Rotating contact structure of vacuum arc-extinguishing chamber suitable for capacitive load switching

A technology of vacuum interrupter and rotating contact, which is applied in high-voltage air circuit breaker, switchgear setting, switchgear and other directions, can solve the problems of heavy breakdown and the insulation performance decline of vacuum interrupter, and improve the insulation characteristics. , the effect of eliminating insulation weaknesses, significant aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

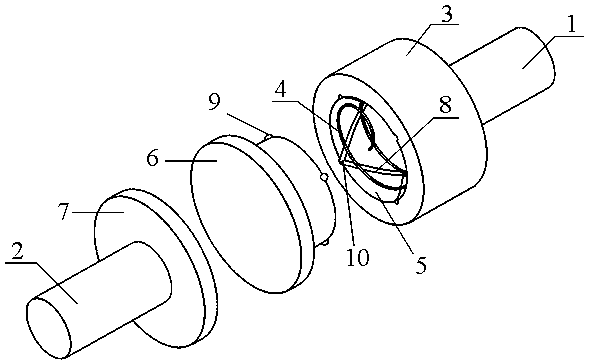

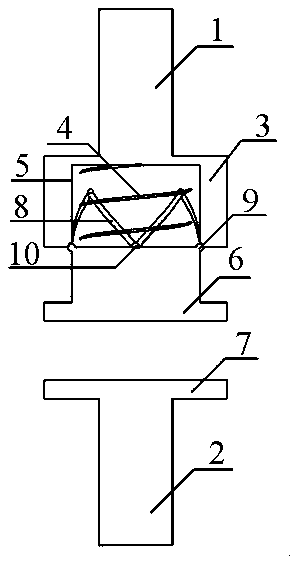

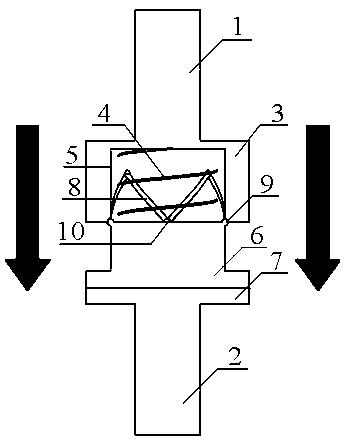

[0032] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0033] Such as figure 1 and figure 2 As shown, a rotary contact structure suitable for capacitive load switching vacuum interrupter consists of a moving conductive rod 1, a static conductive rod 2, a moving end cup holder 3, a moving end rotating contact 6 and a static end contact The static end contact 7 is fixedly connected to the static conductive rod 2, the moving end cup holder 3 is fixedly connected to the moving conductive rod 1, and a downward opening moving contact groove 5 is provided in the moving end cup holder 3. A spring 4 placed vertically is arranged in the movable contact groove 5, the top of the spring 4 is fixed on the top in the movable contact groove 5, and the bottom end of the spring 4 is fixed on the top of the movable end rotary contact 6, so that the movable end The rotary contact 6 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com