Skeleton structure of a tensioned expandable space capsule segment

A skeleton structure and space capsule technology, applied in the field of manned spaceflight, can solve problems such as difficult expansion and carrying, and large structural quality, and achieve the effects of mature processing technology, high material utilization rate, and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

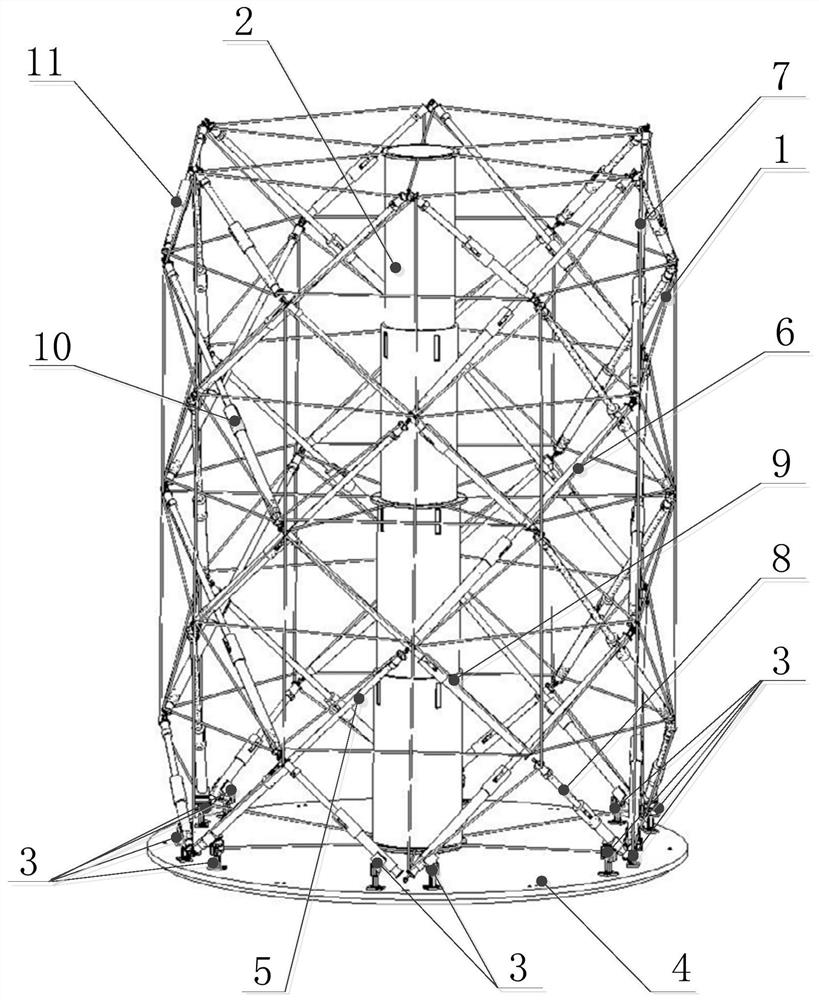

[0033] Specific implementation mode one: combine figure 1 , image 3 and Figure 4 Describe this embodiment, a tension-type expandable space capsule segment skeleton structure of this embodiment, which includes a tension overall frame structure 1, a central retractable core mechanism 2, multiple pairs of connecting frames 3 and a base 4,

[0034]The base 4 is a circular base, the central telescopic core mechanism 2 is vertically arranged at the center of the base 4, the tensegrity frame structure 1 is set on the central telescopic core mechanism 2, and multiple pairs of connecting frames 3 are evenly arranged on the base 4 Above, the tensegrity frame structure 1 is connected to the base 4 through a plurality of pairs of connecting frames 3, the axis of the tensioner frame structure 1 coincides with the axis of the central telescopic stem mechanism 2, and the tensioner frame structure 1 is composed of several The rods and several ropes form a cylindrical net-like telescopic s...

