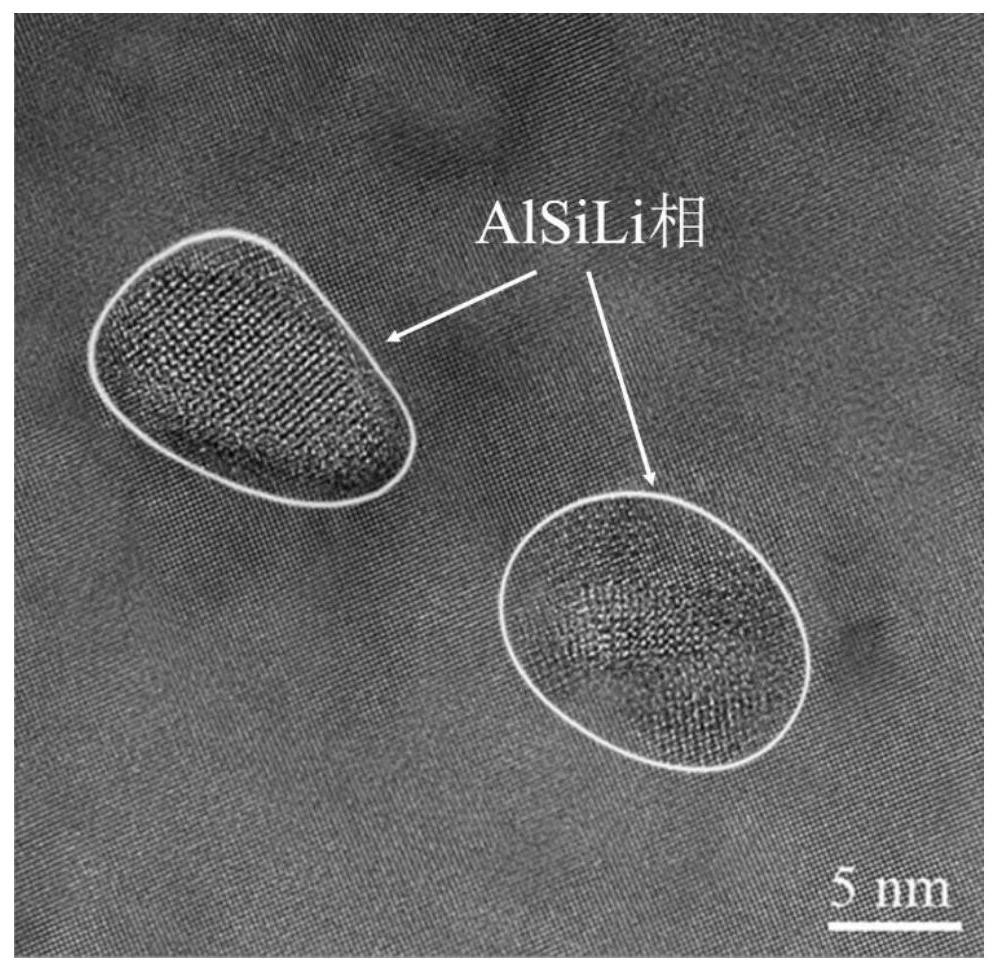

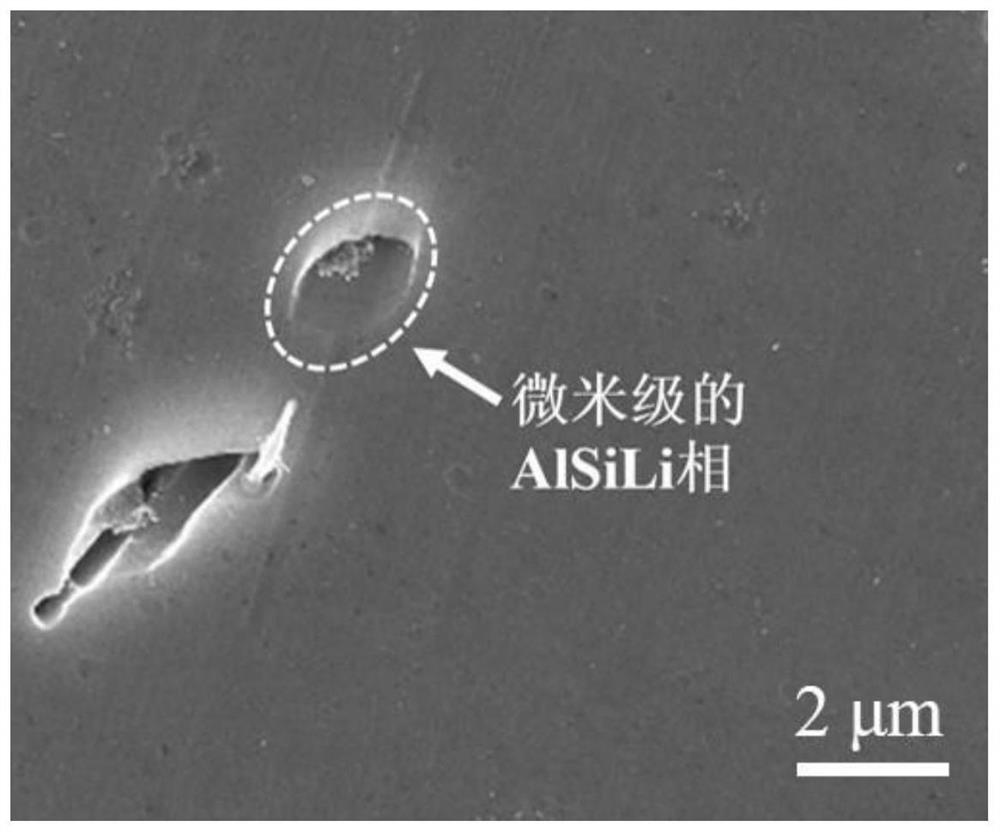

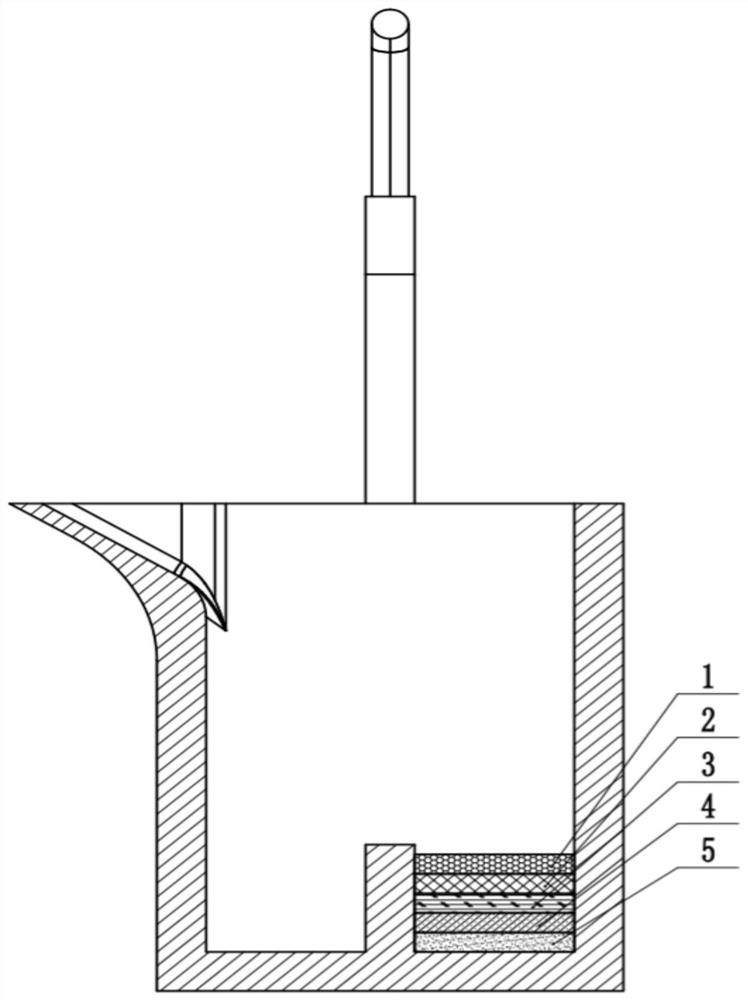

AlSiLi phase aging strengthening type low-density aluminum alloy and preparation method thereof

ActiveCN113737060ALow densityLightweight advantage is obviousAdditive manufacturing apparatusIncreasing energy efficiencyNonferrous metalDie casting

The invention discloses an AlSiLi phase aging strengthening type low-density aluminum alloy and a preparation method thereof, and belongs to the technical field of nonferrous metal preparation and processing. The aluminum alloy comprises the following basic components in percentage by weight: 0.01%-1.0% of Si, 0.01%-1.0% of Li and the balance of Al, and at least one of the following elements in percentage by mass: 0.01-1.0% of Mg, Ca, Sr, Ti, B, Cu, Zn, Mn, Ag, Sc, Zr, Fe, Cr and Ge can be further added; the microstructure of the aluminum alloy is characterized in that AlSiLi precipitated phases with the size smaller than 30 nm are dispersed and distributed in an aging peak state aluminum matrix, and a remarkable aging strengthening effect is achieved. The preparation method comprises the steps of die casting, high-temperature solid solution treatment and aging heat treatment, or casting, high-temperature solid solution, plastic deformation and aging heat treatment, or atomization powder preparation, 3D printing and aging heat treatment. According to the aluminum alloy, the room-temperature yield strength is 90-380 MPa, the tensile strength is 150-550 MPa, the ductility is not lower than 2%, the density is lower than that of pure aluminum, and the aluminum alloy has the advantages of light weight and high strength and can be used for preparing aircraft crankcases, cylinder covers, vehicle bodies, containers and the like.

Owner:UNIV OF SCI & TECH BEIJING

Production method of ultra-high strength toughness ductile iron crankshaft with pearlite matrix

ActiveCN111687380BProduction Method AdvantagesImprove roundnessFoundry mouldsFurnace typesFerrosiliconDuctile iron

The production method of the pearlite matrix ultra-high strength ductile ductile iron crankshaft provided by the present invention selects low-sulfur and low-titanium pig iron, ordinary carbon steel and self-produced recycled iron as the main charge, and adds specific proportions of 75% ferrosilicon and 65% high-carbon manganese Iron, electrolytic copper and graphite-type recarburizers; smelted at a specific frequency in an intermediate frequency furnace, adding nodulizers, inoculants, silicon-calcium-manganese deoxidizers, and then tapped for nodularization. The nodularization process requires a specific tapping position, speed, and tapping The first step is to select a specific inoculant flow rate and total amount during the pouring process, and adopt a specific normalizing process for the crankshaft casting to prepare an ultra-high-strength ductile ductile iron material with a strength exceeding 1000 MPa, an elongation ≥ 5%, and a matrix material of pearlite type. Its comprehensive performance far exceeds that of ordinary ductile iron and ADI materials with the same tensile strength. The preparation method is applied to J4200 crankshaft, JX400 crankshaft and other parts to realize the preparation of ultra-high strength and toughness material with pearlite matrix, reduce the cost and obtain remarkable benefits.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

