Novel oil tank support manufactured based on magnesium alloy or aluminum alloy and manufacturing process of novel oil tank support

A magnesium alloy bracket and aluminum alloy bracket technology, applied in the field of automobile manufacturing, can solve the problems of fuel tank bracket structure, complex forming and installation steps, low convenience and flexibility of use, and inability to disassemble, etc., to achieve strong practicability and improved service life , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

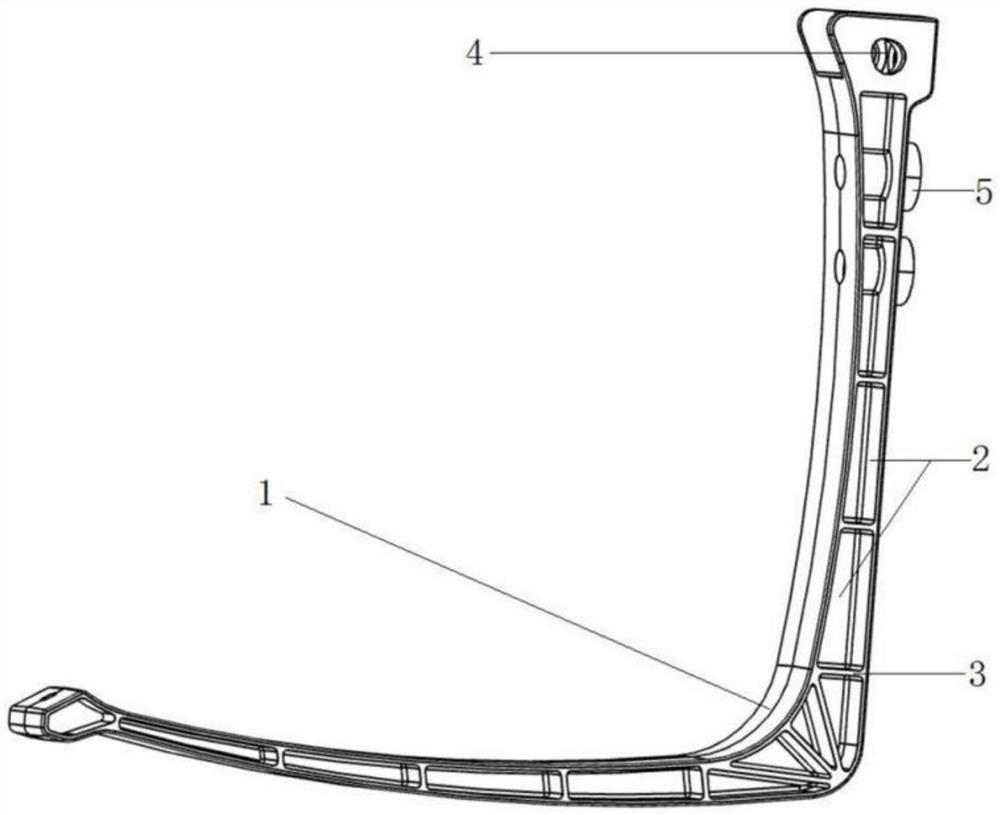

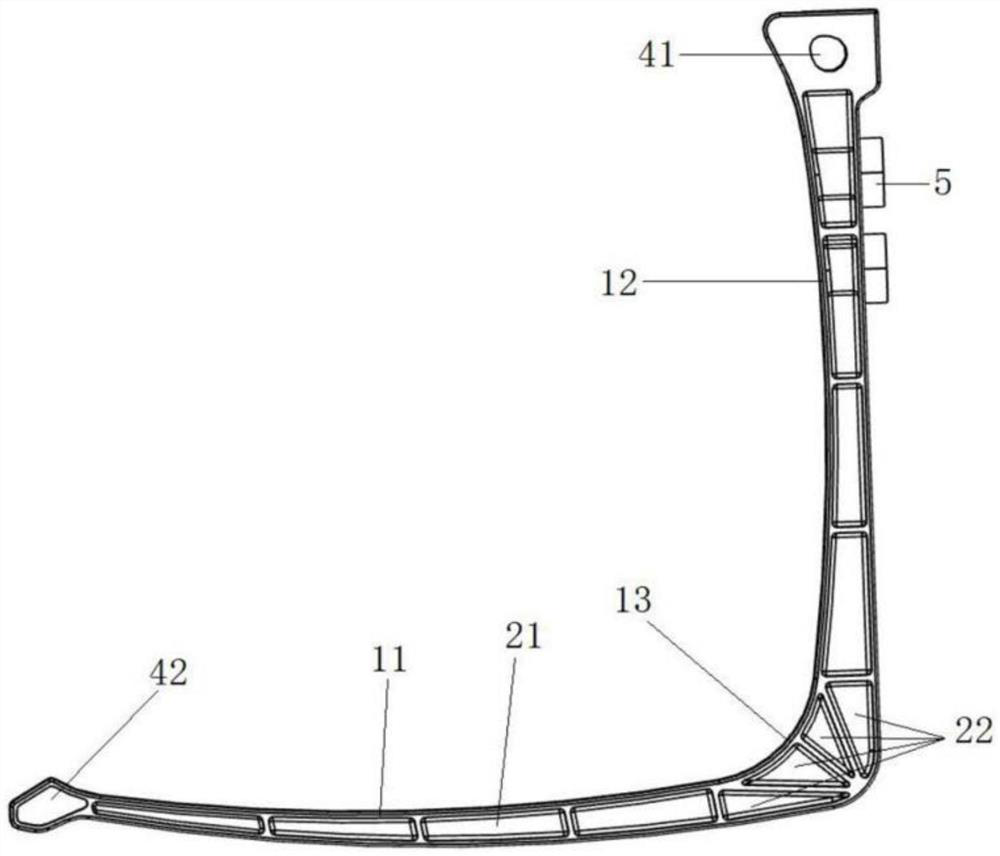

[0043] Such as Figure 2-6As shown, this embodiment provides a novel fuel tank bracket based on magnesium alloy, which includes a magnesium alloy bracket body 1 , and the magnesium alloy bracket body 1 has an inverted "L"-shaped corner structure. Both sides of the magnesium alloy bracket body 1 are dug inward to form a number of grooves 2, and reinforcing ribs 3 are formed between adjacent grooves 2, and the reinforcing ribs 3 are formed by digging inward raw materials, which not only reduces the overall weight of the bracket, Moreover, while increasing the effective cross-sectional area, the weight of the fuel tank bracket is greatly reduced; wherein, the reinforcing rib 3 is a plate-shaped reinforcing rib. Both ends of the magnesium alloy bracket body 1 are provided with sockets 4 for straps to pass through, and the straps (not shown in the figure) are used to fasten the fuel tank on the magnesium alloy bracket body 1 . The above-mentioned reinforcing ribs 3, jacks 4 and ma...

Embodiment 2

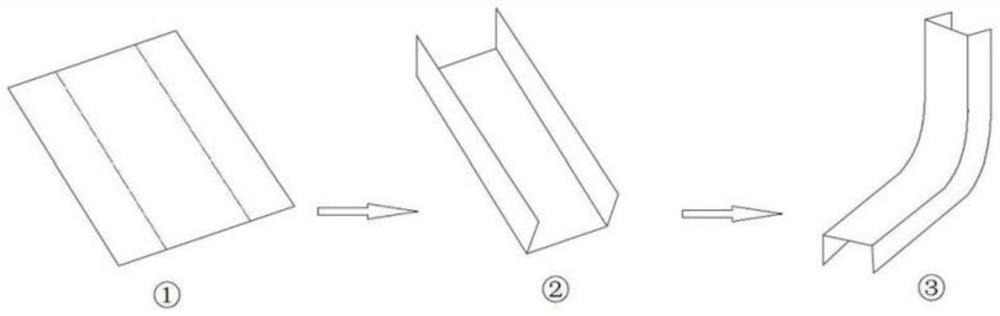

