A sliding oblique insertion type single-leaf sliding door mechanism for passenger cars

An oblique insertion and sliding technology, which is applied in the direction of the wing leaf control mechanism, power control mechanism, door, etc., can solve the high assembly precision requirements of the plug door mechanism, poor lightweight effect, and reduce the degree of freedom in the design of the air duct section and other issues, to achieve the effect of obvious advantages in light weight, improve design freedom, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

[0049] The invention is a sliding oblique insertion type single-leaf plug door mechanism with a new mechanism design, which can realize the action posture of "translational sliding + oblique insertion + pulling back and locking".

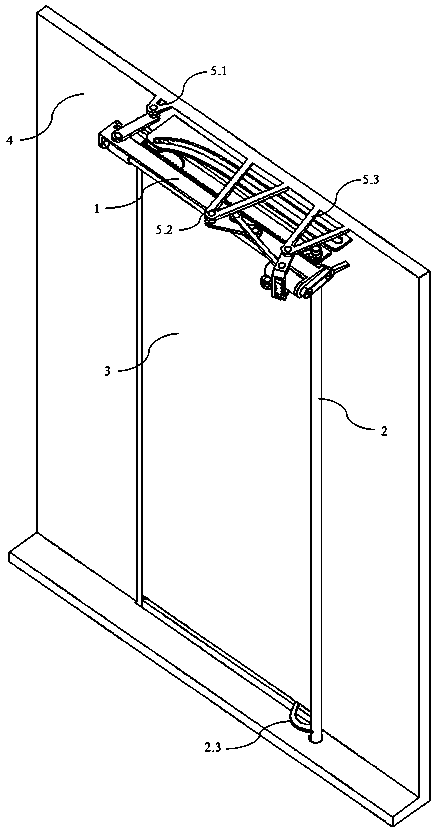

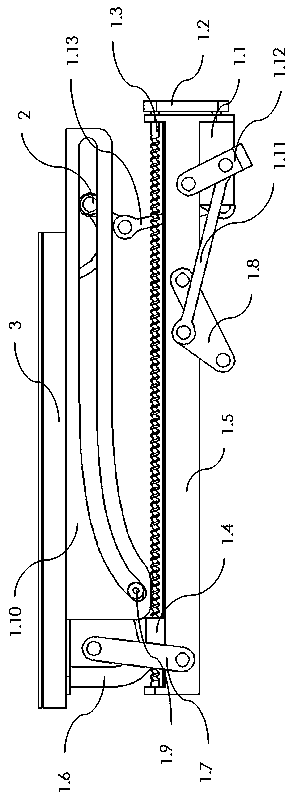

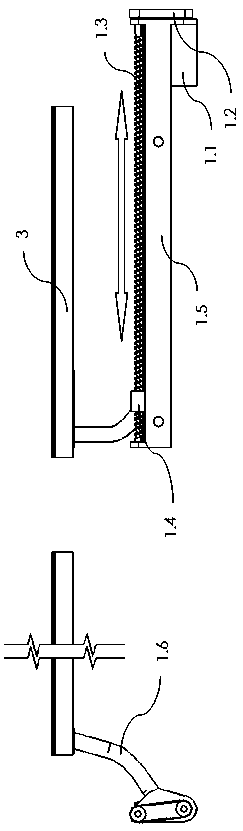

[0050] Such as figure 1 As shown, the present invention includes a driving actuator 1, a fixed-track door shaft 2, a passenger door body 3 and a body side wall 4, wherein the driving actuator 1 is responsible for carrying the passenger door body 3, leading to complete the "passenger door body 3" Translational sliding + oblique insertion + pull back to lock” posture; the fixed track door shaft 2 is responsible for limiting the rotational freedom of the passenger door body 3 along the X direction of the vehicle body, and assists the driving actuator 1 to complete the passenger door action posture. Under the state, be responsible for further t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com