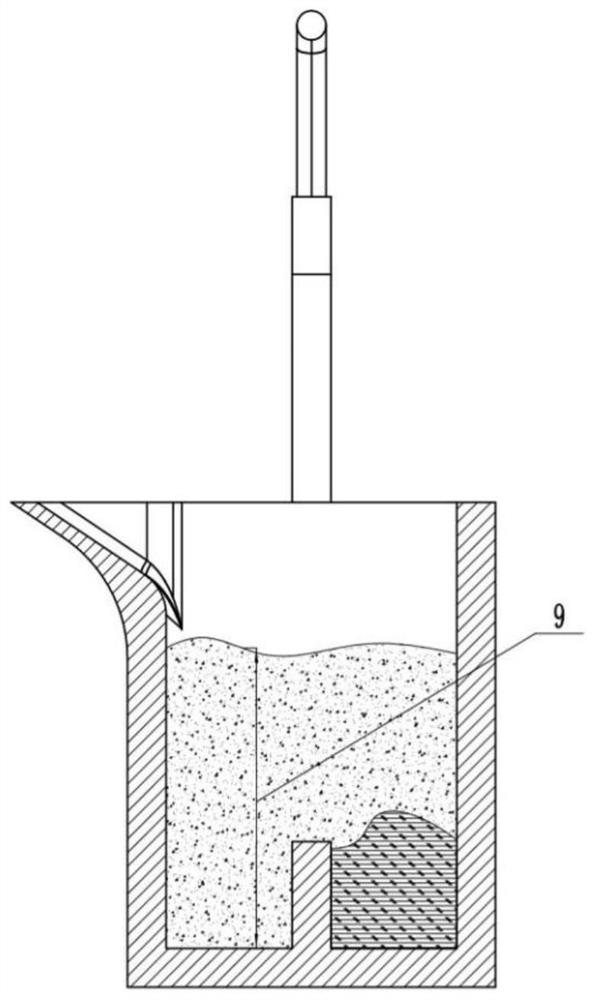

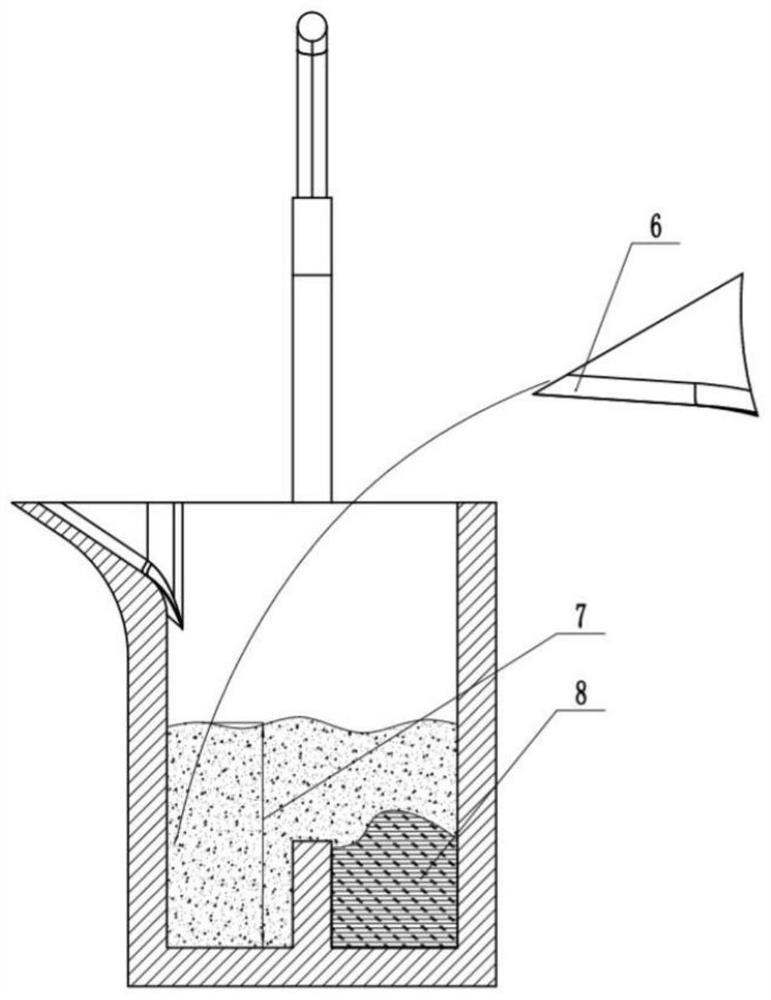

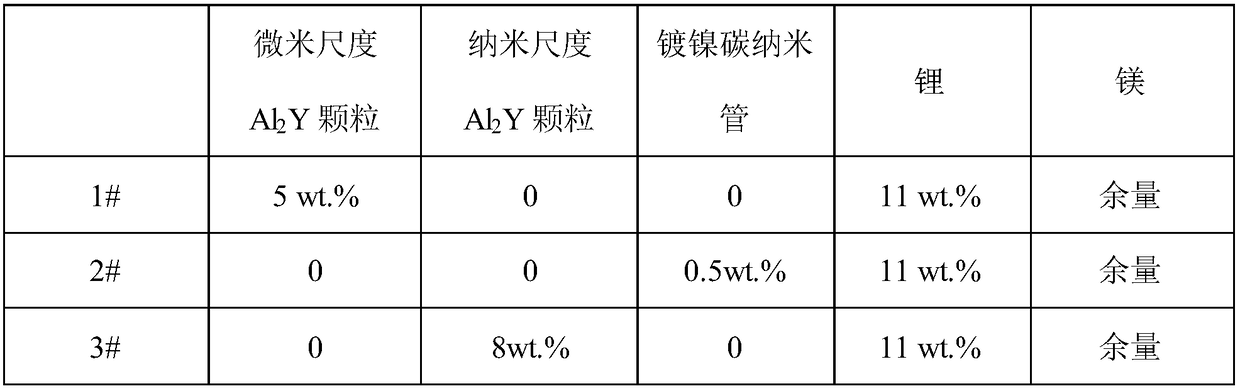

Al2Y particle and carbon nano tube hybrid reinforced ultra-light magnesium-lithium-based composite material and preparation method thereof

ActiveCN109321793ALightweight advantage is obviousAchieving the effect of synergistic reinforcementLiquid/solution decomposition chemical coatingMicron scaleCarbon nanotube

The invention relates to the technical field of metal materials, in particular to an Al2Y particle and carbon nano tube hybrid reinforced ultra-light magnesium-lithium-based composite material and a preparation method thereof. The magnesium-lithium-based composite material comprises the following components of, by weight, 5-20wt.% of micron-scale Al2Y particles, 1-5wt.% of nano-scale Al2Y particles, 0.5-3wt.% of a surface-nickel-plated carbon nano tube, 11-25wt.% of Li, and the balance Mg, and the total amount of impurity elements of Si, Fe, Cu and Ni is less than 0.02wt.%. The preparation method comprises the three steps of pre-treatment of the micron / nano-scale Al2Y particles, pre-treatment of the carbon nano tube and smelting. According to the composite material and the preparation method thereof, a beta-Li single-phase ultra-light magnesium lithium alloy is used as a matrix, and reinforcing phases with lower density are selected, so that the obtained magnesium-lithium-based composite material still has the excellent light-weight advantage; and the micron / nano-scale Al2Y particles and the carbon nano tube are used as reinforcing phases, so that different functions of the reinforcing phases of different types and scales in the reinforcement aspect are exerted, the cooperative reinforcement effect is achieved by utilizing hybrid reinforcement, the reinforcement effect is farhigher than that of a traditional reinforcing phase reinforced magnesium-lithium-based composite material of a single type and a single scale.

Owner:JIANGSU UNIV OF TECH

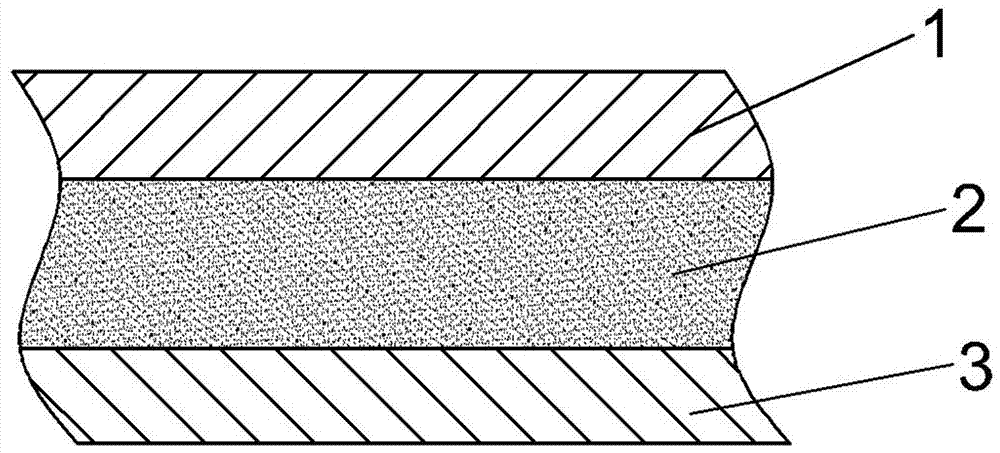

Sandwiched composite material for top skirt plates and floors of passenger cars

InactiveCN107128374ASmall smellHigh strengthSynthetic resin layered productsSuperstructure subunitsGlass fiberMetallurgy

The invention provides a sandwiched composite material for top skirt plates and floors of passenger cars. The sandwiched composite material comprises an upper aluminum plate, glass fiber reinforced thermoplastic and a lower aluminum plate which are arranged sequentially from top to bottom. The glass fiber reinforced thermoplastic is bonded with the upper aluminum plate and the lower aluminum plate by polyethylene film through hot melting, so that the symmetrically-structured high-strength sandwiched composite material for skirt plates and the floors of passenger cars is formed. When used for top skirt plates, the sandwiched composite material is 2.5-5 mm in thickness and 1200-2000 g / m<2> in surface density; when used for floors, the sandwiched composite material is 6-15 mm in thickness and 5000-8000 g / m<2> in surface density. The sandwiched composite material for top skirt plates and the floors of passenger cars has the advantages that the VOCs (volatile organic compounds) content conforms to national standards specified for environment-friendly composite materials; the sandwiched composite material is low in surface density and has remarkable lightweight advantage.

