AlSiLi phase aging strengthening type low-density aluminum alloy and preparation method thereof

A technology of aging strengthening and aluminum alloy, which is applied in the direction of additive manufacturing, energy efficiency improvement, process efficiency improvement, etc., can solve the problems that aluminum alloy strengthening and light weight cannot be combined, and achieve the effect of obvious advantages in light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

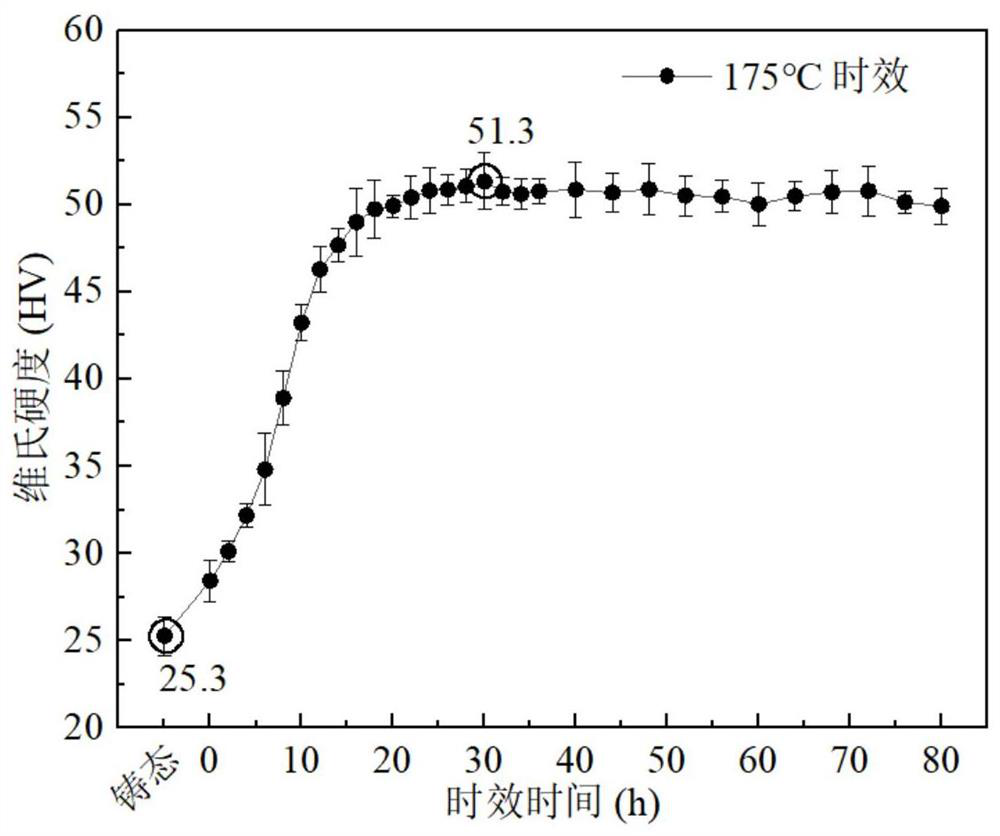

[0060] Example 1: Al-Si-Li ternary aluminum alloy and its preparation and processing

[0061] In the inventive aluminum alloy of this example, the content of alloying elements added to Al is shown in Table 1, and the preparation method is: die casting → high temperature solid solution → single-stage aging heat treatment.

[0062] The first step of die casting: According to the ratio of raw materials in Table 1, Si and Li are added in the form of Al-20Si and Al-10Li master alloys respectively. Put the prepared raw materials into the crucible and melt in the vacuum induction melting furnace. After evacuating, argon protection is introduced, the temperature is raised to 720-750°C and kept for 10-20 minutes, and commercial aluminum alloy refining agent C is added. 2 Cl 6 Refining for 5-10 minutes. The melt was then purified using a commercial rotary degassing technique and maintained at a temperature of 680-700 °C. The alloy melt is injected into the pressure chamber of the di...

