Patents

Literature

37results about How to "Significant aging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

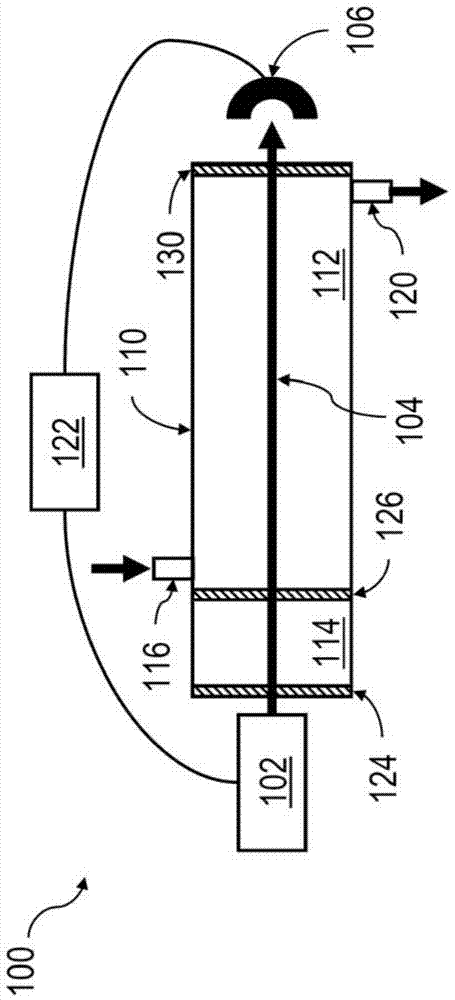

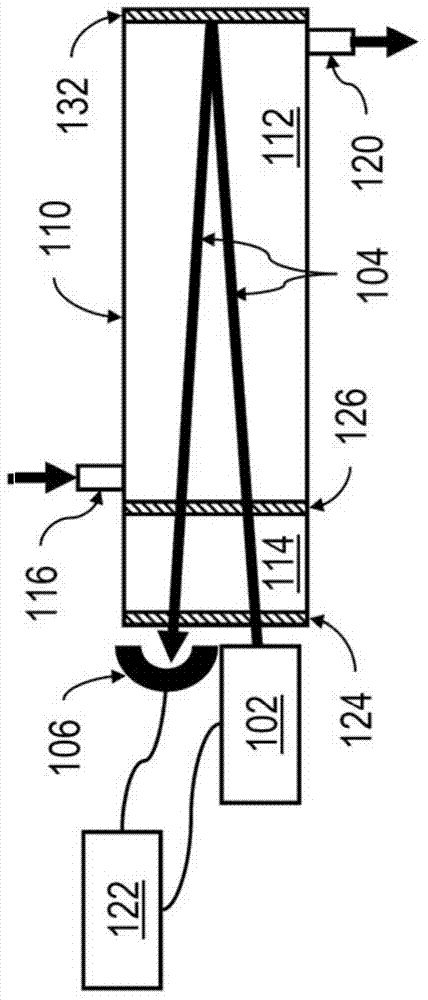

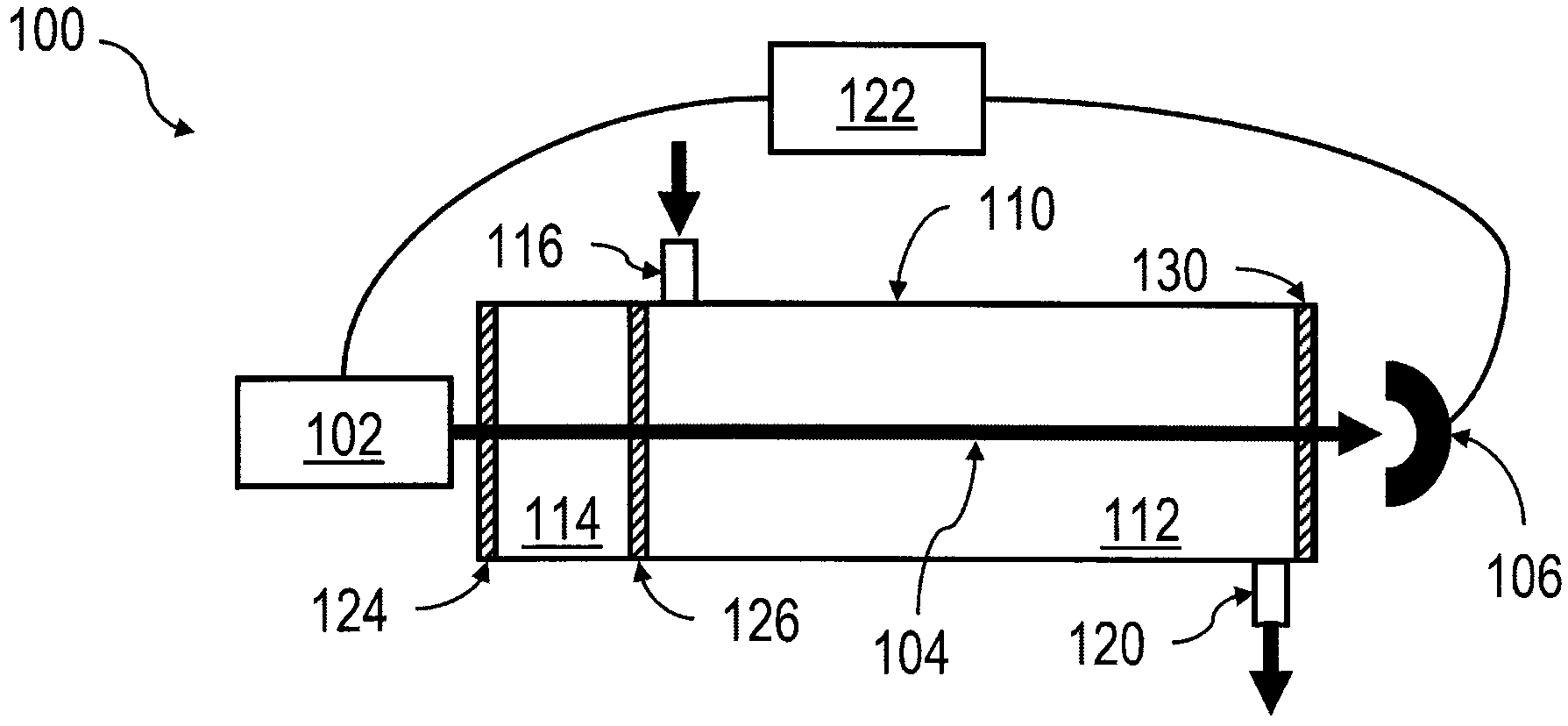

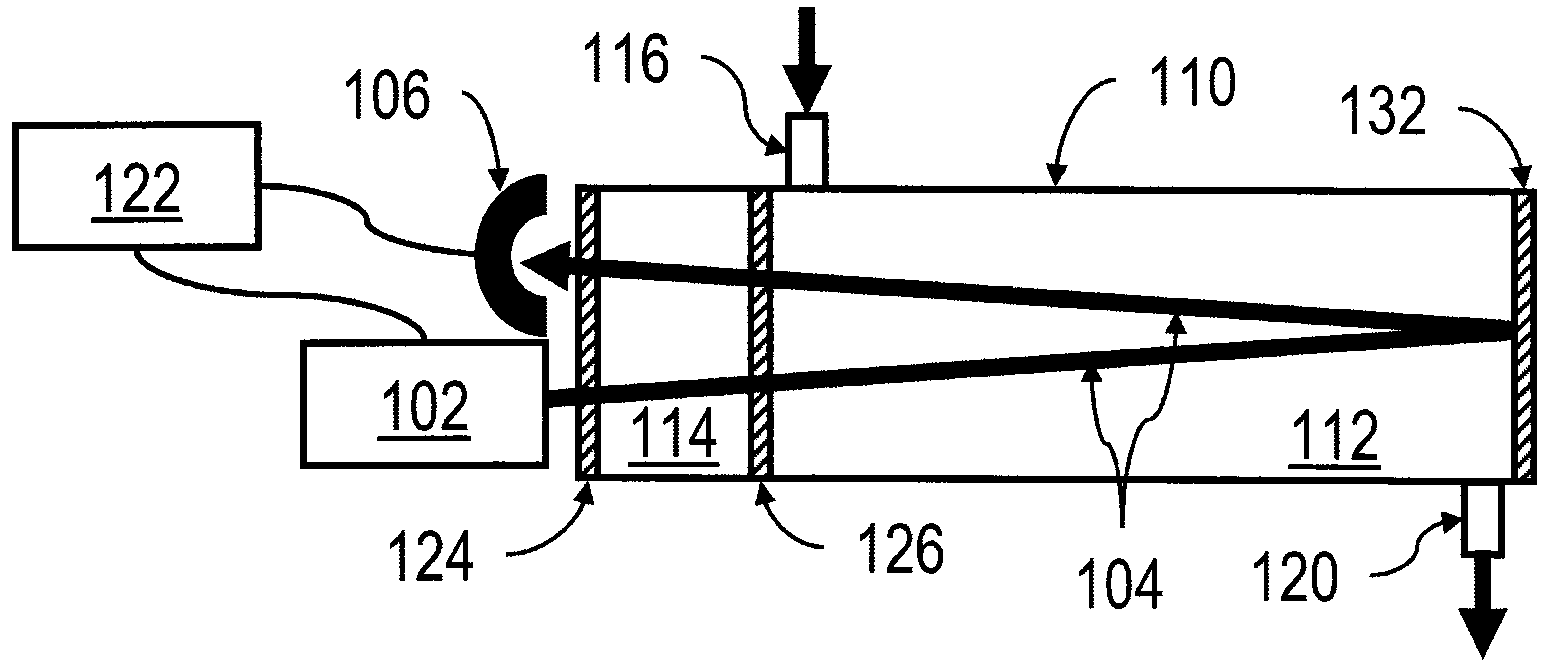

Spectrometer with validation cell

ActiveCN104215579AEliminate shelf life issuesEliminate Mixing Related IssuesAbsorption/flicker/reflection spectroscopyColor/spectral properties measurementsGas analysisTarget analysis

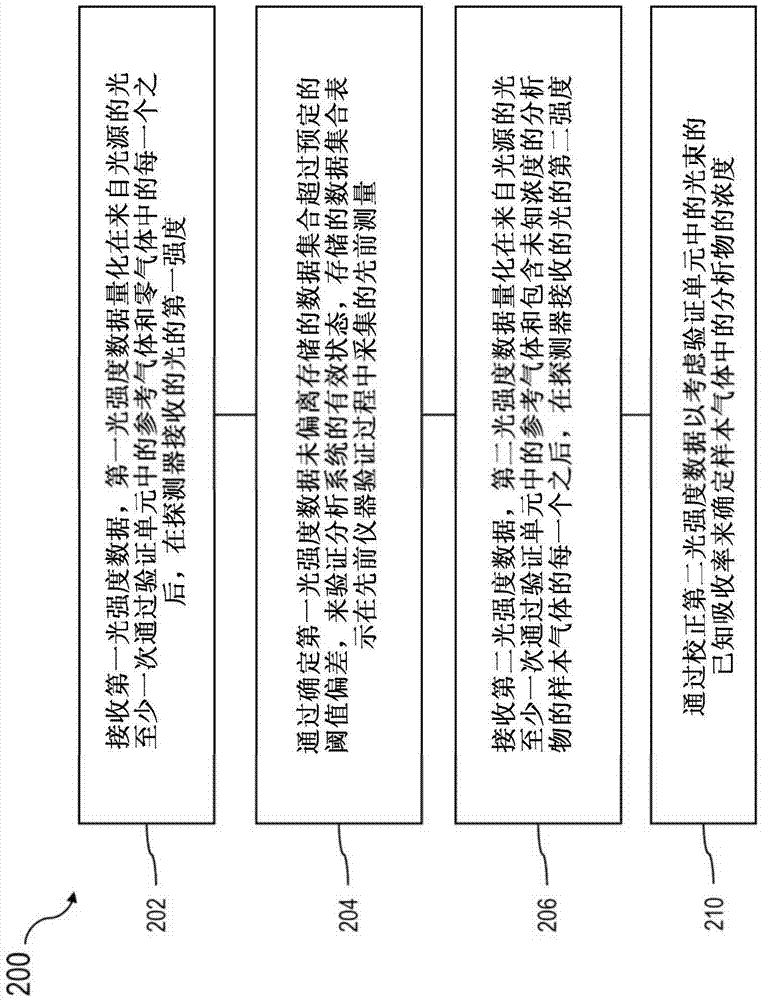

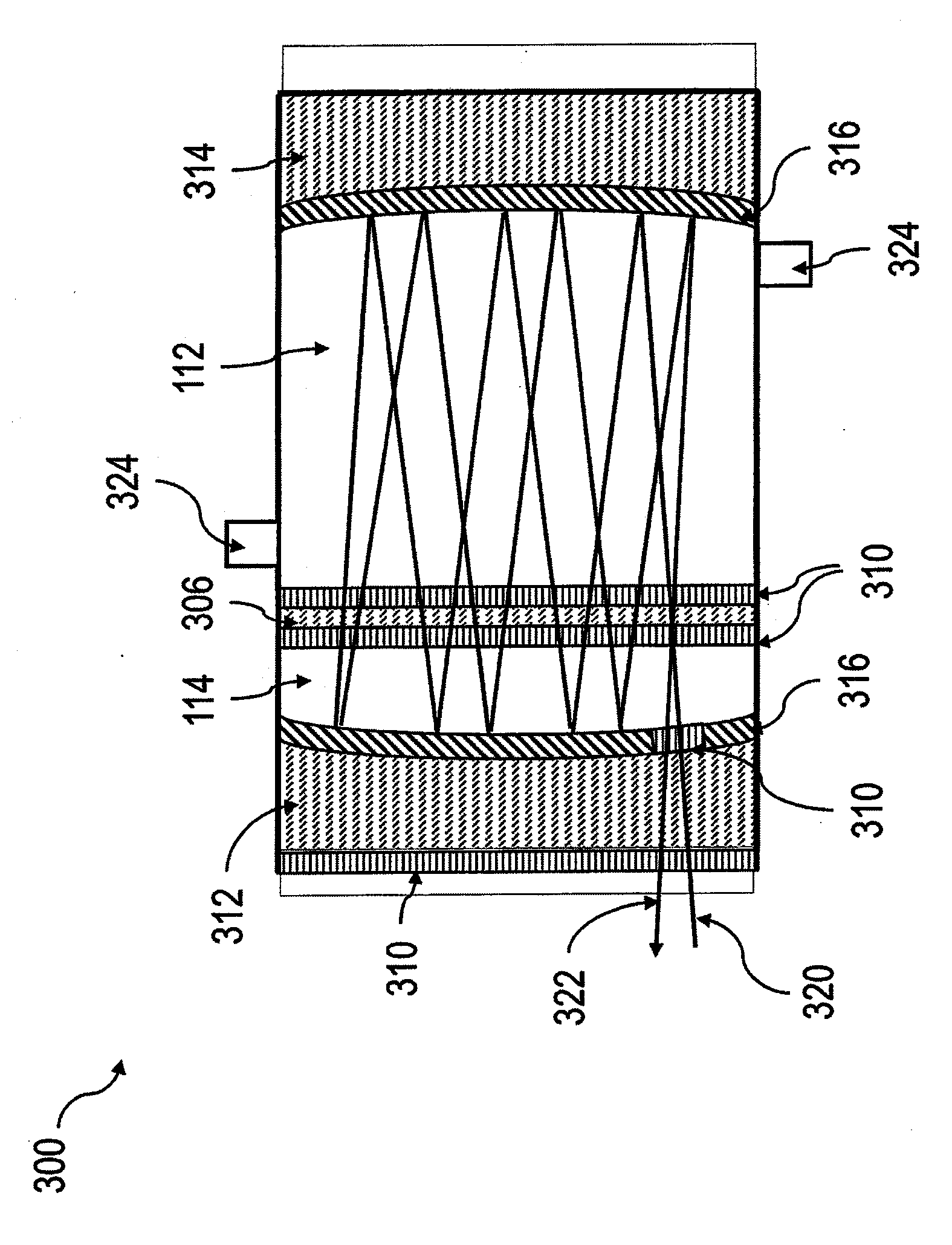

A valid state of an analytical system that includes a light source and a detector can be verified by determining that deviation of first light intensity data quantifying a first intensity of light received at the detector from the light source after the light has passed at least once through each of a reference gas in a validation cell and a zero gas from a stored data set does not exceed a pre-defined threshold deviation. The stored data set can represent at least one previous measurement collected during a previous instrument validation process performed on the analytical system. The reference gas can include a known amount of an analyte. A concentration of the analyte in a sample gas can be determined by correcting second light intensity data quantifying a second intensity of the light received at the detector after the light passes at least once through each of the reference gas in the validation cell and a sample gas containing an unknown concentration of the analyte compound. Related systems, methods, and articles of manufacture are also described.

Owner:ENDRESS + HAUSER OPTICAL ANALYSIS INC

Spectrometer with validation cell

ActiveCN102656441AEliminate shelf life issuesEliminate Mixing Related IssuesTransmissivity measurementsAbsorption/flicker/reflection spectroscopyAnalyteData set

A valid state of an analytical system that includes a light source and a detector can be verified by determining that deviation of first light intensity data quantifying a first intensity of light received at the detector from the light source after the light has passed at least once through each of a reference gas in a validation cell and a zero gas from a stored data set does not exceed a pre-defined threshold deviation. The stored data set can represent at least one previous measurement collected during a previous instrument validation process performed on the analytical system. The reference gas can include a known amount of an analyte. A concentration of the analyte in a sample gas in a measurement cell can be determined by correcting second light intensity data quantifying a second intensity of the light received at the detector after the light passes at least once through each of the reference gas in the validation cell and a sample gas containing an unknown concentration of the analyte compound. Related systems, methods, and articles of manufacture are also described.

Owner:ENDRESS + HAUSER OPTICAL ANALYSIS INC

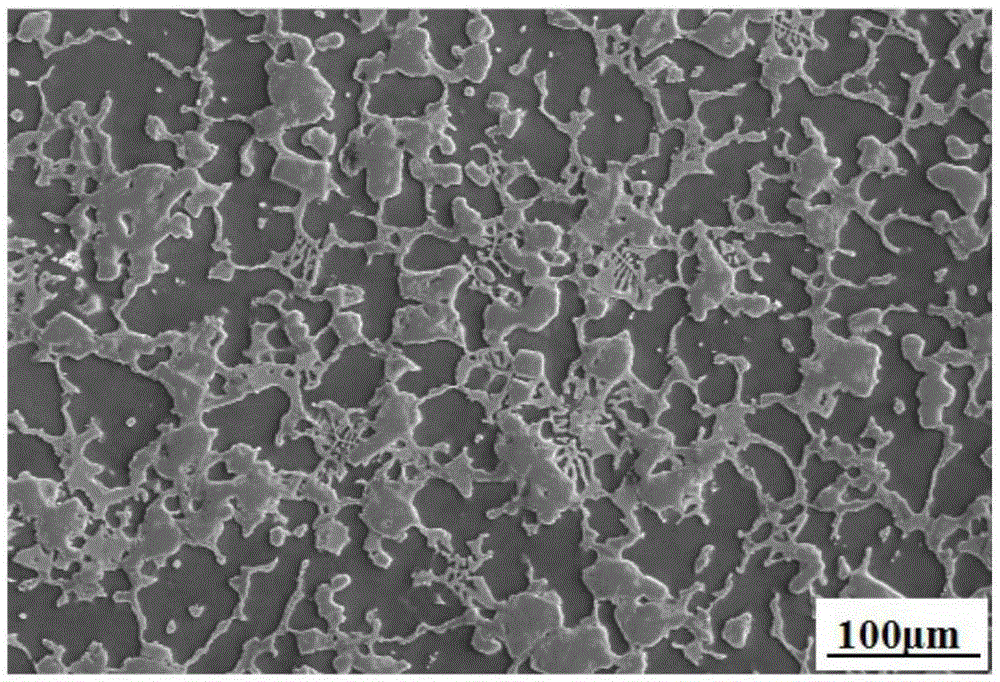

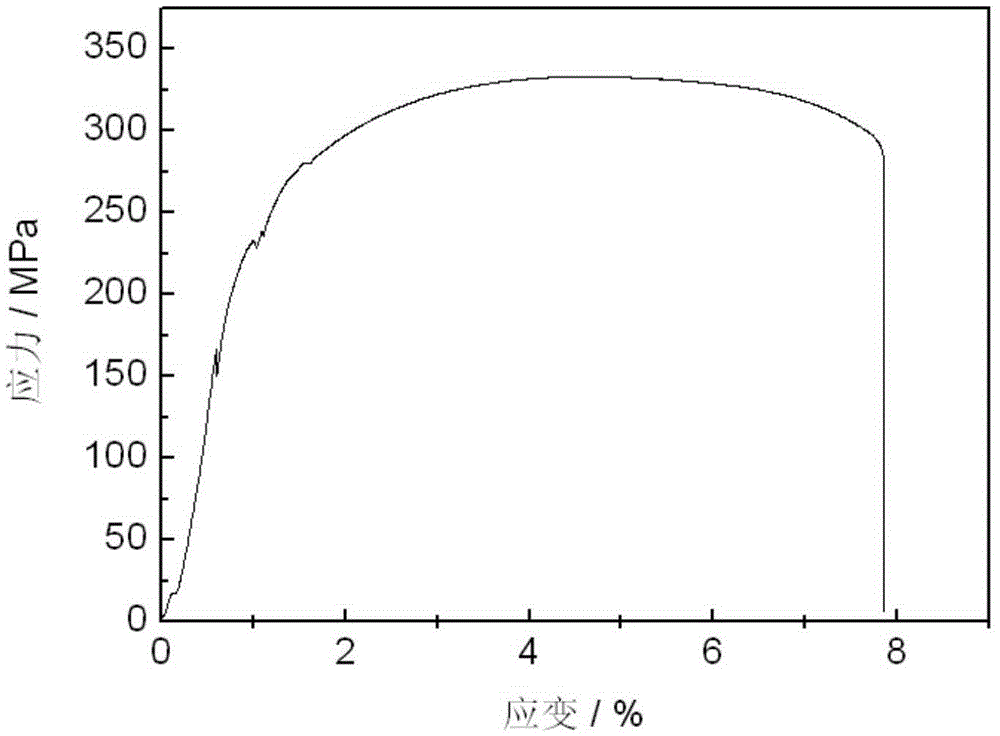

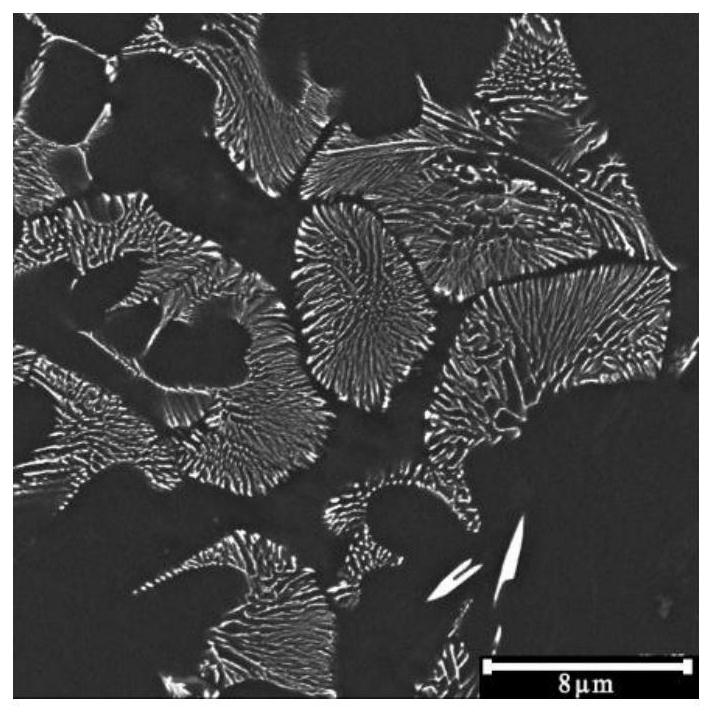

Heated and reinforced high-strength cast magnesium alloy and preparation method thereof

The invention provides a heated and reinforced high-strength cast magnesium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 8.0-10.0 of Zn, 1.0-5.0 of Al, 1.0-5.0 of Sn, 0.1-1.0 of Cu, 0.3-0.8 of Mn, 0.3-0.5 of Ca, and the balance of Mg and inevitable impurity elements. According to the high-strength cast magnesium alloy, under a room-temperature stretch test, the tensile strength reaches 320-350 MPa, and the yield strength reaches 220-260 MPa. A heat treatment process of the magnesium alloy comprises solution treatment by 4-8 hours at a temperature of 330-380 DEG C, air cooling, aging by 8-16 hours at a temperature of 150-220 DEG C and obtaining of the high-strength cast magnesium alloy. The heat treatment process of the alloy is simple and easy to realize; and the aging treatment can form a lot of nanoscale strengthening phases in an alloy structure, so that the alloy strength can be prominently improved. The alloy contains no such noble metal as rare earth, and is an alloy system with low cost and wide applicability.