Owner:ZHENGZHOU YUTONG BUS CO LTD

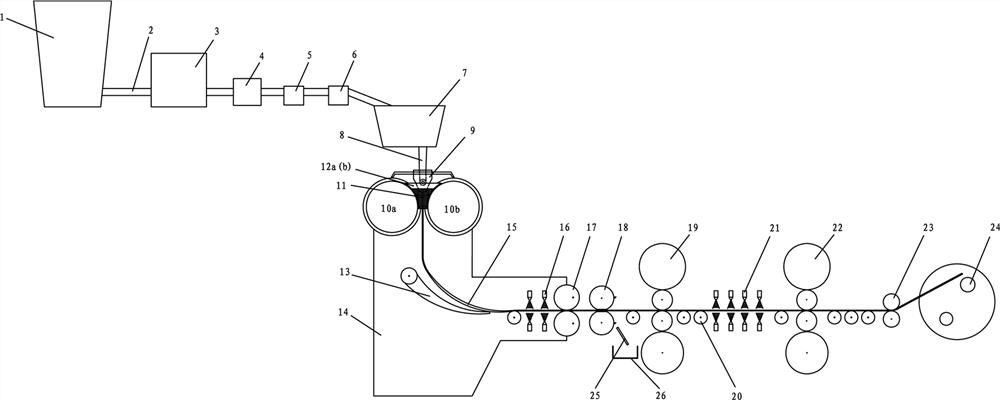

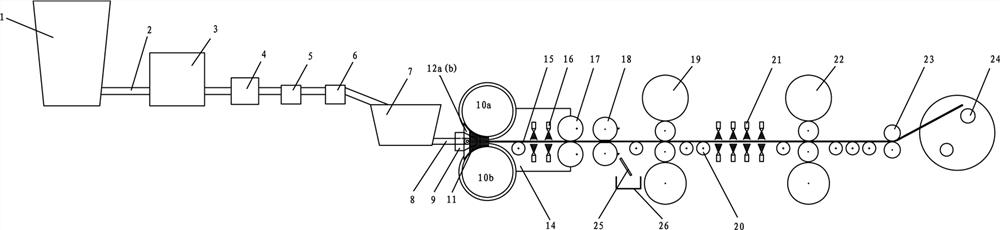

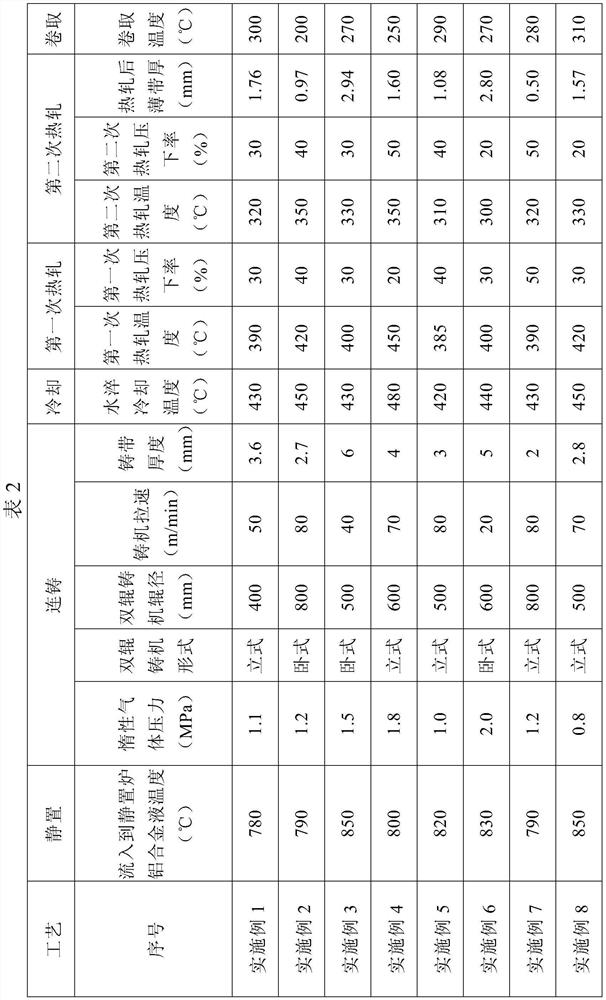

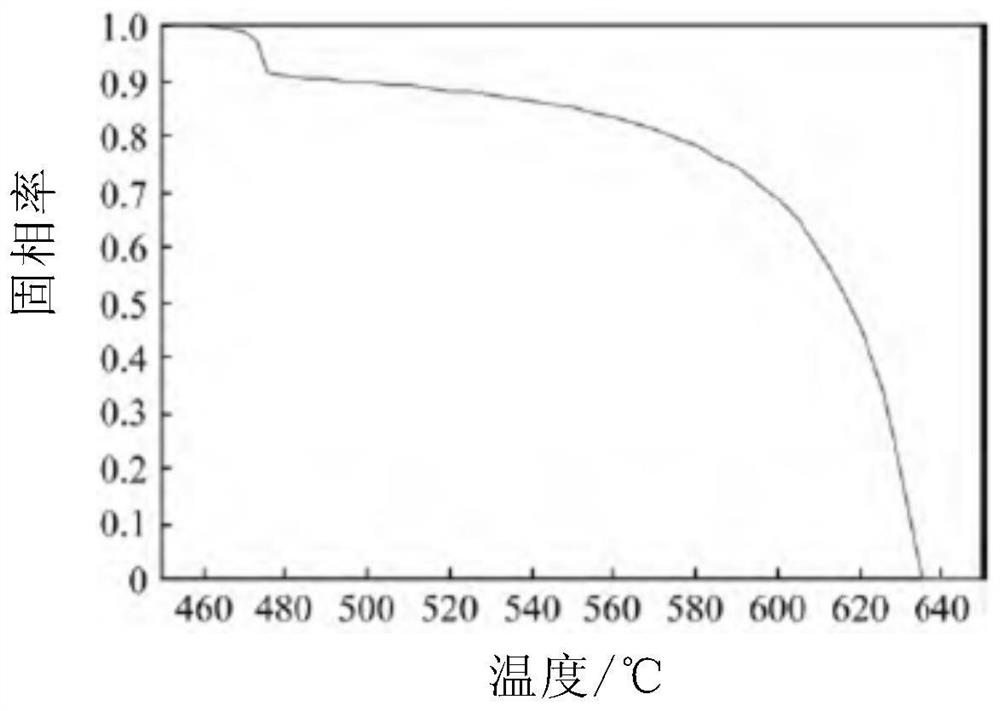

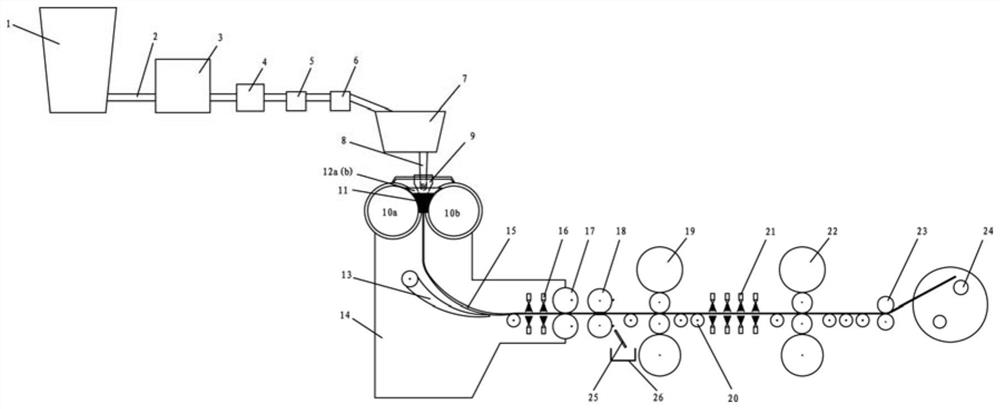

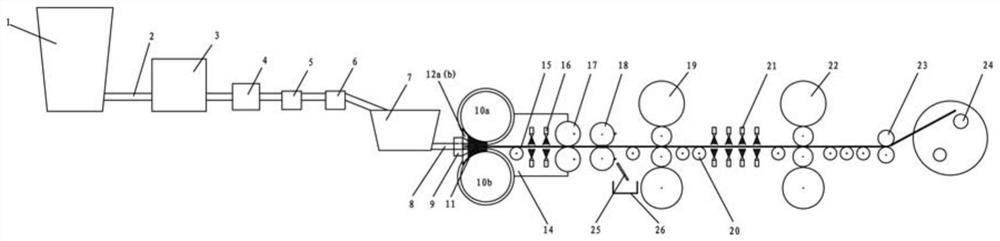

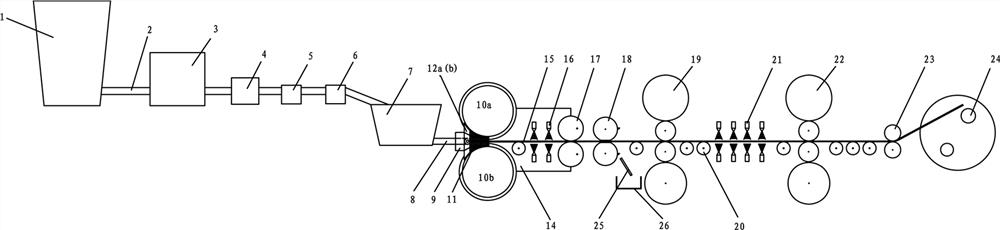

Thin-strip continuous casting high-performance 6XXX aluminum alloy plate strip and preparation method thereof

ActiveCN114107744AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsAuto industryFender

The invention discloses a thin-strip continuous casting high-performance 6XXX aluminum alloy plate strip and a preparation method thereof, the aluminum alloy plate strip comprises the following components in percentage by mass: 0.5-1.5% of Si, 0.1-2.0% of Mg, 0.1-1.0% of Fe, 0.05-0.5% of Mn, 0.02-0.2% of Cu, 0.01-0.08% of Ti, 0.001-0.008% of B and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.05%, and the content of total impurities is less than or equal to 0.15%. According to the preparation method, semisolid treatment is combined with a twin-roll thin-strip continuous casting process, and compared with an existing 6XXX aluminum alloy, the strength of the prepared 6XXX aluminum alloy plate strip is improved by 20% or above, and the formability is improved by 30% or above; and compared with a steel plate for an automobile, the weight is reduced by more than 40% easily. The produced aluminum alloy plate strip is a second-generation ABS aluminum alloy product, is widely applied to the field of automobiles, particularly can be used for automobile engine covering parts and can also be used for parts such as fenders, automobile doors, automobile roofs and trunk lids, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of environment-friendly composite mineral insulation board and its preparation process

The invention discloses an environmentally-friendly composite mineral thermal-insulation board and a preparation process thereof, belonging to the technical field of building materials. The compositemineral thermal-insulation board includes the following components: 15 to 85 parts of non-metallic minerals, 6 to 85 parts of expanded polystyrene, 0.3 to 26 parts of polystyrene fibers, 0.5 to 28 parts of titanium dioxide aerogel, and 3 to 23 parts of nanometer titanium dioxide particles. The preparation process comprises the following steps: preparing a composite aerogel composed of the nanometer titanium dioxide particles, the non-metallic minerals and titanium dioxide, and then subjecting the obtained mixture and polystyrene foam beads to heating and foaming so as to obtain the environmentally-friendly composite mineral thermal-insulation board. The thermal-insulation board has a large number of pores, rich pore structures, and good thermal insulation, sound insulation and flame retardant properties, and can meet the demands of building construction.

Owner:福建省鑫坤建设工程有限公司

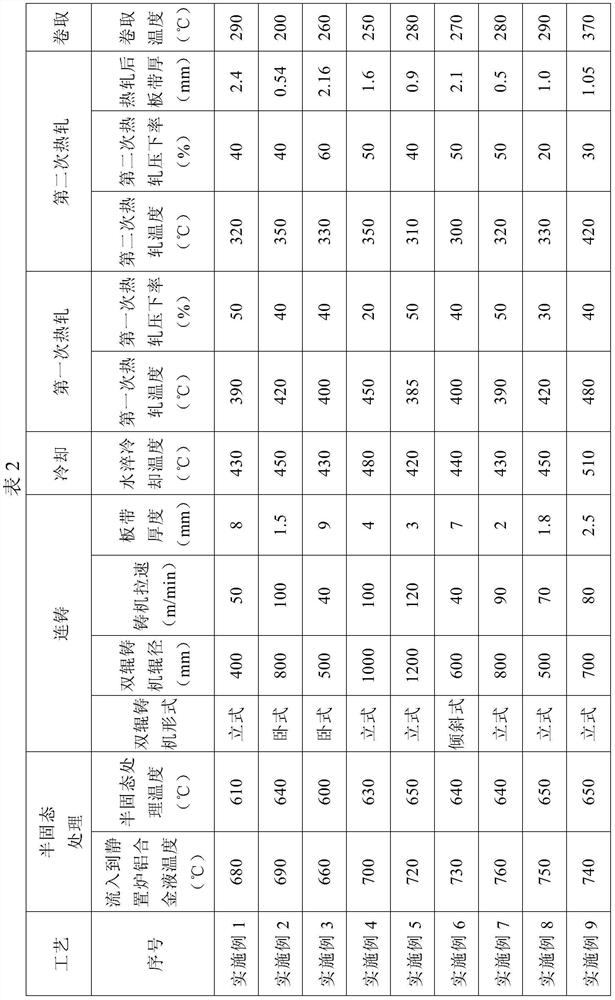

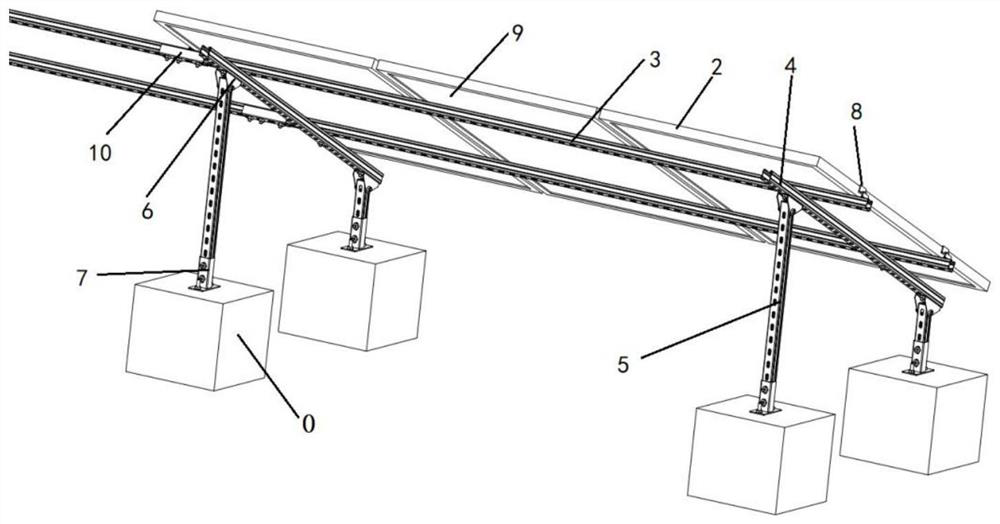

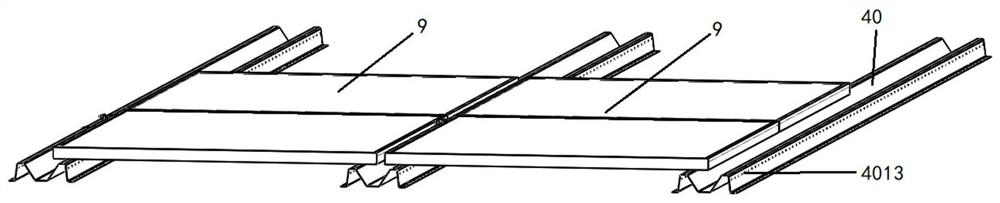

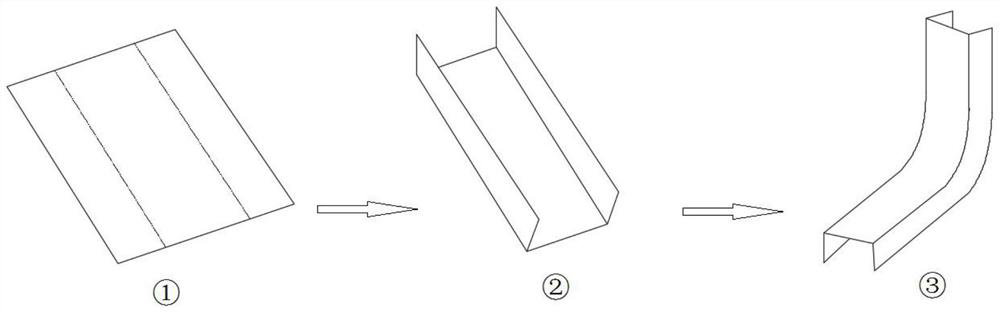

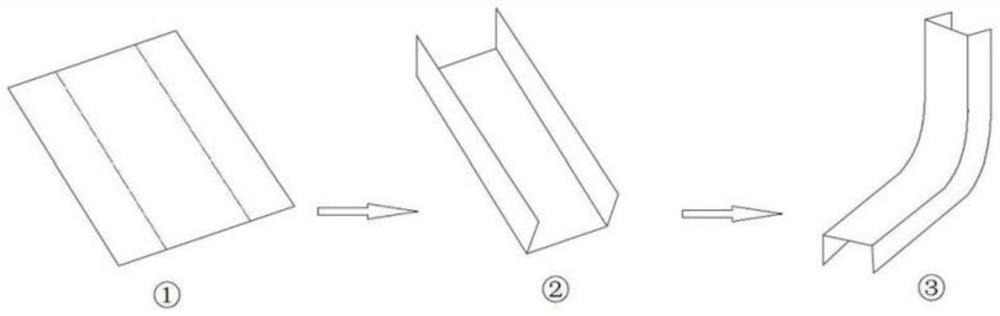

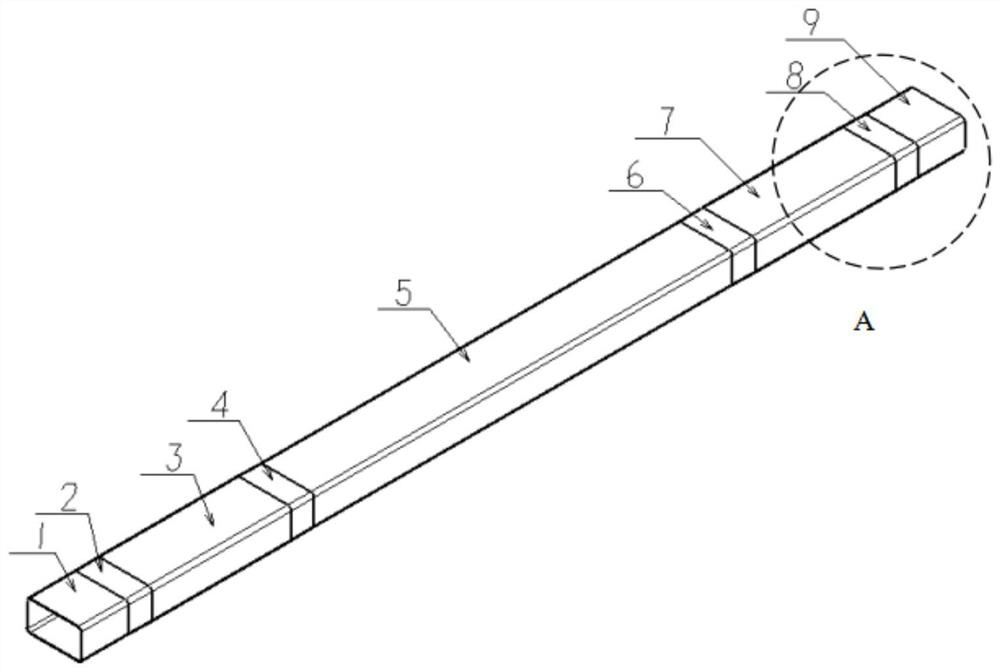

Photovoltaic support structure and forming process

PendingCN114465558AReduce weightHigh strengthPhotovoltaic supportsPhotovoltaic energy generationMaterials processingSteel belt

The invention relates to the field of material processing, and provides a photovoltaic support structure and a forming process thereof.The photovoltaic support structure comprises a photovoltaic support, a photovoltaic panel frame and a water guiding gutter.The photovoltaic support is provided with a photovoltaic panel, and the four edges of the photovoltaic panel are embedded in the photovoltaic panel frame; the photovoltaic panel frame and the photovoltaic support are formed by integrally-formed ultrahigh-strength steel rollers in a pressing mode. The high-strength steel lightweight manufacturing technology is adopted, the weight of the product is reduced by 30-40%, and the strength is improved by 20-30%. The light weight advantage is very obvious, the unit comprehensive manufacturing cost is lower than that of a common profile, and compared with the common profile, the high cost performance advantage is achieved; the photovoltaic panel frame is of a complex closed structure, the steel belt is formed at a time through multiple times of rolling, and the steel belt is closed through the self-closing technology; the surfaces of the materials of the photovoltaic panel frame and the photovoltaic support are subjected to aluminum-magnesium-zinc coating treatment, the corrosion resistance meets the requirement that no red rust exists within 600 hours, and the tensile strength reaches 400-1200 Mpa.

