A kind of high-performance mg-y-mn-gd deformed magnesium alloy and its preparation method

A mg-y-mn-gd, wrought magnesium alloy technology, applied in the field of magnesium alloys, can solve the problems of low mechanical properties, high cost of heavy rare earth magnesium alloys, complicated preparation processes, etc., and achieve the effect of low Gd content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

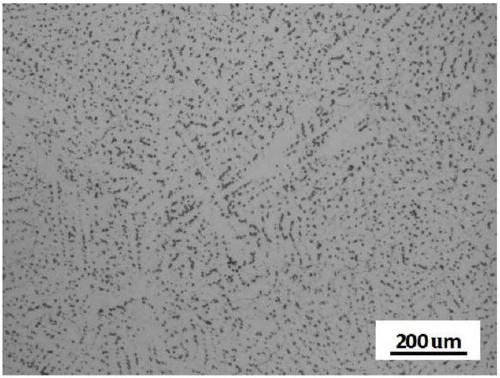

[0042] The composition (mass percentage) of the deformed alloy is: Y 8.0%, Mn 0.4%, Gd 0.3%; the rest is magnesium and unavoidable impurities.

[0043] According to the composition ratio of Example 1, the deformed magnesium alloy of the present invention is obtained by the following preparation method:

[0044] (1) Alloy smelting and casting: first preheat pure Mg, Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy at 150°C for 30min; 2 and SF 6 Heat pure magnesium in a resistance furnace protected by mixed gas, keep warm at 700°C to melt the masterbatch, then add preheated Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy, and heat up to 730°C Keep it warm for 30 minutes, wait until the alloying elements are completely melted, stir evenly, let it stand for 20 minutes, then cool down to 690°C, in CO 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and SF 6 In the mixed gas, by volume percentage, CO 2 Accounting for 99~99.5%, SF 6 ...

Embodiment 2

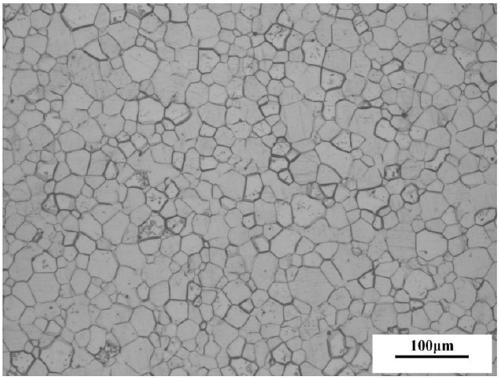

[0048] The composition (mass percentage) of the deformed magnesium alloy is: Y 10.0%, Mn 0.4%, Gd 0.3%; the rest is magnesium and unavoidable impurities.

[0049] According to the composition ratio of Example 2, the deformed magnesium alloy of the present invention is obtained by the following preparation method:

[0050] (1) Alloy smelting and casting: first preheat pure Mg, Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy at 180°C for 25min; 2 and SF 6 Heat pure magnesium in a resistance furnace protected by mixed gas, keep warm at 720°C to melt the masterbatch, then add the preheated Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy, and heat up to 740°C Keep warm for 25 minutes, wait until the alloying elements are completely melted, stir evenly, let stand for 20 minutes, then cool down to 700°C, in CO 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and SF 6 In the mixed gas, by volume percentage, CO 2 Accounting for 99~99.5...

Embodiment 3

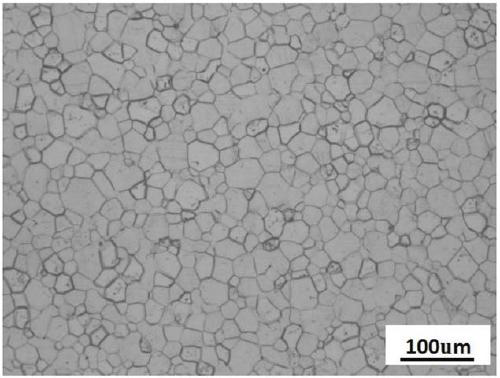

[0054] The composition (mass percentage) of the deformed magnesium alloy is: Y 12.0%, Mn 0.4%, Gd 0.3%; the rest is magnesium and unavoidable impurities.

[0055] According to the composition ratio of Example 3, the deformed magnesium alloy of the present invention is obtained by the following preparation method:

[0056] (1) Alloy smelting and casting: first preheat pure Mg, Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy at 200°C for 20min; 2 and SF 6 Heat pure magnesium in a resistance furnace protected by mixed gas, keep warm at 710°C to melt the masterbatch, then add the preheated Mg-Y master alloy, Mg-Mn master alloy and Mg-Gd master alloy, and heat up to 750°C Keep warm for 20 minutes, wait until the alloying elements are completely melted, stir evenly, let stand for 20 minutes, then cool down to 710°C, in CO 2 and SF 6 Cast into ingots under the protection of mixed gas; CO 2 and SF 6 In the mixed gas, by volume percentage, CO 2 Accounting for 99~99.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com