Owner:山东山科智镁新材料科技有限公司

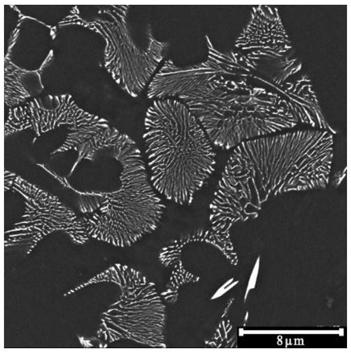

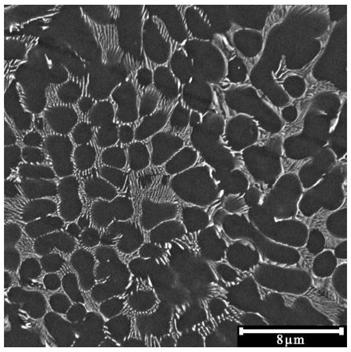

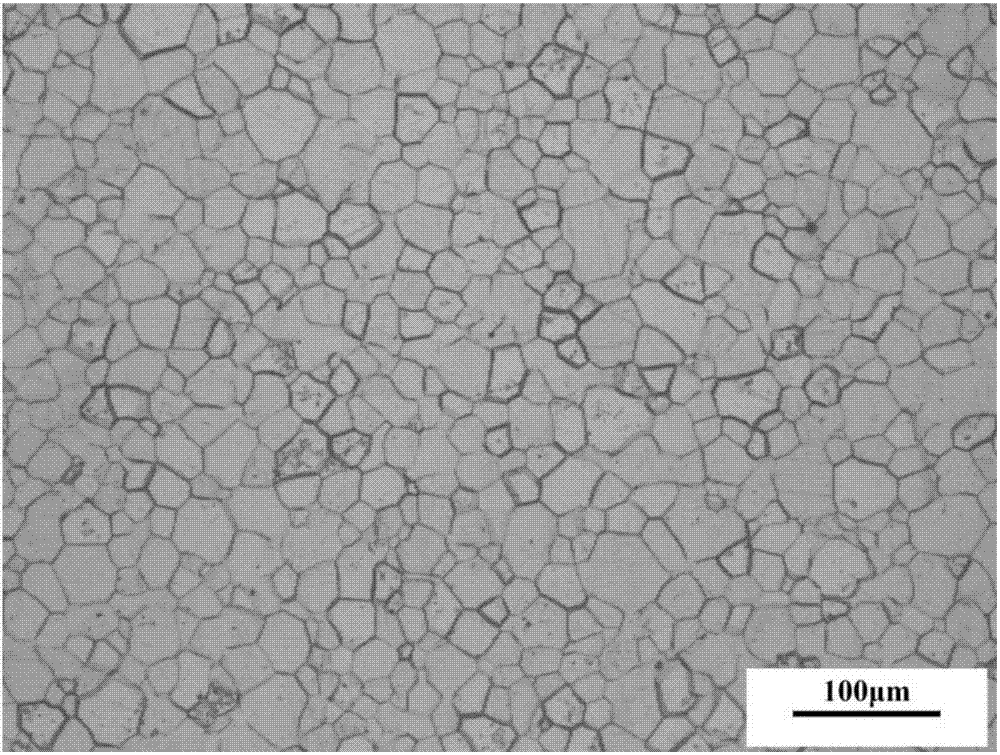

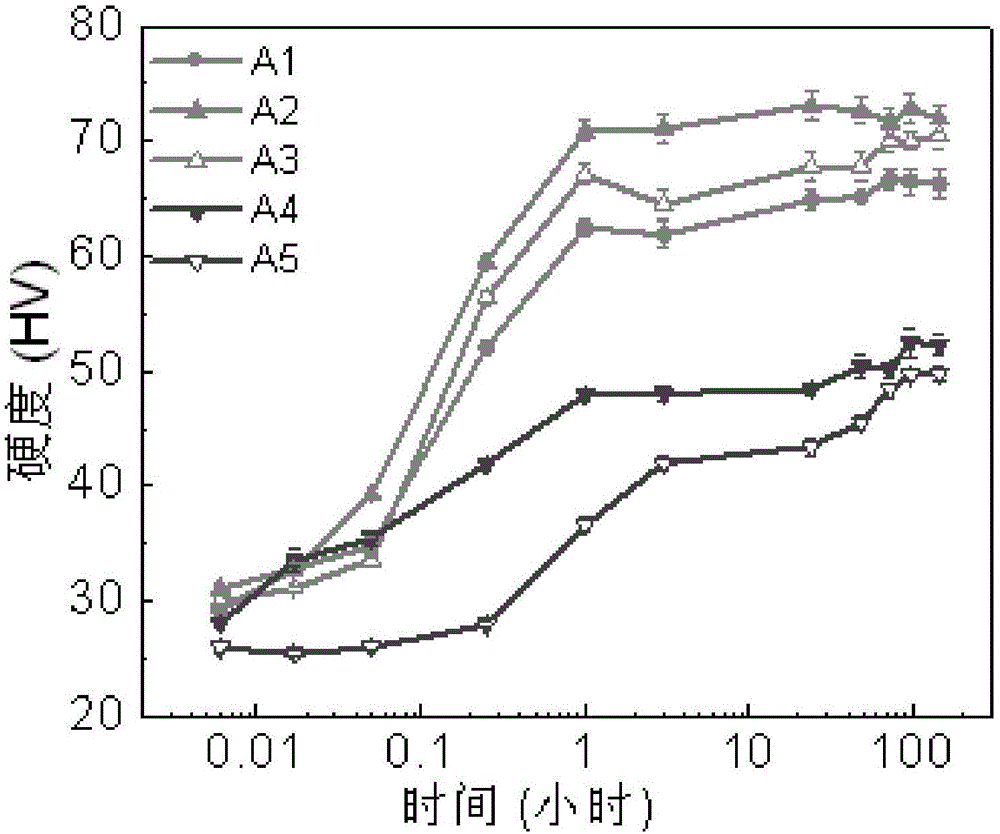

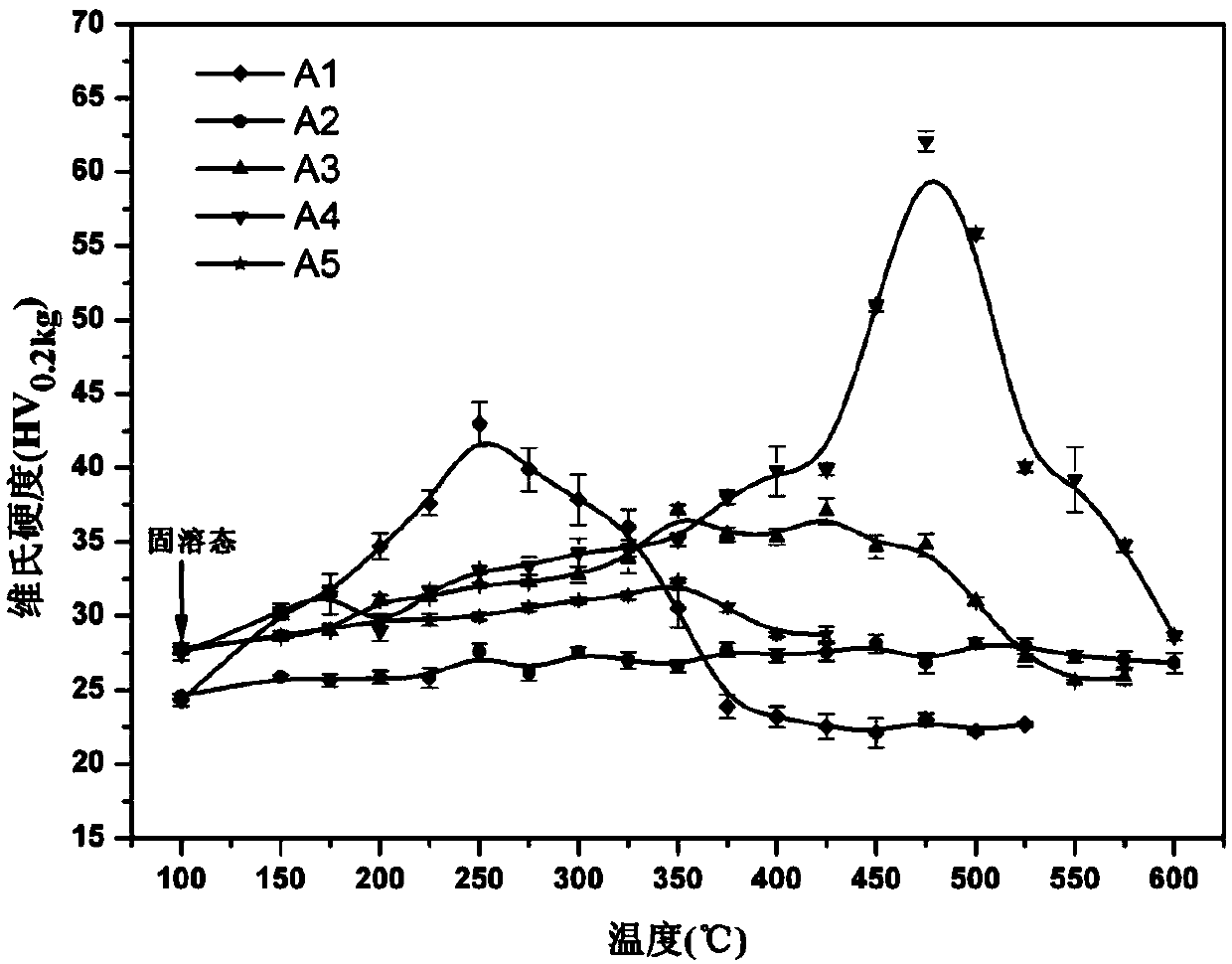

Al-Yb-Zr heatproof aluminium alloy and its heat treatment technology

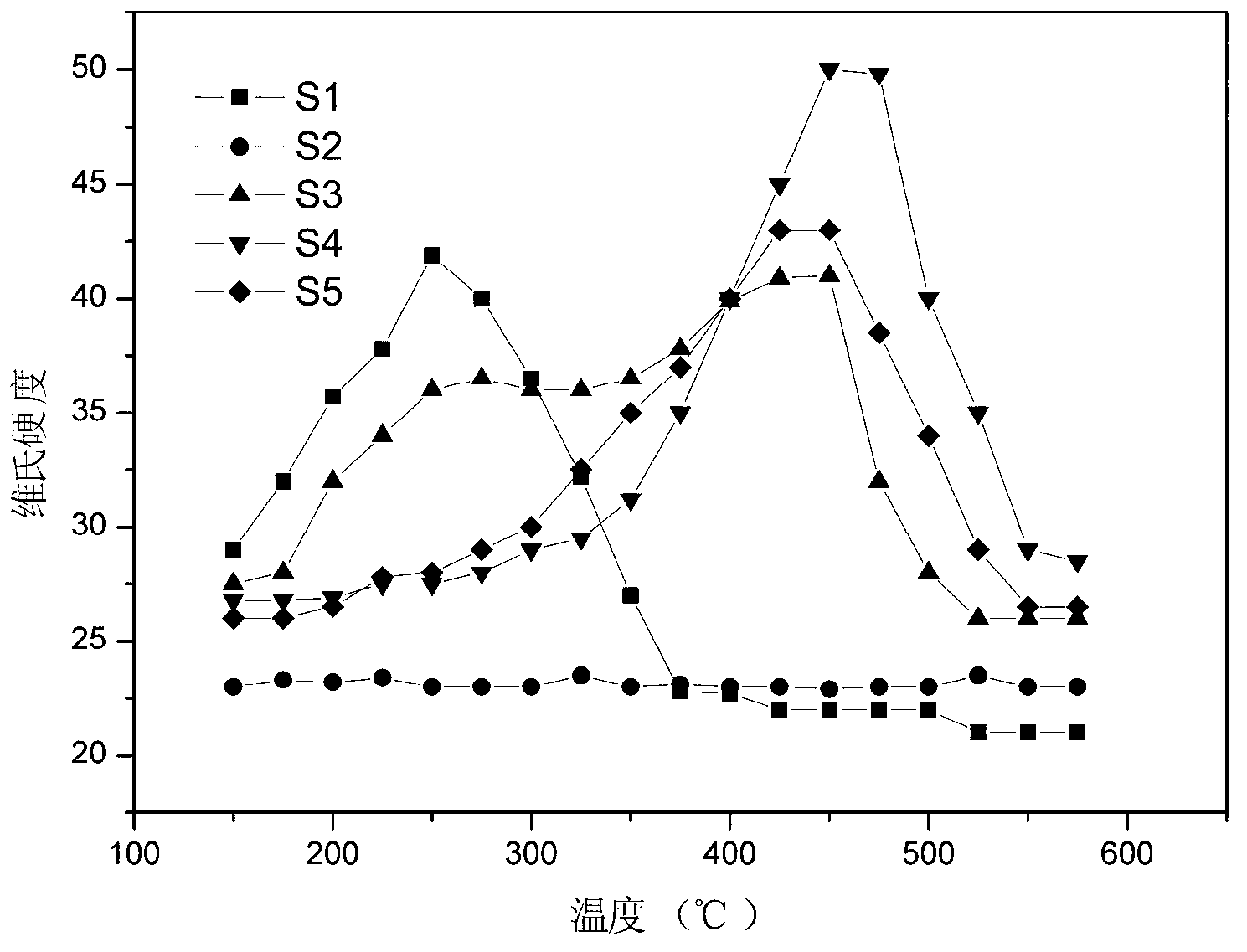

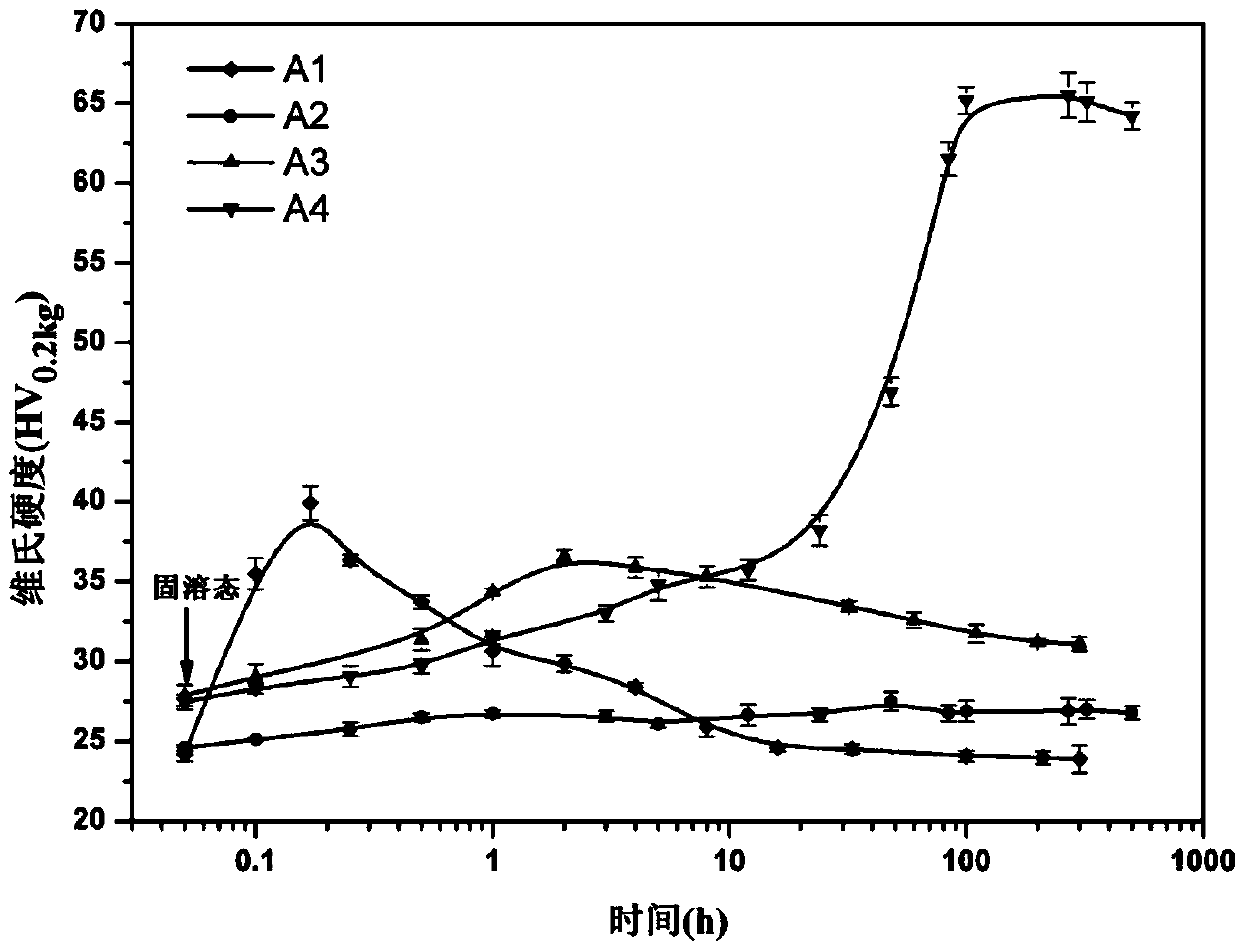

An Al-Yb-Zr heatproof aluminium alloy and its heat treatment technology belong to the technical field of alloy. 0.07-0.25 wt% of Yb, 0.15-0.3 wt% of Zr and other unavoidable impurities are added into an aluminium matrix. A solid solution and ageing heat treatment process of the alloy comprises the following steps: firstly carrying out solid solution at 620+ / -10 DEG C for 20-30 h, carrying out water quenching to room temperature, and carrying out isochronic ageing every 25 DEG C within 150-575 DEG C for 3 h. By Yb / Zr composite microalloying, the alloy provided by the invention has a very prominent ageing strengthening effect. In comparison with an Al-Er alloy, ageing strengthening effect and heat stability of the alloy are raised; in comparison with an Al-Zr alloy, the ageing precipitation process is obviously accelerated; and the alloy has good heat stability.

Owner:BEIJING UNIV OF TECH

Extrusion casting magnesium alloy material and preparation method thereof

The invention belongs to the field of structural metallic materials, and particularly relates to an extrusion casting magnesium alloy material and a preparation method thereof. The material is prepared from the following elements in percentage by mass: a% of Al, b% of one or more of La, Ce and Pr, c% of Mn, d% in total of one or more of RE rare earth elements Gd, Y, Sm, Nd, Er, Eu, Ho, Tm, Lu, Dyand Yb, less than 0.2% of impurities and the balance Mg, wherein a, b, c and d satisfy the following conditions: a is greater than or equal to 3.5 and less than or equal to 4.5, b is greater than or equal to 3.5 and less than or equal to 4.5, c is greater than or equal to 0.2 and less than or equal to 0.5, and d is greater than or equal to 0.01 and less than or equal to 3.0. The material has the advantages of being excellent in mechanical property, good in casting performance and capable of expanding the application field of the magnesium alloy material. The invention further provides a preparation technology. The preparation technology has the advantages of being good in stability and high in controllability.