Owner:NINGBO XIANGLU AUTO PARTS

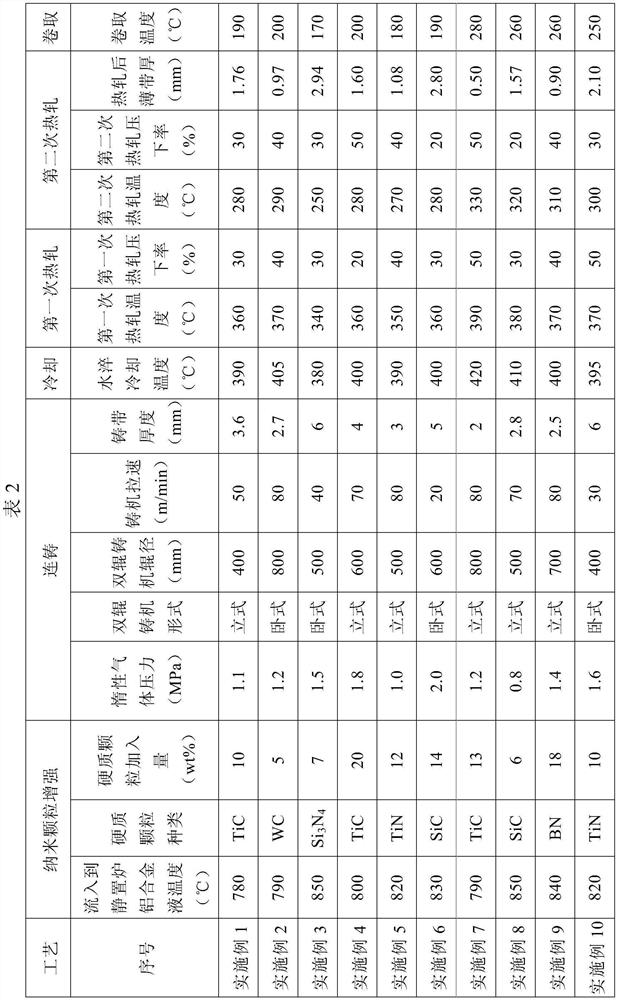

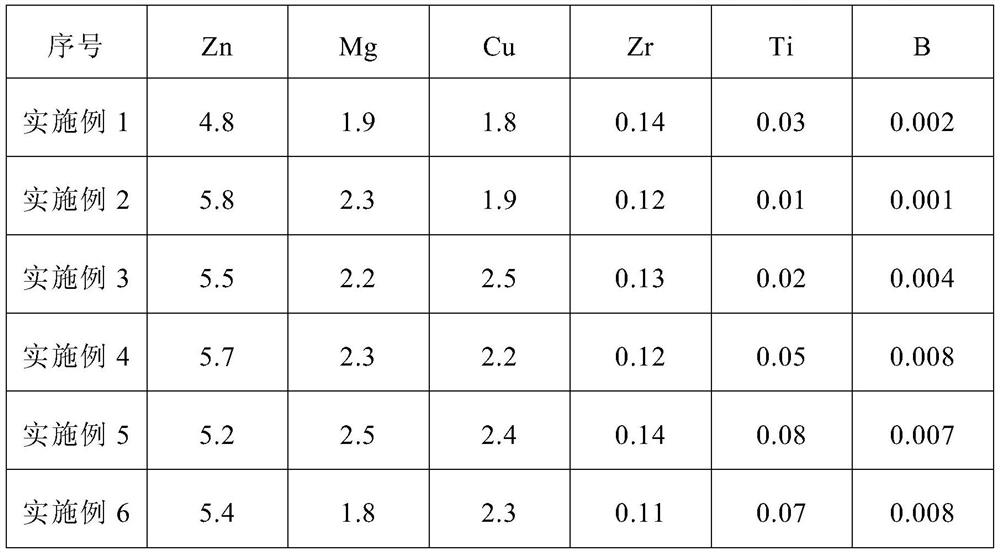

Preparation method of novel 7XXX aluminum alloy thin strip with high performance through jet casting and rolling

The invention relates to a preparation method of a novel 7XXX aluminum alloy thin strip with high performance by jet casting, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) spray deposition and continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip cast and rolled through the spray deposition combined double-roller thin strip cast rolling technology has the advantages that the strength is improved by 25% or above, and the ductility is improved by 35% or above; compared with a steel plate, the weight is reduced by 50% or more.

Owner:BAOSHAN IRON & STEEL CO LTD

al 2 Ca particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium matrix composite material and preparation method

ActiveCN109321794BLightweight advantage is obviousAchieving the effect of synergistic reinforcementLiquid/solution decomposition chemical coatingMicron scaleLithium

The invention relates to the technical field of metal materials, especially an Al 2 Ca particles and carbon nanotube hybrid reinforced ultra-light magnesium-lithium-based composite material and preparation method thereof, comprising the following components in weight percent: 5-20wt.% micron-scale Al 2 Ca particles, 1~5wt.% submicron scale Al 2 Ca particles, 0.5-3wt% of nickel-plated carbon nanotubes on the surface, 11-25wt.% of Li, the balance of Mg, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt.%. Preparation methods include micron / submicron scale Al 2 There are three steps of Ca particle pretreatment, carbon nanotube pretreatment and smelting. By using β-Li single-phase ultra-light magnesium-lithium alloy as the matrix and selecting a reinforcement phase with a lower density, the obtained magnesium-lithium matrix composite still has excellent lightweight advantages; micron / submicron scale Al 2 Ca particles and carbon nanotubes are used as reinforcing phases to play different roles in strengthening of different types and scales of reinforcing phases. Hybrid reinforcement is used to achieve synergistic strengthening effects, and the strengthening effect is far superior to that of traditional single-type and single-scale reinforcing phases. composite material.

Owner:JIANGSU UNIV OF TECH

High-strength flexible wear-resistant bionic composite joint material and preparation method thereof

ActiveCN114225114AImprove toughnessImprove impact resistanceTissue regenerationAluminium oxynitridesAluminum oxynitrideWear resistance

The invention relates to a high-strength flexible wear-resistant aluminum oxynitride / polyphenylene sulfide bionic composite joint material and a preparation method thereof, and belongs to the crossing field of biomedical science and material science. The invention provides a wear-resistant bionic composite joint material. The composite joint material comprises the following raw materials in parts by weight: 35-90 parts of polyphenylene sulfide and 10-65 parts of aluminum oxynitride. According to the invention, PPS and AlON are compounded for the first time to prepare the bionic composite joint material, and the obtained composite joint material is low in density and has high strength, high toughness and excellent wear resistance.