specific Embodiment approach 2

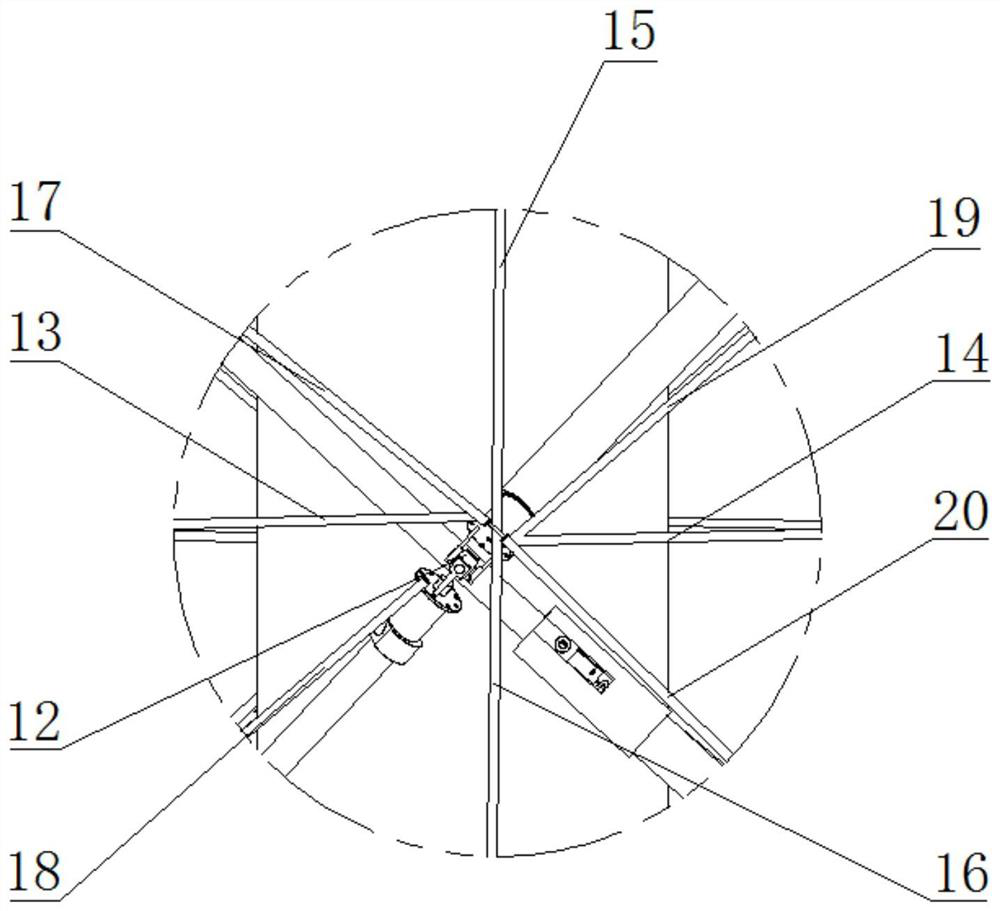

[0035] Specific implementation mode two: combination figure 2 and image 3 To illustrate this embodiment, there is a node between two adjacent rods in the tensegrity frame structure 1 of this embodiment, and a universal joint 12 is arranged at each node, and a universal joint 12 is arranged between two adjacent rods. Connected to the joints 12, the nodes of the tensegrity frame structure 1 are distributed at different levels, from bottom to top are the first layer node unit 21, the second layer node unit 22...the Nth layer node unit, two adjacent Layer node units are equally spaced in the vertical direction, and multiple nodes in each layer node unit are evenly distributed on the same circle. In this way, a universal joint 12 is arranged at each node, so that any angle can be formed between the two connected rods. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

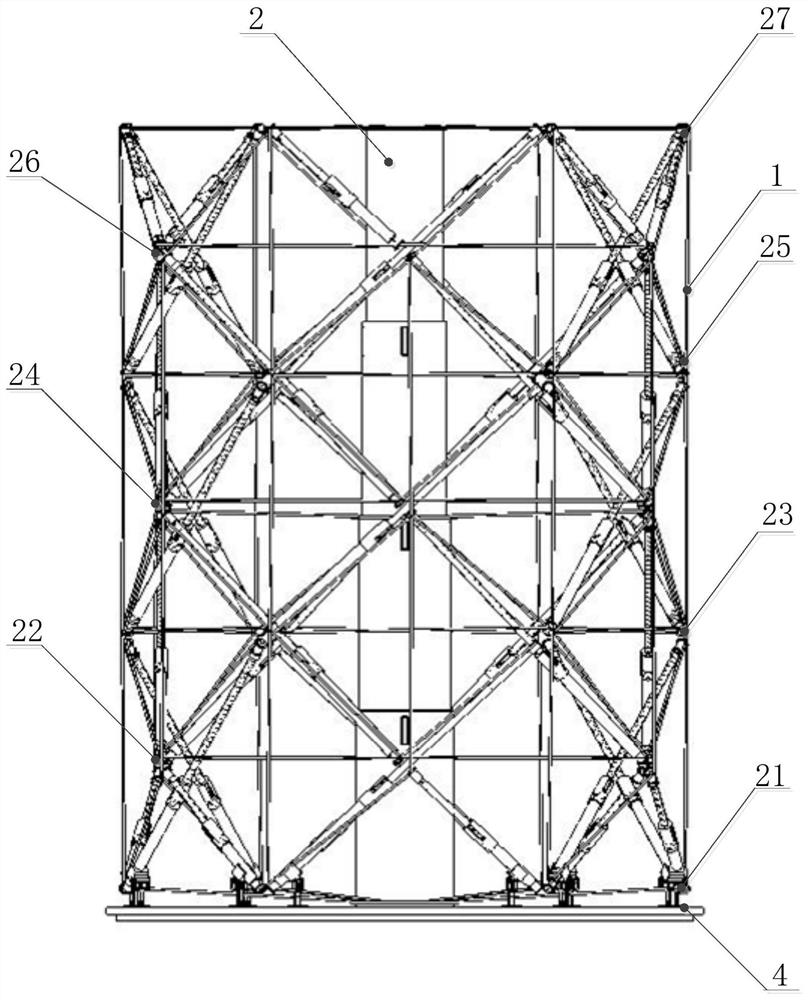

[0036] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, there are 42 nodes in the tensegrity frame structure 1 of this embodiment, and the nodes of the tensegrity frame structure 1 are distributed on 7 different levels, and from bottom to top are the first layer of node units 21 , the second layer node unit 22, the third layer node unit 23, the fourth layer node unit 24, the fifth layer node unit 25, the sixth layer node unit 26 and the seventh layer node unit 27, in each layer node unit The six nodes are evenly distributed on the same circle, and the central angle corresponding to the adjacent nodes is 60°;

[0037] The rods of the tensegrity frame structure 1 include multiple long rods and multiple short rods with the same structure and different lengths. Starting from a node in the node unit 21 of the first layer, the three long rods are inclined counterclockwise upward along the circumferential direction. Arrangement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com