[0051] This embodiment provides a manufacturing process based on the novel fuel tank bracket described in Embodiment 1, which mainly includes the following steps:

[0052] Step S1: melting magnesium alloy granular material or magnesium ingot into liquid magnesium alloy;

[0053] Step S2: Pour the liquid magnesium alloy into the forming mold of the die-casting machine;

[0054] Step S3: Start the die-casting machine, and integrally form the magnesium alloy material into the magnesium alloy bracket body 1 through die-casting; or start the forging press, and integrally form the magnesium alloy material into the magnesium alloy bracket body by forging; the magnesium alloy bracket body 1 is Including groove 2, rib 3, socket 4 and hole 5.

[0055] Different from the traditional fuel tank bracket technology, the new fuel tank bracket made of magnesium alloy in this embodiment adopts the integrated die-casting or forging-press molding process. The pressure-bearing cross-sectional are...

Embodiment 3

[0058] This embodiment provides a new fuel tank bracket made of aluminum alloy. The difference between the new fuel tank bracket made of aluminum alloy provided in this embodiment and the new fuel tank bracket made of magnesium alloy provided by the embodiment is only that: This embodiment is based on the material of the bracket body in the new fuel tank bracket made of aluminum alloy is aluminum alloy instead of magnesium alloy. This embodiment is based on the aluminum alloy bracket body in the new fuel tank bracket made of aluminum alloy Manufactured by forging process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com