Owner:SOUTHWEST UNIV

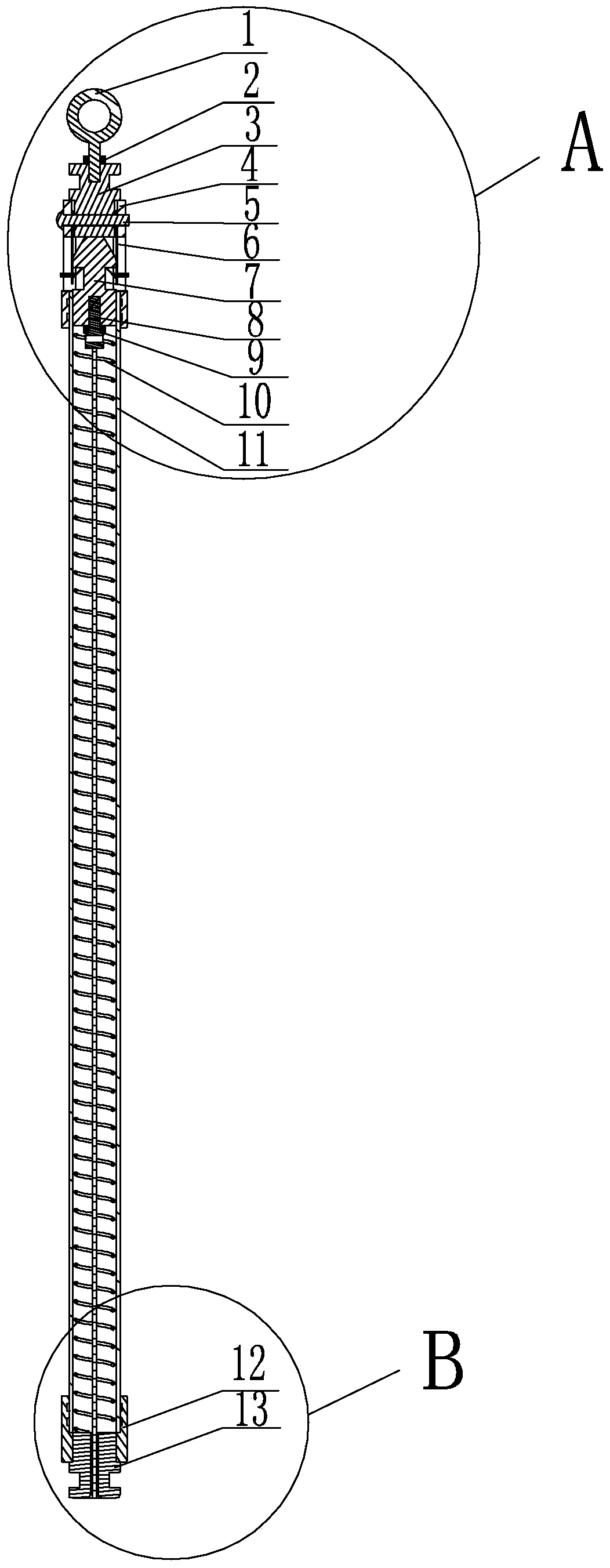

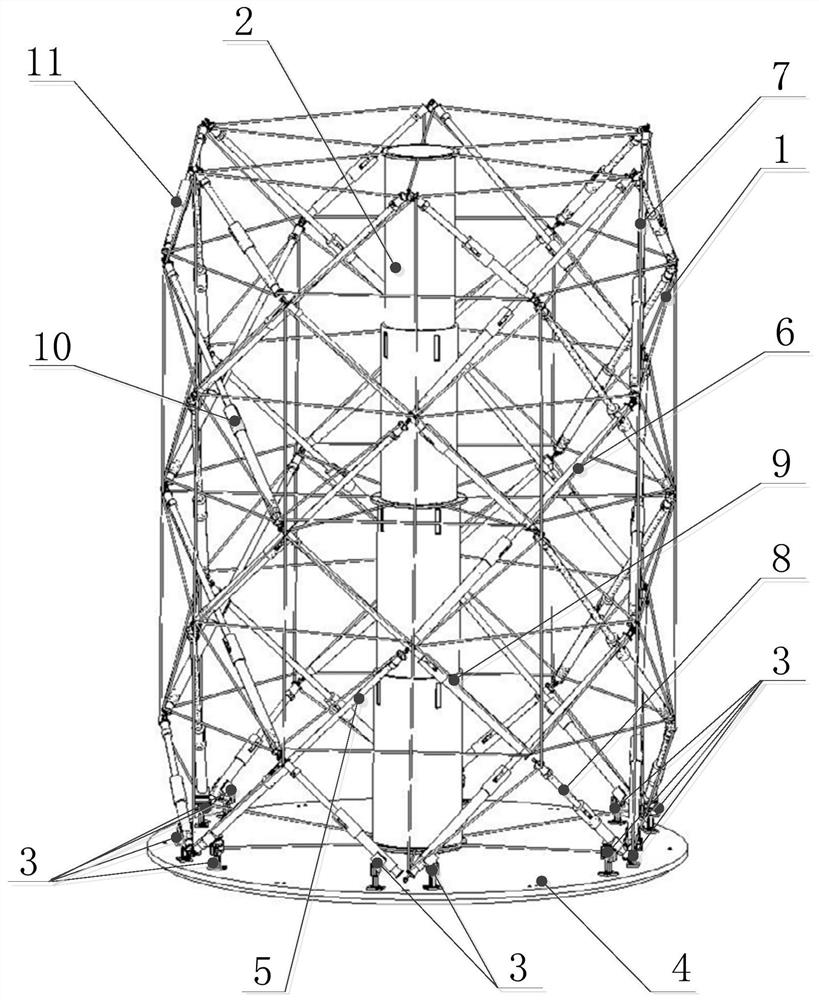

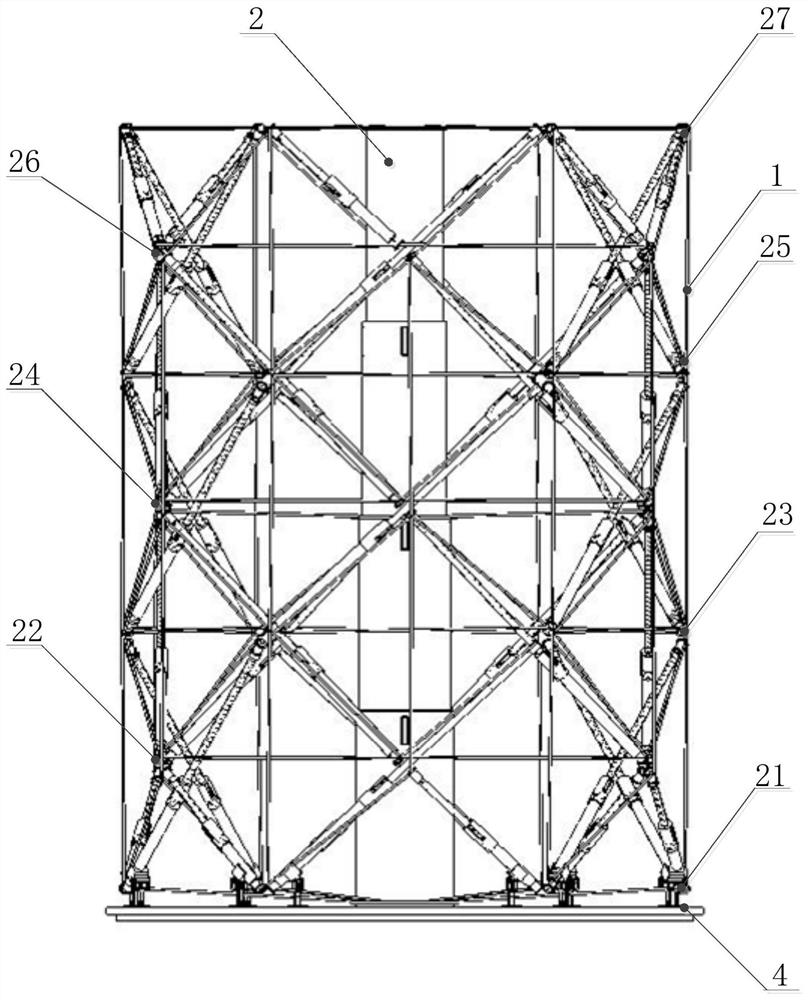

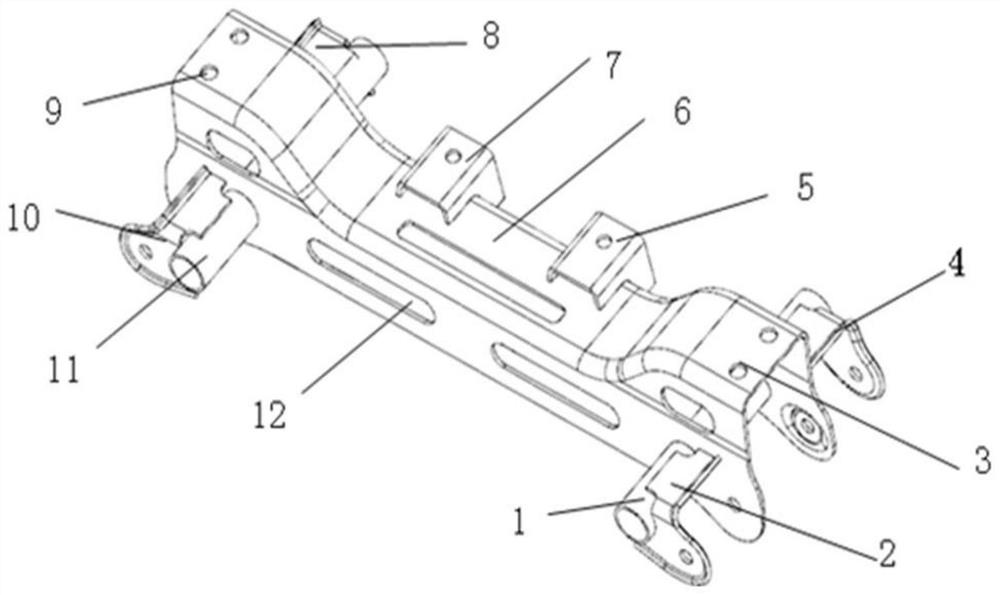

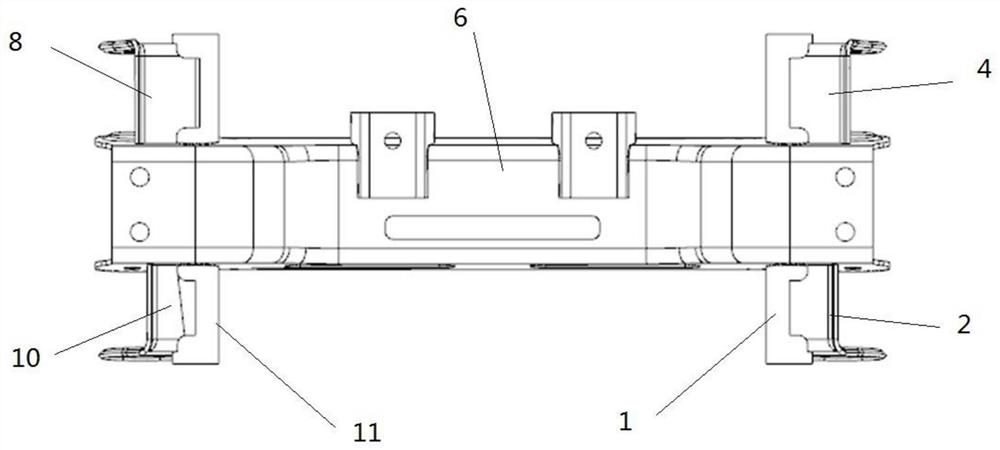

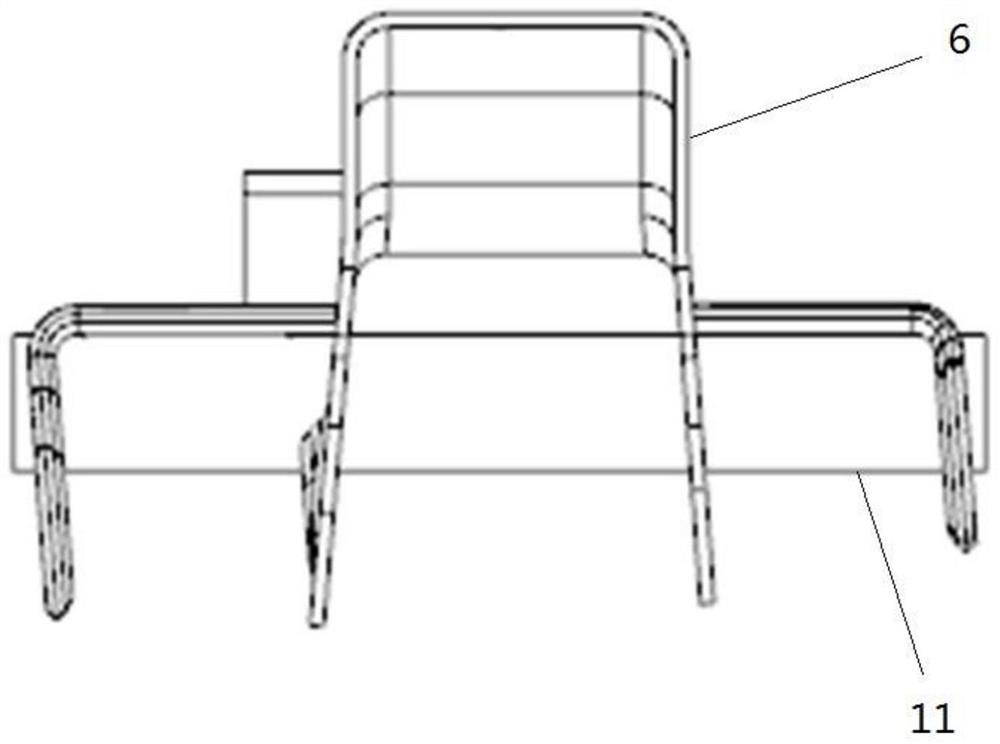

Skeleton structure of a tensioned expandable space capsule segment

ActiveCN108528762BLight in massLightweight advantage is obviousCosmonautic crew accomodationsArtificial satellitesStructural engineeringSpaceflight

The invention discloses a stretch-draw type expansible space capsule section skeleton structure, and relates to the field of manned space flight. The problems that an existing space capsule section islarge in structure mass and hard to expand or convey are solved. A base is a circular base, a central stretchable core column mechanism is perpendicularly arranged in the center of the base, the central stretchable core column mechanism is sleeved with a whole stretch-draw frame structure, multiple pairs of connecting frames are evenly arranged on the base, the whole stretch-draw frame structureis connected with the base through multiple pair of connecting frames, the axis of the whole stretch-draw frame structure coincides with the axis of the central stretchable core column mechanism, andthe whole stretch-draw frame structure is a net-shaped stretchable structure composed of a plurality of rod pieces and a plurality of ropes, wherein the appearance of the net-shaped stretchable structure is cylindrical; the rod pieces of the whole stretch-draw frame structure are all stretchable rod pieces, the whole frame can be expanded by means of stretching and retracting of the rod pieces, and meanwhile, the central stretchable core column mechanism is expanded under the drive of external force. The stretch-draw type expansible space capsule section skeleton structure is high in expansibility and the folding space is normal.

Owner:HARBIN INST OF TECH

Production method of pearlite matrix ultrahigh-strength ductile cast iron crankshaft

ActiveCN111687380AProduction Method AdvantagesImprove roundnessFoundry mouldsFurnace typesFerrosiliconDuctile iron

The invention provides a production method of a pearlite matrix ultrahigh-strength ductile cast iron crankshaft. The production method comprises the following steps of: selecting low-sulfur low-titanium pig iron, common carbon steel and self-produced recirculated iron as main furnace charges, and adding 75 ferrosilicon, 65 high-carbon ferromanganese, electrolytic copper and a graphite type carburant in a specific proportion; smelting in an intermediate frequency furnace at a specific frequency, adding a nodulizer, an inoculant and a silicon-calcium-manganese deoxidizer, and then tapping and nodulizing, wherein the nodulizing process requires a specific tapping position, speed and tapping steps, and the pouring process selects a specific inoculant flow rate and total amount; and performinga specific normalizing process on a crankshaft casting to prepare an ultrahigh-strength ductile cast iron material of which the strength exceeds 1000MPa, the elongation is greater than or equal to 5%and the matrix material is pearlite. The comprehensive performance of the ultrahigh-strength ductile cast iron material is far better than that of common ductile iron and ADI (all-purpose ductile iron) materials with the same tensile strength. The preparation method is applied to parts such as J4200 crankshafts and JX400 crankshafts to realize the preparation of the pearlite matrix ultrahigh-strength ductile material, and the cost is reduced and remarkable benefits are obtained.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

Longitudinal-beam-free middle floor assembly structure

PendingCN112373578AStructural advantagesSimple structureSuperstructure subunitsSide impactMechanical engineering

The invention discloses a longitudinal-beam-free middle floor assembly structure. The structure comprises a middle floor left side edge beam, a middle floor right side edge beam, a middle floor frontcross beam, a middle floor rear cross beam, a middle floor and a plurality of edge beam connecting plug-in pieces, and the middle floor comprises a middle floor front section plate, a middle floor middle section plate and a middle floor rear section plate. The front ends and the rear ends of the middle floor left side edge beam and the middle floor right side edge beam are connected with a plurality of edge beam connecting inserting pieces respectively, and the middle floor front cross beam and the middle floor rear cross beam are parallel to each other and connected between the middle floor left side edge beam and the middle floor right side edge beam. A mounting frame for mounting the middle floor front section plate, the middle floor middle section plate and the middle floor rear section plate is formed between the middle floor left side edge beam and the middle floor right side edge beam and between the middle floor front cross beam and the middle floor rear cross beam. The middlefloor assembly structure is light in overall weight, high in light weight advantage, good in side impact safety and high in practicability, and the bending and torsion resistance of the middle floor is effectively improved.