Owner:SHANGHAI JIAO TONG UNIV

Wrought magnesium alloy and preparation method thereof

The invention provides a wrought magnesium alloy and a preparation method thereof and relates to the technical field of alloy materials. The wrought magnesium alloy is prepared from raw materials, by weight percent, 4.0%-8.0% of zinc, 1.0%-6.0% of bismuth, 0.2%-1.0% of magnesium and the balance magnesium and unavoidable impurities. The wrought magnesium alloy has the characteristics of high strength and high plasticity and excellent mechanical performance, does not contain precious metal, is low in cost and has relatively-good economic benefits. The preparation method of the wrought magnesium alloy comprises the steps that in protection of mixed gas containing SF6, preheated magnesium is heated to be molten, preheated zinc, bismuth and magnesium are added, the temperature is raised, and after the raw materials are molten, the raw materials are cast into an ingot; and the ingot is subjected to extrusion processing and heat treatment. The method is simple in preparation process, high in controllability, low in preparation cost and suitable for large-scale production.

Owner:山东山科智镁新材料科技有限公司

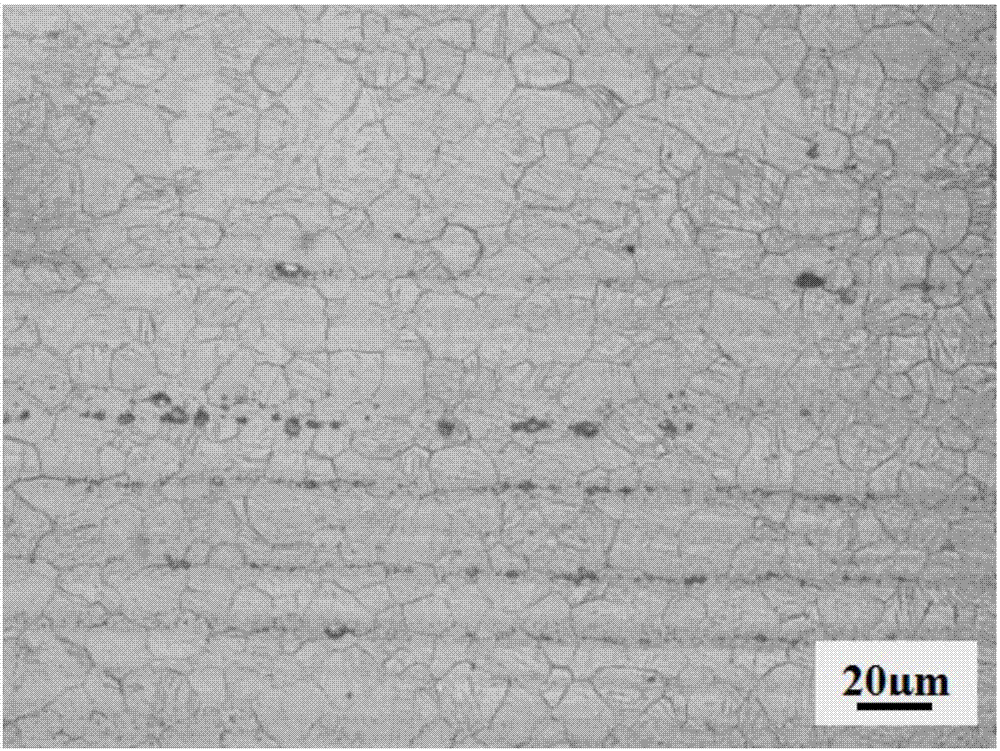

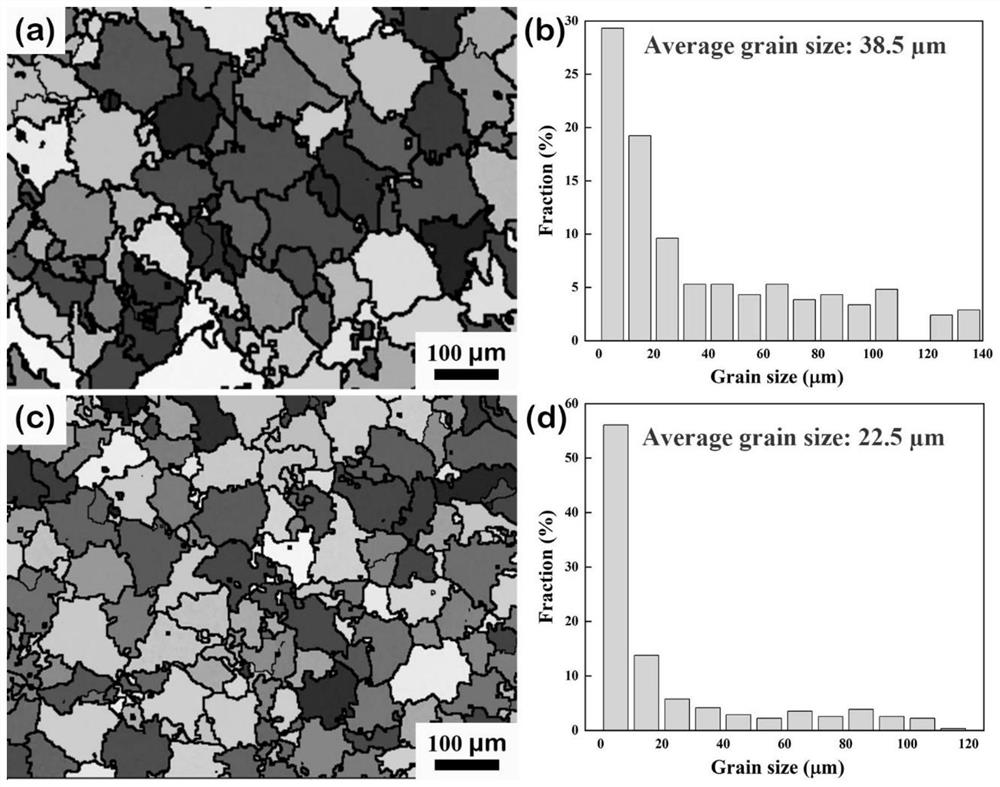

High-performance Mg-Y-Mn-Gd deformed magnesium alloy and preparation method thereof

The invention relates to the field of magnesium alloys, in particular to a high-performance Mg-Y-Mn-Gd deformed magnesium alloy and a preparation method thereof. The magnesium alloy is prepared from the following elements in percentage by mass: 8.0-12.0% of Y, 0.3-0.5% of Mn, 0.2-0.4% of Gd and the balance of magnesium and inevitable impurities. The high-performance Mg-Y-Mn-Gd deformed magnesium alloy adopts industrial pure magnesium ingot, Mg-Y intermediate alloy, Mg-Mn intermediate alloy and Mg-Gd intermediate alloy as raw materials, and the raw materials are subjected to alloy smelting and casting, alloy extrusion processing and double-stage ageing thermal treatment of extruded materials to obtain the magnesium alloy. The magnesium alloy has good extrusion properties and forming properties, can obtain excellent plasticity under an extrusion-state condition, and can obtain high strength after ageing treatment; the preparation method is simple in preparation process, and is low in preparation cost; the prepared deformed magnesium alloy has high strength and high plasticity, so that the problems that the magnesium alloy not containing rare earth is relatively low in mechanical property or the magnesium alloy containing a great deal of rare earth is relatively high in cost and is relatively great in density in the prior art are solved.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Nutritional food beauty-nourishing tea electuary for nourishing beauty

The invention relates to nutritional food beauty-nourishing tea electuary for nourishing beauty, belonging to the field of nutritional foods. The nutritional food beauty-nourishing tea electuary disclosed by the invention aims to be good and rapid in effect. The nutritional food beauty-nourishing tea electuary disclosed by the invention is prepared from the raw materials, such as prepared rehmannia root, Carthamus tinctorius, China rose, Astragalus mongholicus, grape pips, black tea and the like. The nutritional food beauty-nourishing tea electuary disclosed by the invention has the functionsof strengthening body resistance, tonifying qi, nourishing blood, promoting blood circulation, removing stasis and nourishing beauty and has the advantages of being good and rapid in effect.

Owner:南通市灵通生物科技研究所

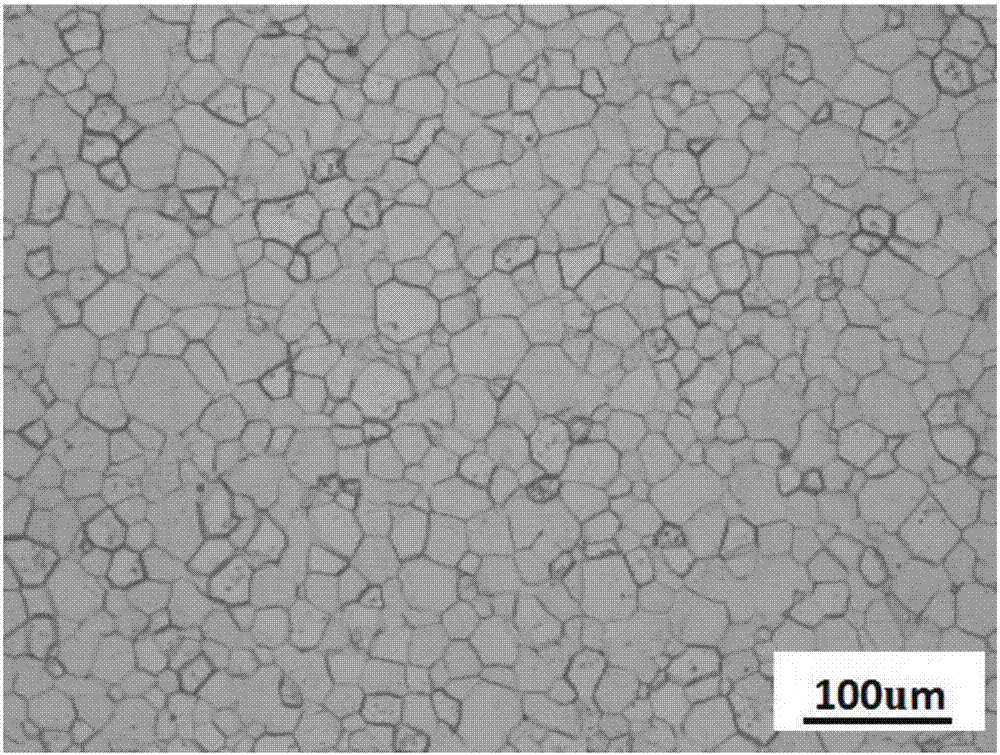

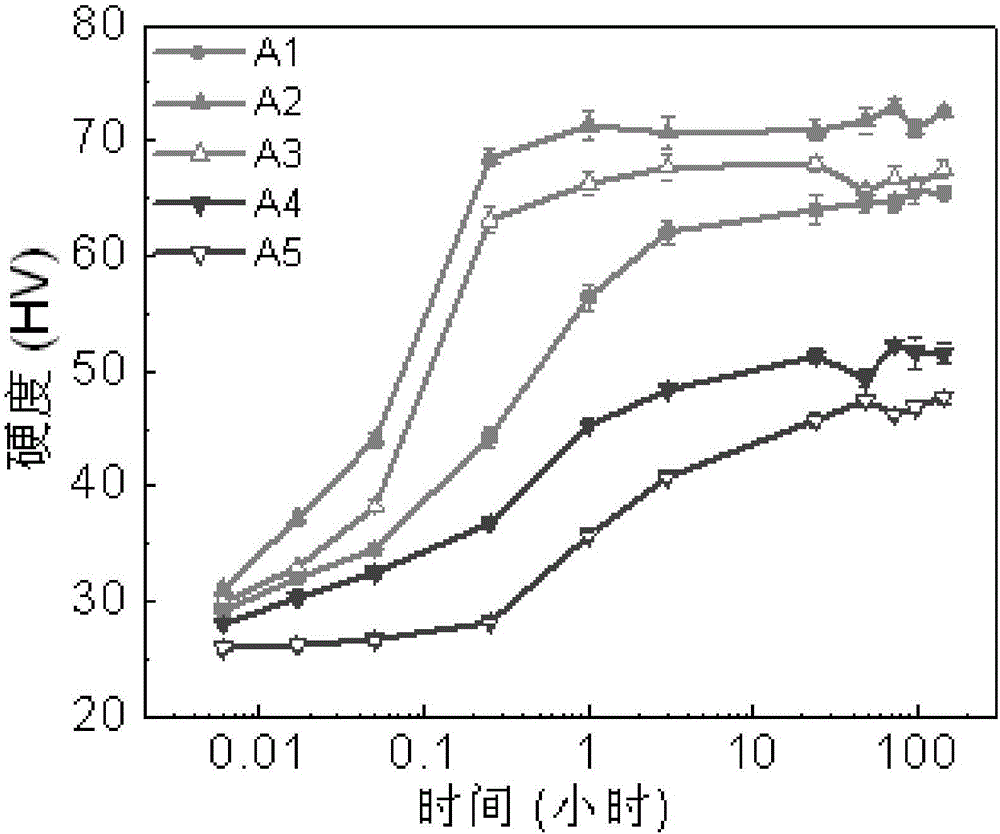

High-cost-performance high-strength high-conductivity Al-Sc-Zr-Yb alloy and heat treatment technique thereof

The invention relates to a high-cost-performance high-strength high-conductivity Al-Sc-Zr-Yb alloy and a heat treatment technique thereof, belonging to the technical field of alloys. The alloy is prepared by adding 0.193-0.256 wt% of Sc, 0.187-0.243% wt% of Zr and 0.077-0.109 wt% of Yb into an aluminum matrix. The heat treatment technique of the alloy comprises the following steps: carrying out solution treatment at 640+ / -10 DEG C for 40-50 hours, carrying out water quenching to room temperature, and carrying out isothermal aging at 350-400 DEG C for 96-144 hours. By adopting Sc-Zr-Yb composite microalloying, the alloy has obvious aging strengthening effect and favorable electric conductivity; and under the condition of obtaining the same hardness value, the price of the Al-Sc-Zr-Yb alloy can be lowered by 30 yuan / kg as compared with the Al-Sc-Zr alloy, and thus, the Al-Sc-Zr-Yb alloy has high cost performance.

Owner:BEIJING UNIV OF TECH

Body-care skin-care face-beautifying compound essential oil

InactiveCN103705422APromotes skin cell growthBalances and softens skinCosmetic preparationsToilet preparationsInjury mouthDry skin

The invention relates to a cosmetic and health care product, and particularly relates to body-care skin-care face-beautifying compound essential oil. The body-care skin-care face-beautifying compound essential oil comprises the following raw material components: sandalwood essential oil, chamomile essential oil, rose essential oil, jasmine essential oil and base oil, wherein the sandalwood essential oil can fast rehabilitate a wound or a scar so as to have elasticity and shrinkage effects, balance and soften skin and improve dry and dehydrated skin; the chamomile essential oil can relieve stress, calm mood and repair sensitive, inflamed and eczematous skin; the rose essential oil has very good face-beautifying and skin-care effects and can improve skin dryness and restore skin elasticity; the jasmine essential oil has the outstanding effects of conditioning dry and sensitive skin, increasing the skin elasticity and delaying skin aging. Thus, the compound essential oil disclosed by the invention can be used for slimming the body, repairing the sensitive skin, increasing the skin elasticity, delaying the skin aging and softening the skin, and has very good body-care skin-care face-beautifying effects.

Owner:QINGDAO YONGTONG ELEVATOR ENG

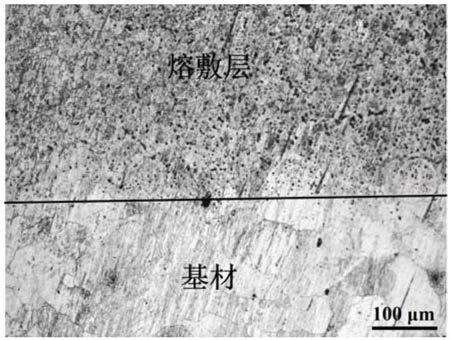

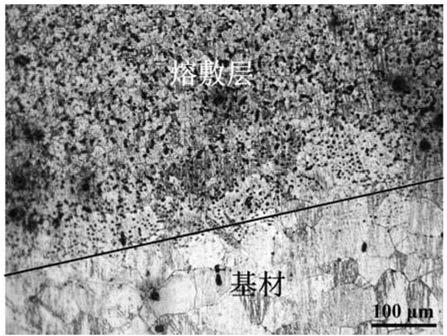

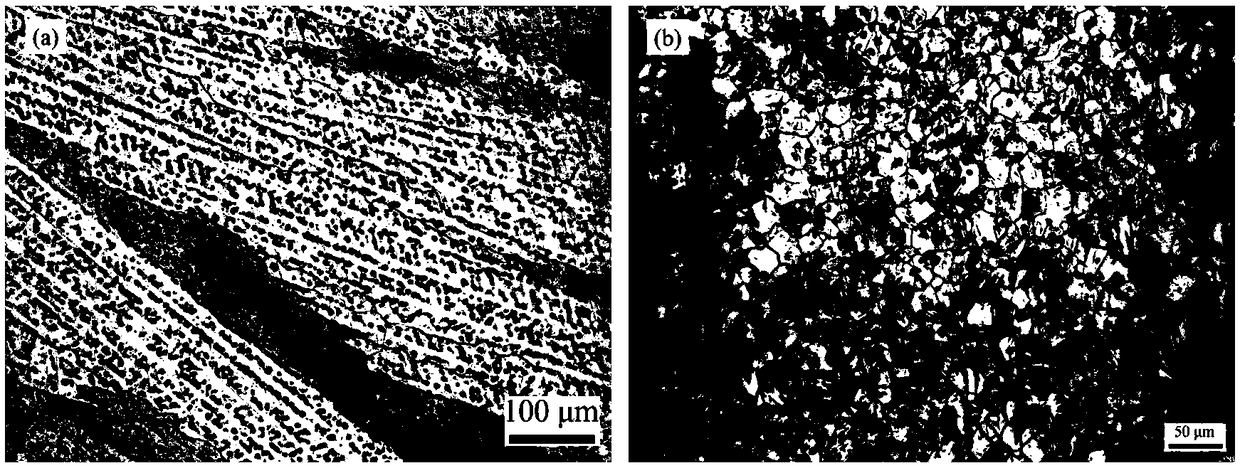

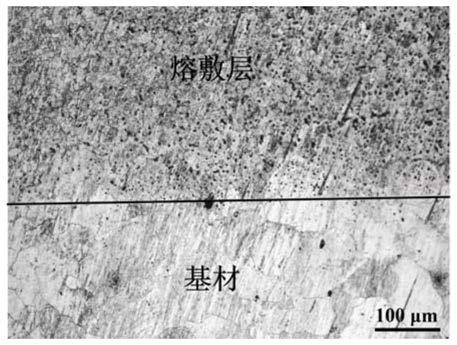

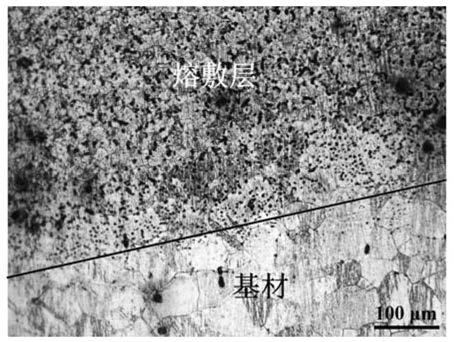

Method for improving magnesium alloy welded joint through surface microalloying

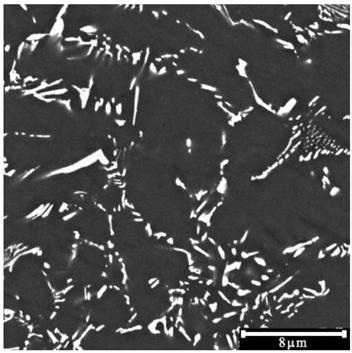

ActiveCN108977805AHigh yield strengthHigh tensile strengthMetallic material coating processesRare-earth elementWeld seam

The invention discloses a method for improving a magnesium alloy welded joint through surface microalloying, and belongs to the technical field of welding technologies in material processing. Mixed powder composed of metal powder including Al, Ti, Cr, Mn and Ni and rare earth element powder including Sc and Nd is developed, and a laser microalloying technology is used for conducting surface modification on a magnesium alloy welding seam area to improve the comprehensive performance of the magnesium alloy welded joint, wherein the power comprises the components in percentage by mass: 9.1%-9.4%of Al, 5.4-5.8% of Ti, 4.1-4.3% of Cr, 0.05-0.2% of Mn, 0.03-0.2% of Sc, 0.8%-2.2% of Nd and the balance Ni, and the grain size of laser microalloyed powder is 100-300 meshes. The laser microalloyingtechnology is adopted to obtain a nanophase-containing cladding layer good in performance on the surface of the magnesium alloy welded joint, and rare earth elements, the other alloy elements and a Mgalloy substrate molten layer can generate a large number of alloy compound wild phases and can effectively refine a microstructure of the cladding layer, improve the mechanical performance of the magnesium alloy welded joint and greatly improve the corrosion resistance performance of the magnesium alloy welded joint.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

Degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588AEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisOsteoblastDie casting

The invention provides a degradable antibacterial magnesium alloy and a preparation method of the degradable antibacterial magnesium alloy, and relates to the field of metal biomedical materials. Thedegradable antibacterial magnesium alloy comprises main active elements of Ag, Cu, Zn and Sr, and by means of composition optimization design of the magnesium alloy, the components comprise, by mass,1.35-1.65% of Ag, 0.9-1.1% of Cu, 3.6-4.4% of Zn, 0.9-1.1% of Sr, 0.36-0.44% of Ca and the balance Mg and other inevitable impurities. After the magnesium alloy material implant finishes the action, the magnesium alloy material implant can be completely degraded to avoid secondary operation removal, the medical cost and the pain of patients are reduced, the antibacterial property of the implant isimproved, and the magnesium alloy material implant has the functions of promoting osteoblast formation and inhibiting osteoclast bone absorption; the degradable antibacterial magnesium alloy adopts asemi-solid rheological die casting process, the microstructure of the product is uniformly distributed, the internal structure is compact, the defects of pores, segregation and the like are few, andthe requirements for high quality and high precision of implant products can be met.

