Al-Yb-Zr heatproof aluminium alloy and its heat treatment technology

An al-yb-zr, alloy technology, applied in the field of metal alloys, can solve the problems of slow Zr precipitation process, achieve good thermal stability, improve the effect of aging strengthening, and significantly improve the effect of aging strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0010] Example 1: An alloy ingot was prepared by melting in a graphite crucible and casting in an iron mold. The raw materials used were pure aluminum and Al-3Yb and Al-4Zr master alloys, and the melting temperature was 780±10°C. After reaching the melting temperature, keep it warm for 30 minutes, and then cast it with an iron mold. Five alloys with different compositions were prepared, and their actual compositions were tested by XRF, as shown in Table 1 below. The S1 and S2 samples are Al-Yb and Al-Zr binary alloys, respectively, for comparison.

[0011] Table 1 Experimental alloy composition

[0012] sample

[0013] S2

example 2

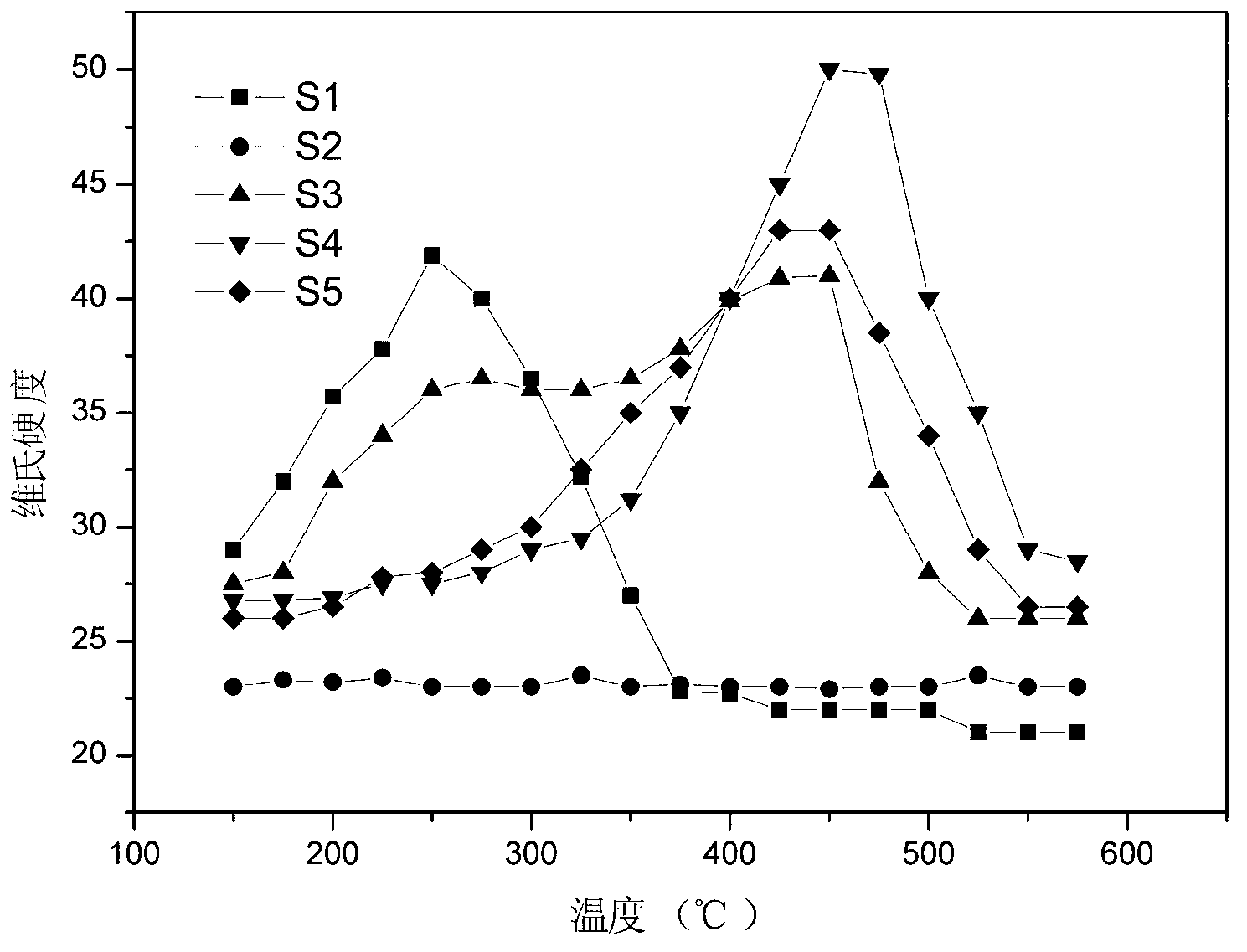

[0014] Example 2: The alloy in Example 1 was dissolved at 620±10°C for 20 hours, water quenched to room temperature, and then annealed at intervals of 25°C for 3 hours between 150°C and 575°C. figure 1 The hardness at different temperatures is given, from which it can be seen that the S4 alloy reaches a maximum hardness value of about 50HV at 400°C, which is much higher than the maximum hardness value of the S1 Al-Yb alloy. Moreover, the hardness of the alloy added with Zr decreases more slowly than that of the Al-Yb alloy with the increase of temperature, indicating that the thermal stability of the Al-Yb-Zr alloy is better than that of the Al-Yb alloy. In addition, Al-Zr alloy did not appear strengthening phenomenon, which is because the precipitation process of Al-Zr alloy is too slow, 3 hours annealing is not enough to make it precipitate.