Owner:苏州同捷汽车工程技术股份有限公司

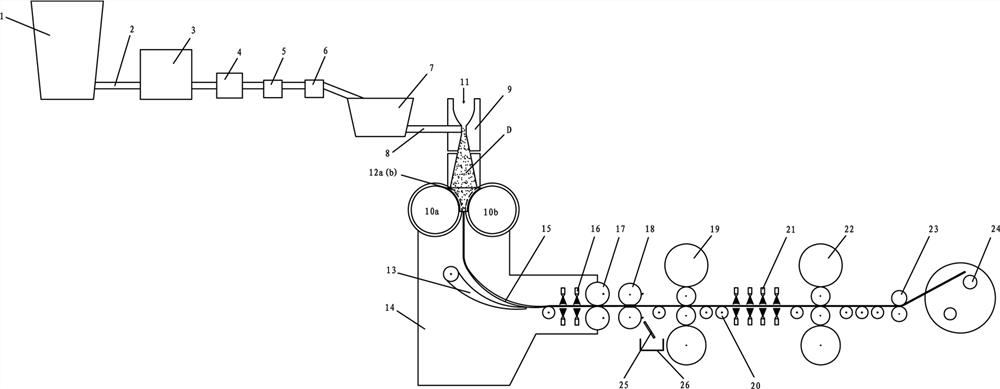

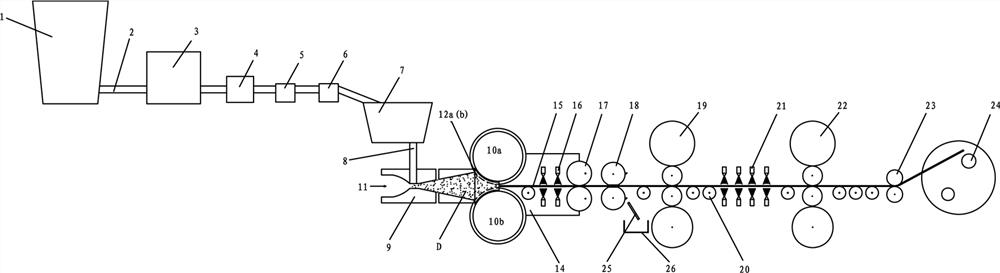

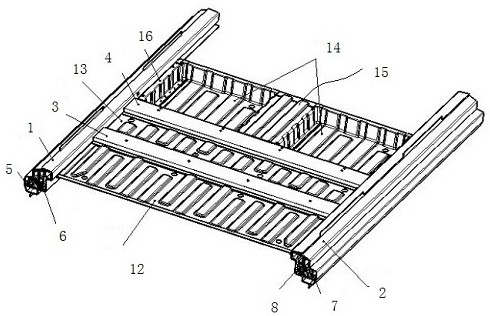

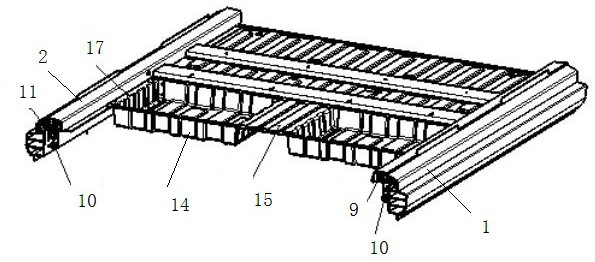

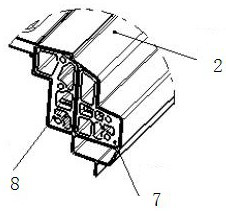

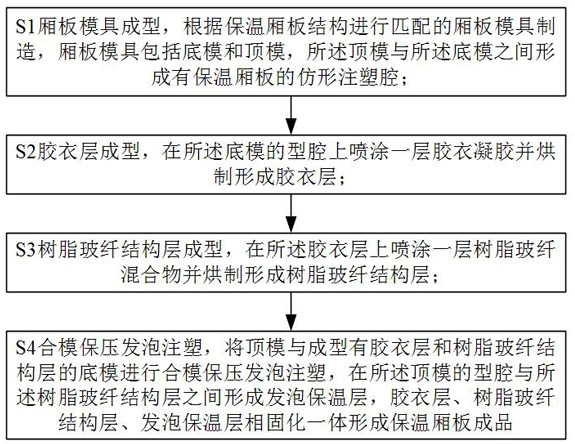

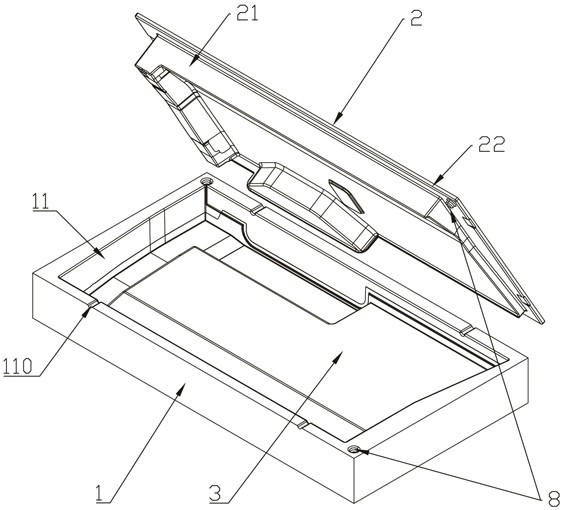

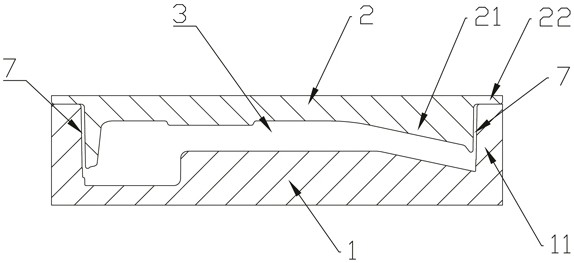

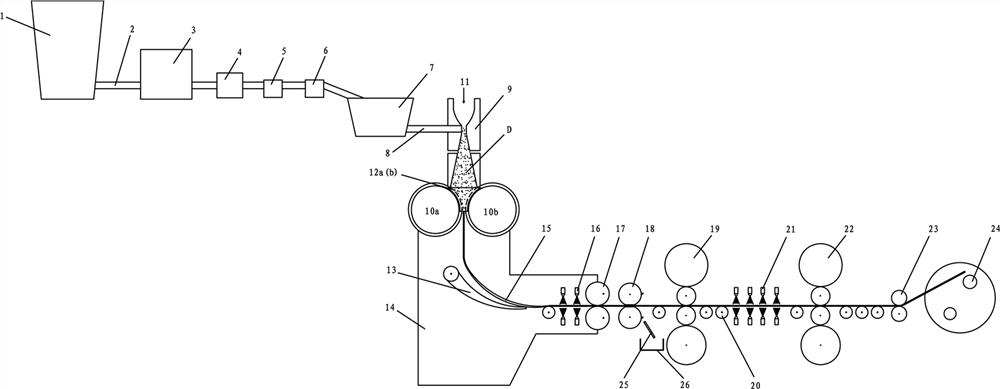

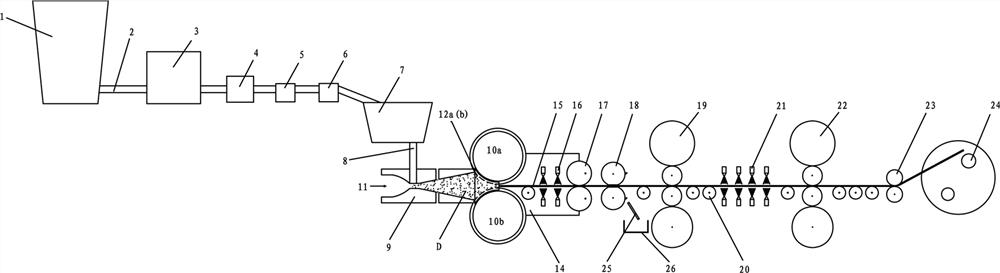

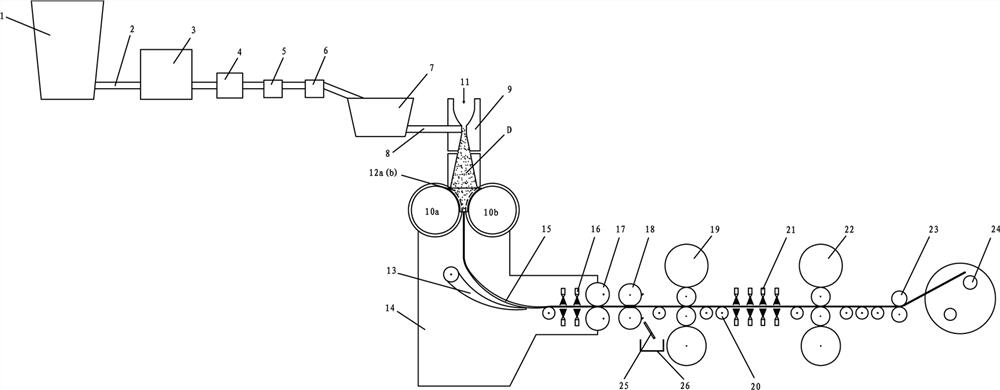

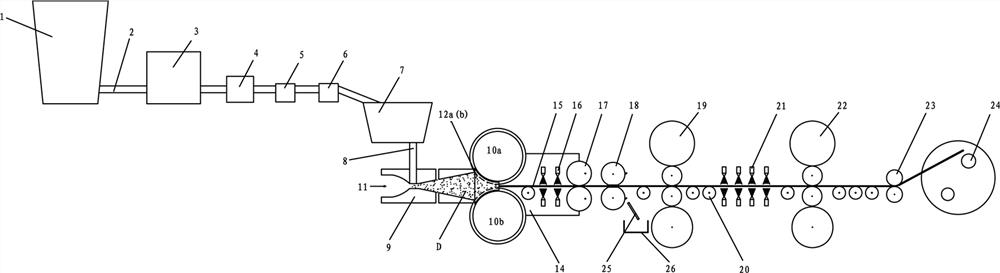

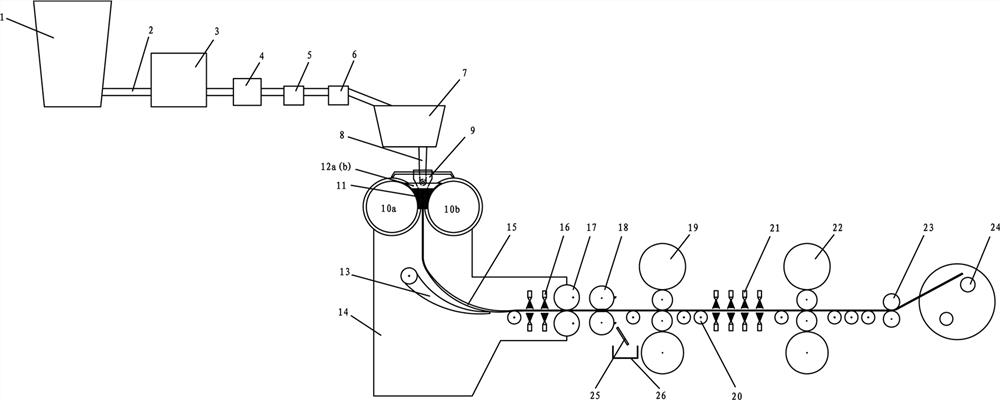

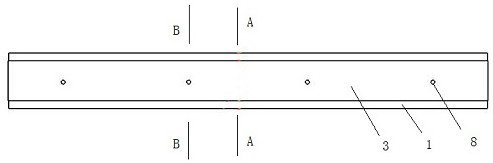

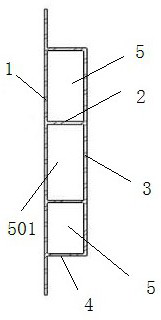

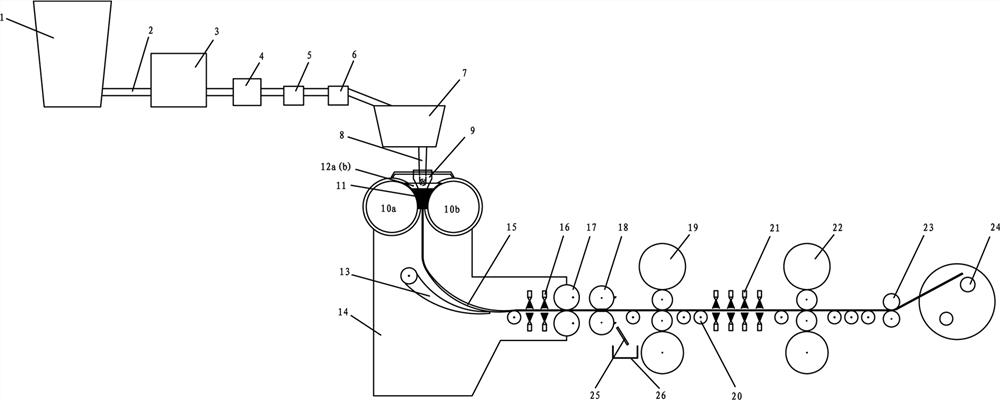

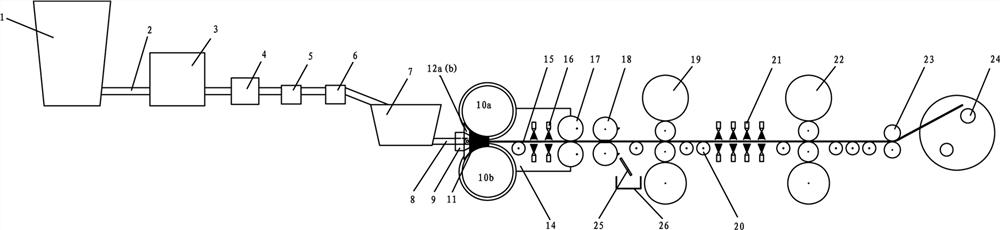

Manufacturing method and manufacturing production line of closed type refrigerator car heat preservation compartment plate

PendingCN114714638AImprove assembly accuracyReduce the difficulty of assemblyFlat articlesRefrigerator carGlass fiber

The invention discloses a manufacturing method and a manufacturing production line of a closed type refrigerator car heat preservation compartment plate. The manufacturing method comprises the steps of compartment plate mold forming; forming a gel coat layer; molding the resin glass fiber structure layer; and mold closing, pressure maintaining, foaming and injection molding. According to the invention, the spraying of the profiling mold is combined with the foaming injection molding matched process, so that the profiling forming of the high-precision heat-insulating compartment plate is realized, the assembly precision of the heat-insulating compartment plate is improved, and the assembly difficulty of the heat-insulating compartment plate is reduced. The laminated composite technology combining spraying and foaming is adopted, the requirements for composite stability and structural strength can be met without adhesives, meanwhile, the laminated structure is improved, the material cost and the composite forming technology cost are reduced, and the formed heat preservation compartment plate is obvious in light weight advantage and easy to transport, carry and assemble. The preparation method is simple, reasonable and ingenious in step, and can meet the automatic circulating flow production requirement of the thermal insulation carriage plate by being matched with a manufacturing production line, so that the production efficiency is greatly improved, the production period is shortened, and the product uniformity and the qualification rate are guaranteed.