Owner:NORTHEASTERN UNIV

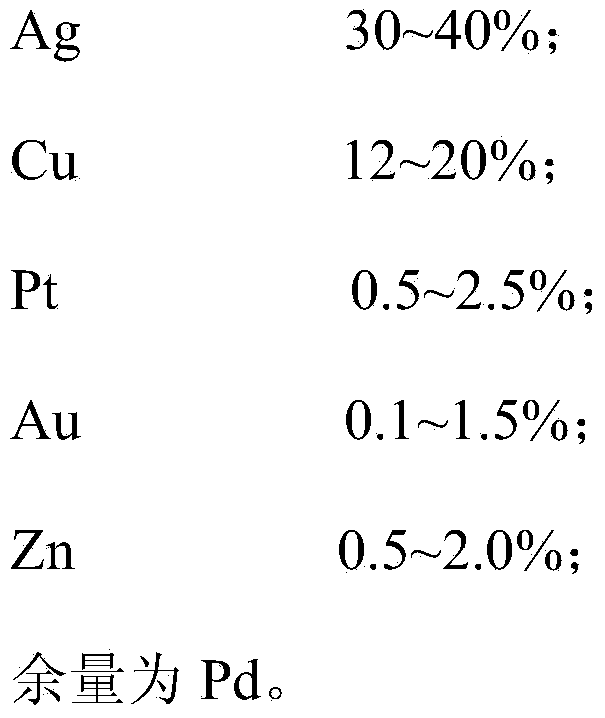

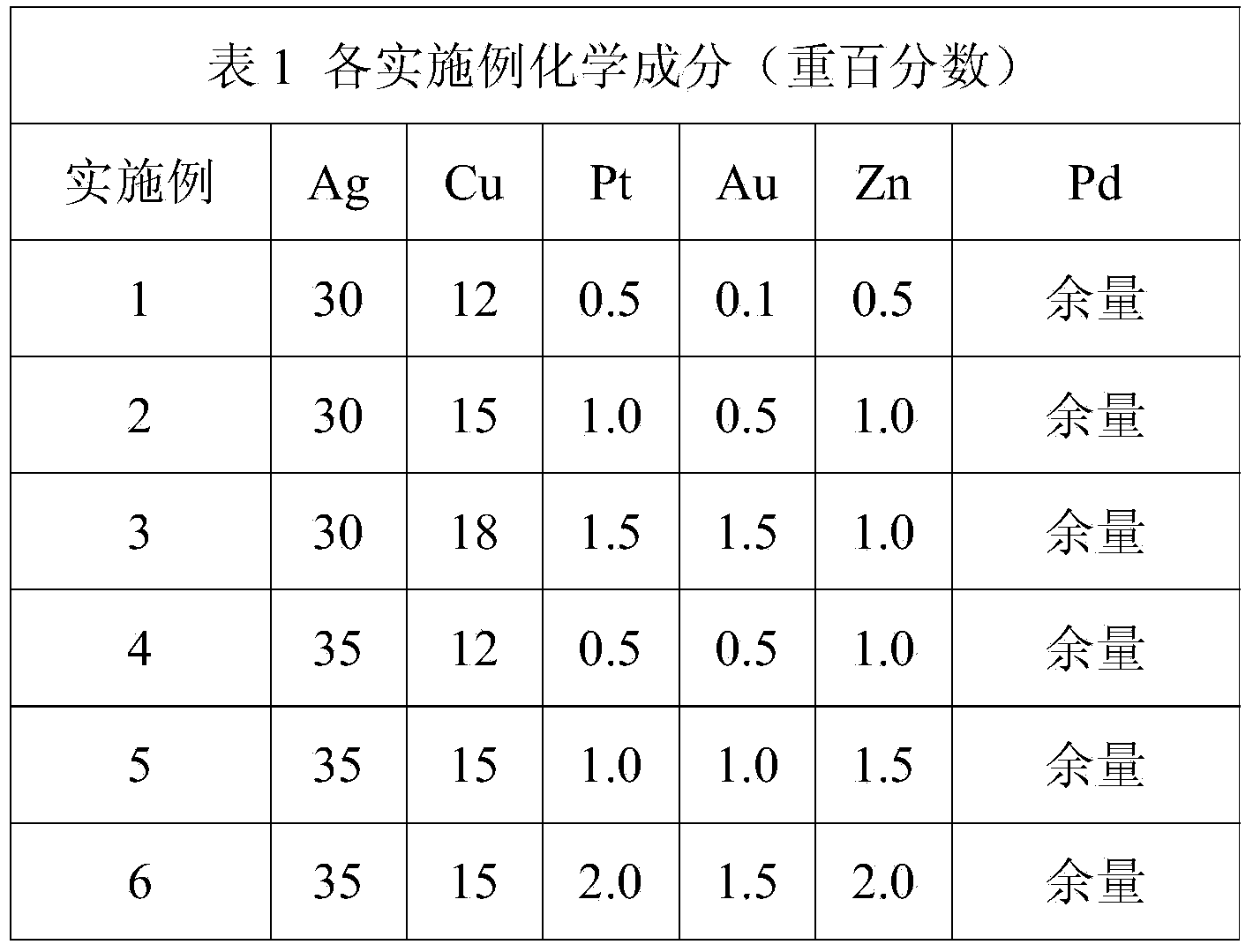

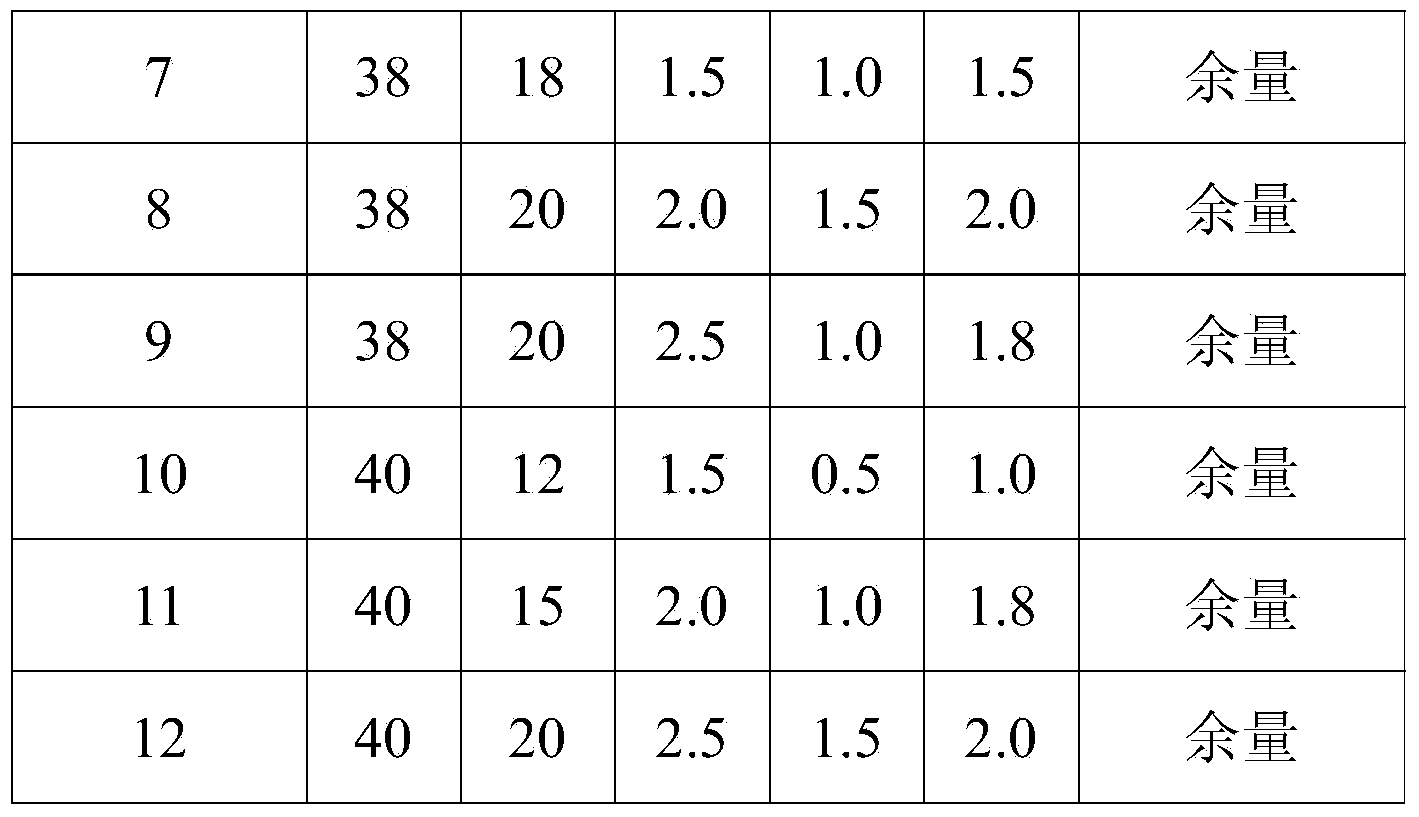

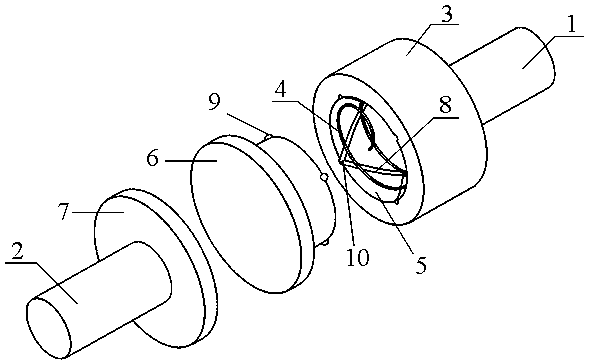

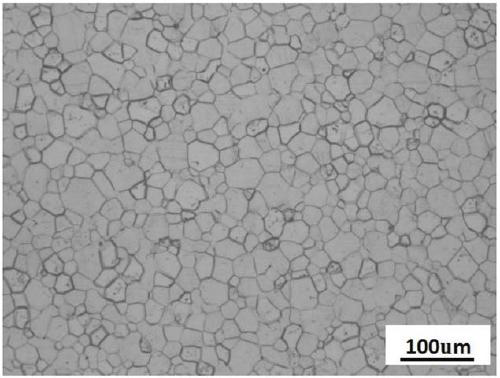

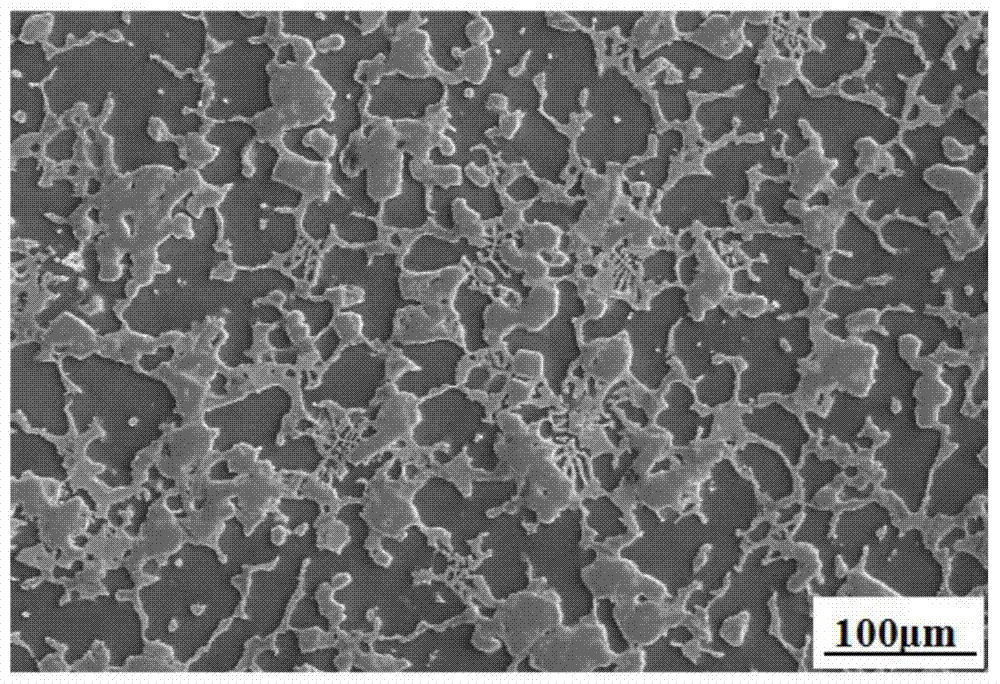

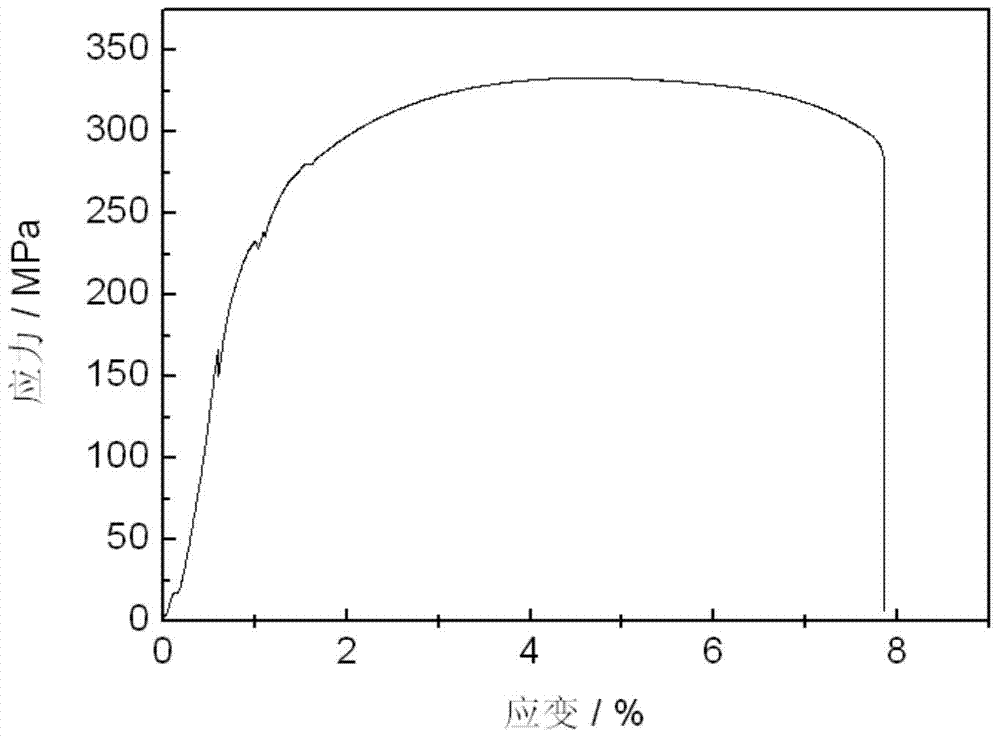

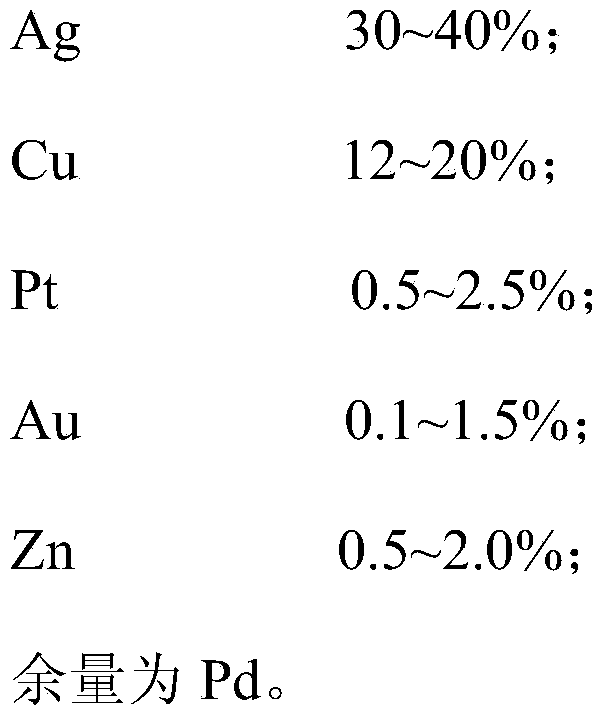

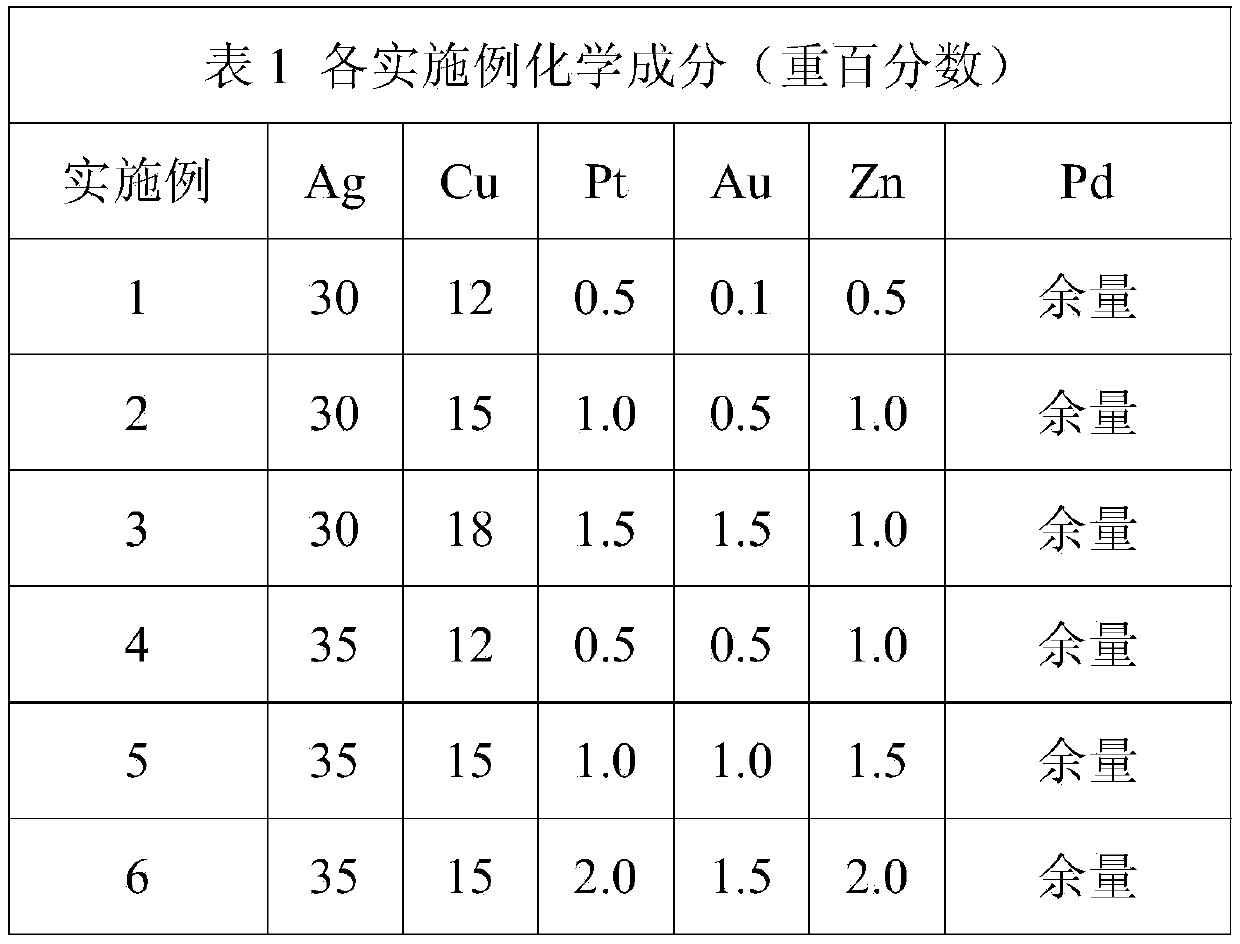

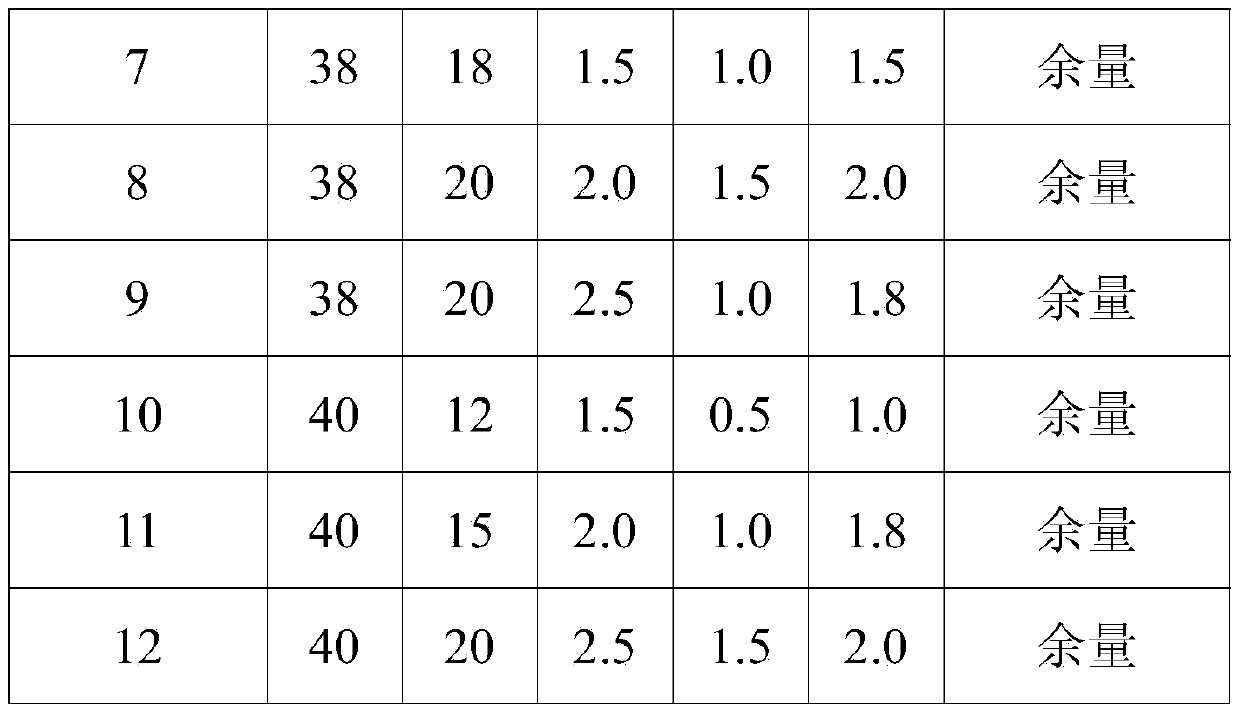

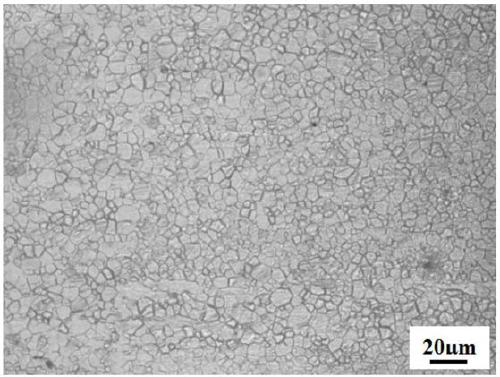

Electric brush with age-hardening effect and use thereof

ActiveCN103757460ASignificant aging effectImprove high temperature stabilityRotary current collectorNon-rotary current collectorMechanical properties of carbon nanotubesHardness

The invention discloses an electric brush with an age-hardening effect. The alloy comprises the following components in percentage by weight: 30-40% of Ag, 12-20% of Cu, 0.5-2.5% of Pt, 0.1-1.5% of Au, 0.5-2.0% of Zn and the balance of Pd; the alloy contains ordered phases Cu3Pt and Cu3Au through solid-solution treatment and aging treatment. The material contains the ordered phases Cu3Pt and Cu3Au, and thus is improved in hardness and wearability at a high temperature; the material is applicable to the working layer of the electric brush of a small-sized direct-current motor at an environment temperature ranging from 80 DEG C to 150 DEG C; the alloy is combined on the surface of the copper alloy, so that the cost can be saved and the mechanical properties can be improved, and therefore, the properties of the two layers of materials can be developed sufficiently.