example 3

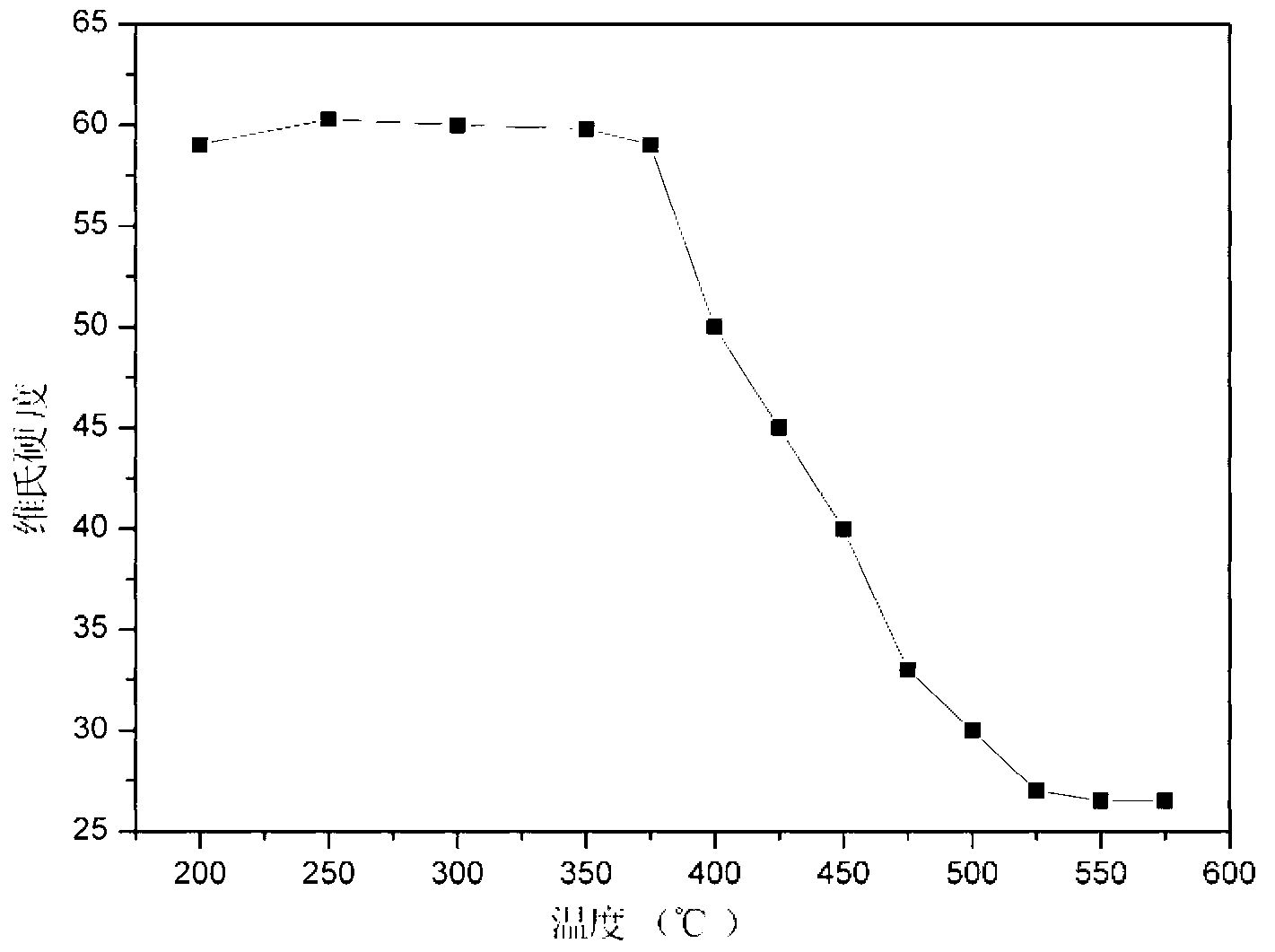

[0015] Example 3: Homogenize alloy S4 in Example 1 at 620±10°C for 20 hours, water quench to room temperature, and then anneal every 25°C for 3 hours from 150°C to 450°C. Afterwards, the rolling deformation is 70% by cold rolling. After rolling, it is annealed at 200-575°C for 1 hour, and the hardness changes as follows: figure 2 As shown, it can be seen that in the temperature range of 200-375 °C, the hardness of the alloy hardly decreases significantly, and the hardness of the alloy decreases significantly at temperatures above 375 °C. figure 2 It shows that the recrystallization temperature of the alloy is about 400℃, and it has good heat resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| recrystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com