Owner:兰博(昆山)运载装备制造有限公司

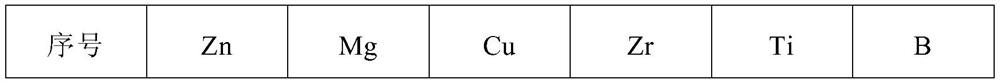

Jet cast rolling high-performance 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107764AImprove mechanical propertiesReduced hot cracking tendencyMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a jet cast rolling high-performance 7XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, and the content of total impurities is less than or equal to 0.2%. Compared with an existing 7XXX aluminum alloy, the 7XXX aluminum alloy thin strip prepared through the spray deposition and double-roller thin strip cast rolling combined technology has the advantages that the strength is higher by 20% or above, and the ductility is higher by 30% or above; compared with a steel plate, the weight is reduced by more than 40%. The produced aluminum alloy thin strip can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and a wide space can be provided for aerospace high strengthening, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel oil tank support manufactured based on magnesium alloy and manufacturing process of novel oil tank support

InactiveCN112810431AReasonable structureEasy to assemble and disassembleFuel supplyMetallurgyDie casting

The invention discloses a novel fuel tank support manufactured based on magnesium alloy and a manufacturing process thereof, and relates to the technical field of automobile manufacturing, the novel fuel tank support comprises a magnesium alloy support body, the two side faces of the magnesium alloy support body are both dug inwards to form a plurality of grooves, and reinforcing ribs are formed between the adjacent grooves; the two ends of the magnesium alloy support body are each provided with an insertion hole for a bandage to penetrate through, and the bandage is used for fastening an oil tank. The reinforcing ribs, the inserting holes and the magnesium alloy support body are integrally formed in a die-casting mode. During manufacturing, firstly, magnesium alloy particle materials or magnesium ingots are melted into semi-solid or liquid magnesium alloy, then the semi-solid or liquid magnesium alloy is injected into a forming die of a die casting machine, and finally, the magnesium alloy materials are integrally formed into the magnesium alloy support body through die casting. The problem of light weight of an existing fuel tank support is solved by adopting a magnesium alloy material, meanwhile, a special structural design is adopted, the defect that the physical strength of the magnesium alloy material is poorer than that of steel is perfectly avoided, the service life of the novel fuel tank support is greatly prolonged, and the strength of the novel fuel tank support is greatly improved.

Owner:安徽西马新能源技术有限公司

Novel oil tank support manufactured based on magnesium alloy or aluminum alloy and manufacturing process of novel oil tank support

PendingCN114559809AReasonable structureEasy to assemble and disassembleFuel supplyMetallurgyDie casting

The invention discloses a novel fuel tank support manufactured based on magnesium alloy or aluminum alloy and a manufacturing process thereof, the novel fuel tank support comprises a support body, the support body is made of magnesium alloy or aluminum alloy, the two side faces of the support body are dug inwards to form a plurality of grooves, and reinforcing ribs are formed between the adjacent grooves; the two ends of the support body are each provided with an insertion hole used for a bandage to penetrate through, and the bandage is used for fastening an oil tank. The reinforcing ribs, the inserting holes and the support body are integrally formed in a die-casting mode or a forging and pressing mode. When the magnesium alloy is adopted, firstly, magnesium alloy particle materials or magnesium ingots are melted into semi-solid or liquid magnesium alloy, then the semi-solid or liquid magnesium alloy is injected into a forming die of a die casting machine or a forging press, and finally the magnesium alloy materials are integrally formed into the support body through die casting or forging. When aluminum alloy is adopted, the support body is manufactured through an aluminum alloy die-casting process or an aluminum alloy forging process. The oil tank support is light in weight, reasonable in structure and convenient to disassemble and assemble.

Owner:深圳市高斯科技投资有限公司

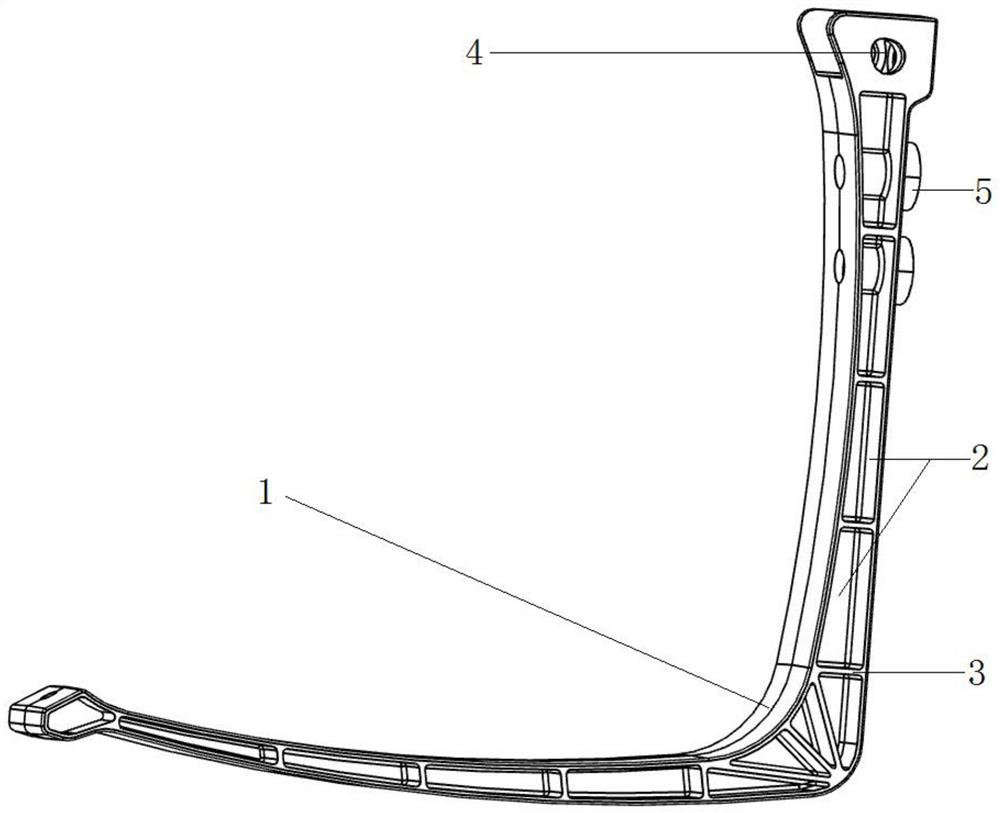

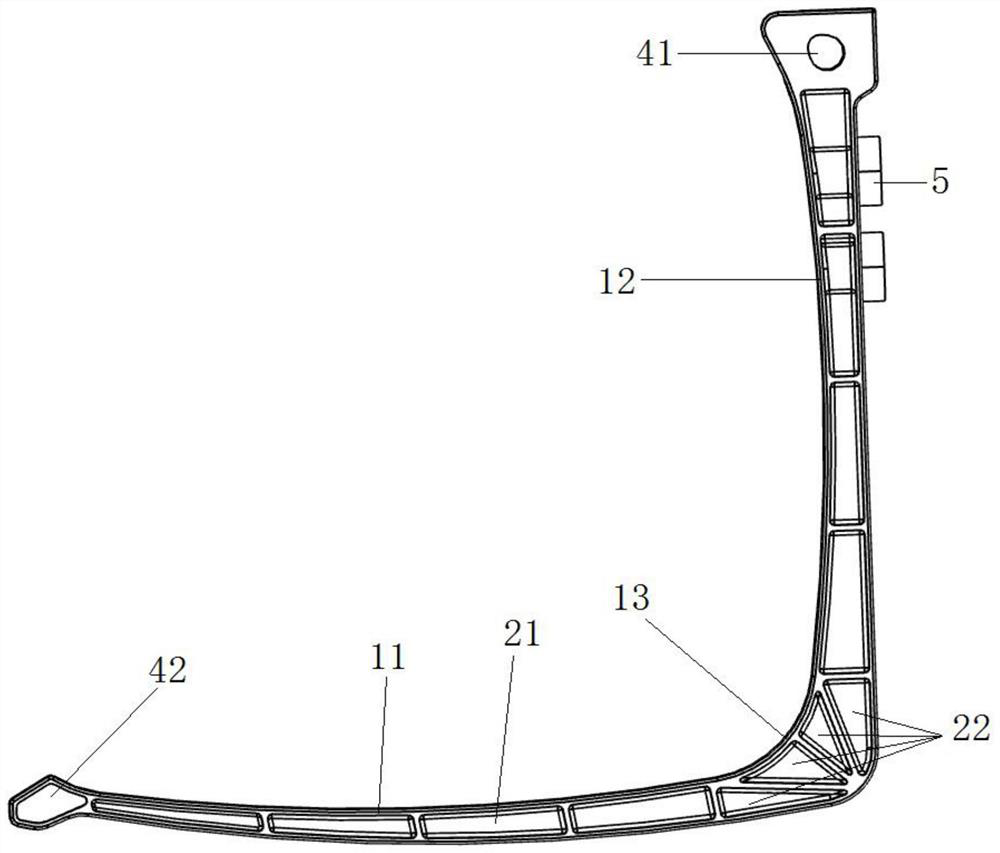

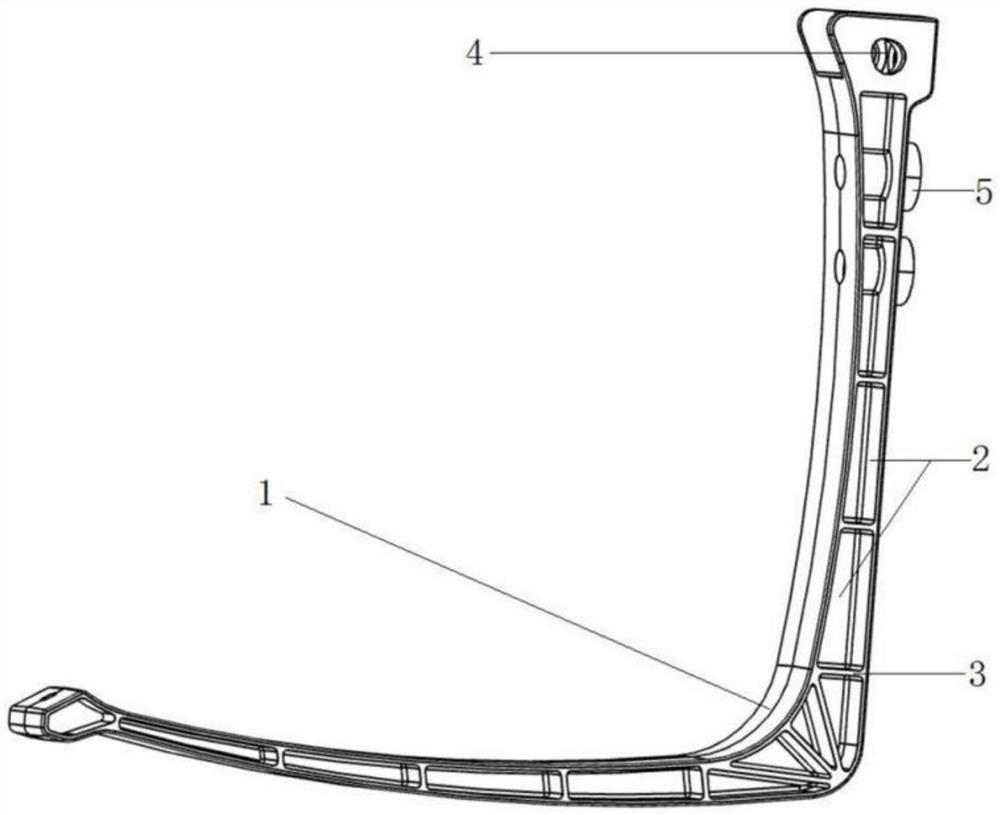

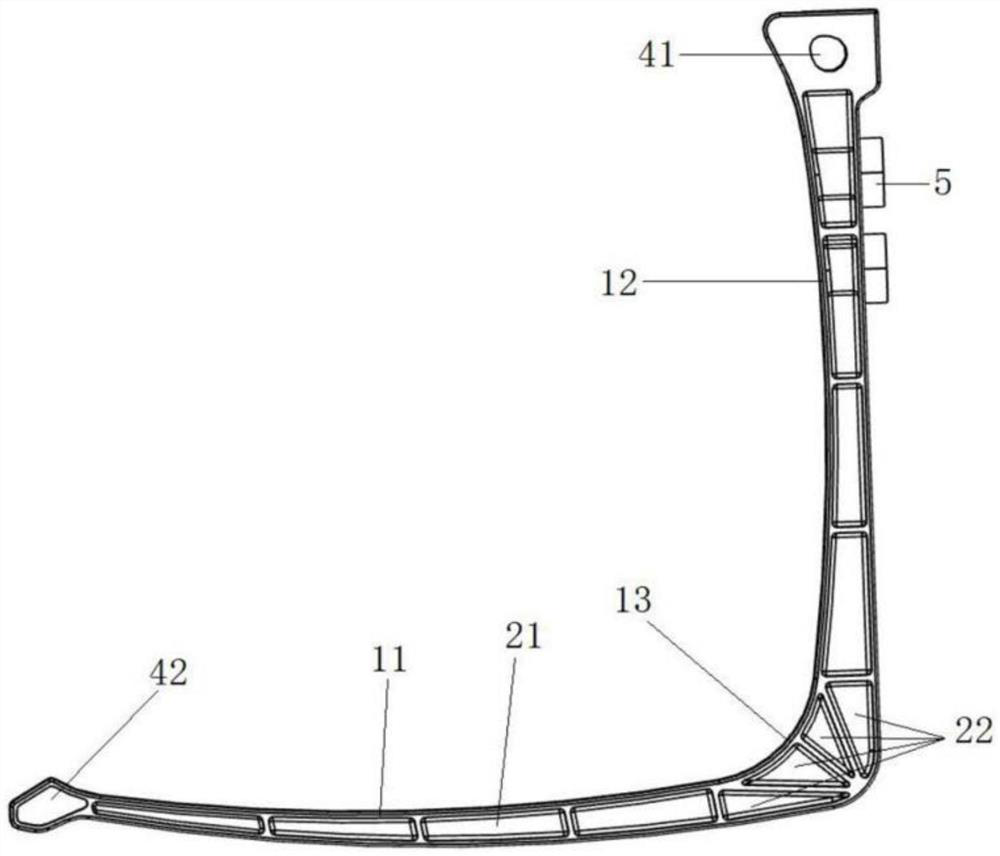

Vehicle front lower protection cross beam, assembly and vehicle

PendingCN113734081AAvoid excess thicknessGive full play to the effect of thicknessBumpersEngineeringStructural engineering

The invention discloses a vehicle front lower protection cross beam which is provided with a middle section located in the middle in the length direction of the vehicle front lower protection cross beam, and a strengthening transition section, a strengthening section, a far-end transition section and a far-end section located at the end of the vehicle front lower protection cross beam are sequentially arranged from the middle section to the two ends respectively. The wall thickness of the strengthening section is larger than that of all other sections; the strengthening section, the middle section and the far-end section are each of an equal-thickness structure with the constant wall thickness in the length direction. The strengthening transition section and the far-end transition section are each of a variable-thickness structure, and the wall thickness of the variable-thickness structure changes continuously in the length direction. In addition, the invention further discloses a vehicle front lower protection cross beam assembly and a vehicle. The front lower protection cross beam of the vehicle has the advantages of being simple in structure, capable of being locally strengthened, obvious in light weight advantage and the like, light weight of the vehicle body is achieved under the condition that the safety performance requirement is met, and the front lower protection cross beam has good popularization prospects and application value.