Owner:CHONGQING CHUANYI AUTOMATION

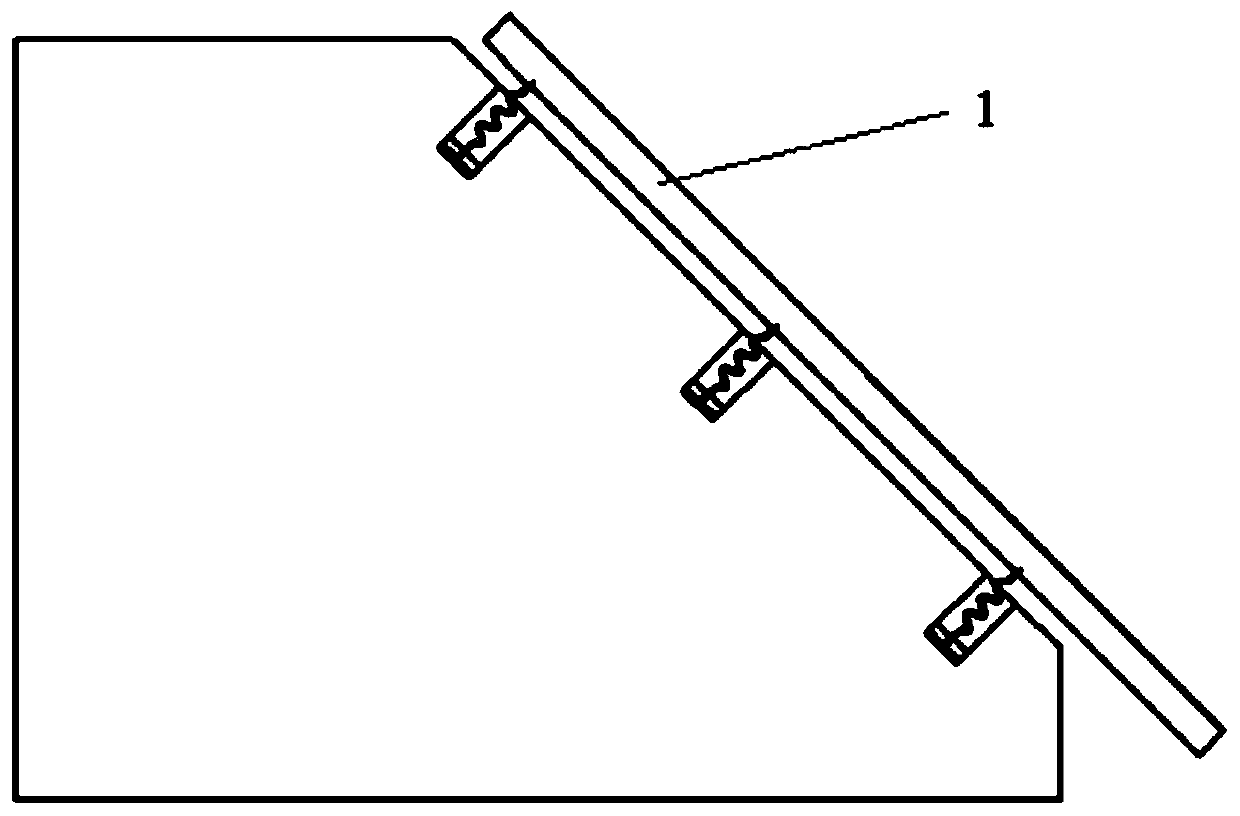

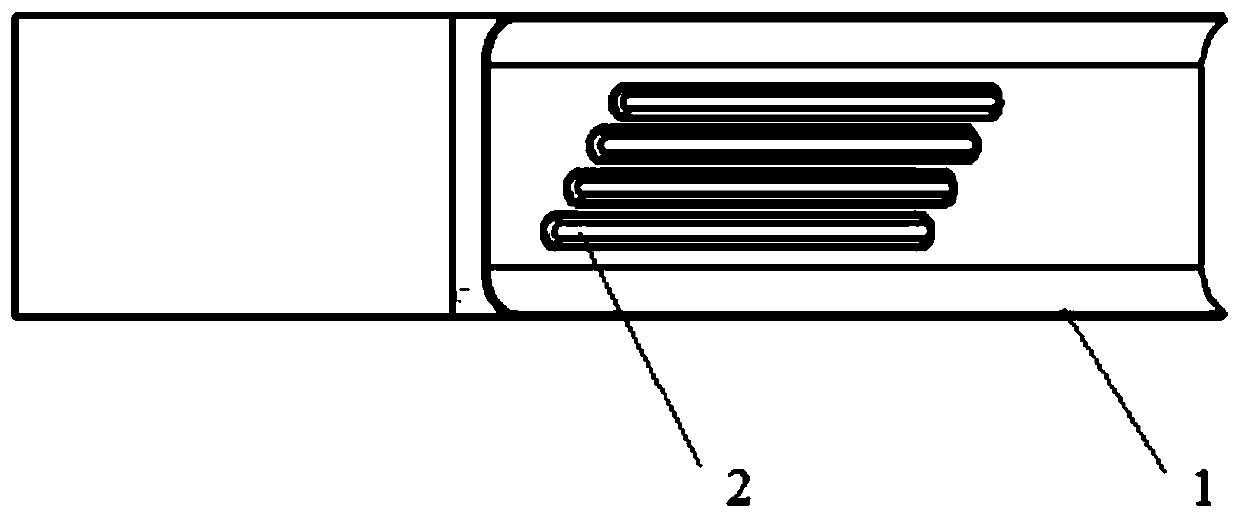

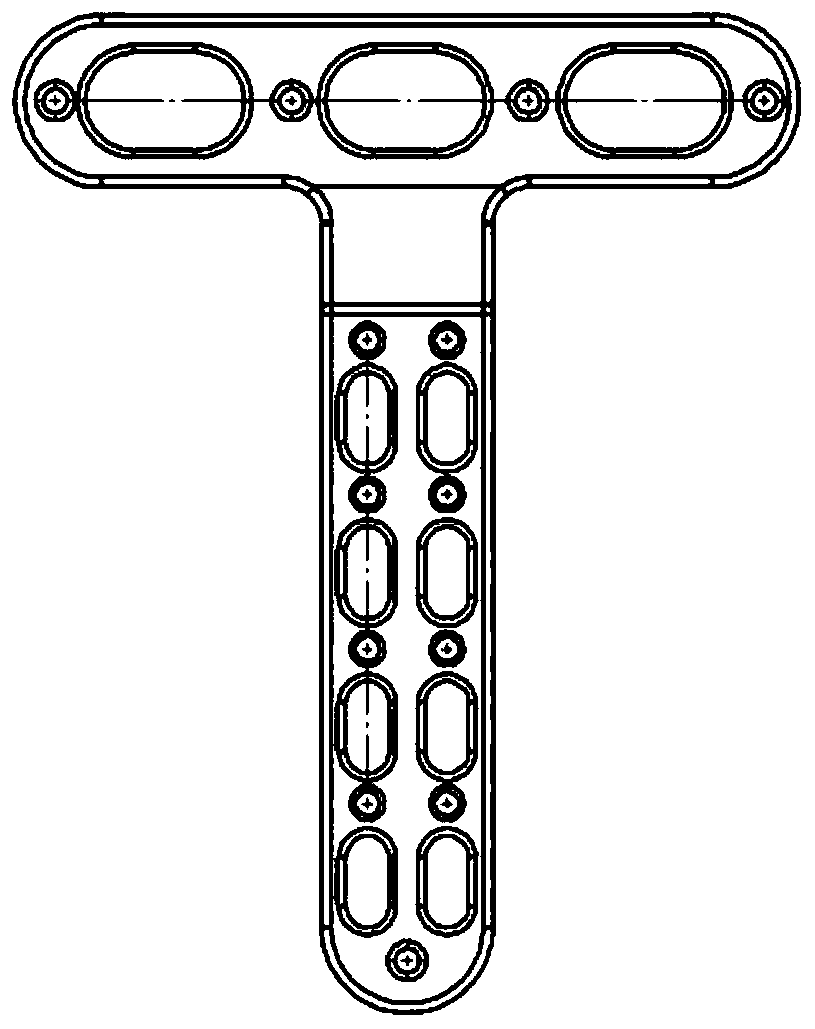

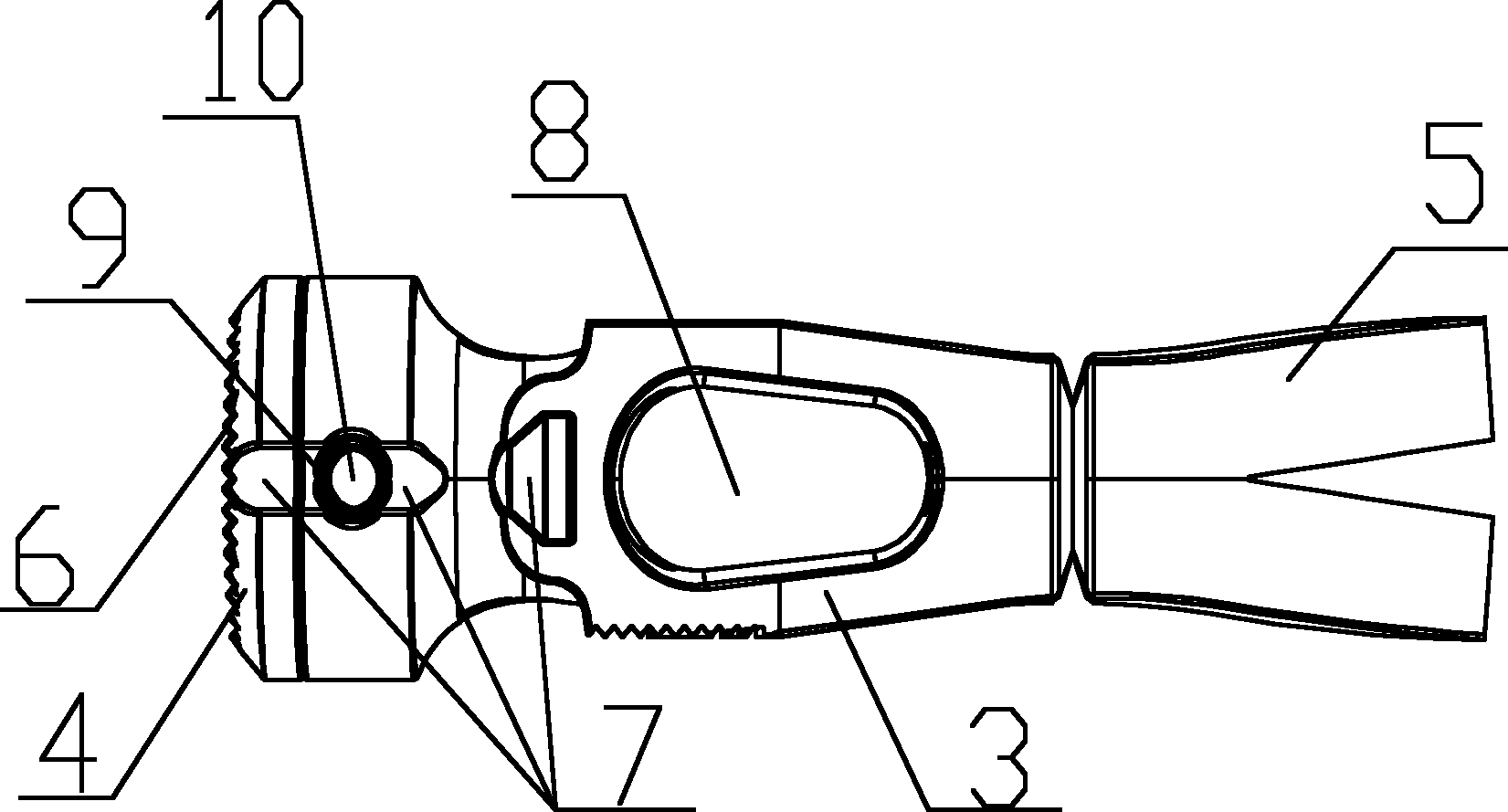

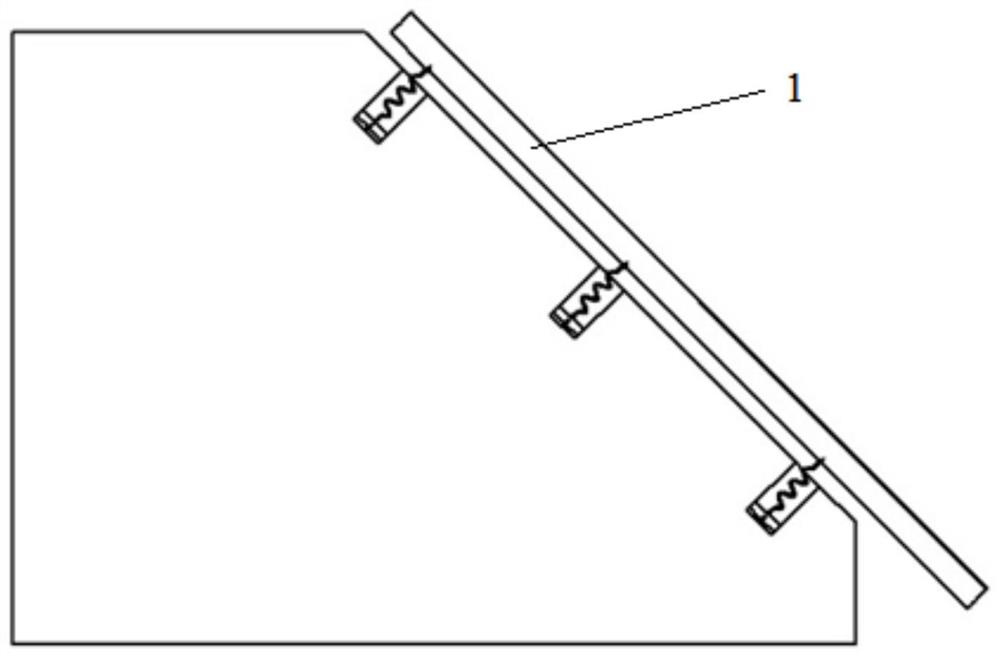

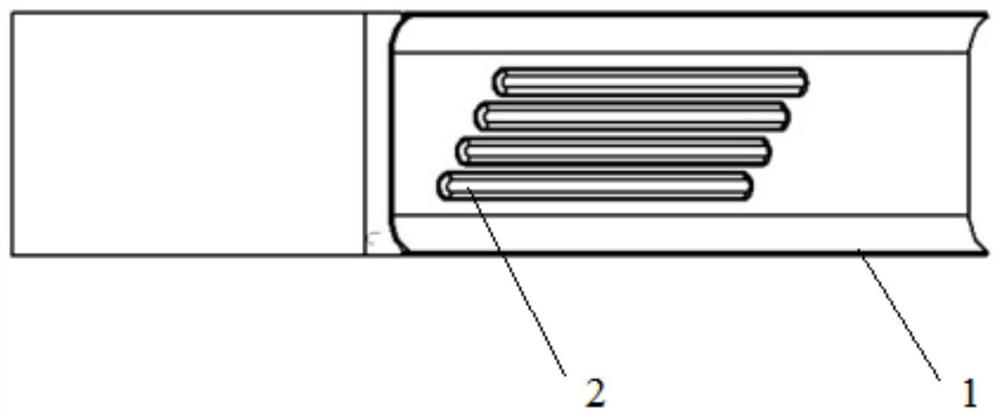

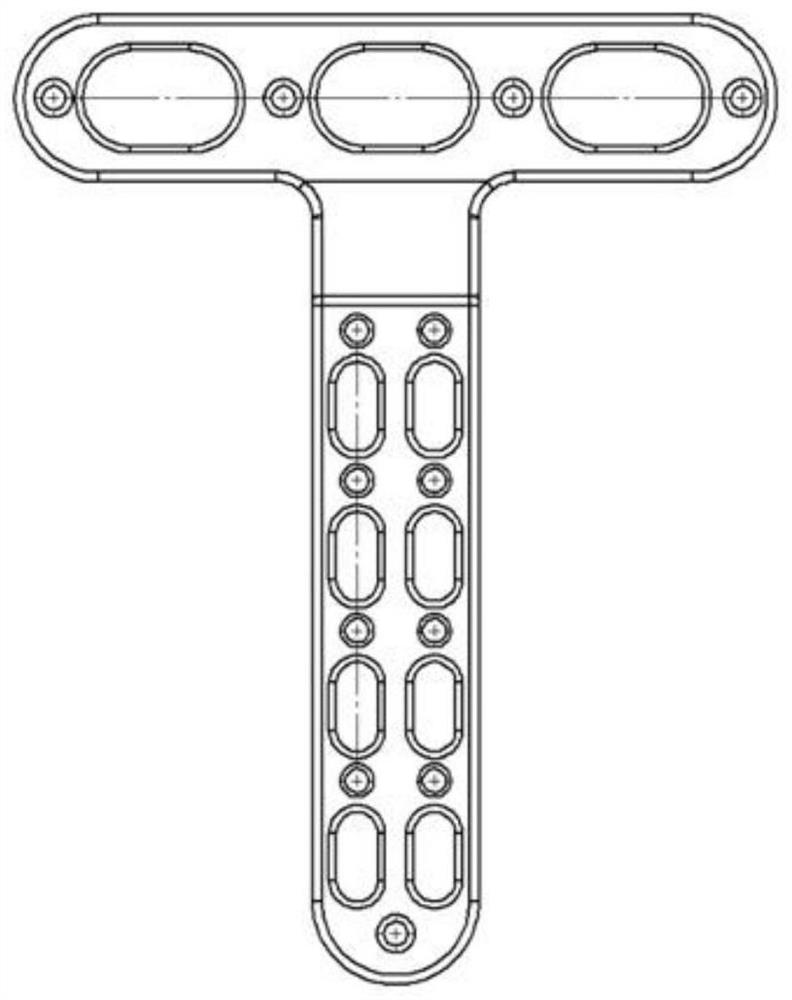

Rotating contact structure of vacuum arc-extinguishing chamber suitable for capacitive load switching

InactiveCN110556265AReduced insulation weaknessesGood insulation propertiesSwitchgear arrangementsReactive power adjustment/elimination/compensationElectric power systemEngineering

The invention discloses a rotating contact structure of a vacuum arc-extinguishing chamber suitable for capacitive load switching. The structure is composed of a moving conducting rod, a static conducting rod, a moving end cup seat, a moving end rotating contact and a static end contact. A spring is arranged in a moving contact groove of the moving end cup seat, and the moving end rotating contactis fixedly connected with the moving end cup seat through the spring. The moving end rotating contact is in sliding connection with the moving end cup seat through a contact point and a sliding groove. A lower surface of the moving end rotating contact is in surface contact with an upper surface of the static end contact. One-way valves are arranged at two ends of the sliding groove. In an operation process of the vacuum arc-extinguishing chamber, the moving end rotating contact always rotates; static fusion welding of the surface of the contact in a closing process can be avoided; and sliding friction between the lower surface of the moving end rotating contact and the upper surface of the static end contact is used to reduce insulation weaknesses of the contact surface so that a rebreakdown probability of capacitive load switching of the vacuum arc-extinguishing chamber can be effectively reduced. The structure can be used for a switching capacitive load, and is particularly suitable for the reactive compensation field of a power system.

