Preparation method of all-polyolefin bulletproof composite material

A bulletproof composite material, polyolefin technology, applied in the direction of flat products, household appliances, other household appliances, etc., can solve the problems of insufficient interface adhesion, low density, low ballistic performance, etc., and achieve outstanding lightweight advantages and low density. , The effect of excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

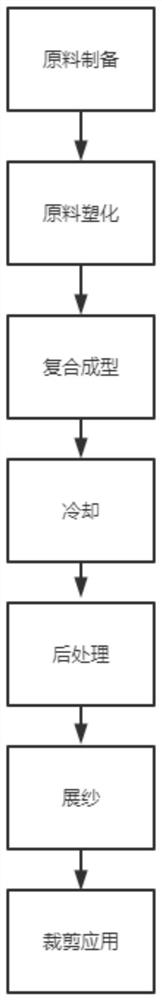

[0033] like Figure 1-2 As shown, a preparation method of an all-polyolefin bulletproof composite material comprises the following steps:

[0034] S1, raw material preparation, the raw materials include material A and material B, wherein material A is a mixed solution of paraffin oil added with UHMWPE, and material B is thermoplastic polyolefin resin; the composite mass ratio of material A and material B is preferably 90:10 -98:2,

[0035] S2, plasticizing the raw material, adding material A into the twin-screw extruder, dissolving and plasticizing in the twin-screw extruder uniformly, to obtain material C; adding material B into the single-screw extruder, and extruding it in the single-screw extruder Dissolve and plasticize evenly in the machine to obtain D material;

[0036] S3, compound molding, the C material extruded from the twin-screw extruder and the D material extruded from the single-screw extruder enter the compound spinning die to prepare the UHMWPE / thermoplastic...

Embodiment 2

[0042] like Figure 1-2 As shown, a preparation method of an all-polyolefin bulletproof composite material comprises the following steps:

[0043] S1, raw material preparation, the raw materials include material A and material B, wherein material A is a mixed solution of paraffin oil added with UHMWPE, and material B is thermoplastic polyolefin resin; the composite mass ratio of material A and material B is preferably 90:10 -98:2,

[0044] The thermoplastic polyolefin resin is a mixture of polyethylene, polypropylene, polybutene, PE-PP copolymer, PE-PB copolymer and PP-PB copolymer,

[0045] S2, plasticizing the raw material, adding material A into the twin-screw extruder, dissolving and plasticizing in the twin-screw extruder uniformly, to obtain material C; adding material B into the single-screw extruder, and extruding it in the single-screw extruder Dissolve and plasticize evenly in the machine to obtain D material;

[0046] S3, compound molding, the C material extruded...

Embodiment 3

[0055] like Figure 1-2 As shown, a preparation method of an all-polyolefin bulletproof composite material comprises the following steps:

[0056] S1, raw material preparation, the raw materials include material A and material B, wherein material A is a mixed solution of paraffin oil added with UHMWPE, material B is thermoplastic polyolefin resin; the composite mass ratio of material A and material B is preferably 90:10 -98:2,

[0057] The thermoplastic polyolefin resin is a mixture of polyethylene, polypropylene, polybutene, PE-PP copolymer, PE-PB copolymer and PP-PB copolymer,

[0058] S2, plasticizing the raw material, adding material A into the twin-screw extruder, dissolving and plasticizing uniformly in the twin-screw extruder to obtain material C; adding material B into the single-screw extruder, and extruding it in the single-screw extruder Dissolve and plasticize evenly in the machine to obtain D material;

[0059] S3, compound molding, the C material extruded in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com