Embodiment 2

[0069] Example 2: Al-Si-Li-based quaternary aluminum alloy and its preparation and processing

[0070] In the inventive aluminum alloy of this example, the content of alloying elements added to Al is shown in Table 2, and the preparation method is: casting → high temperature solid solution → extrusion → double-stage aging heat treatment.

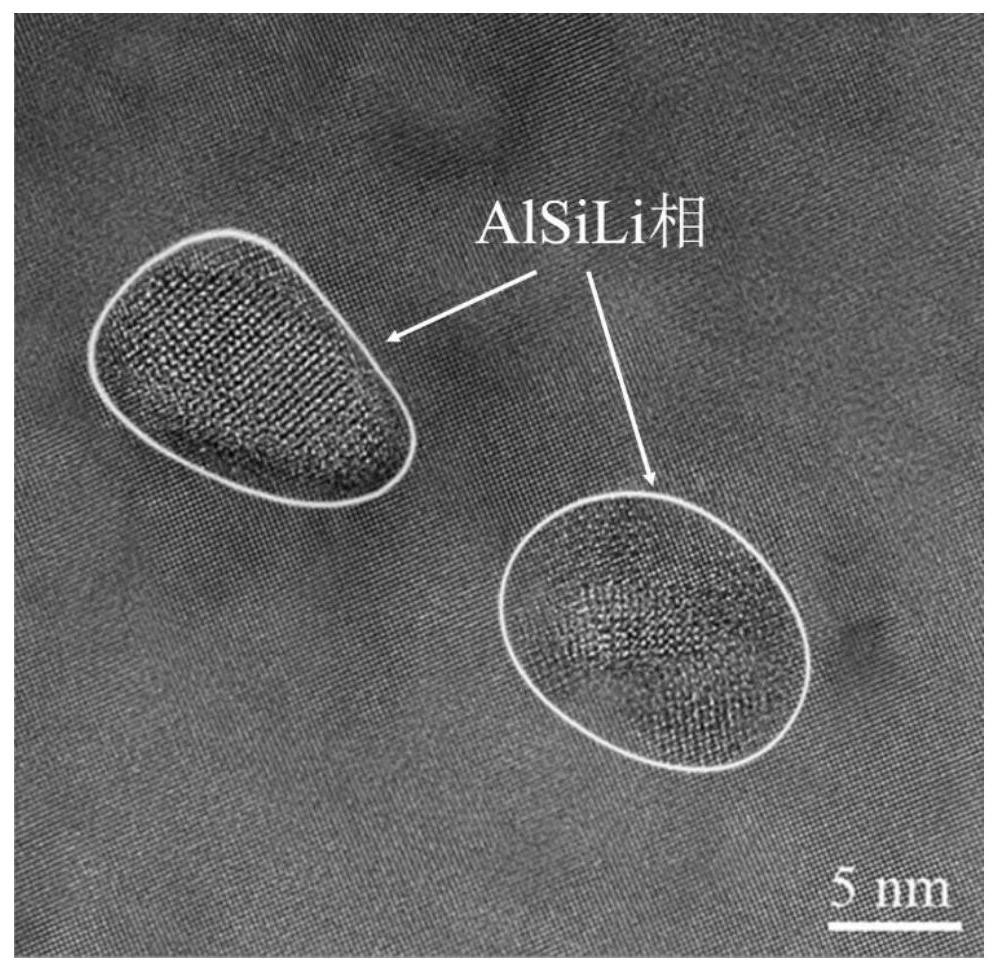

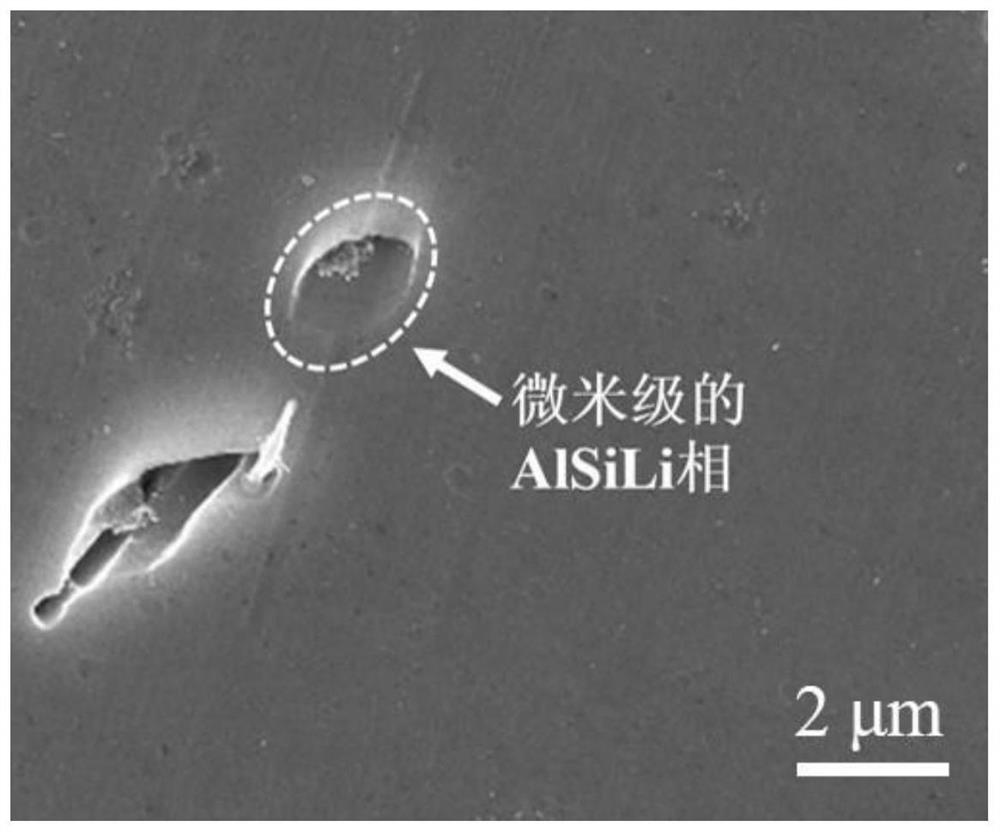

[0071] The first step of casting: According to the ratio of raw materials in Table 2, Si and Li are added in the form of Al-10Si and Al-5Li master alloys respectively. Put the prepared raw materials into the crucible and melt in the vacuum induction melting furnace. After evacuating, argon protection is introduced, the temperature is raised to 750-770°C and kept for 10-20 minutes, and the commercial aluminum alloy refining agent CCl is added 4 Refining for 10-15 minutes. Then, the alloy melt was poured into a graphite mold and cooled to room temperature to obtain an ingot containing micron-sized AlSiLi phases.

[0072] The second step is ...

Embodiment 3

[0078] Embodiment 3: Al-Si-Li-based multi-element aluminum alloy and rolling aging thereof

[0079] In the inventive aluminum alloy of this example, the content of alloying elements added to Al is shown in Table 3, and the preparation method is: casting → high temperature solid solution → cumulative stack rolling → single-stage aging heat treatment → cryogenic rolling → double-stage Aging heat treatment.

[0080] The first step of casting: According to the ratio of raw materials in Table 3, Si and Li are added in the form of Al-10Si and Al-10Li master alloys respectively. Put the prepared raw materials into the crucible and melt in the vacuum induction melting furnace. After evacuating, put in argon protection, raise the temperature to 700-760°C and keep it warm for 10-15 minutes, then add commercial aluminum alloy refining agent C 2 Cl 6 Refining for 5-15 minutes. Then, the alloy melt was poured into a graphite mold and cooled to room temperature. Observation by scanning...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com