Owner:EAST CHINA JIAOTONG UNIVERSITY

AlSiLi phase aging strengthening type low-density aluminum alloy and preparation method thereof

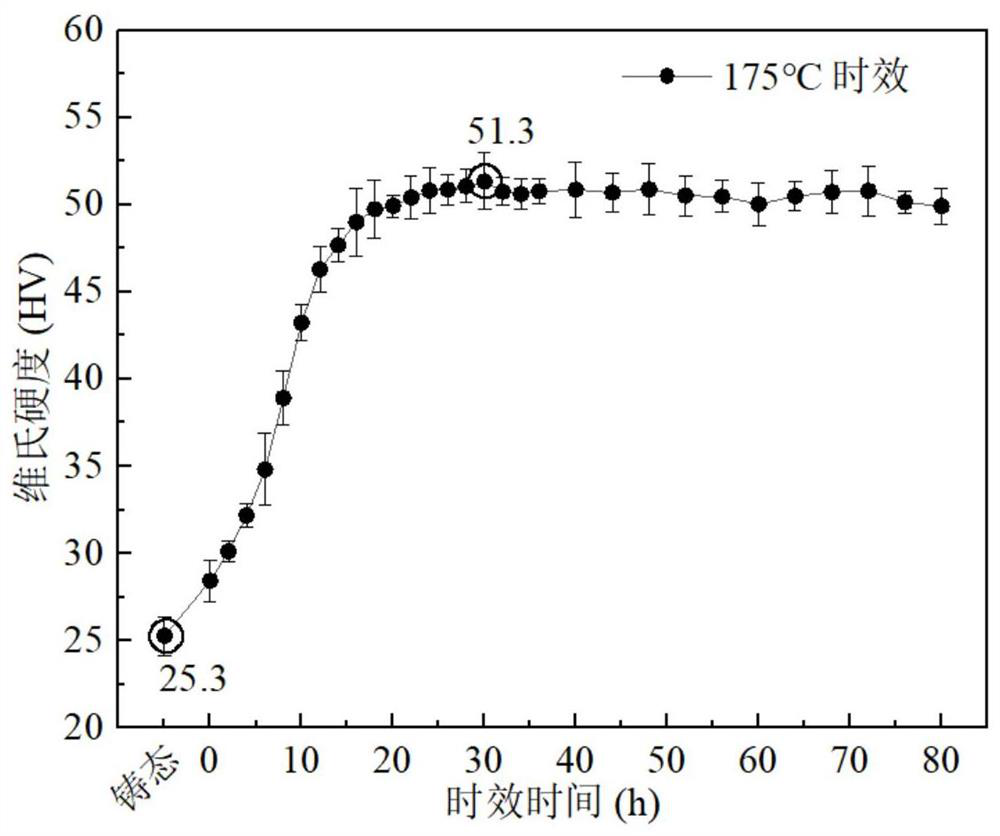

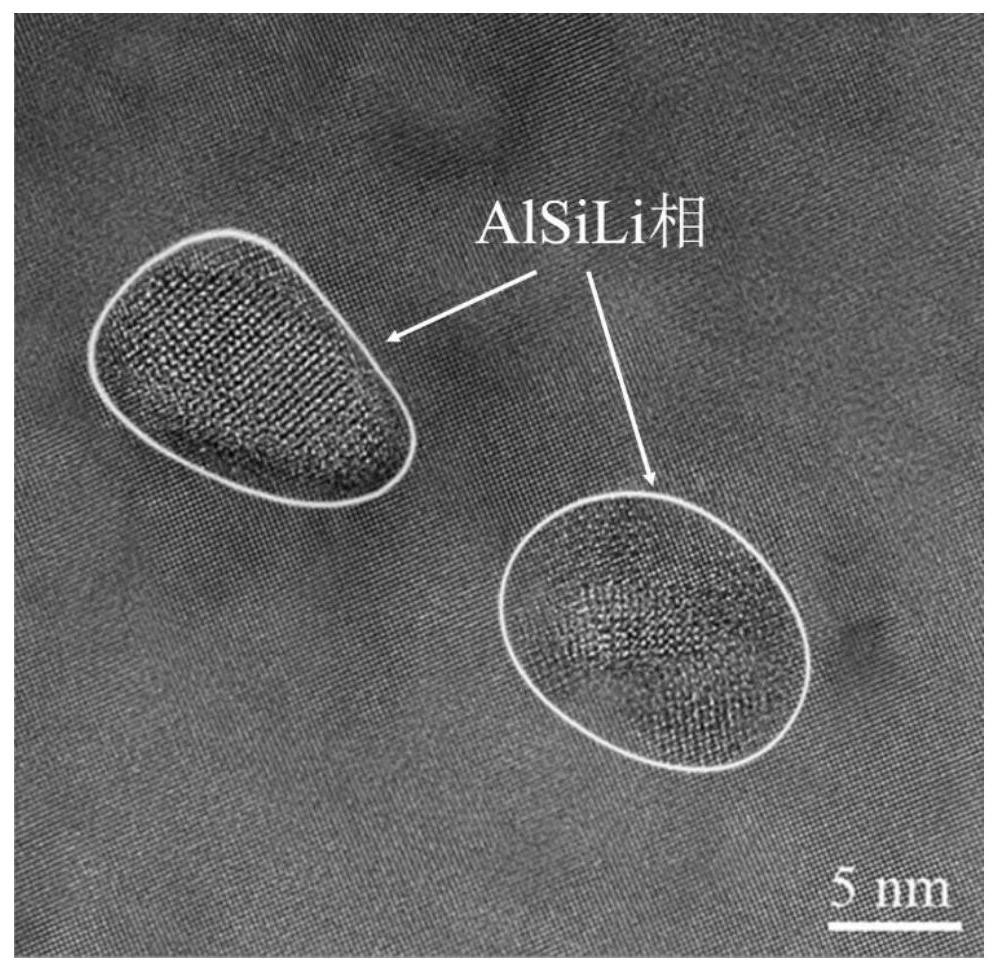

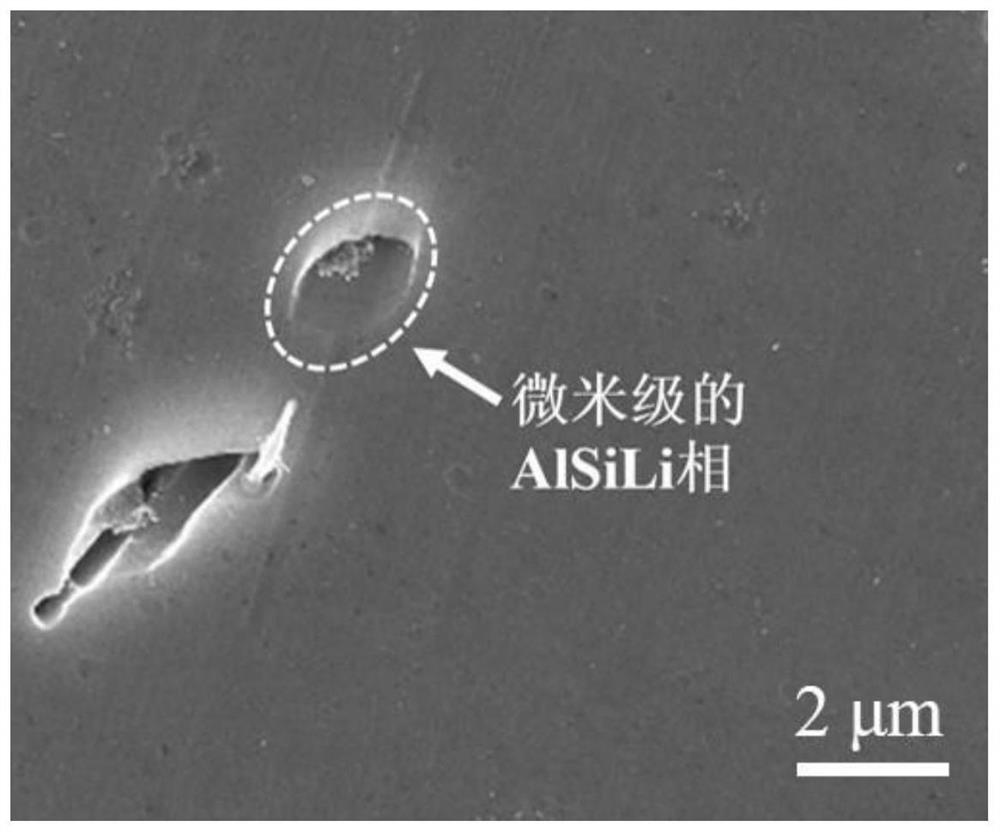

ActiveCN113737060ALow densityLightweight advantage is obviousAdditive manufacturing apparatusIncreasing energy efficiencyNonferrous metalDie casting

The invention discloses an AlSiLi phase aging strengthening type low-density aluminum alloy and a preparation method thereof, and belongs to the technical field of nonferrous metal preparation and processing. The aluminum alloy comprises the following basic components in percentage by weight: 0.01%-1.0% of Si, 0.01%-1.0% of Li and the balance of Al, and at least one of the following elements in percentage by mass: 0.01-1.0% of Mg, Ca, Sr, Ti, B, Cu, Zn, Mn, Ag, Sc, Zr, Fe, Cr and Ge can be further added; the microstructure of the aluminum alloy is characterized in that AlSiLi precipitated phases with the size smaller than 30 nm are dispersed and distributed in an aging peak state aluminum matrix, and a remarkable aging strengthening effect is achieved. The preparation method comprises the steps of die casting, high-temperature solid solution treatment and aging heat treatment, or casting, high-temperature solid solution, plastic deformation and aging heat treatment, or atomization powder preparation, 3D printing and aging heat treatment. According to the aluminum alloy, the room-temperature yield strength is 90-380 MPa, the tensile strength is 150-550 MPa, the ductility is not lower than 2%, the density is lower than that of pure aluminum, and the aluminum alloy has the advantages of light weight and high strength and can be used for preparing aircraft crankcases, cylinder covers, vehicle bodies, containers and the like.

Owner:UNIV OF SCI & TECH BEIJING

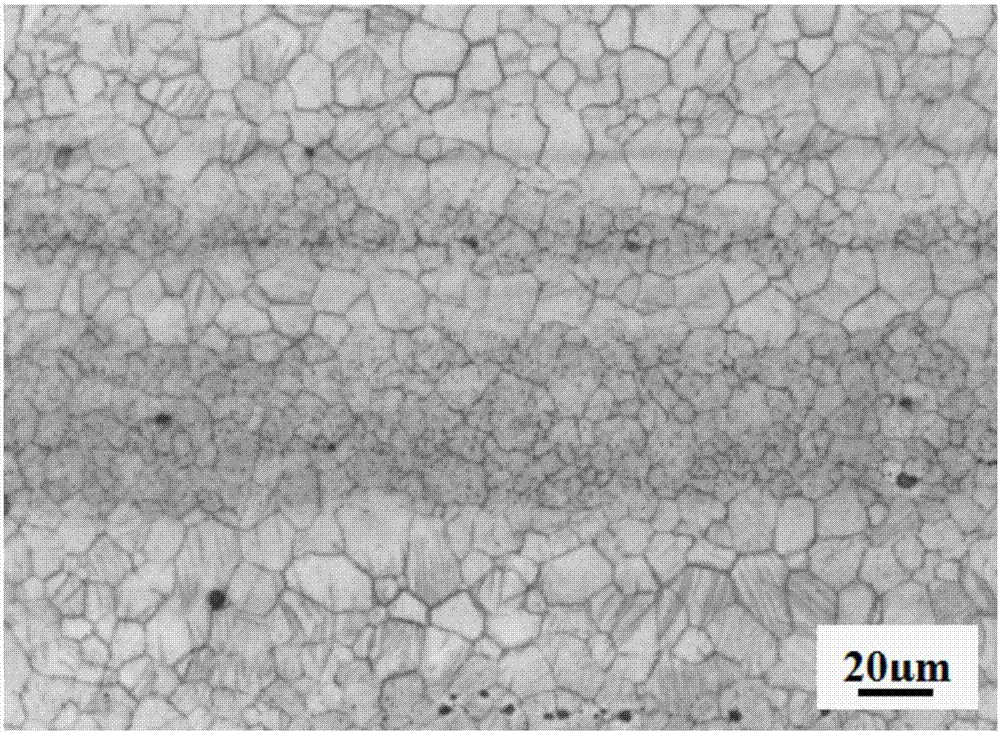

Welding wire for effectively improving the welding structure of Mg-Al series magnesium alloy

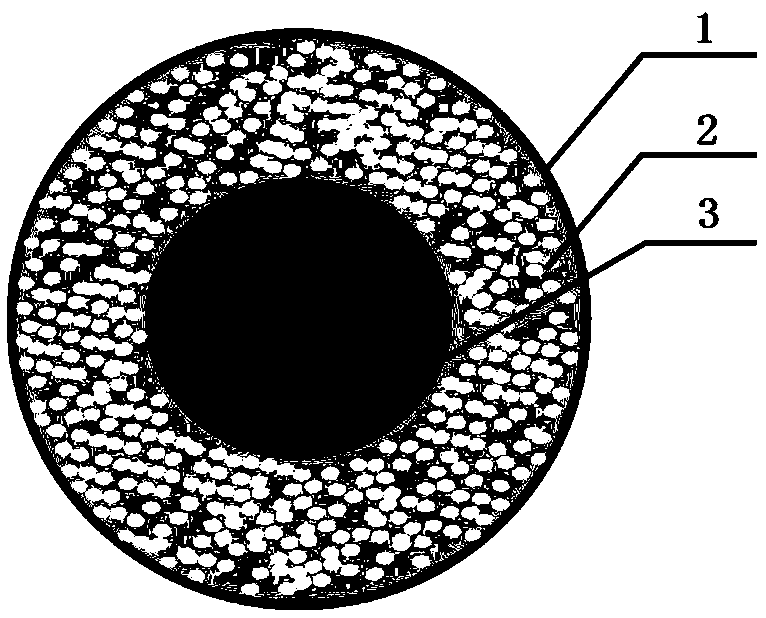

ActiveCN109366036AGuaranteed forming qualityGood formabilityWelding/cutting media/materialsSoldering mediaWeld seamMaterials processing

The invention relates to a welding wire for effectively improving the welding structure of Mg-Al series magnesium alloy, and belongs to the technical field of welding technologies in material processing. An inner core (Mg-Al series magnesium alloy), a flux-cored powder(the flux-cored powder comprises the following components of, in percentage by mass, 0.2-0.8% of Zn, 0.3-0.6% of Mn, 3.2-3.7% of MgCO3, 0.1-2.7% of Sr, 0.03-0.6% of Ce, 0.05-0.5% of Nd, and the balance Al-Mg alloy powder) and a sheath material form a magnesium alloy flux-cored wire. The method is mainly suitable for Mg-Al magnesium alloy welding, the grain of the welding seam can be greatly refined in the welding process of the coated flux-cored powder, the number of the Mg17Al12 hard brittle precipitation phases is reduced,air holes and the thermal cracking tendency are reduced, the microstructure and the mechanical property of the magnesium alloy welding joint are greatly improved, the welding wire has important significance for promoting engineering application of magnesium alloy.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Regulation and control method for strengthening and toughening of rare earth magnesium alloy

ActiveCN114381677AIncrease supersaturationIncrease toughnessMetal-working apparatusIncreasing energy efficiencySolution treatmentMechanical property

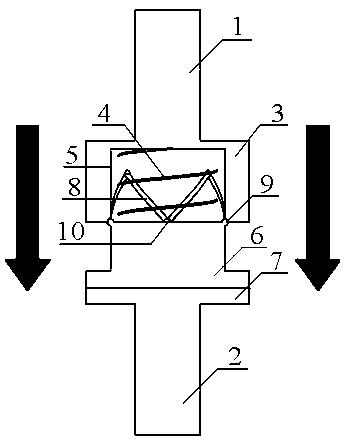

The invention discloses a rare earth magnesium alloy strengthening and toughening regulation and control method. The method comprises the following steps: (1) carrying out high-temperature solution treatment of an external pressure field on a target rare earth magnesium alloy; (2) the rare earth magnesium alloy component obtained after solution treatment is completed is subjected to cooling multi-pass multi-axis forging treatment; after each pass of forging is finished, the magnesium alloy is subjected to quenching treatment, and then electromagnetic induction heating is conducted to reheat the magnesium alloy to the temperature required by subsequent pass of forging; and (3) finally, the alloy is subjected to external stress and electrostatic field assisted aging heat treatment. Through regulation and control of the method, the strengthening and toughening degree of the rare earth magnesium alloy is improved, the tensile strength and the ductility are improved, the comprehensive performance is more excellent, and the use requirements are better met. Compared with a traditional treatment process (T5 and the like), the process is more detailed and comprehensive, and the mechanical property improvement effect of the rare earth magnesium alloy is more remarkable.

Owner:GRIMAT ENG INST CO LTD

Multifunctional skin-friendly compound essential oil

InactiveCN109394578ARestore elasticityImprove dullness and yellowingCosmetic preparationsNervous disorderSkin colorAllergy

The invention relates to multifunctional skin-friendly compound essential oil and belongs to the technical field of functional essential oils. The multifunctional skin-friendly compound essential oilis made from, by weight, 10-20 parts of orange blossom essential oil, 6-12 parts of frankincense essential oil, 6-8 parts of jasmine essential oil, 10-20 parts of lavender essential oil, 10-15 parts of geranium essential oil, 10-20 parts of palmarosa essential oil, 5-12 parts of Cananga odorata flower essential oil, and 55-70 parts of jojoba essential oil. The multifunctional skin-friendly compound essential oil may act directly on the skin, is convenient to use, can supplement moisture to the skin to restore skin elasticity and fade wrinkles, can provide calming and diminish inflammation, canrelieve and prevent allergy, skin acnes and other problems, can converge pores, can improve dark and yellow skin and brighten the skin, and can whiten the skin and lighten skin pigment.

