al 2 Ca particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium matrix composite material and preparation method

A technology of carbon nanotubes and composite materials, applied in metal material coating technology, liquid chemical plating, coating, etc., can solve problems such as low strength of magnesium-lithium binary alloys, poor stability of alloy structure and performance, and overaging , to achieve excellent lightweight advantages, improve the bonding situation, and the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

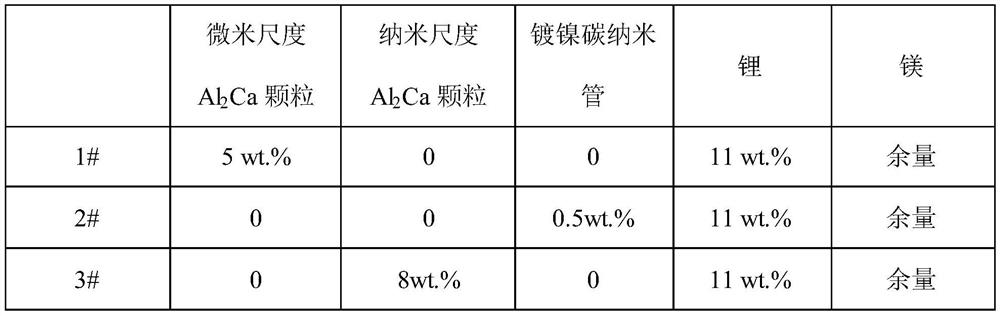

Image

Examples

Embodiment 1

[0026] an Al 2 Ca particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium-based composite containing the following components in weight percent: 5 wt % micron-scale Al 2 Ca particles, 1 wt% submicron-scale Al 2 Ca particles, 0.5 wt % of nickel-plated carbon nanotubes, 11 wt % of Li, the balance being Mg, and the total amount of impurity elements Si, Fe, Cu and Ni less than 0.02 wt %. Microscale Al 2 The particle size of the Ca particles is 5 to 30 μm. Submicron scale Al 2 The particle size of the Ca particles is 0.01 to 5 μm. The carbon nanotubes are single-walled or multi-walled carbon nanotubes with an aspect ratio greater than 20.

[0027] The Al 2 The preparation method of Ca particles and carbon nanotubes hybrid reinforced ultra-light magnesium-lithium matrix composites is as follows:

[0028] The first step is to convert the micron / submicron scale Al 2 The Ca particles are mixed with magnesium powder, and after mixing, they are ball-milled in...

Embodiment 2

[0033] an Al 2 Ca particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium-based composite containing the following components in weight percent: 10 wt % of micron-scale Al 2 Ca particles, 3wt% submicron-scale Al 2 Ca particles, 1 wt % of nickel-coated carbon nanotubes, 16 wt % of Li, the balance being Mg, and the total amount of impurity elements Si, Fe, Cu and Ni less than 0.02 wt %. Microscale Al 2 The particle size of the Ca particles is 5 to 30 μm. Submicron scale Al 2 The particle size of the Ca particles is 0.01 to 5 μm. The carbon nanotubes are single-walled or multi-walled carbon nanotubes with an aspect ratio greater than 20.

[0034] The Al 2 The preparation method of Ca particles and carbon nanotubes hybrid reinforced ultra-light magnesium-lithium matrix composites is as follows:

[0035] The first step is to convert the micron / submicron scale Al 2 The Ca particles are mixed with magnesium powder, and after mixing, they are ball-milled in ...

Embodiment 3

[0040] an Al 2 Ca particle and carbon nanotube hybrid reinforced ultra-light magnesium-lithium-based composite containing the following components in weight percent: 20 wt % of micron-scale Al 2 Ca particles, 5wt% submicron-scale Al 2 Ca particles, 3 wt % of nickel-plated carbon nanotubes, 25 wt % of Li, the balance being Mg, and the total amount of impurity elements Si, Fe, Cu and Ni less than 0.02 wt %. Microscale Al 2 The particle size of the Ca particles is 5 to 30 μm. Submicron scale Al 2 The particle size of the Ca particles is 0.01 to 5 μm. The carbon nanotubes are single-walled or multi-walled carbon nanotubes with an aspect ratio greater than 20.

[0041] The Al 2 The preparation method of Ca particles and carbon nanotubes hybrid reinforced ultra-light magnesium-lithium matrix composites is as follows:

[0042] The first step is to convert the micron / submicron scale Al 2 The Ca particles are mixed with magnesium powder, and after mixing, they are ball-milled i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com