Owner:BAOSHAN IRON & STEEL CO LTD

Jet cast rolling high-performance 6XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114101609AImprove mechanical propertiesReduced hot cracking tendencyTemperature control deviceFurnace typesAuto industryFender

The invention relates to a jet cast rolling high-performance 6XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 0.5-1.5% of Si, 0.1-2.0% of Mg, 0.1-1.0% of Fe, 0.05-0.5% of Mn, 0.02-0.2% of Cu, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.05%, and the content of total impurities is less than or equal to 0.15%. Compared with an existing 6XXX aluminum alloy, the 6XXX aluminum alloy thin strip cast and rolled through the spray deposition combined with the double-roller thin strip cast-rolling technology has the advantages that the strength is higher by 30% or above, and the formability is higher by 40% or above; and compared with a steel plate for an automobile, the light weight of more than 50% is easily realized. The aluminum alloy thin strip can be widely applied to the automobile application field, such as automobile engine covering parts, fenders, automobile doors, automobile roofs, trunk lids and other parts, and a wide space is provided for the automobile industry in the aspects of light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip and preparation method thereof

The invention discloses a thin-strip continuous casting high-performance 7XXX aluminum alloy thin strip and a preparation method thereof, the aluminum alloy thin strip comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, and the content of total impurities is less than or equal to 0.2%. The semi-solid treatment is combined with the twin-roll thin strip continuous casting process, the microscopic structure of the prepared aluminum alloy thin strip is a fine isometric crystal matrix structure, and compared with an existing 7XXX aluminum alloy, the strength is improved by 20% or above, and the ductility is improved by 30% or above; compared with a steel plate, more than 40% of light weight is easily realized; the material can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and can provide a wide space for aerospace high reinforcement, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

al 2 Y particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium matrix composite material and preparation method

ActiveCN109321793BLightweight advantage is obviousAchieving the effect of synergistic reinforcementLiquid/solution decomposition chemical coatingMetallic materialsAlloy

The invention relates to the technical field of metal materials, especially an Al 2 Y particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium-based composite material and preparation method, which comprises the following components in weight percent: 5-20wt.% micron-scale Al 2 Y particles, 1~5wt.% nanoscale Al 2 Y particles, 0.5-3wt% of nickel-coated carbon nanotubes on the surface, 11-25wt.% of Li, the balance of Mg, and the total amount of impurity elements Si, Fe, Cu and Ni is less than 0.02wt.%. Fabrication methods include micro / nanoscale Al 2 Three steps of Y particle pretreatment, carbon nanotube pretreatment and smelting. By using β-Li single-phase ultra-light magnesium-lithium alloy as the matrix and selecting a reinforcement phase with a lower density, the magnesium-lithium-based composite material still has excellent lightweight advantages; micron / nanoscale Al 2 Y particles and carbon nanotubes are used as reinforcing phases to play different roles in strengthening of different types and scales of reinforcing phases. Hybrid reinforcement is used to achieve synergistic strengthening effects, and the strengthening effect is far superior to that of traditional single-type and single-scale reinforcing phases. composite material.

Owner:JIANGSU UNIV OF TECH

I-shaped front auxiliary frame with simple and stable structure for electric vehicle

The invention provides an I-shaped front auxiliary frame with simple and stable structure for an electric vehicle, which comprises an auxiliary frame main body beam, the left end of the auxiliary frame main body beam is connected with a swing arm mounting support left supporting beam, and the right end of the auxiliary frame main body beam is connected with a swing arm mounting support right supporting beam. The swing arm mounting support left supporting beam penetrates through the left end of the auxiliary frame main body beam in the front-back direction, the swing arm mounting support right supporting beam penetrates through the right end of the auxiliary frame main body beam in the front-back direction, and the swing arm mounting support left supporting beam and the swing arm mounting support right supporting beam are parallel. And the swing arm mounting bracket left supporting beam, the auxiliary frame main body beam and the swing arm mounting bracket right supporting beam are arranged in an I shape. The invention has the beneficial effects that the H-shaped structural design is adopted, the structure is simple, the layout is compact, the light weight advantage is obvious, and the cost is low.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Novel particle-reinforced 7XXX aluminum alloy thin strip and preparation method thereof

ActiveCN114107760AImprove mechanical propertiesHigh strengthMetal rolling arrangementsNacelleFlight vehicle

The invention relates to a novel particle-reinforced 7XXX aluminum alloy ribbon and a preparation method thereof, the aluminum alloy ribbon comprises the following components in percentage by mass: 4.8-6.3% of Zn, 1.6-2.5% of Mg, 1.6-2.5% of Cu, 0.1-0.15% of Zr, 0.01-0.08% of Ti, 0.001-0.008% of B, and the balance of Al and other inevitable impurities, the content of a single impurity is less than or equal to 0.1%, the content of a total impurity is less than or equal to 0.2%, and the microstructure of the aluminum alloy ribbon is a fine isometric crystal matrix structure and dispersively distributed hard particles. Compared with an existing 7XXX aluminum alloy, the strength of the prepared 7XXX aluminum alloy thin strip is improved by 25% or above, and the ductility is improved by 35% or above by adopting the nanoparticle reinforcement and double-roller thin strip continuous casting technology; compared with a steel plate, the weight is reduced by 50% or more. The material can be widely applied to the field of aerospace, such as various aircraft fuselages, wing beams, cabin wallboards, aircraft high-stress structural parts, aircraft skins, high-strength structural parts in aircraft rockets and the like, and can provide a wide space for aerospace high reinforcement, light weight, energy consumption reduction and fuel economy improvement.

Owner:BAOSHAN IRON & STEEL CO LTD

A kind of high-strength, flexible and wear-resistant bionic composite joint material and preparation method thereof

ActiveCN114225114BImprove toughnessImprove impact resistanceTissue regenerationAluminium oxynitridesLow densityAluminum oxynitride

The invention relates to a high-strength, flexible and wear-resistant aluminum oxynitride / polyphenylene sulfide bionic composite joint material and a preparation method, and belongs to the cross field of biomedicine and material science. The invention provides a wear-resistant bionic composite joint material, the composite joint material comprises raw materials in the following proportions: 35-90 parts by weight of polyphenylene sulfide and 10-65 parts by weight of aluminum oxynitride. In the present invention, a bionic composite joint material is prepared by compounding PPS and AlON for the first time, and the obtained compound joint material has low density, high strength, high toughness and excellent wear resistance.

Owner:SOUTHWEST UNIV

Aluminum profile middle floor beam structure

PendingCN112373579AStructural advantagesIncreased torsional stiffnessSuperstructure subunitsEngineeringStructural engineering

Owner:苏州同捷汽车工程技术股份有限公司

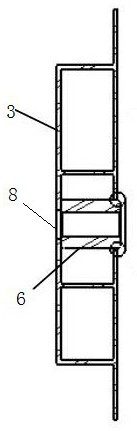

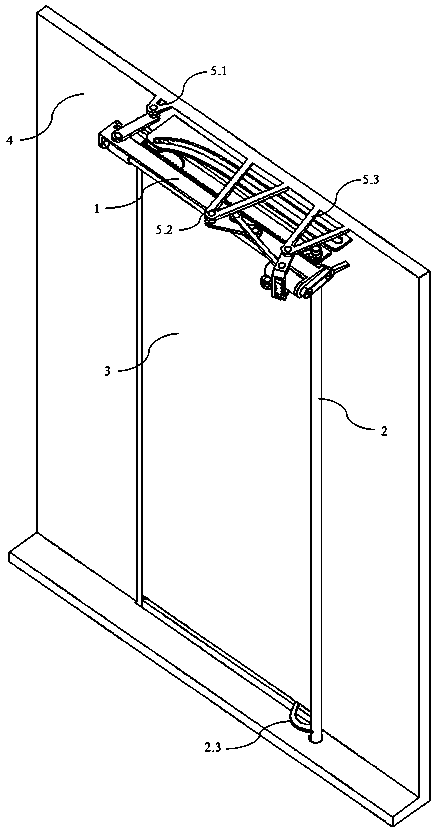

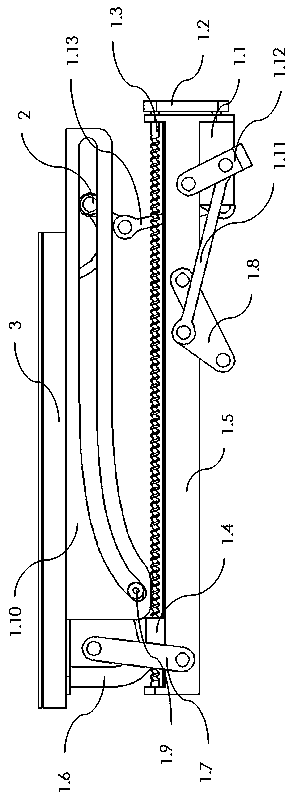

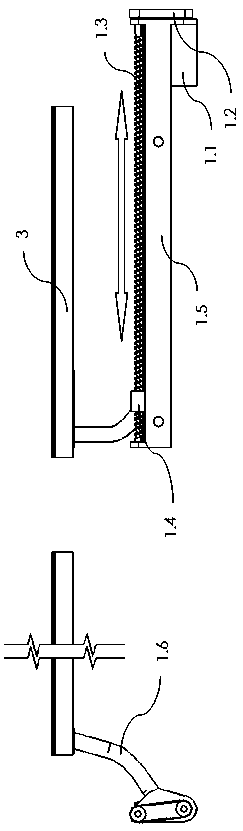

A sliding oblique insertion type single-leaf sliding door mechanism for passenger cars

ActiveCN107989521BImprove discomfortImprove securityPower-operated mechanismWing arrangementsInterior spaceInternal pressure

The invention provides a sliding and oblique insertion type single sliding door mechanism for a passenger car. The sliding and oblique insertion type single sliding door mechanism for the passenger car includes driving actuating mechanisms, a fixed track door shaft, door body of a passenger door and a side wall of a car body. The driving actuating mechanisms are installed on the door body of the passenger door and the side wall of the car body simultaneously. The driving actuating mechanisms drive the door body of the passenger door to rotate through the fixed track door shaft. The action posture of "flat sliding, oblique insertion and pull back locking" of the passenger door is achieved, the problem of the discomfort of ears of a passenger caused by the sudden change of the internal pressure of the vehicle due to the overall movement of the door when the door is just opened or is to be closed while an existing sliding door is used in the small interior space of vehicles is solved. Atthe same time, compared with existing single sliding door series, the innovative door opening and closing action postures carried out by the novel sliding and oblique insertion type single sliding door mechanism can further improve the anti-pinching safety of the passenger door when the door is to be closed.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Preparation method of novel particle-reinforced 7XXX aluminum alloy thin strip

The invention relates to a preparation method of a particle-reinforced novel 7XXX aluminum alloy thin strip, which comprises the following steps of: 1) smelting according to the following chemical components in percentage by weight: 4.8 to 6.3 percent of Zn, 1.6 to 2.5 percent of Mg, 1.6 to 2.5 percent of Cu, 0.1 to 0.15 percent of Zr and the balance of Al and other inevitable impurities; the single impurity content is less than or equal to 0.1%, and the total impurity content is less than or equal to 0.2 (2) nano-particle enhancement; 3) continuous casting; 4) cooling; 5) primary hot rolling; (6) cooling and secondary hot rolling; (7) coiling; and 8) post-processing. According to the preparation method, the 7XXX aluminum alloy thin strip is prepared by combining nanoparticle reinforcement with a double-roller thin strip continuous casting process, and compared with an existing 7XXX aluminum alloy, the strength of the obtained aluminum alloy thin strip is higher than 20%, and the ductility is higher than 30%; and compared with a steel plate, the weight can be easily reduced by more than 40%.

Owner:BAOSHAN IRON & STEEL CO LTD

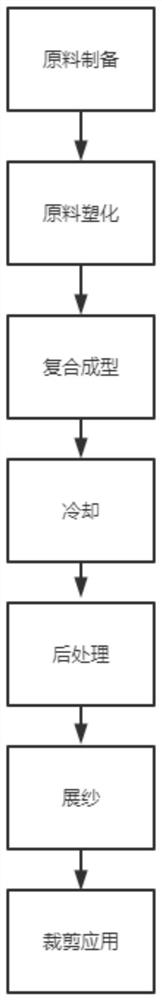

Preparation method of all-polyolefin bulletproof composite material

PendingCN114770985ASolve the problem of low bulletproof performanceLow densityFlat articlesFiberYarn

The invention relates to the technical field of material preparation, in particular to a preparation method of an all-polyolefin bulletproof composite material. Comprising the following steps: S1, preparing raw materials; s2, plasticizing the raw materials; s3, composite forming; s4, cooling; s5, carrying out post-treatment; s6, spreading the yarn; and S7, cutting application: after the prepared all-polyolefin unidirectional film is cut by a certain size, orthogonally overlapping a certain number of layers at 0 / 90 degrees, and molding in a heating mold pressing manner to obtain the all-polyolefin bulletproof composite material. The problem that a conventional UHMWPE fiber bulletproof composite material is low in bulletproof performance due to the fact that the interface cohesiveness between the PE fiber and the heterogeneous resin matrix is insufficient is solved, and the composite material is lower in density and more prominent in light weight advantage.

Owner:江苏安卡新材料科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com