Owner:黄岳娇

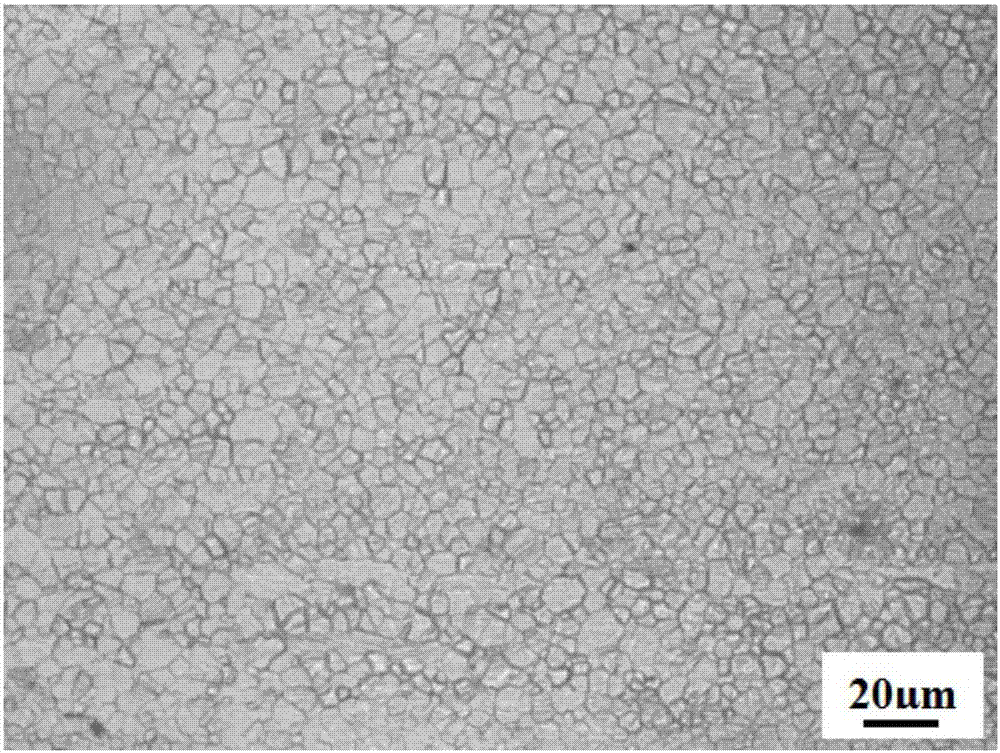

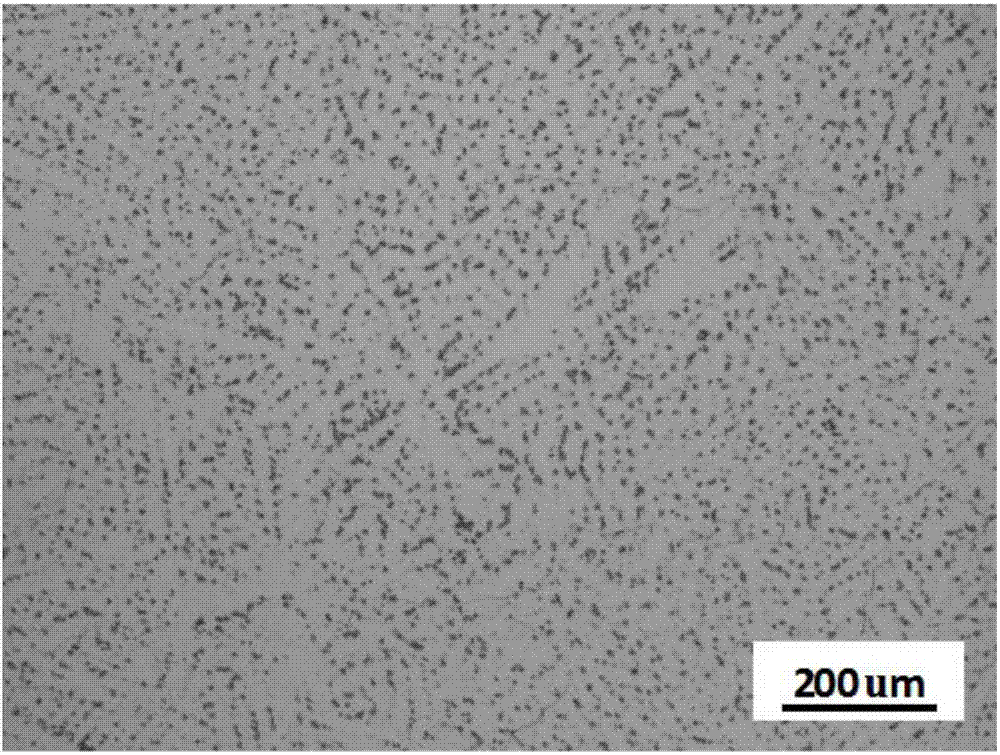

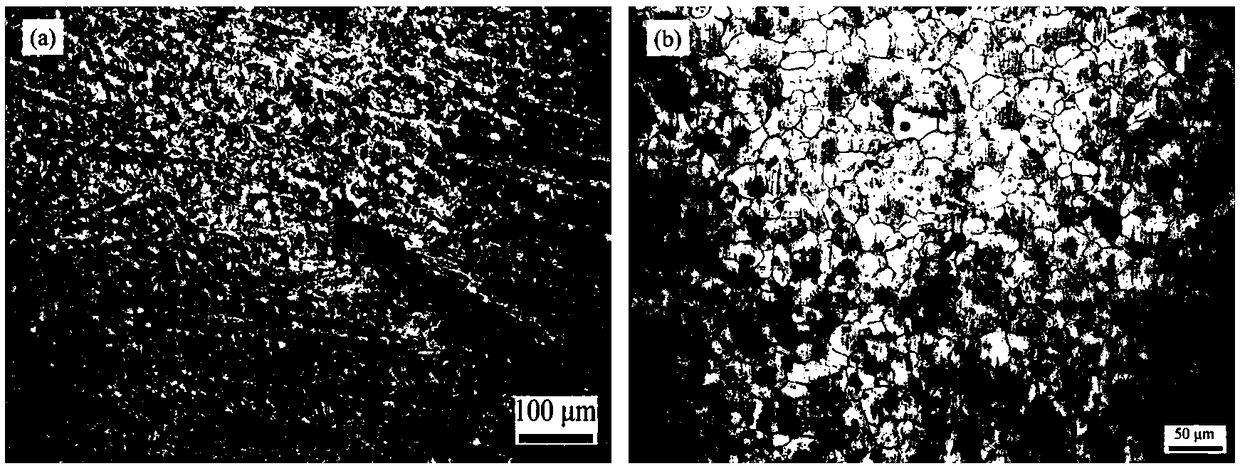

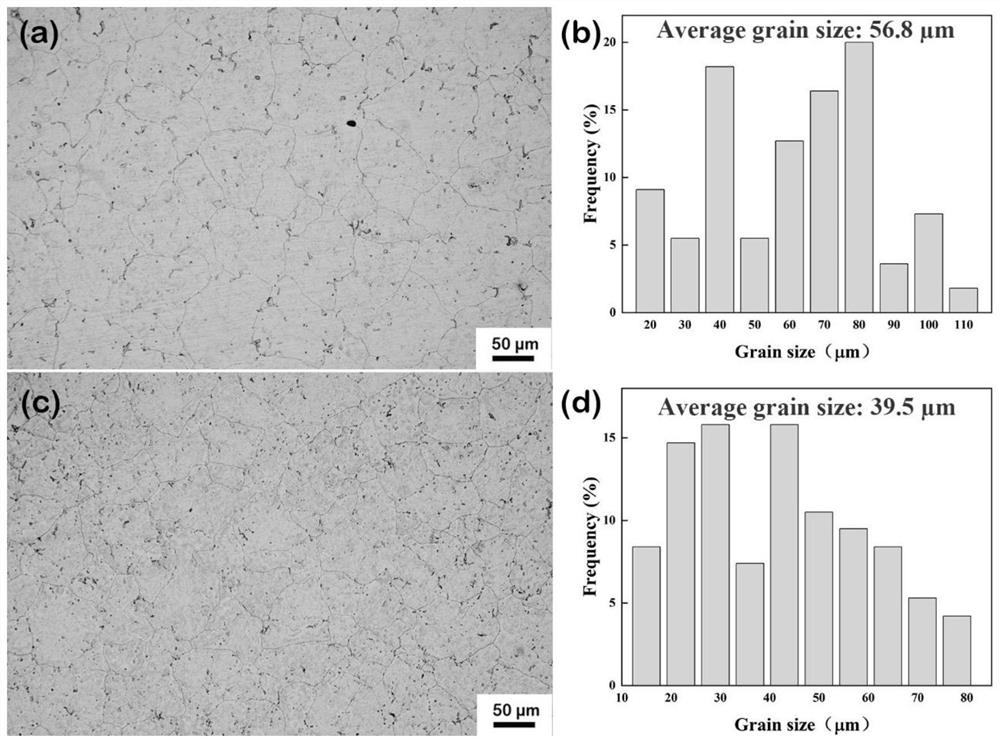

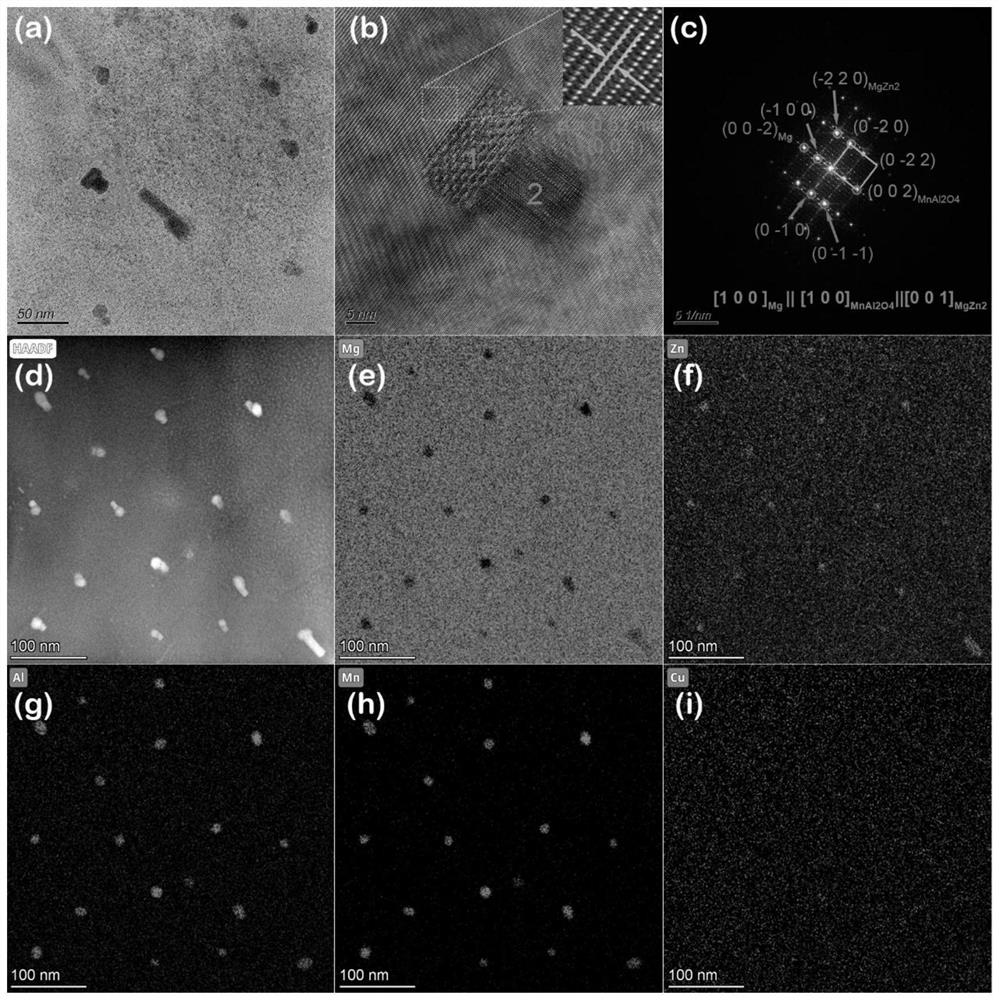

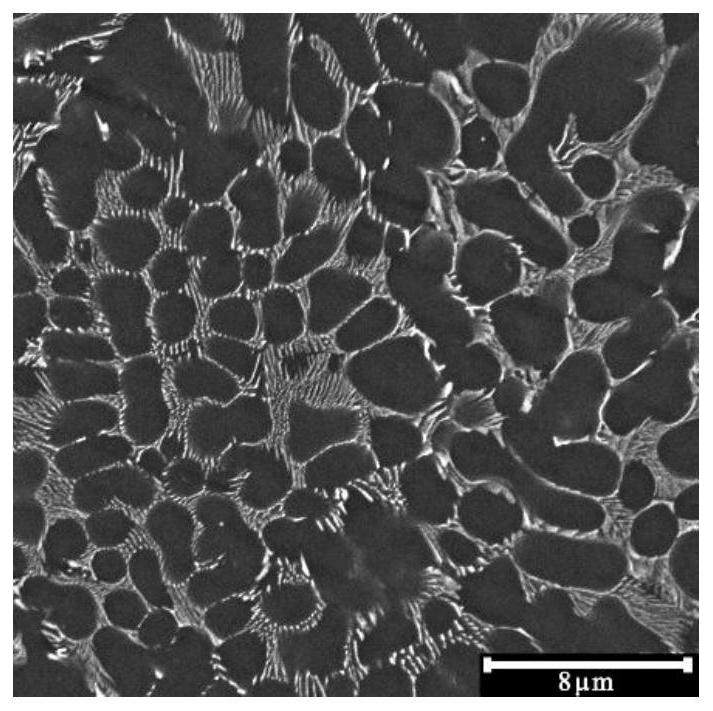

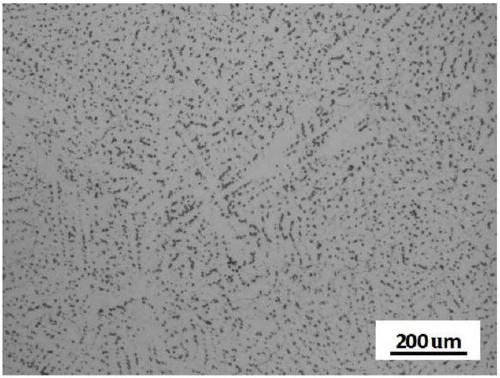

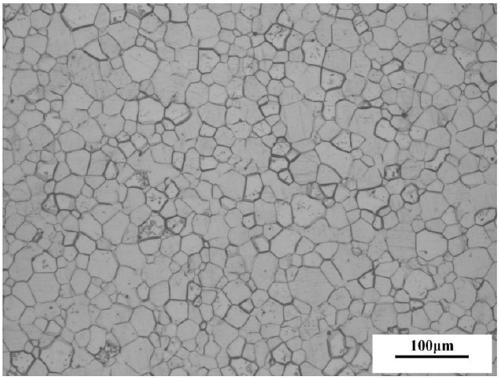

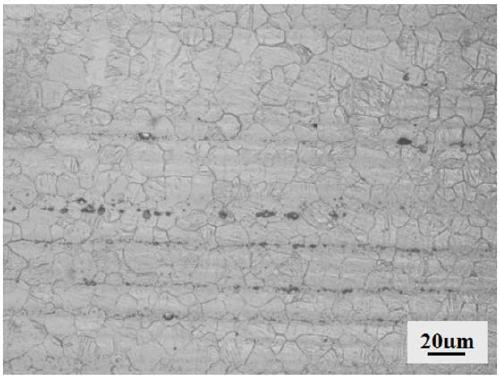

Method for refining Mn-containing Mg-Zn-Al series cast magnesium alloy grains

PendingCN114703388AGrain refinementHigh yield strengthProcess efficiency improvementShielding gasIngot

The invention relates to a method for refining Mn-containing Mg-Zn-Al series cast magnesium alloy grains, and belongs to the field of Mg-Zn-Al series cast magnesium alloy preparation. The preparation method comprises the following steps: preheating raw materials, putting metal Mg, metal Al, metal Zn, metal Cu and Mg-5wt.% Mn intermediate alloy into a smelting furnace, introducing protective gas, smelting at the temperature of 720-760 DEG C until the metal is completely molten, and keeping the temperature for 10-15 minutes to obtain an alloy melt A; adding dry magnesium carbonate powder into the alloy melt A, uniformly stirring, slagging, and standing for 10-20 minutes to obtain a grain refined alloy melt B; an RJ-6 refining agent is adopted for conducting purification and refining treatment on the alloy melt B obtained after grain refinement for 5-10 min, the temperature of the melt is adjusted to 720-740 DEG C after slagging-off treatment, standing is conducted for 20-40 min, and a refined alloy melt C is obtained; pouring the refined alloy melt C into a preheating mold, demolding, and cooling to room temperature in air to obtain an alloy ingot; and the alloy ingot is subjected to solid solution-two-stage aging treatment to obtain the magnesium alloy ingot. Cast magnesium alloy grains are refined through magnesium carbonate, and the magnesium alloy is high in yield strength and good in plasticity after heat treatment.

Owner:CHONGQING UNIV

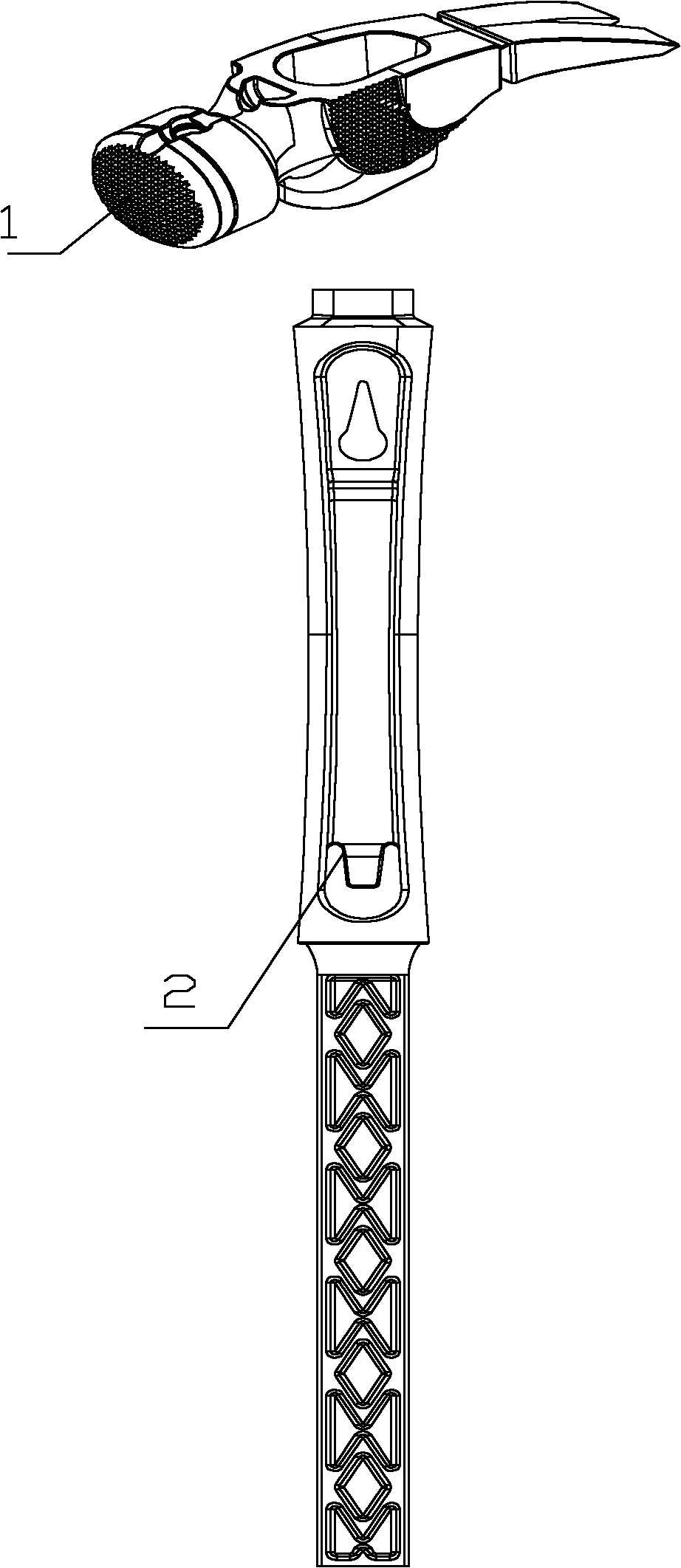

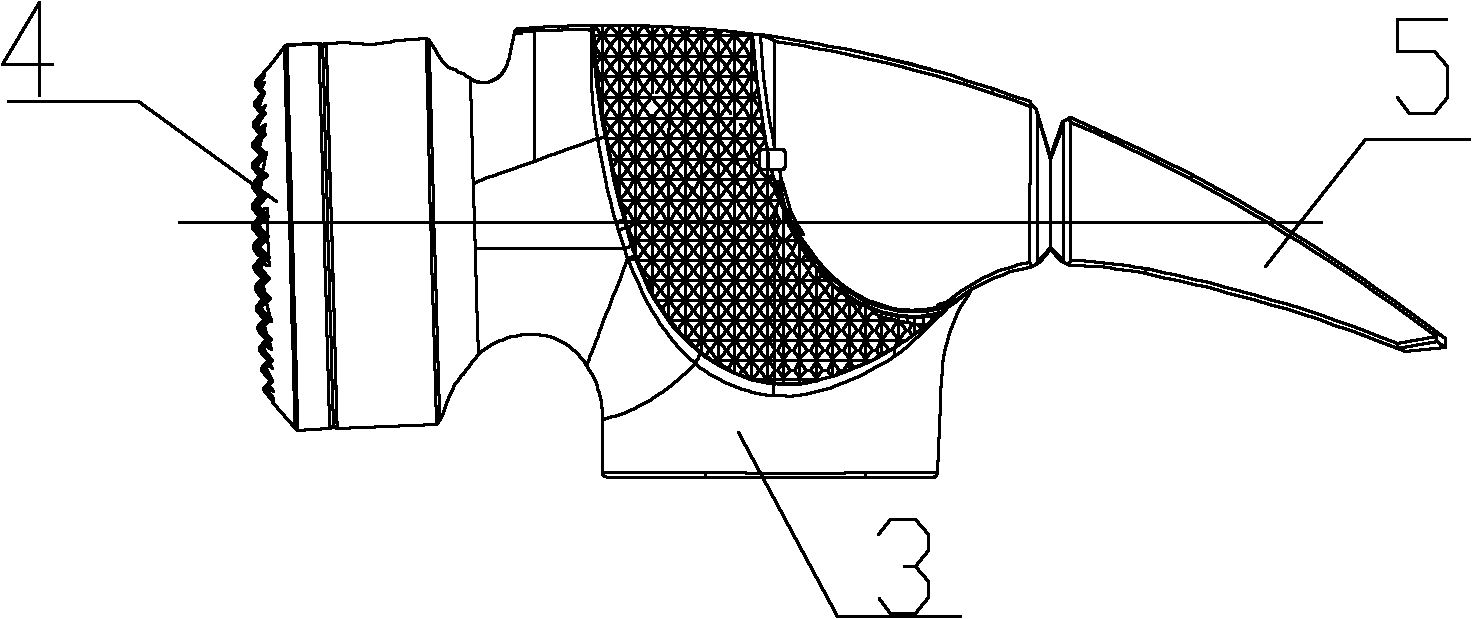

Combined titanium alloy hammer

InactiveCN102059682ADifferent performanceReduced strength requirementsHand hammersMetal-working hand toolsHardnessTitanium alloy

The invention provides a combined titanium alloy hammer, which comprises a hammer head and a handle, wherein the hammer head is sleeved at one end of the handle through a connecting hole; and the hammer head has a split structure and consists of a body, a knocking body and a cleat which are fixedly connected into a whole. The combined titanium alloy hammer is favorable for well solving the technical problem of differential distribution of hardness on the same hammer head, so that the complex shape design can be fully realized in production; and meanwhile, the refining degree of product appearance is improved, the manufacturing cost of the product is reduced, and the hammer has a very high practical value.

Owner:贺望萱

A kind of extrusion casting magnesium alloy material and preparation method thereof

The invention belongs to the field of structural metallic materials, and particularly relates to an extrusion casting magnesium alloy material and a preparation method thereof. The material is prepared from the following elements in percentage by mass: a% of Al, b% of one or more of La, Ce and Pr, c% of Mn, d% in total of one or more of RE rare earth elements Gd, Y, Sm, Nd, Er, Eu, Ho, Tm, Lu, Dyand Yb, less than 0.2% of impurities and the balance Mg, wherein a, b, c and d satisfy the following conditions: a is greater than or equal to 3.5 and less than or equal to 4.5, b is greater than or equal to 3.5 and less than or equal to 4.5, c is greater than or equal to 0.2 and less than or equal to 0.5, and d is greater than or equal to 0.01 and less than or equal to 3.0. The material has the advantages of being excellent in mechanical property, good in casting performance and capable of expanding the application field of the magnesium alloy material. The invention further provides a preparation technology. The preparation technology has the advantages of being good in stability and high in controllability.

Owner:SHANGHAI JIAOTONG UNIV

A kind of degradable antibacterial magnesium alloy and preparation method thereof

ActiveCN110373588BEnhance biological antibacterial effectImprove antibacterial propertiesTissue regenerationProsthesisMg alloysMetallurgy

The invention provides a degradable antibacterial magnesium alloy and a preparation method thereof, and relates to the field of metal biomedical materials. The main active elements of the degradable antibacterial magnesium alloy material are Ag, Cu, Zn and Sr. Through the optimized design of magnesium alloy components, The corresponding mass fractions of each component are: Ag: 1.35~1.65%, Cu: 0.9~1.1%, Zn: 3.6~4.4%, Sr: 0.9~1.1%, Ca: 0.36~0.44%, the balance is Mg and others unavoidable impurities. After the magnesium alloy material implant is completed, it can be completely degraded to avoid secondary surgical removal, reducing medical costs and patient pain. At the same time, it improves the antibacterial property of the implant, promotes the formation of osteoblasts and inhibits osteoclasts. The function of cellular bone absorption; the degradable antibacterial magnesium alloy adopts a semi-solid rheological die-casting process. The microstructure of the product is evenly distributed, the internal tissue is dense, and there are few defects such as pores and segregation, which can meet the high quality and high performance of implant products. Accuracy requirements.

Owner:NORTHEASTERN UNIV LIAONING

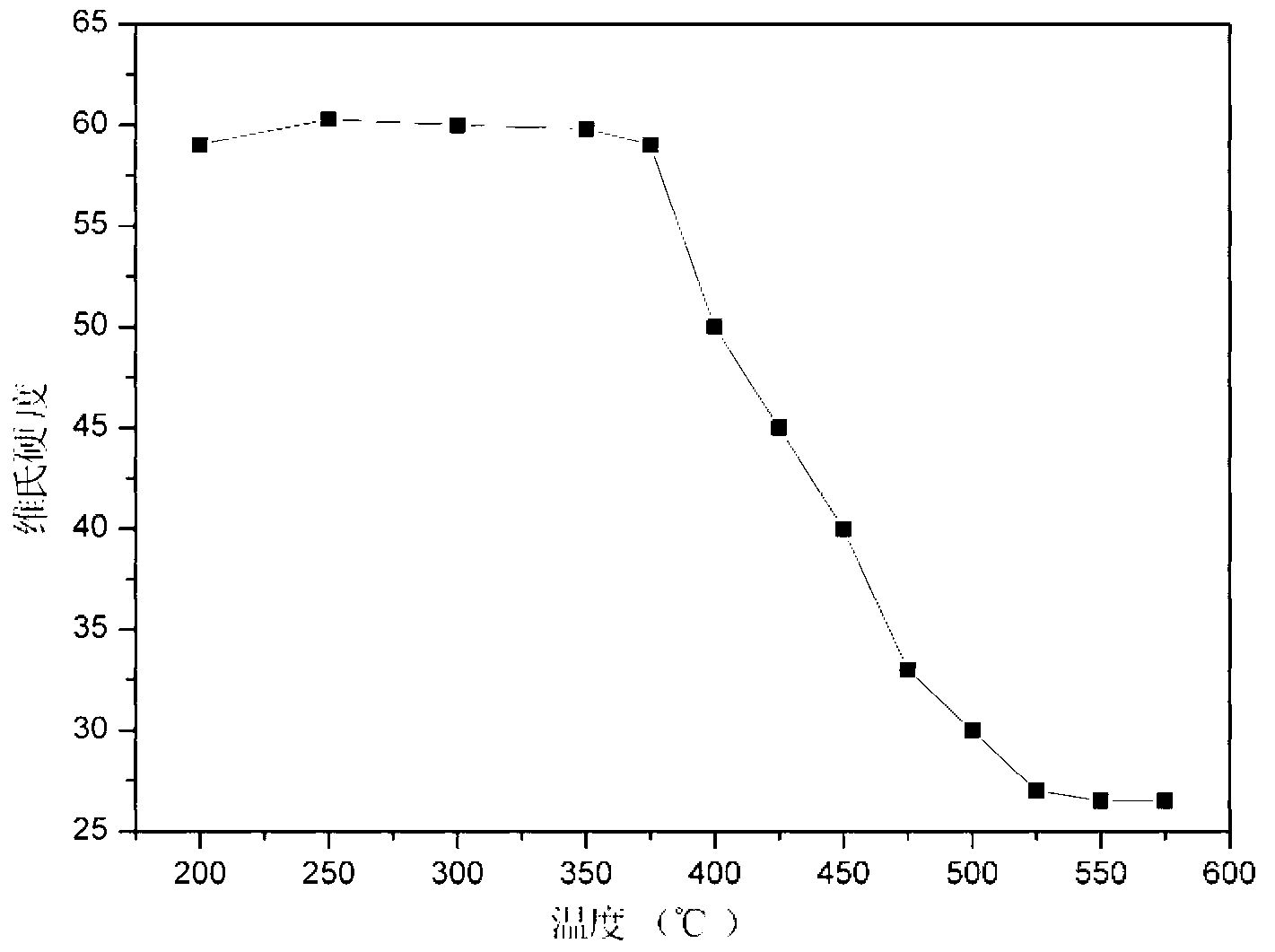

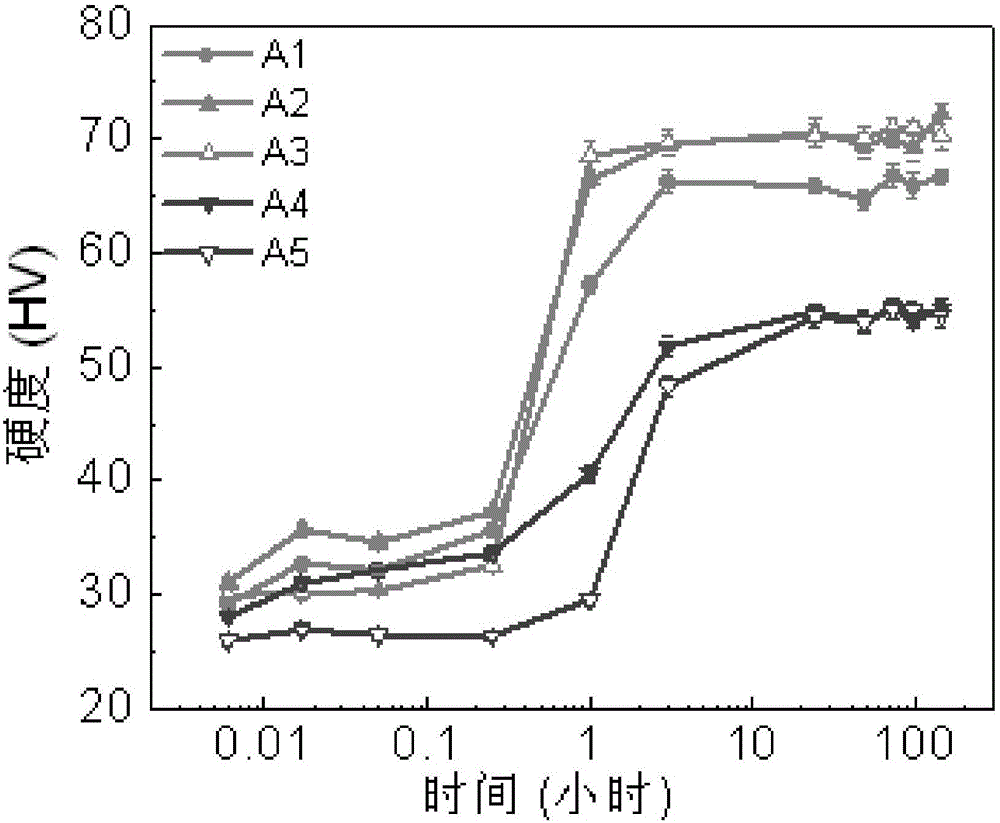

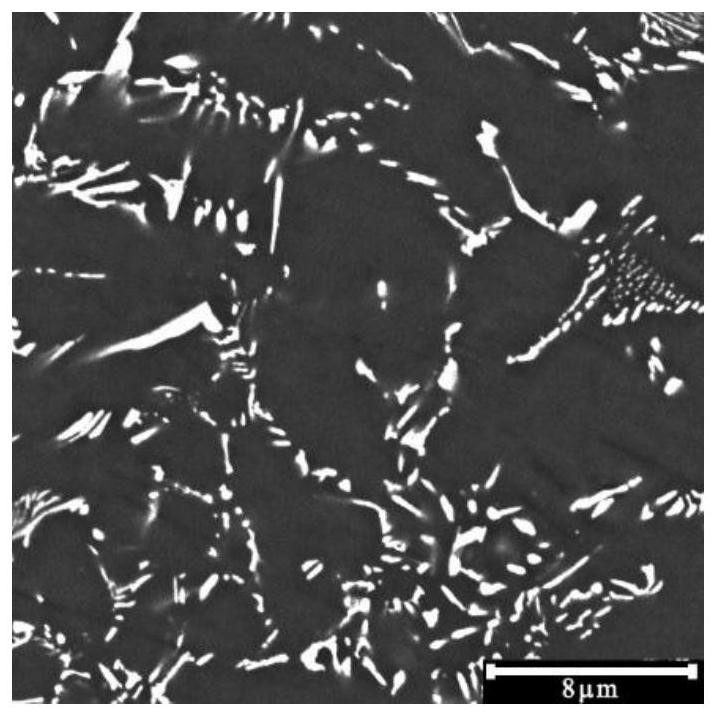

Al-Er-Hf alloy and heat treatment process thereof

ActiveCN103725926ASignificant aging effectGood high temperature thermal stabilityAluminium matrixSolution treatment

The invention relates to an Al-Er-Hf alloy and a heat treatment process thereof, and belongs to the technical field of alloy. The alloy is obtained by adding 0.12 to 0.25 weight percent of Er and 0.45 to 1.2 weight percent of Hf into a pure aluminium matrix. A solution and aging treatment process of the alloy comprises the following steps: firstly, carrying out solution treatment for 24 to 48h at a temperature of 635 plus and minus 10 DEG C and then carrying out water quenching to the room temperature; then carrying out isochronous aging for 3h on the solution alloy at intervals of 25 DEG C at a temperature of 150 to (425 to 600) DEG C; or carrying out isothermal aging treatment on the solution alloy at a temperature of 350 DEG C. According to the invention, Er and Hf are adopted to carry out multi-microalloying, so that the alloy not only has an obvious aging strengthening effect, but also has excellent high-temperature thermal stability; relative to an Al-Er alloy, the Al-Er-Hf alloy improves the aging strengthening effect and the high-temperature heat resistance; relative to an Al-Hf alloy, the Al-Er-Hf alloy enables the aging precipitation process to be obviously accelerated.

Owner:BEIJING UNIV OF TECH

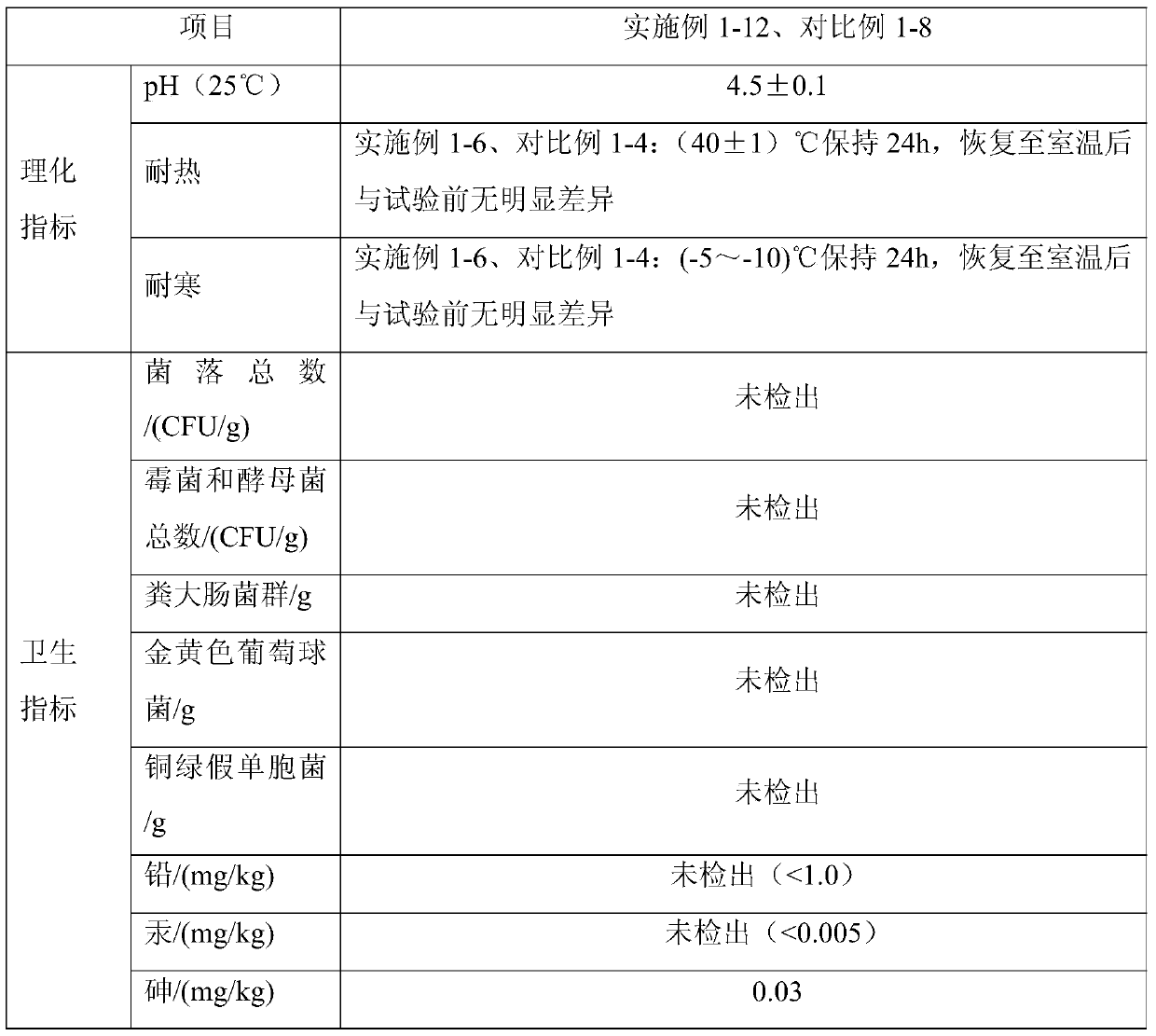

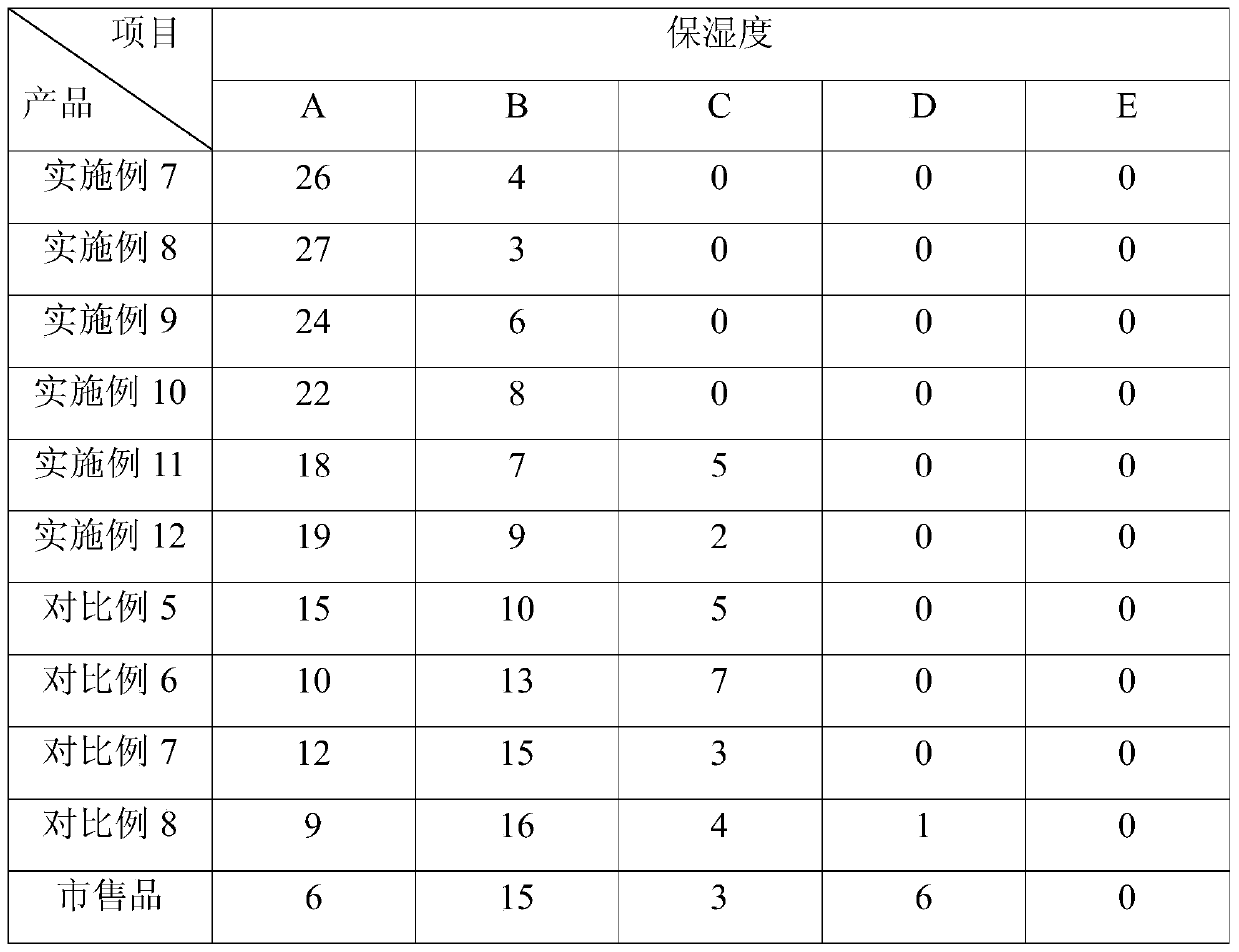

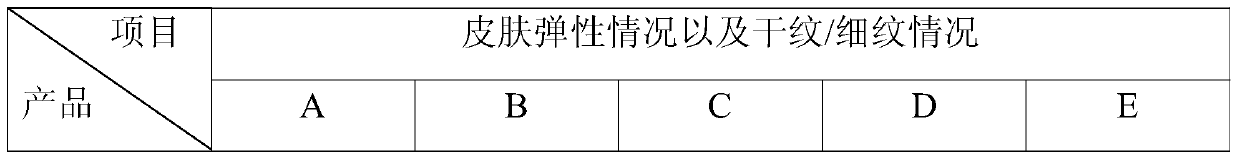

A moisturizing and rejuvenating essence based on sheep placenta and moisturizing and rejuvenating cosmetics

ActiveCN105395451BGive full play to the expertise of personalityReflect the magical effect of groupCosmetic preparationsToilet preparationsIrritationActive component

The invention relates to the technical field of cosmetics, and discloses skin moisturizing and restoring essence taking sheep placenta essence as a main component and a skin moisturizing and restoring cosmetic product. The skin moisturizing and restoring essence contains an active component and a base component, wherein the active component contains sheep placenta essence extract and at least one of largehead atractylodes rhizome extract and aloe extract. The skin moisturizing and restoring essence and the skin moisturizing and restoring cosmetic product are free of irritation to skin, and can effectively keep the moisture of the skin, promote the repairing and regeneration, delay skin ageing and restore the elasticity of the skin.

Owner:QINGDAO CHUNGHAO TISSUE ENG

A Method of Surface Microalloying to Improve Magnesium Alloy Welded Joints

ActiveCN108977805BHigh yield strengthHigh tensile strengthMetallic material coating processesRare-earth elementWeld seam

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI +1

A kind of high-performance mg-y-mn-gd deformed magnesium alloy and its preparation method

The invention relates to the field of magnesium alloys, in particular to a high-performance Mg-Y-Mn-Gd deformed magnesium alloy and a preparation method thereof. The magnesium alloy is prepared from the following elements in percentage by mass: 8.0-12.0% of Y, 0.3-0.5% of Mn, 0.2-0.4% of Gd and the balance of magnesium and inevitable impurities. The high-performance Mg-Y-Mn-Gd deformed magnesium alloy adopts industrial pure magnesium ingot, Mg-Y intermediate alloy, Mg-Mn intermediate alloy and Mg-Gd intermediate alloy as raw materials, and the raw materials are subjected to alloy smelting and casting, alloy extrusion processing and double-stage ageing thermal treatment of extruded materials to obtain the magnesium alloy. The magnesium alloy has good extrusion properties and forming properties, can obtain excellent plasticity under an extrusion-state condition, and can obtain high strength after ageing treatment; the preparation method is simple in preparation process, and is low in preparation cost; the prepared deformed magnesium alloy has high strength and high plasticity, so that the problems that the magnesium alloy not containing rare earth is relatively low in mechanical property or the magnesium alloy containing a great deal of rare earth is relatively high in cost and is relatively great in density in the prior art are solved.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

A heat treatment strengthened high-strength cast magnesium alloy and its preparation method

Owner:山东山科智镁新材料科技有限公司

Brush Alloy with Age Hardening Effect and Its Application

ActiveCN103757460BSignificant aging effectImprove high temperature stabilityRotary current collectorNon-rotary current collectorSolution treatmentHardness

The invention discloses an electric brush with an age-hardening effect. The alloy comprises the following components in percentage by weight: 30-40% of Ag, 12-20% of Cu, 0.5-2.5% of Pt, 0.1-1.5% of Au, 0.5-2.0% of Zn and the balance of Pd; the alloy contains ordered phases Cu3Pt and Cu3Au through solid-solution treatment and aging treatment. The material contains the ordered phases Cu3Pt and Cu3Au, and thus is improved in hardness and wearability at a high temperature; the material is applicable to the working layer of the electric brush of a small-sized direct-current motor at an environment temperature ranging from 80 DEG C to 150 DEG C; the alloy is combined on the surface of the copper alloy, so that the cost can be saved and the mechanical properties can be improved, and therefore, the properties of the two layers of materials can be developed sufficiently.

Owner:CHONGQING CHUANYI AUTOMATION

A kind of wrought magnesium alloy and preparation method thereof

ActiveCN107201471BImprove plastic deformation abilityImprove high temperature performanceManganeseControllability

The invention provides a wrought magnesium alloy and a preparation method thereof and relates to the technical field of alloy materials. The wrought magnesium alloy is prepared from raw materials, by weight percent, 4.0%-8.0% of zinc, 1.0%-6.0% of bismuth, 0.2%-1.0% of magnesium and the balance magnesium and unavoidable impurities. The wrought magnesium alloy has the characteristics of high strength and high plasticity and excellent mechanical performance, does not contain precious metal, is low in cost and has relatively-good economic benefits. The preparation method of the wrought magnesium alloy comprises the steps that in protection of mixed gas containing SF6, preheated magnesium is heated to be molten, preheated zinc, bismuth and magnesium are added, the temperature is raised, and after the raw materials are molten, the raw materials are cast into an ingot; and the ingot is subjected to extrusion processing and heat treatment. The method is simple in preparation process, high in controllability, low in preparation cost and suitable for large-scale production.

Owner:山东山科智镁新材料科技有限公司

Enriching Anti-aging Essence and Enriching Anti-aging Cosmetics based on marine materials

ActiveCN105395407BRich in nutrientsMoisturizingCosmetic preparationsToilet preparationsMedicineActive component

The invention relates to the technical field of cosmetics, and discloses a moisturizing and anti-aging essence and a moisturizing and anti-aging cosmetic mainly containing ocean materials. The moisturizing and anti-aging essence consists of active components and a base component, wherein the active components include at least two of a spirulina extract, a fucus vesiculosus extract and a zoster amarina extract. The moisturizing and anti-aging essence and the moisturizing and anti-aging cosmetic disclosed by the invention are non-irritant to skin, and are capable of effectively retaining skin moisture, promoting repair and regeneration, delaying skin aging and recovering skin elasticity.

Owner:QINGDAO CHUNGHAO TISSUE ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com